Adhesive sticker material flatness detecting equipment

A technology for testing equipment and flatness, applied in the direction of mechanical roughness/irregularity measurement, etc., can solve the problems of inconvenient operation, out of measurement, and unguaranteed measurement accuracy, and achieve the effect of convenient operation and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

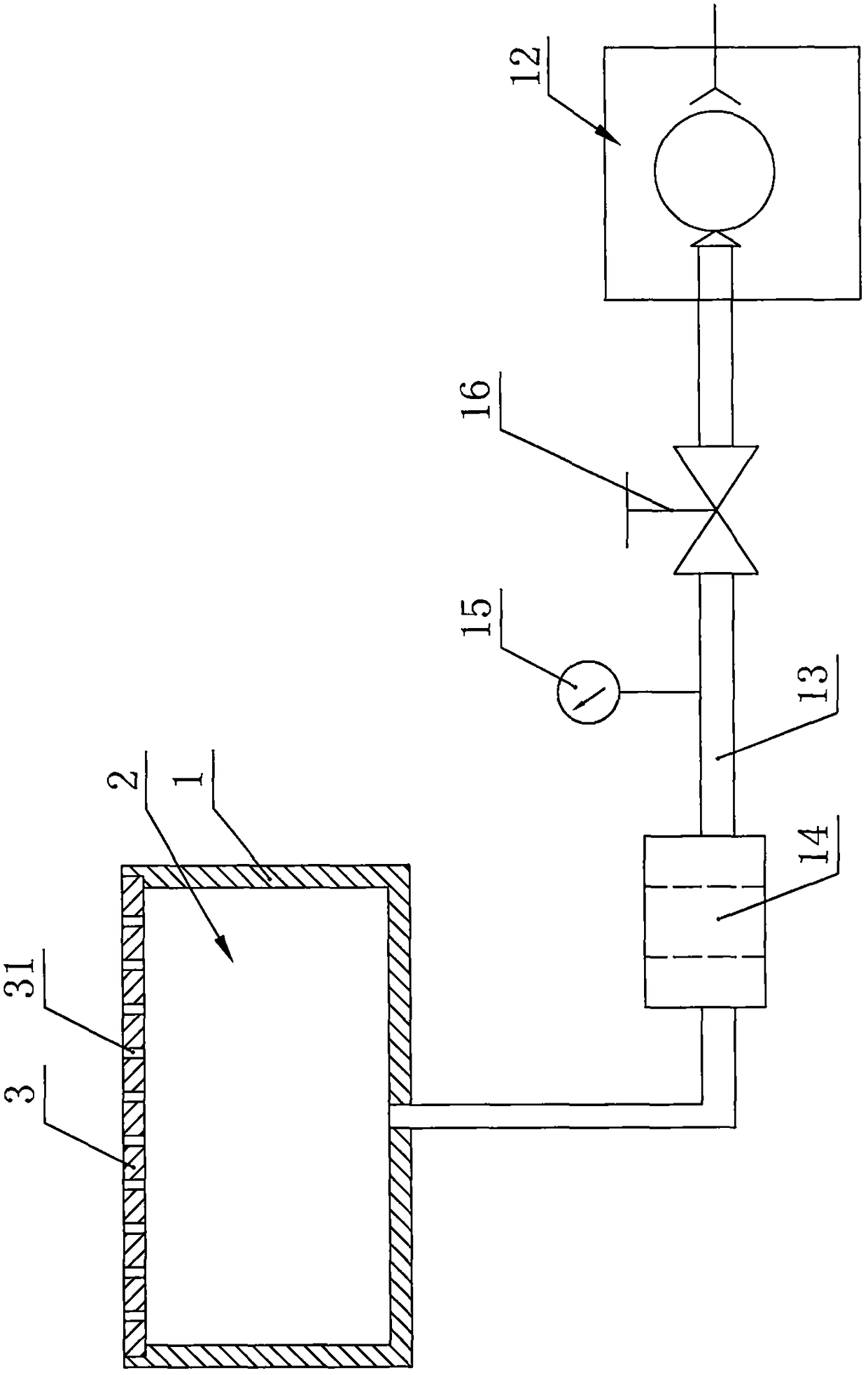

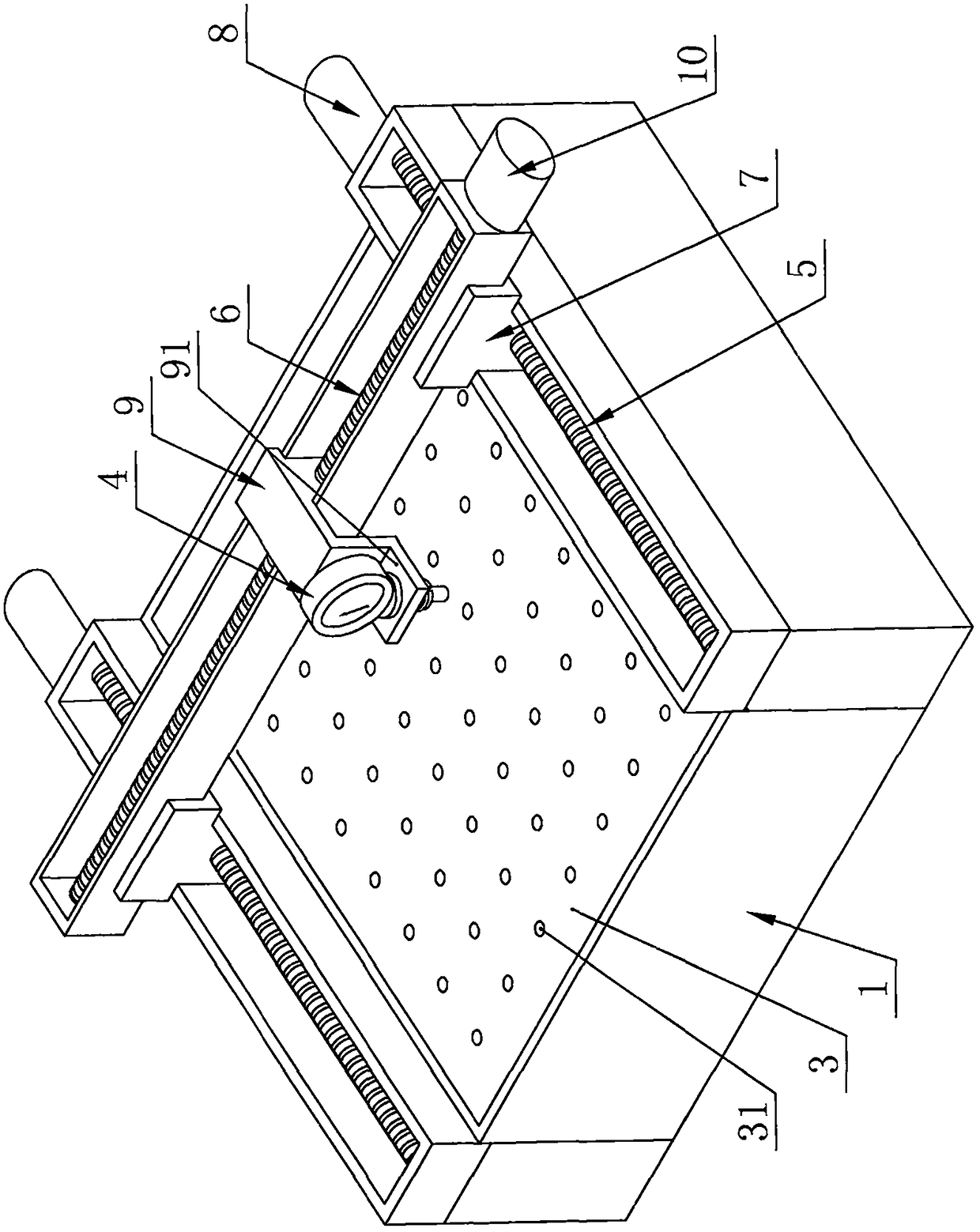

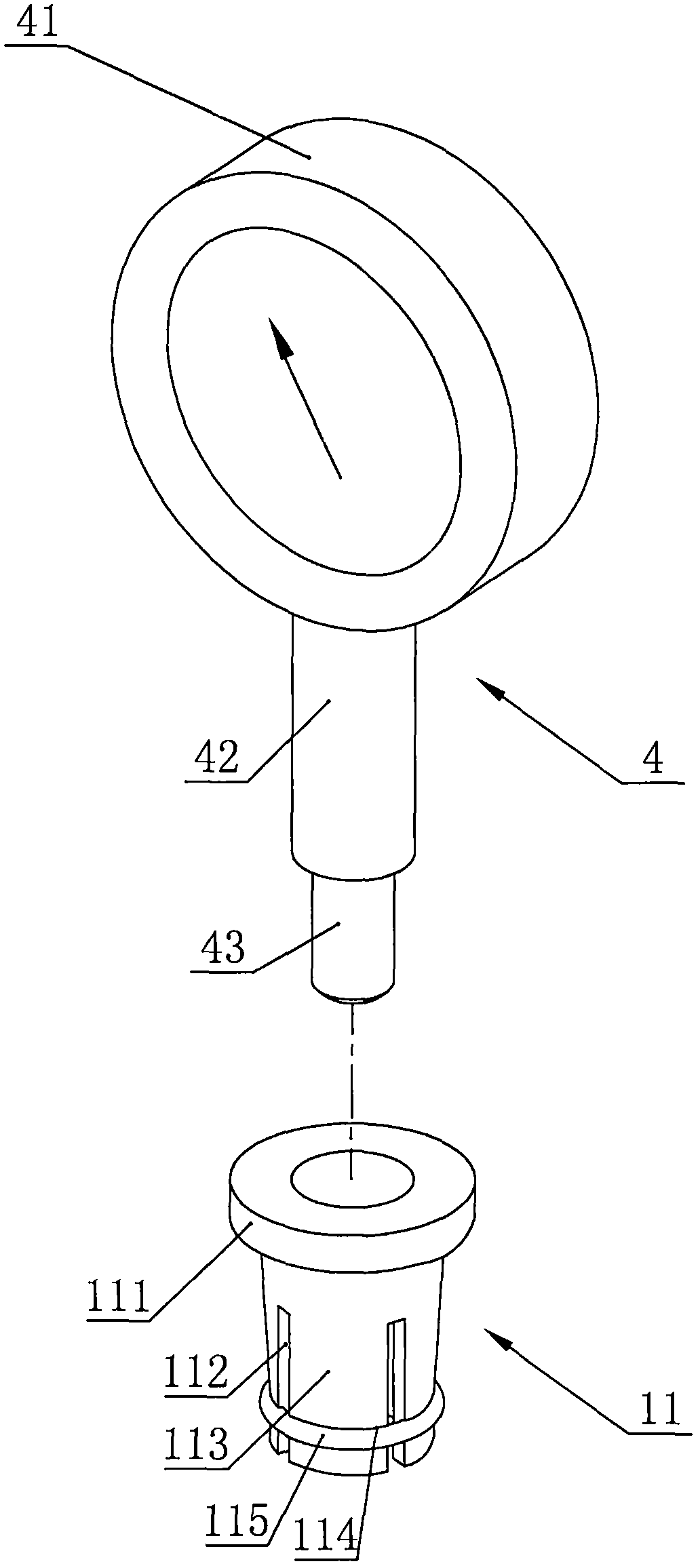

[0014] Such as figure 1 , 2 , 3 shows a self-adhesive material flatness testing equipment, including a workbench 1, a cavity 2 is arranged on the workbench 1, and a cover for the cavity 2 is fixed on the workbench 1 The detection plate 3 of the detection plate 3 is evenly distributed with a plurality of through holes 31 that are in communication with the cavity 2, and the cavity 2 of the workbench 1 is also connected with a vacuum device. The workbench 1 The top is equipped with a measuring device for detecting the flatness of the self-adhesive material laid on the detection plate 3, and the measuring device includes a dial gauge 4 and a moving mechanism for driving the dial gauge 4 to move relative to the detection plate , the moving mechanism includes a longitudinal guide rail 5 and a transverse guide rail 6, the longitudinal guide rail 5 is fixed on the workbench 1, a longitudinal slider 7 is slidably installed on the longitudinal guide rail 5, and the longitudinal slider ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com