Chip material taking mechanism

A chip and reclaiming arm technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of increasing the weight of the chip feeding mechanism, reducing the equipment accuracy, and increasing the equipment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

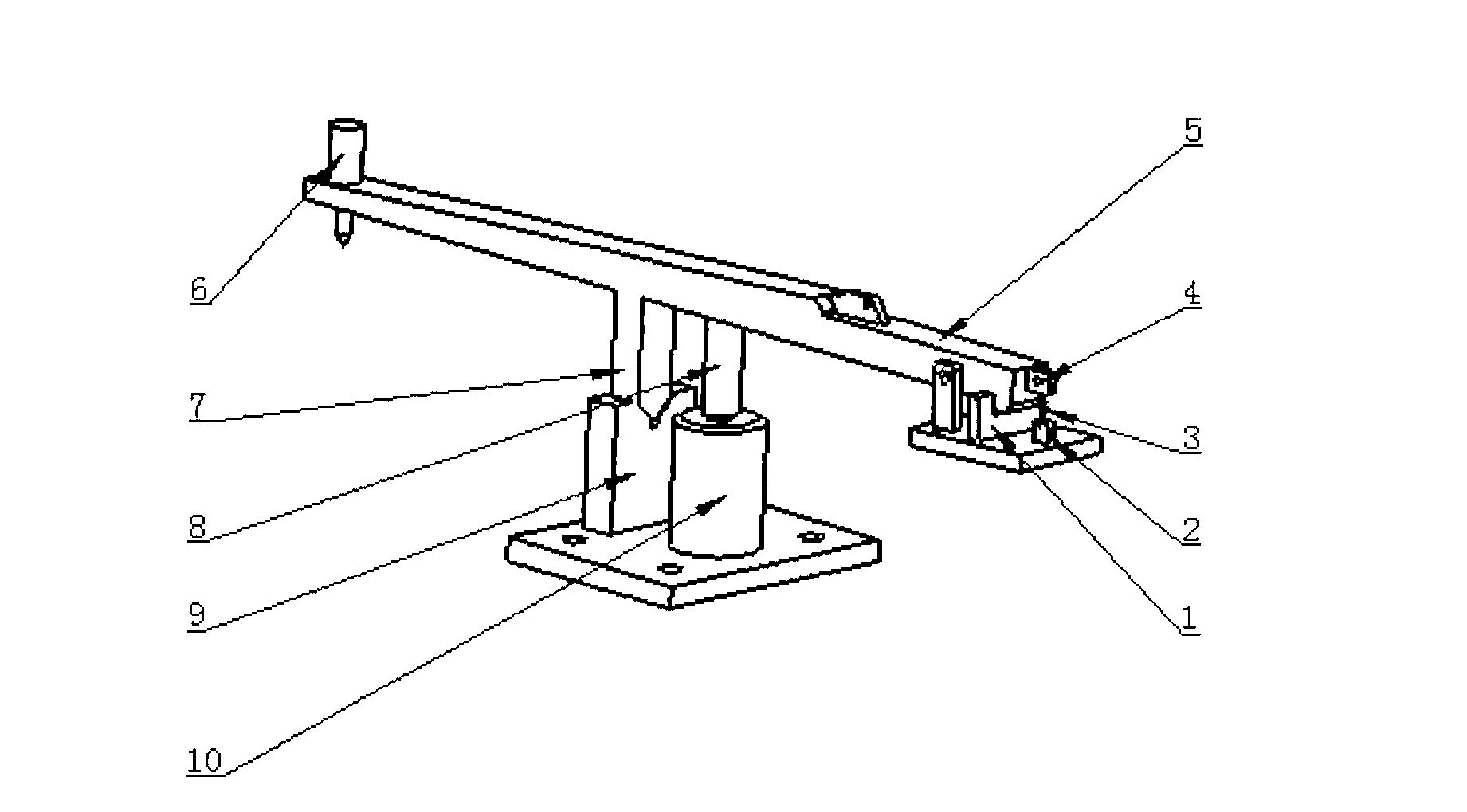

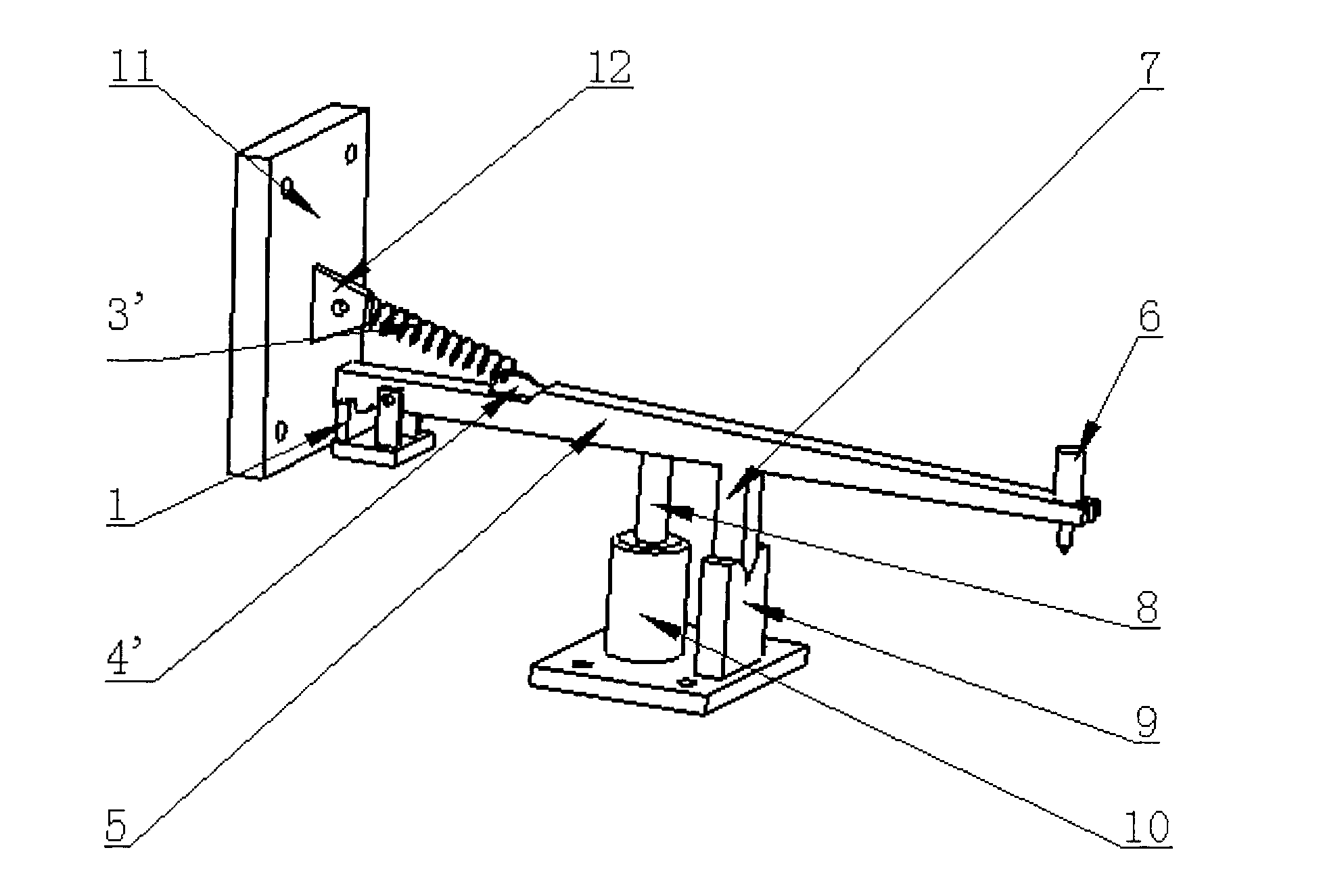

[0005] figure 1 The structural diagram of the pull-down installation of the elastic device is given. One end of the elastic recovery device 3 is connected to the earring structure on the reclaiming arm swivel 2, and the other end is connected to the earring on the reclaiming arm 5 to provide a restoring force to the reclaiming arm; the blocking block structure 4 on the reclaiming arm swivel can Effectively control the rising displacement of the reclaiming arm to ensure that it is within the magnetic attraction range of the electromagnetic suction device 10; Accurate positioning of the retrieving arm ensures accuracy; the electromagnetic suction device 10 is equipped with a pressure sensor, which can measure the pressure during suction, and then feed it back to the control system, so as to control the magnitude of the electromagnetic suction and avoid causing large vibrations of the reclaiming arm; After the arm is sucked down, the vacuum nozzle device 6 sucks up the chip to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com