PCCP steel wire joint and binding method thereof

A technology of steel wire and right end point, which is applied in the field of PCCP prestressed steel wire joint binding structure, can solve problems such as weak joints, non-compliance with regulations, loose binding wires, etc. open effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

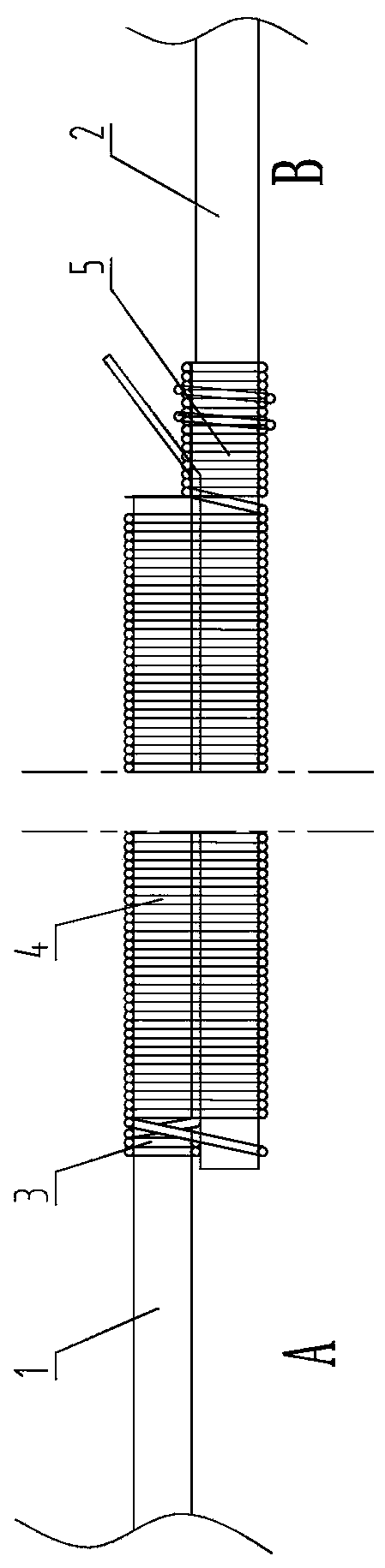

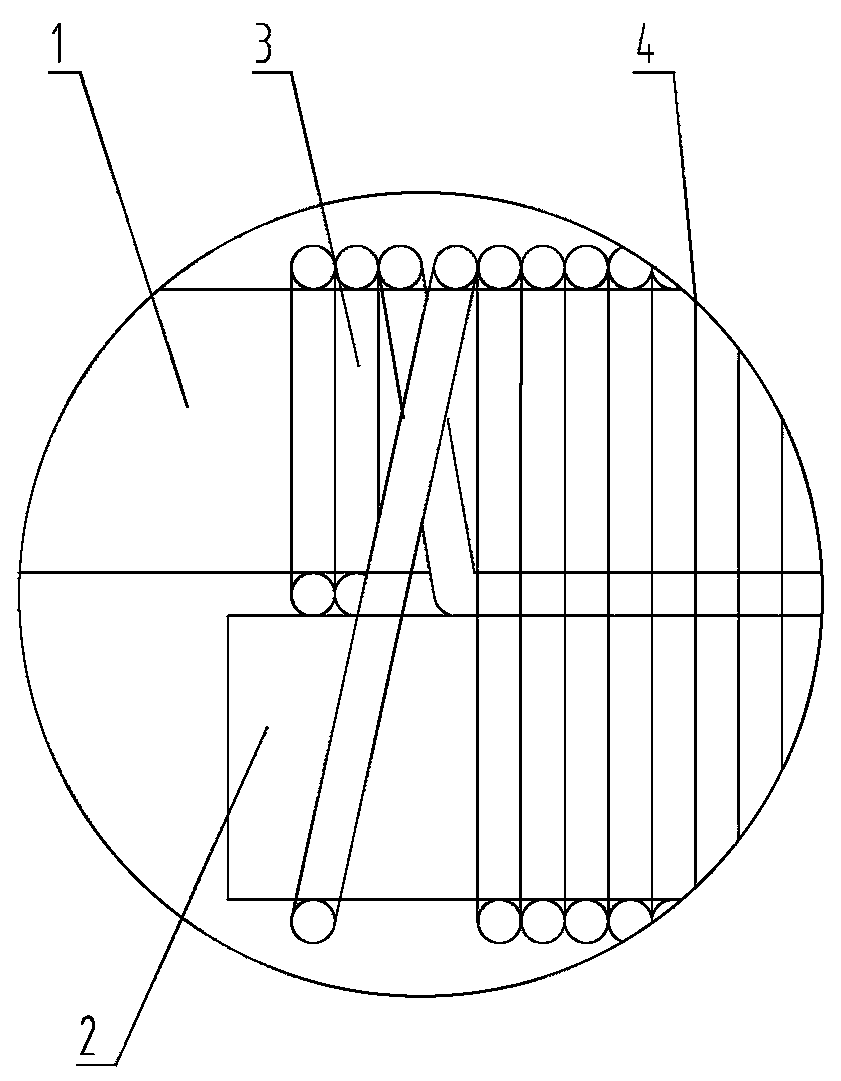

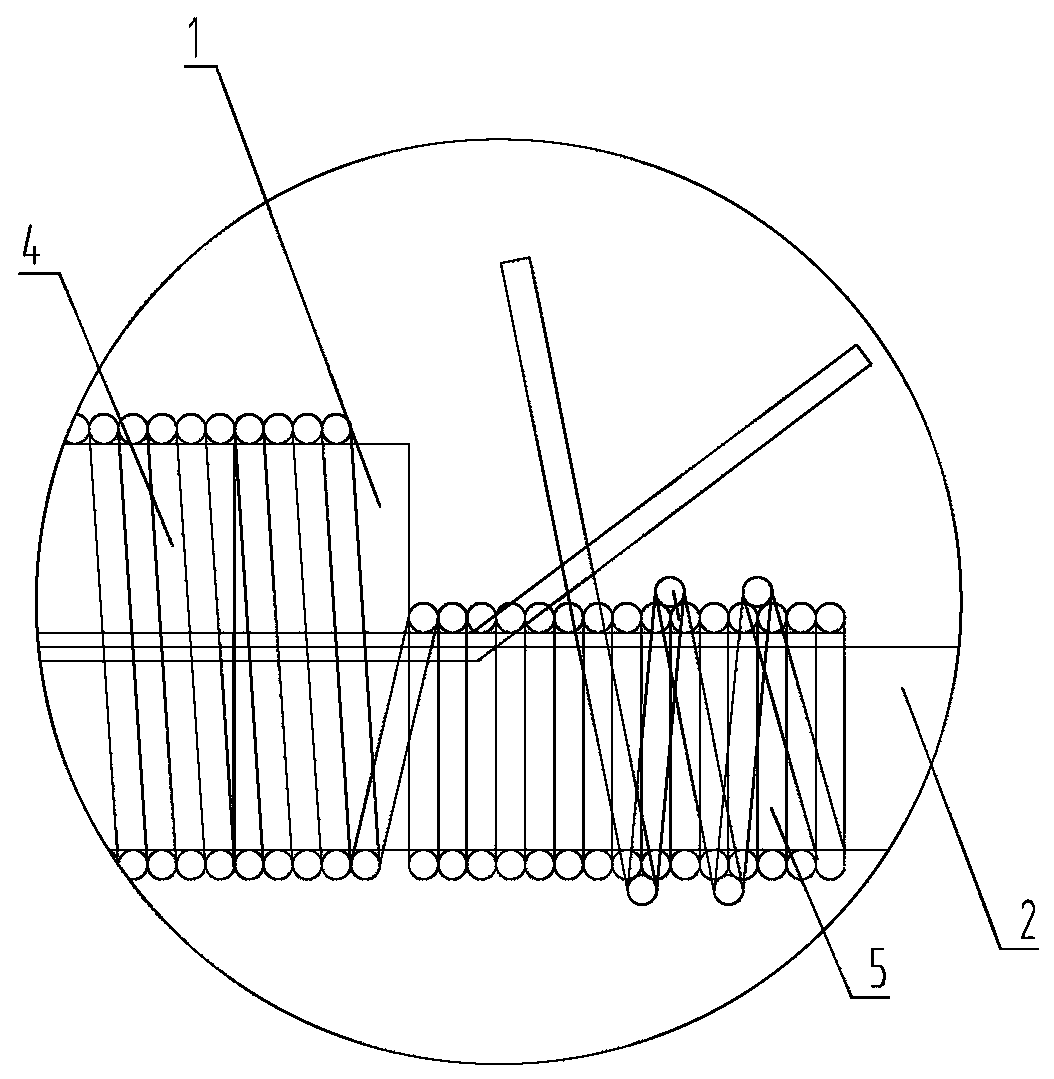

[0019] Example 1, such as Figures 1 to 3 As shown, the PCCP steel wire joint includes the binding wire used for binding and the left steel wire 1 to be bound and the right steel wire 2 to be bound overlapped together; the binding wire includes the left binding wire 3 wound on the left steel wire 1 to be bound, and The total binding wire 4 on the overlapping lap section of the left steel wire 1 to be tied and the right steel wire 2 to be tied, the right binding wire 5 wound on the right steel wire 2 to be tied; The left ends are connected, and the right end of the binding wire 4 is connected with the left end of the left binding wire 3, and the right end of the left binding wire 3 extends to the right binding wire 5 and is connected with the right end of the right binding wire 5 after being tightened.

