Ultrasonic heat meter with improved quality grade

It is a quality-improving, ultrasonic technology, which is applied in the direction of measuring heat, calorimeters, measuring devices, etc. It can solve the problems of complex places used by customers, inconvenient disassembly and assembly, and short service life, so as to improve the waterproof and dustproof level and not Effects on production efficiency and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

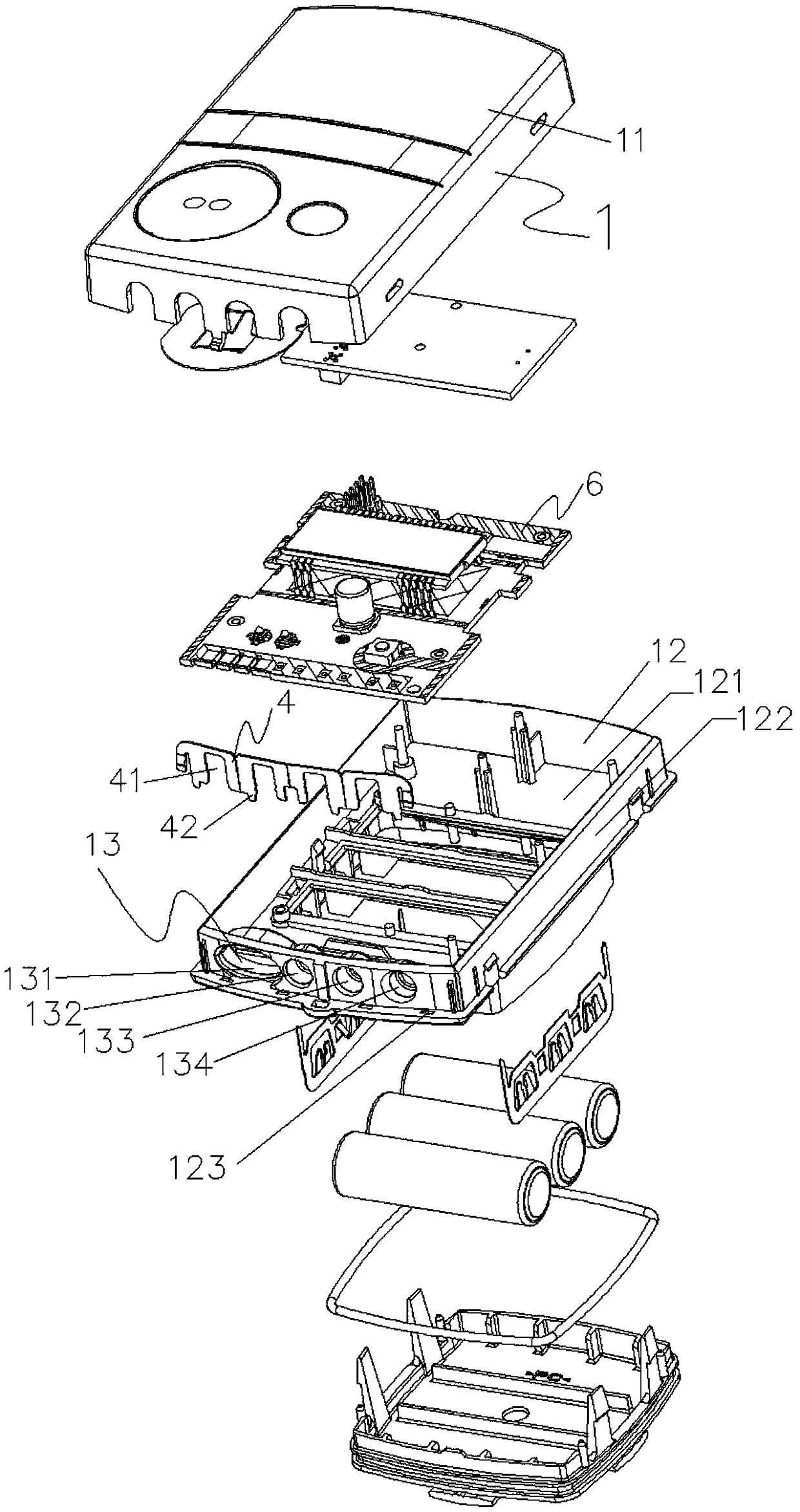

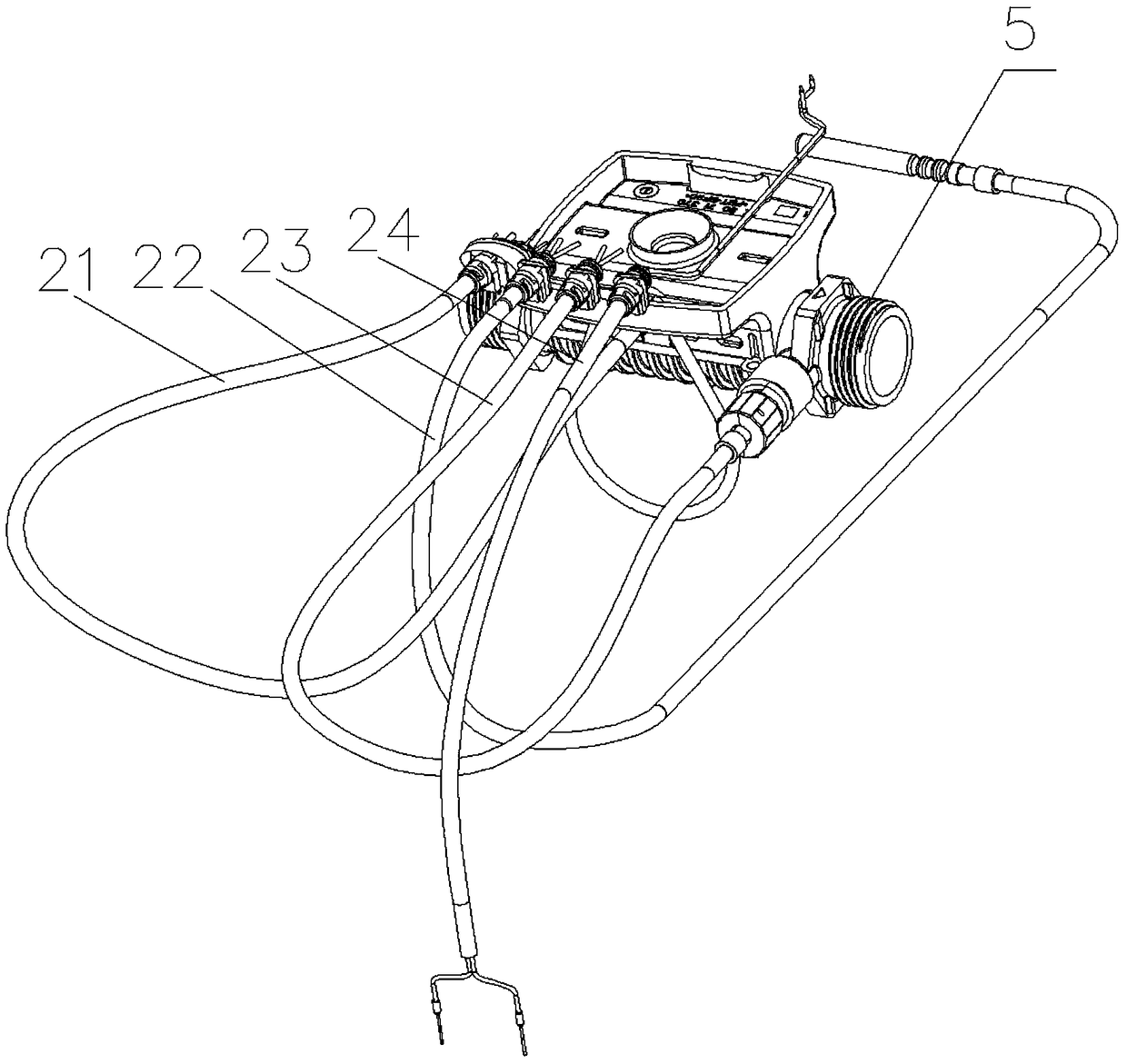

