Paper box spray code detection equipment on production line

A detection equipment, production line technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve problems such as impacting the scanner, scanner skew, affecting scanner scanning and spraying codes, etc., to speed up the processing speed and improve The effect of scanning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

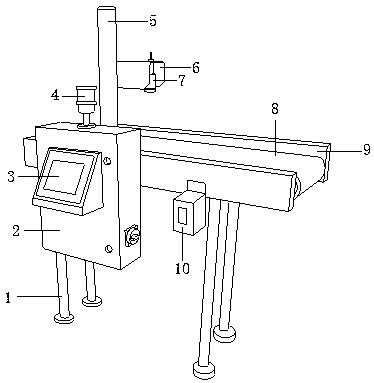

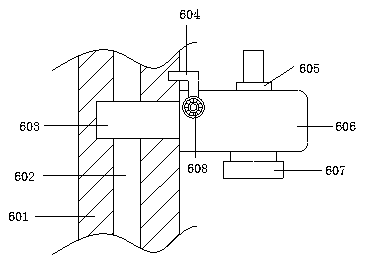

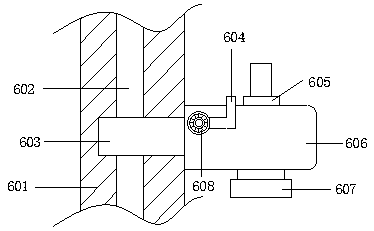

[0021] see Figure 1-Figure 3 , the present invention provides a technical solution for carton coding detection equipment on a production line: its structure includes a support tripod 1, a distribution box 2, a display screen 3, a warning light 4, a support rod 5, a scanning head bracket 6, and a high-definition scanning head 7. Drive belt 8, belt baffle 9, control box 10, the support tripod 1 is installed on the bottom of the belt baffle 9 in a spiral manner, the power distribution box 2 is located at the left end of the belt baffle 9, and the display screen 3 is installed on one-half of the distribution box 2 by embedding, the support rod 5 forms an integrated structure with the distribution box 2 by casting, and the scanning head bracket 6 is i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap