Electronic cigarette heating body and preparation method thereof

A heating body and electronic cigarette technology, applied in the field of electronic cigarettes, can solve the problems of burning e-liquid and oil-guiding cotton, poor atomization effect, bad taste, etc., and achieve the effect of increasing body surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

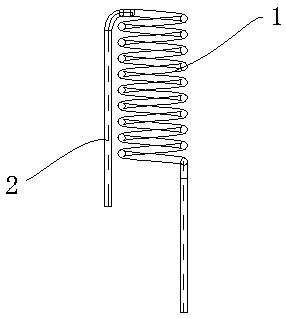

[0023] Example 1, such as figure 1 As shown, the electronic cigarette of this embodiment is a kind of electronic cigarette that generates heat, including a resistor with a set resistance value, and the two ends of the resistor are respectively electrically connected with the cathode and anode of the battery to form an electric heater; The formed spiral body 1 is welded with lead wires 2 at both ends of the spiral body 1 to form the two poles of the electric heating body, and the two poles of the electric heating body are respectively electrically connected to the cathode and the anode of the battery.

[0024] The invention mainly solves the problem that the solid electrothermal alloy wire is wound into a spiral heating element, the heat is excessively concentrated, the contact area between the heating element and the e-liquid is small, the atomization effect is not good, and the e-liquid and the oil-conducting cotton are easily burned and the taste is not good. The problem.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com