Method of making fringes in fabrics

A tassel and fabric technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of difficult production, cumbersome processes, time-consuming, etc., and achieve the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment provides a method for making tassels in woolen fabrics, the method comprising the following steps:

[0040] A method for making tassels in woolen fabrics, the method comprising the steps of:

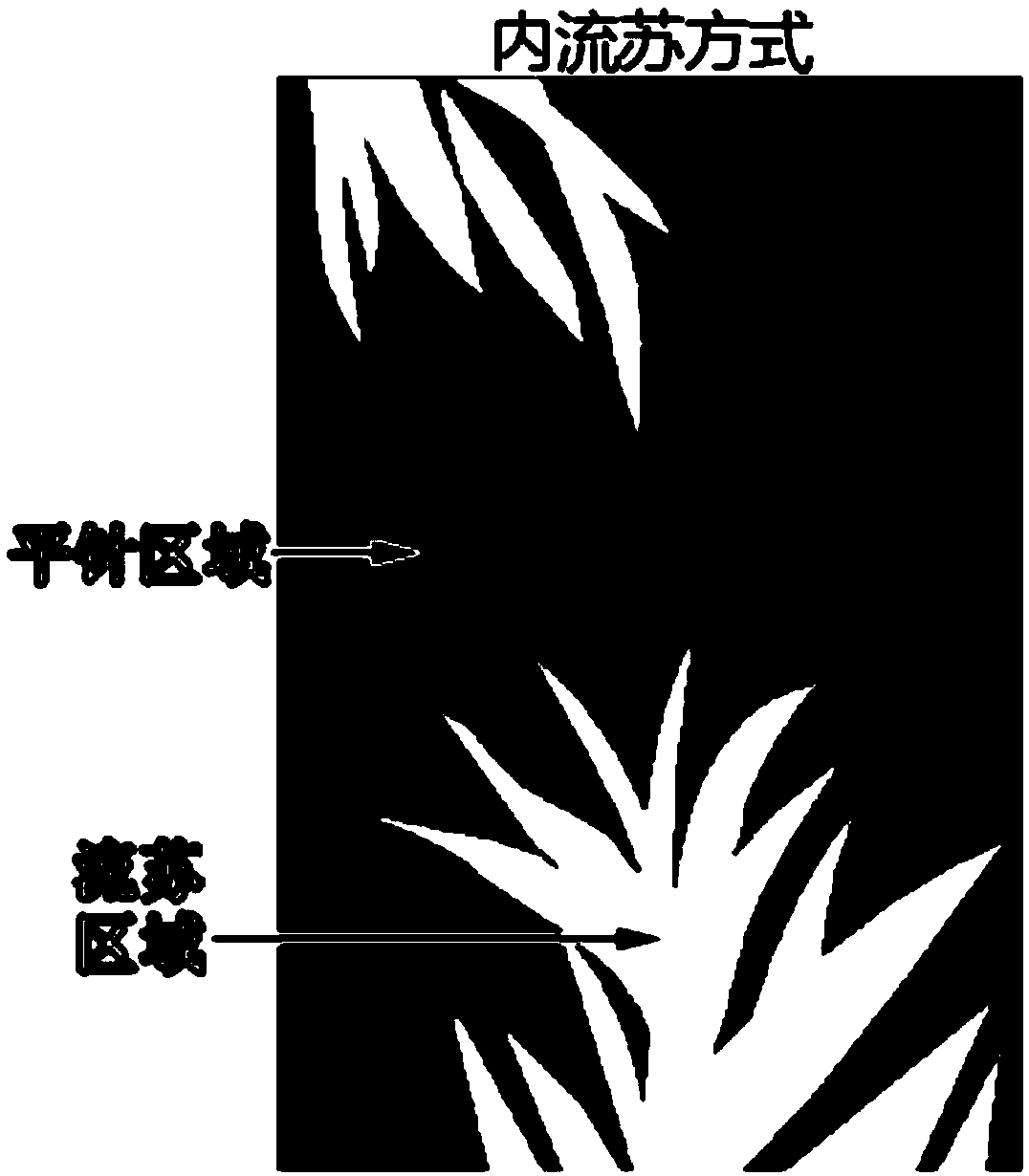

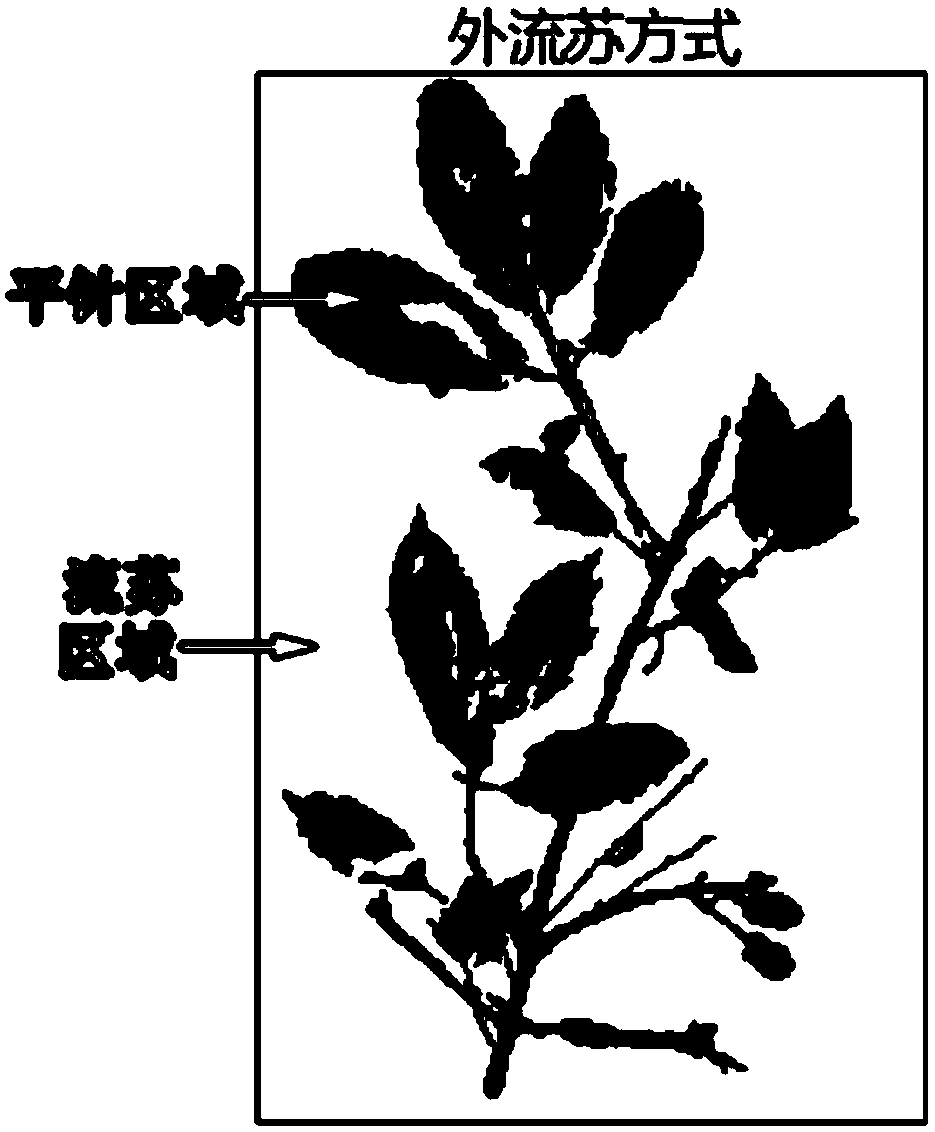

[0041] (1) draw the pattern of woolen fabric, and described fringe pattern comprises plain stitch area and fringe area, see figure 1 ;

