A method and system for monitoring the lubrication state of a wind turbine generator bearing

A technology for generator bearings and wind turbines, applied in the field of wind power, can solve problems such as a specific method for bearing lubrication state monitoring, and achieve the effects of simple and effective monitoring methods, prolonging service life, and preventing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

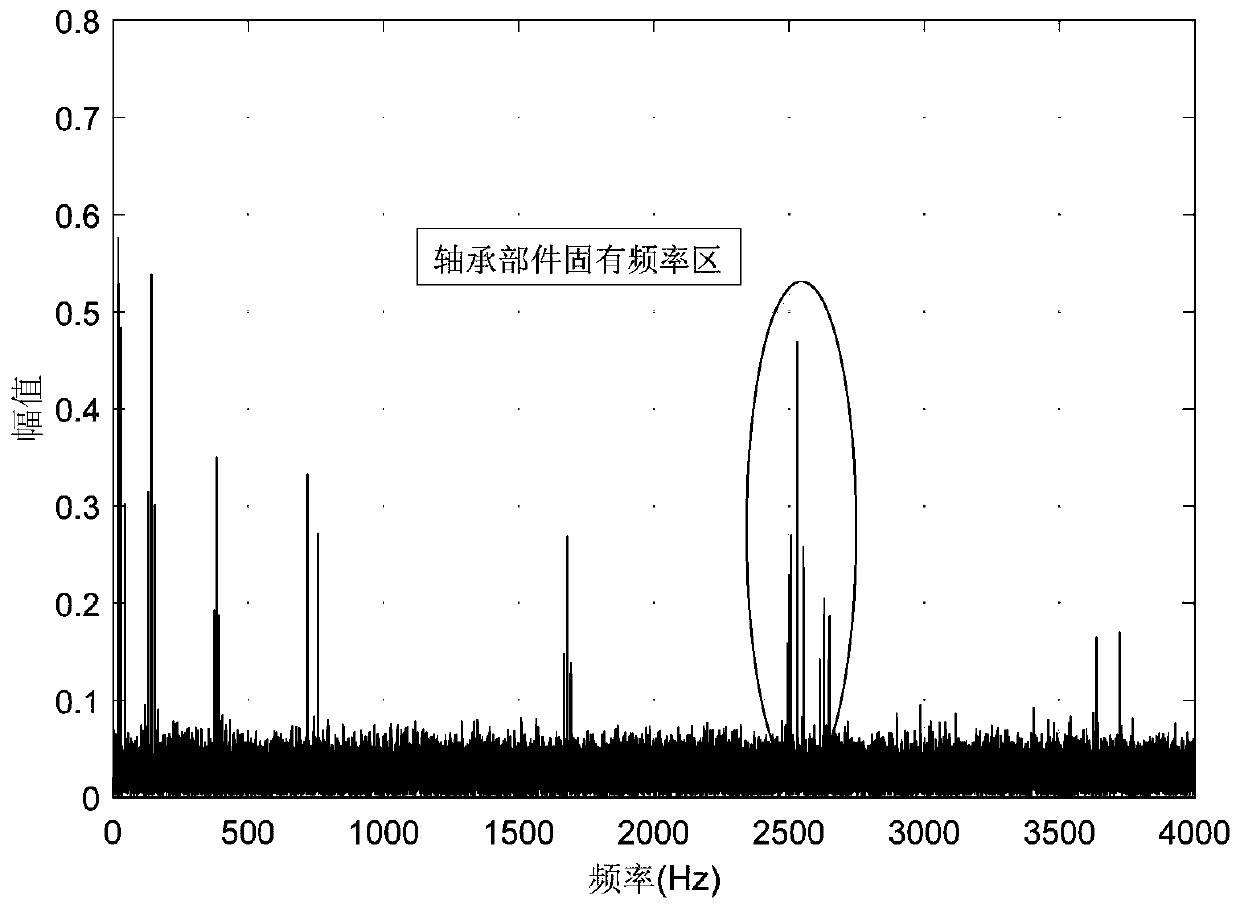

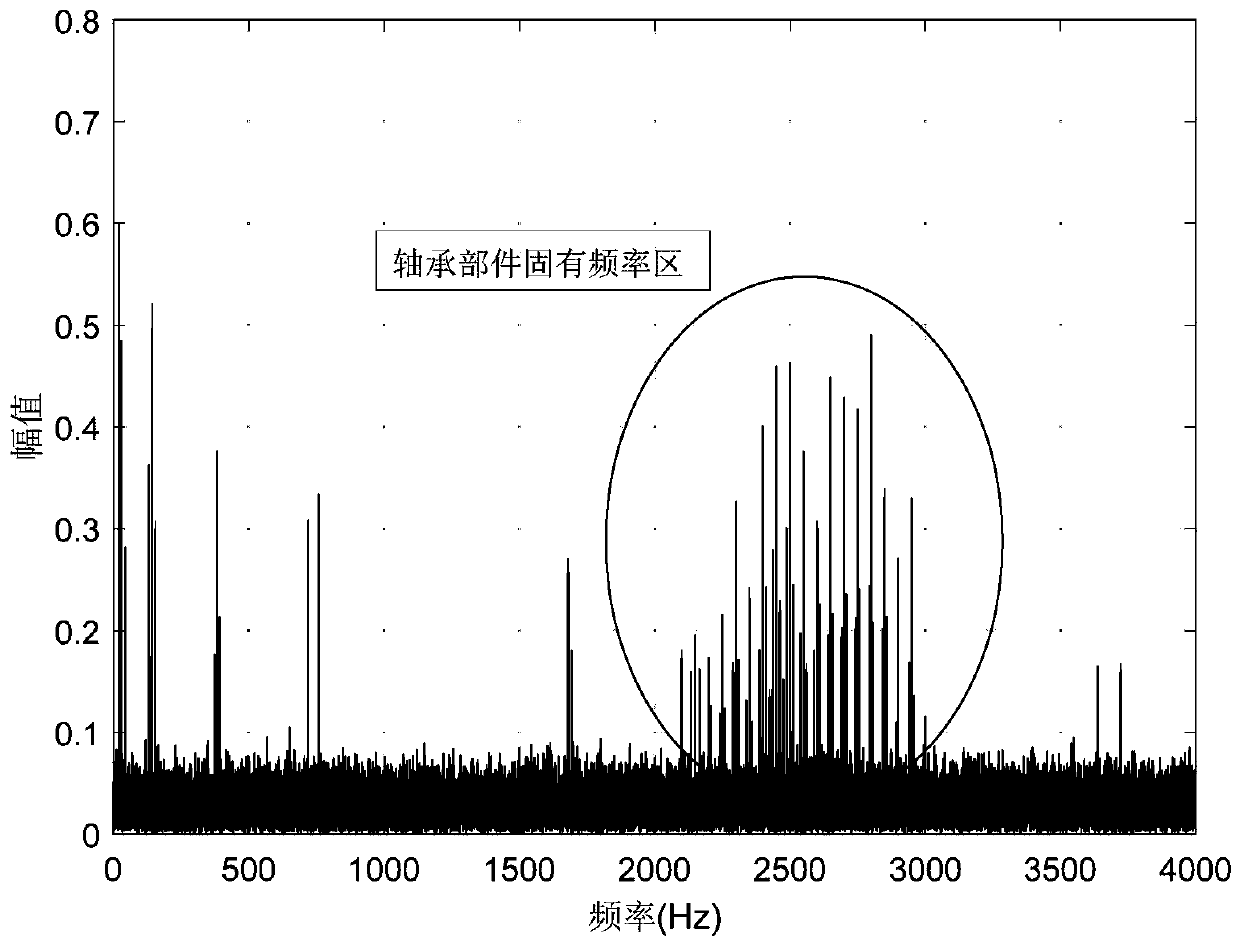