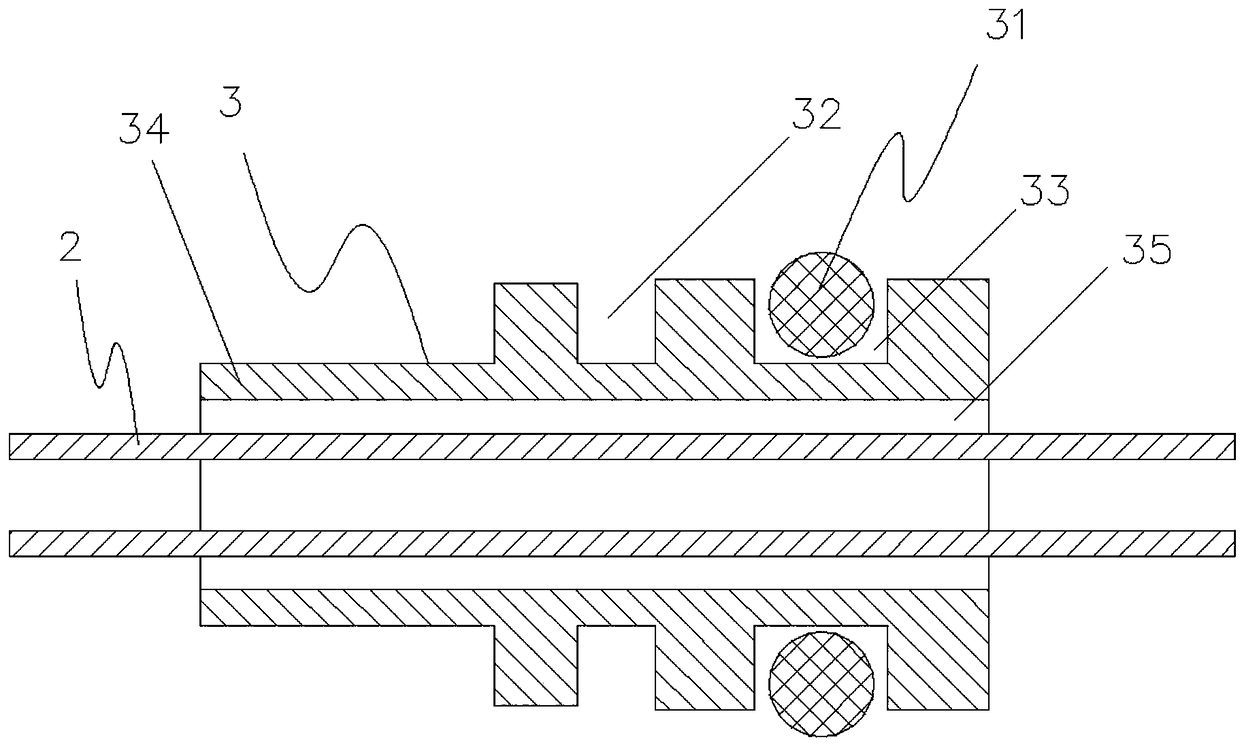

[0029] Such as Figure 1 to Figure 9 As shown, an ultrasonic heat meter with improved quality level of the present invention is provided with a housing 1 and at least one cable 2. The cable 2 is provided with a fixing member 3, and the housing 1 is provided with at least one mating fixing member 3 for connection and The through hole 13 communicates from the outside of the housing 1 to the inside of the housing 1. The through hole 13 is a through hole 13 whose inner side wall is annularly closed and integrally formed. A sealing ring 31 is arranged between the fixing member 3 and the inner wall of the through hole 13.

[0030] The cross section of each through hole 13 can be any one of a circle, an oval, and a square.

[0031] The housing 1 includes a bottom cover 12 and a face cover 11, and the bottom cover 12 and the face cover 11 clamp the fixing member 3.

[0032] The fixing member 3 is provided with a cable fixing hole 35 penetrating from one end to the other end, one of the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com