High speed super wide roller oil supply bearing

An ultra-wide roller and oil supply technology, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of poor chip removal, incomplete, uneven oil supply, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further illustrate the features and advantages of the present patent, the following advances are described in conjunction with the accompanying drawings.

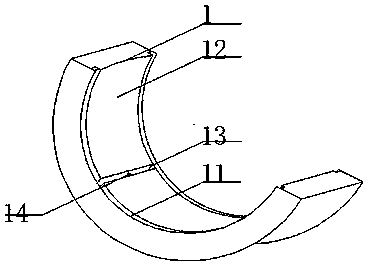

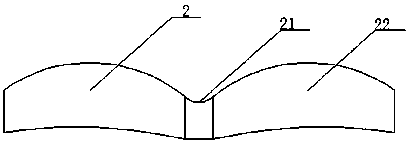

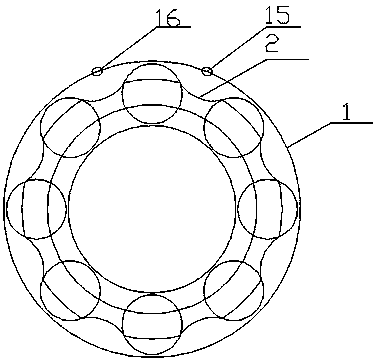

[0012] As shown in the figure: a high-speed and ultra-wide roller oil supply bearing, including: an inner ring, an outer ring 1, rollers, and a roller bracket 2; the outer ring 1 is set on the inner ring, and the rollers are installed on the inner ring. Between two circles; the rollers are multi-row rollers; the inner wall of the outer ring 1 is provided with a flow groove 11 for oil to pass through; a bulging flow groove 12 is provided directly above each row of the rollers ; A communication groove 13 is provided at the position corresponding to the chip outlet at the bottom of the outer ring 1 . The roller support 2 is in the shape of a symmetrical wing; a diversion groove is arranged at the root where the two wings are connected. The inner wall of the inner ring is provided with a bulging flow groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com