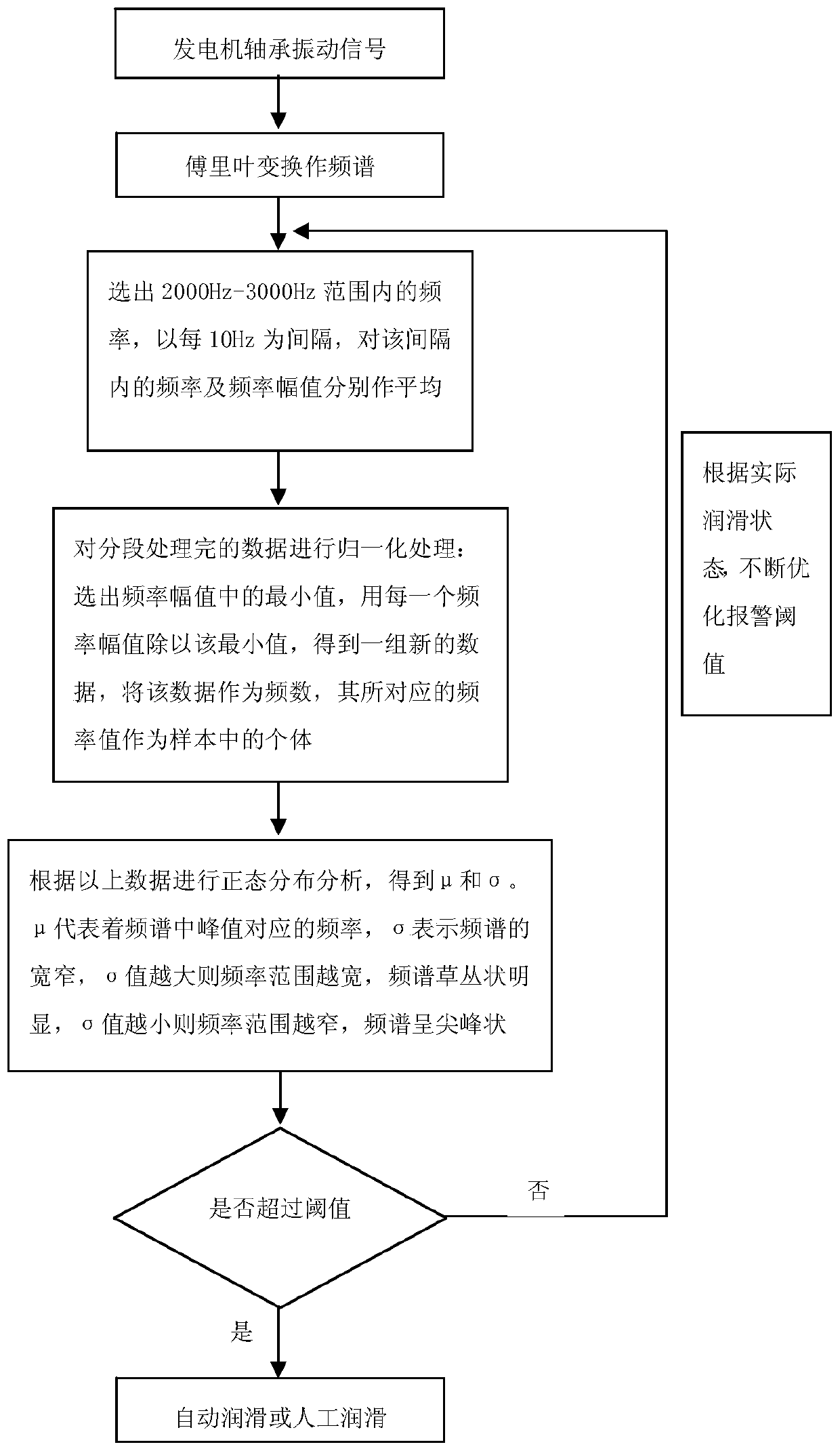

[0039] The basic principle of the present invention for monitoring the lubrication state of the generator bearing of the wind turbine is that the natural frequency of the generator bearing and the components near the bearing seat is generally about 2500 Hz, and the frequency is basically not affected by the operating conditions of the unit. as attached figure 1 As shown, under normal conditions of generator bearing lubrication, the frequency components in the frequency spectrum are relatively single, the center peak frequency is relatively high, and there is no excessive side frequency distribution, showing a peak shape. as attached figure 2 As shown, when the generator bearing is poorly lubricated, the bearing will have dry friction, which will arouse the natural frequency of the bearing and the bearing seat components, and increase the vibration. At this time, the energy distribution is wider and more peak frequencies appear. Appears haystack-like in the spectrum. Based o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com