Camera component and electronic device

A technology for camera components and electronic equipment, which is used in television, photography, electrical components, etc., can solve the problems of small shooting angle, poor shooting effect, and inability to satisfy users, and achieve good shooting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

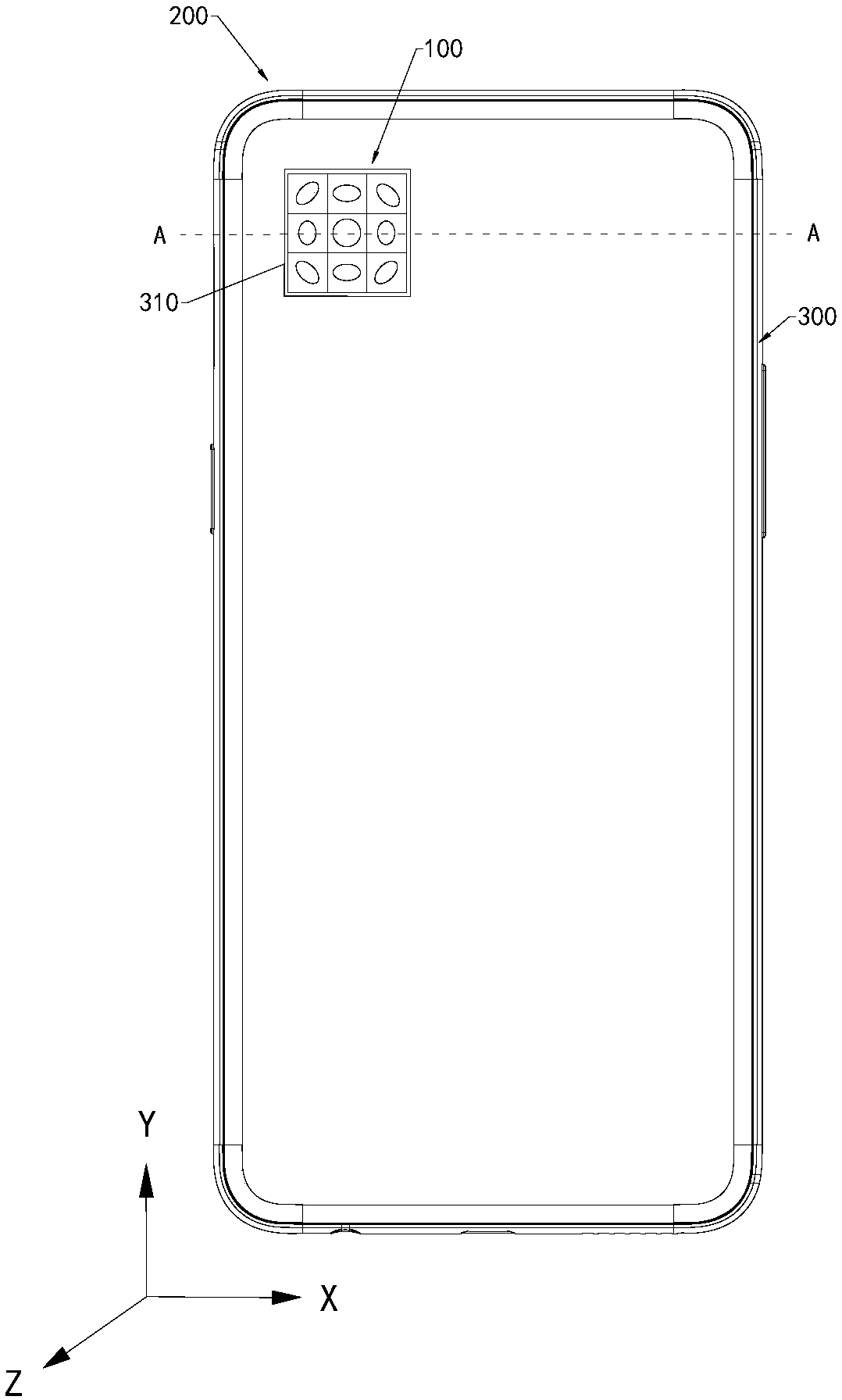

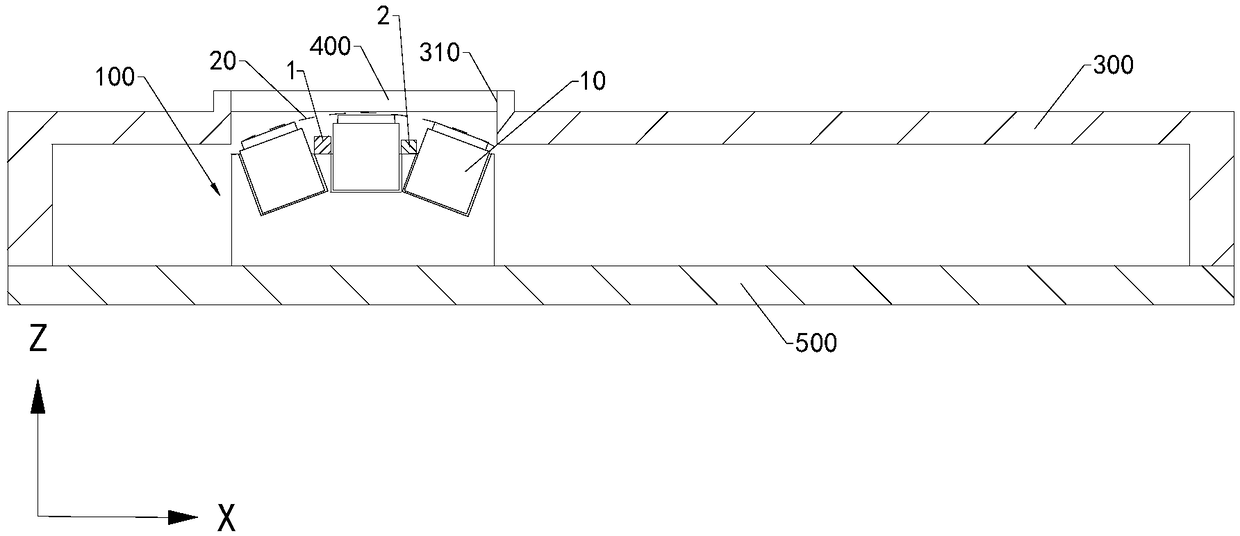

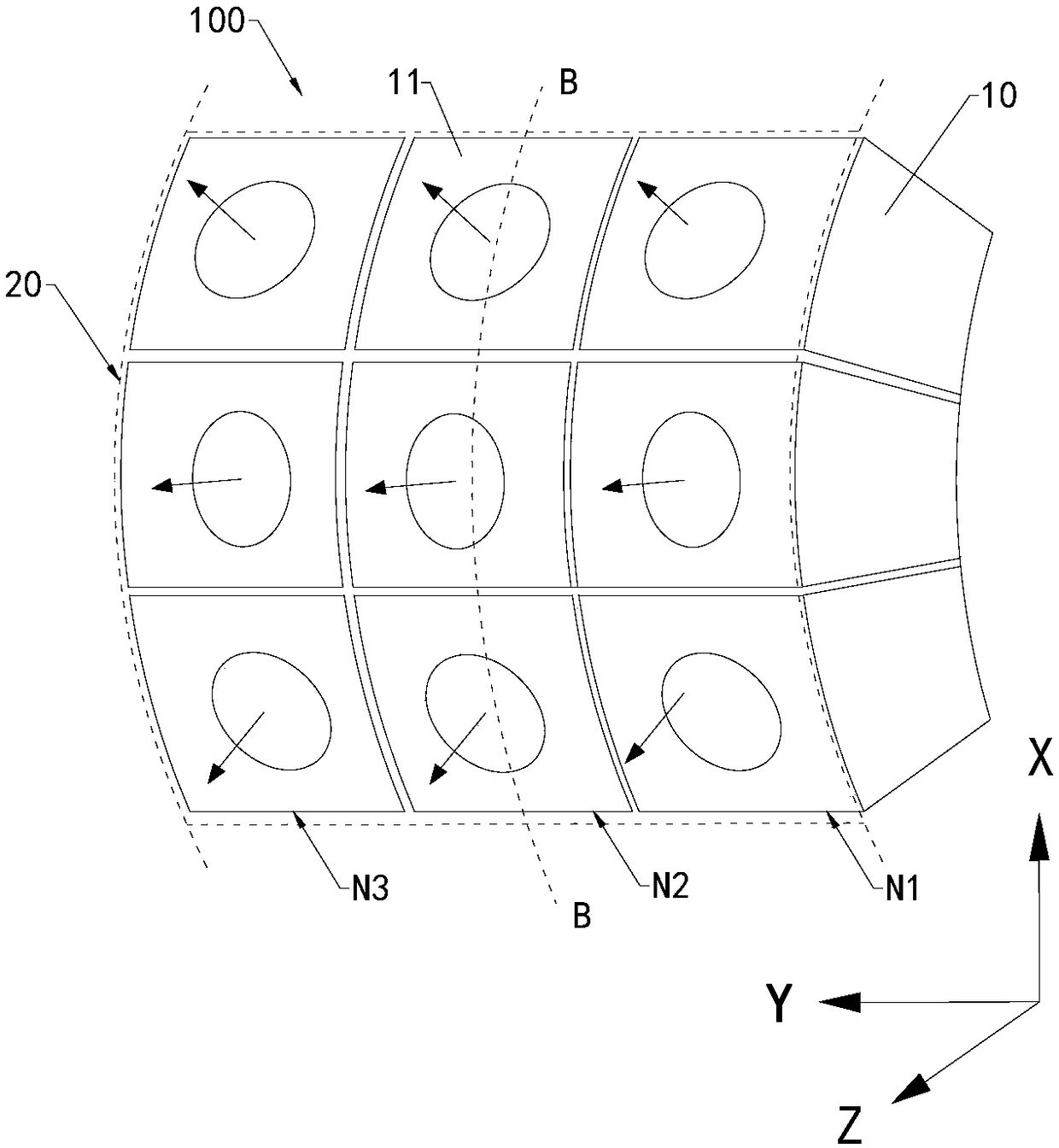

[0031] Embodiment 1: At least three cameras 10 are arranged in an array to form an n×n structure, where n is an integer and satisfies: n≥2. Specifically, nine cameras 10 are arranged in an array to form a 3×3 structure. At this time, the sub-light incident surfaces 11 of each camera 10 are spliced to form a main light incident surface 20 . like image 3 As