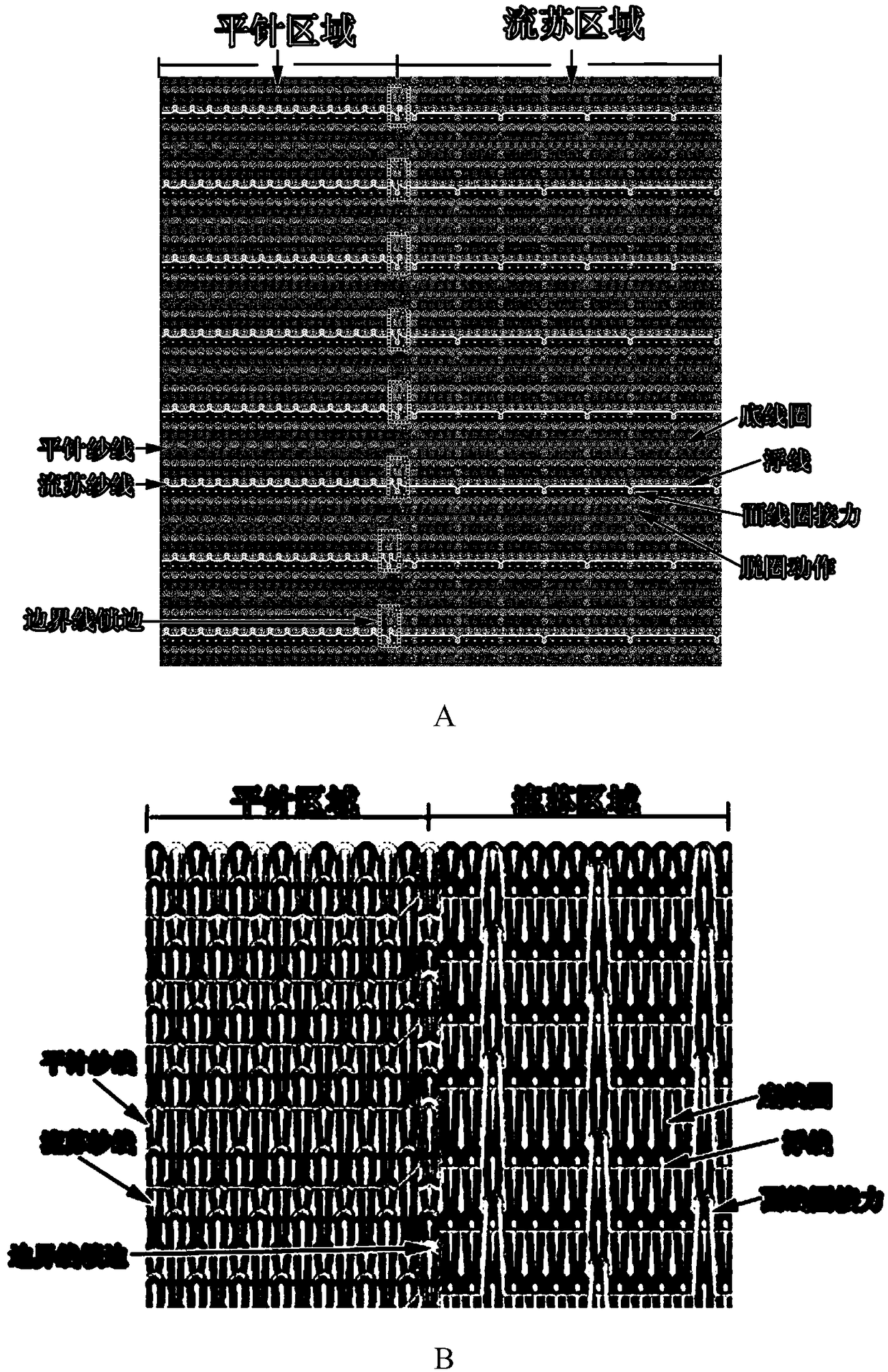

[0042] (2) import the pattern into the computerized flat knitting machine (see image 3 ), and distribute the plain stitch yarn and tassel yarn on different yarn guides for knitting as follows:

[0043] In the plain stitch area, the bottom loop knitted with the plain stitch yarn and the bottom loop knitted with the tassel yarn are knitted together;

[0044] In the fringe area, weave the bottom loop with the flat stitch yarn, weave the surface loop with the fringe yarn and take off the loop, and repeat the steps of knitting the surface loop and taking off the loop at least once to form a tassel floating line; see Figure 4 ;

...

Embodiment 2

[0055] This embodiment provides a method for making tassels in woolen fabrics, the method comprising the following steps:

[0056] (1) draw the pattern of woolen fabric, and described fringe pattern comprises plain stitch area and fringe area, see figure 2 ;

[0057] (2) import the pattern into the computerized flat knitting machine (see image 3 ), and distribute the plain stitch yarn and tassel yarn on different yarn guides for knitting as follows:

[0058] In the plain stitch area, the bottom loop knitted with the plain stitch yarn and the bottom loop knitted with the tassel yarn are knitted together;

[0059] In the fringe area, knit the bottom loop with the plain yarn, knit the top loop with the tassel yarn and take off the loop, repeat the steps of knitting the top loop and knock off the loop to form a tassel floating line; see Figure 6 ;

[0060] (3) Trim the floating thread of the tassel to get final product; Wherein:

[0061] The computerized flat knitting mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com