[0020] This application abandons the technology in the prior art of "winding from one end of the joint to the other end, and after the winding is completed, reversely fold the ...

Embodiment 2

[0024] Example 2, such as Figures 1 to 3 As shown, the PCCP steel wire joint binding method includes the following steps: step one, start winding the left binding wire 3 on the left steel wire 1 to be bound at a distance of 350 mm to 550 mm from the right end point of the left steel wire 1 to be bound; step two, wrap the left steel wire 3 to be bound The left end point of the right steel wire 2 is sent to the winding left starting point of the left binding wire 3, and the left steel wire to be tied and the right steel wire 2 to be bound are overlapped and overlapped; Step 3, the right end point of the left binding wire 3 is aligned 1 and the right steel wire 2 to be tied extend to the right, and the reserved length is 380mm to 590mm; step 4, extend the left end point of the left binding wire 3 around the lap of the left steel wire 1 to be tied and the right steel wire 2 to be tied The connecting part begins to wind until the end of the overlapping part to form a co-binding wi...

Embodiment 3

[0025] Example 3, such as Figures 1 to 3 As shown, the PCCP steel wire joint binding method includes the following steps: Step 1, at a distance of 450 from the right end point of the left steel wire 1 to be tied, start to wind the left binding wire 3 on the left steel wire 1 to be tied, and the number of winding turns is 4 circles; 2. Send the left end point of the right steel wire 2 to be bound to the left starting point of the left binding wire 3, overlap and overlap the left steel wire and the right steel wire 2 to be bound, and the length of the overlapping part is 450 mm; The right end point of the left binding wire 3 extends to the right along the overlapping gap between the left steel wire 1 to be bound and the right steel wire 2 to be bound, and the reserved length is 480mm; step 4, extend the left end point of the left binding wire 3 around the left The overlapping part of the steel wire 1 and the right steel wire 2 to be tied begins to wind until the end of the over...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com