Secondary pouring construction method for pit-in-pit foundation bottom plate in large deep foundation pit

A foundation floor and secondary pouring technology, which is applied in the direction of basic structure engineering, buildings, artificial islands, etc., can solve the problems of high risk in foundation pit construction and long construction period of deep foundation pits, and achieve the reduction of anti-floating requirements and facilitate reinforcement and stability Sexuality, the effect of reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

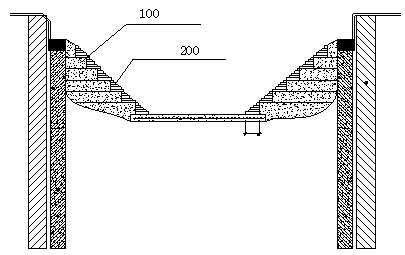

[0031] A secondary pouring construction method for the bottom plate of the pit-in-pit foundation of a large-scale deep foundation pit. First, the earthwork in the pit-in-pit is excavated to the bottom elevation of the cushion layer, and then the cushion layer at the bottom of the pit is poured.

[0032] Specifically, in order to prevent the danger of piping in the foundation pit, the thickness of the cushion layer should be increased as much as possible to 300-400mm. Therefore, during the excavation of the earthwork, attention should be paid to the control of the bottom elevation of the cushion layer.

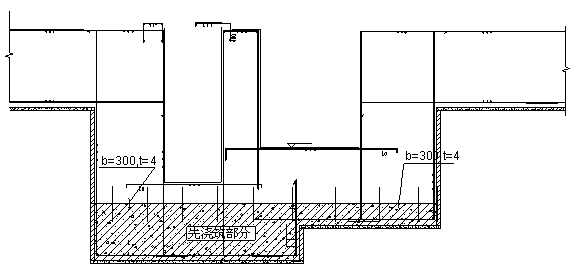

[0033] The cushion concrete adopts ≥C30 impermeable concrete, and the cushion is covered with Ф10@150 single-layer two-way steel mesh, and the scope of cushion pouring is that the bottom of the deep pit is expanded 500-800mm wide, which is convenient for the subsequent retaining wall of masonry.

[0034] After the cushion pouring is completed and cured, the engineering piles wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com