shown, the arc shape of the main light incident surface 20 is a shape formed by a part of the side surface of a cylinder. The camera head 10 of this array structure comprises the first row N1, the second row N2 and the third row N3, and the first row N1, the second row N2 and the third row N3 are provided by the attached image 3 Arranged from right to left. The sub-light incident surfaces 11 of the three cameras 10 in the first row N1 have different orientations. Each sub-light incident surface 11 with different orientations is represented by arrows with different orientations. The sub-light incident surfaces 11 of t...

Embodiment approach 2

[0037] Implementation mode two: if Figure 7 and Figure 8 As shown, at least three cameras 10 include a first-type camera 14 and a second-type camera 15 arranged around the first-type camera 14 . The first type of camera 14 has a first incident axis 141 . Each second-type camera 15 has a second incident light axis 151 . Each second light incident axis 151 is set at an included angle with the first light incident axis 141 . In this embodiment, when the second-type cameras 15 are arranged around the four directions of the first-type cameras 14, and the second incident light axis 151 of each second-type camera 15 is aligned with the first incident axis 151 of the first-type cameras 14 The optical axis 141 is set at an included angle. At this time, multiple cameras 10 cooperate with each other to shoot objects or people from various angles. In other embodiments, the second-type cameras may also be arranged in various directions of the first-type cameras 14 . Set it accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com