Bidirectional rolling shaft multi-stage damping support

A technology of multi-stage shock absorption and roller, which is applied in the field of two-way roller multi-stage shock-absorbing bearings, can solve the problems of difficult recovery of lead core deformation, uneven damping distribution and inability to

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

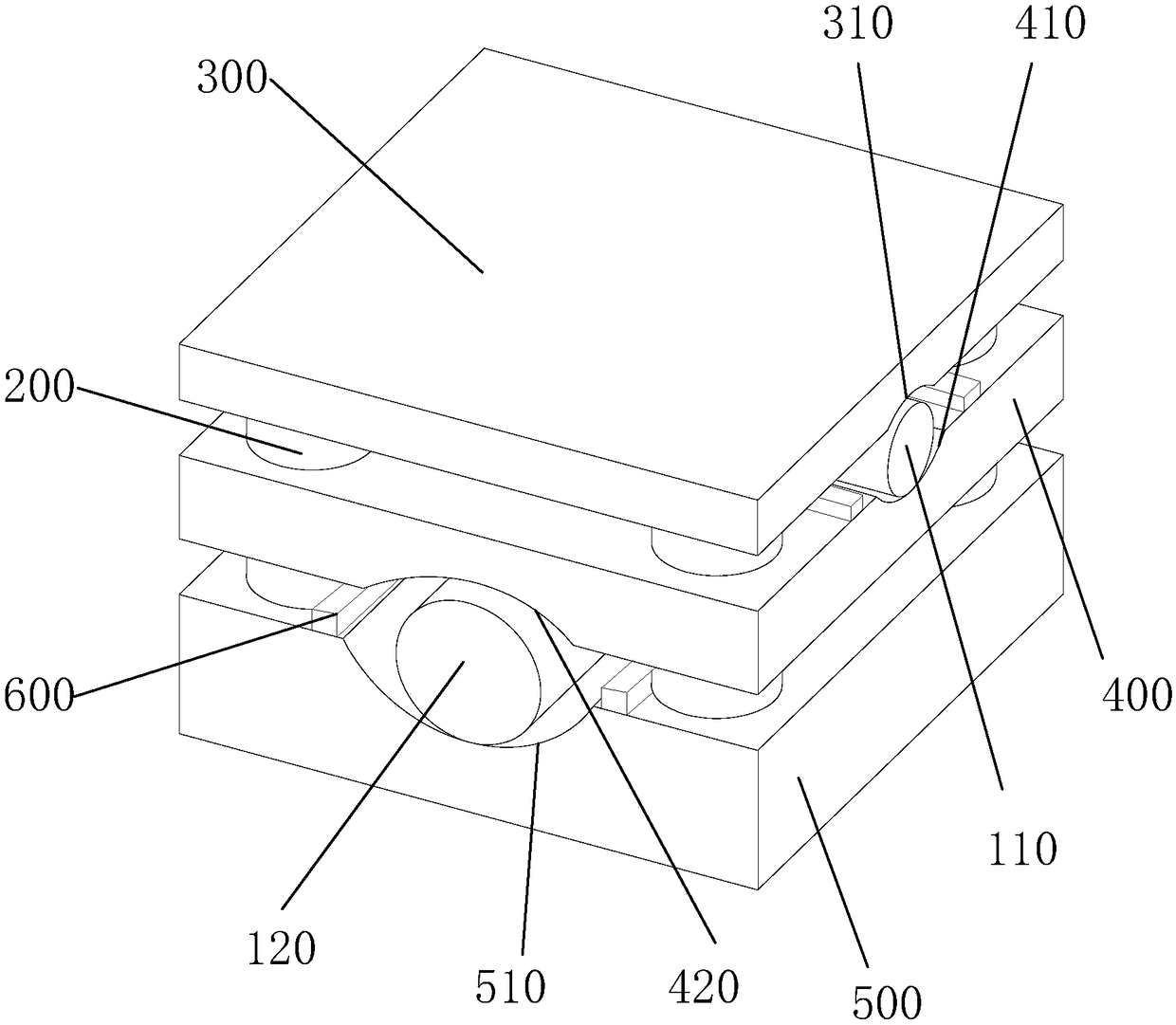

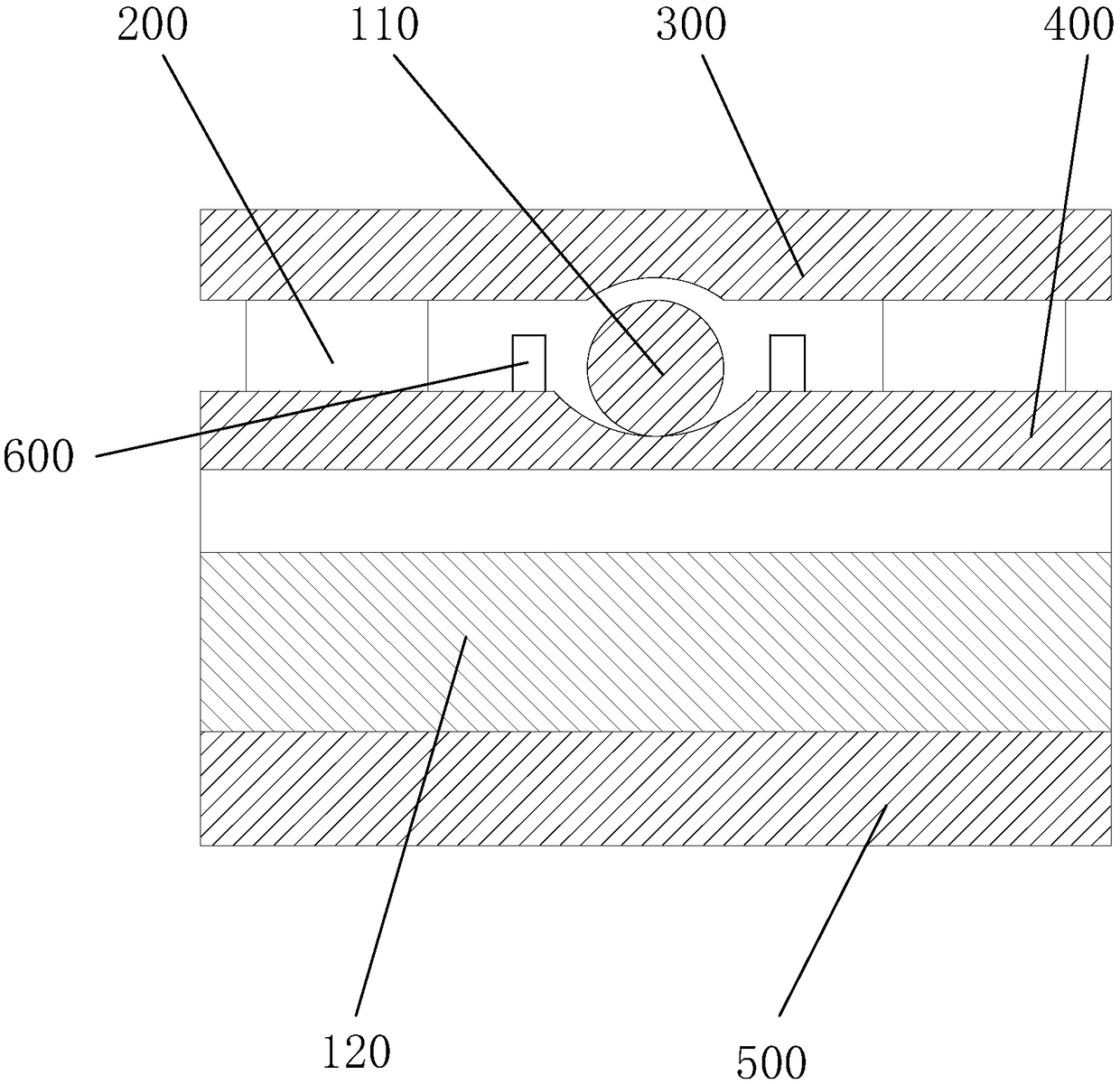

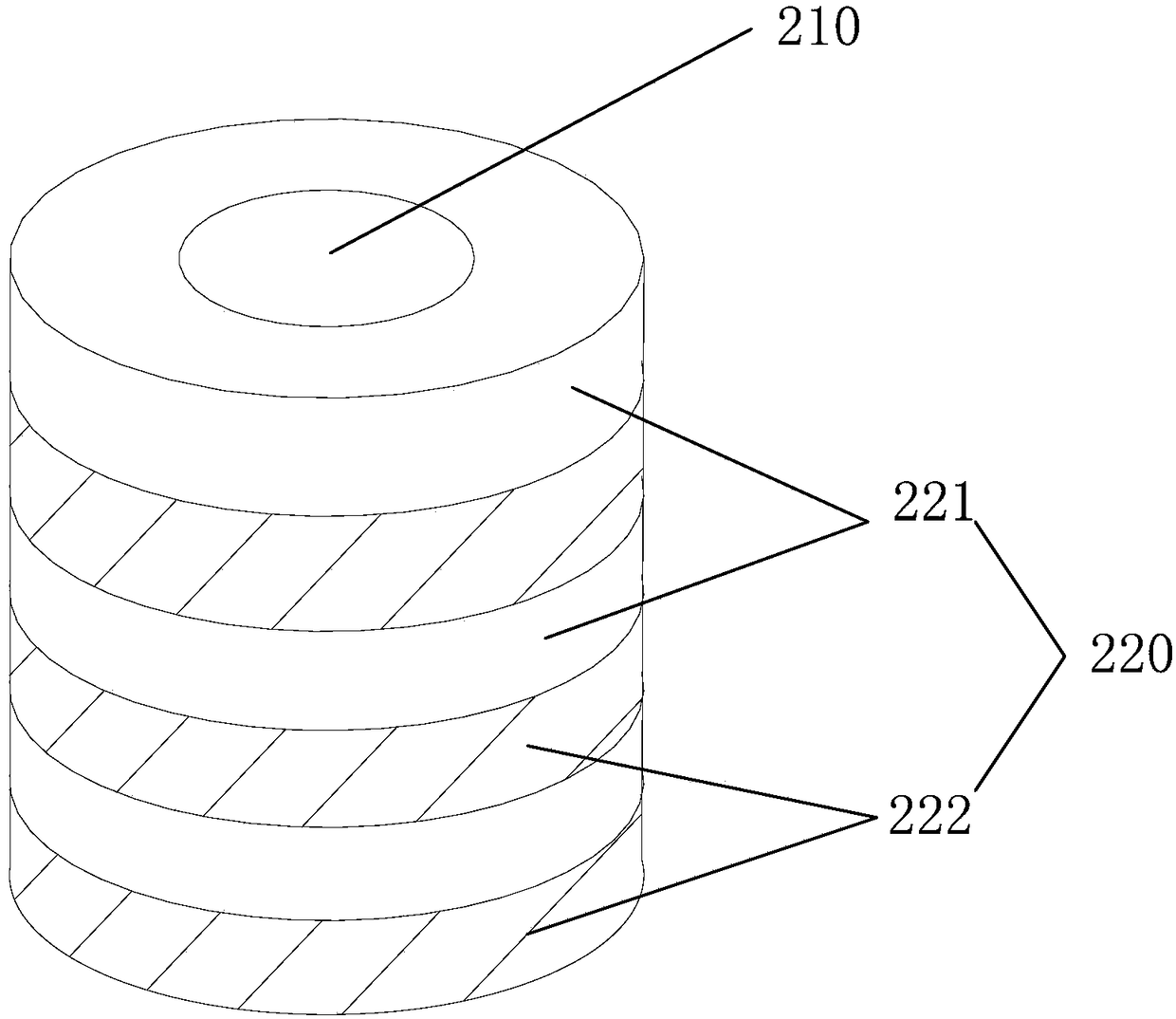

[0065] A bidirectional roller multi-stage shock-absorbing support, including a first shock-absorbing roller 110, a second shock-absorbing roller 120, a lead-core pillar 200, a first connecting plate 300, a second connecting plate 400 and a third connecting plate 500;

[0066] The first connecting plate 300, the second connecting plate 400 and the third connecting plate 500 are arranged at intervals from top to bottom,

[0067] And a first installation space is formed between the first connection plate 300 and the second connection plate 400, and a second installation space is formed between the second connection plate 400 and the third connection plate 500;

[0068] A lead pillar 200 for supporting the first connecting plate 300 and the second connecting plate 400 and a first shock-absorbing roller 110 are provided in the first installation space;

[0069] A lead pillar 200 for supporting the second connecting plate 400 and the third connecting plate 500 and a second shock-absorbing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com