Door sheet carrying device based on anti-collision shock absorption design

A carrier device and anti-collision technology, which is applied in the direction of transportation and packaging, multi-axis trolleys, sleds, etc., can solve the problems of door panel collision, door panel anti-collision protection, collision deformation, etc., and achieve the effect of convenient placement and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

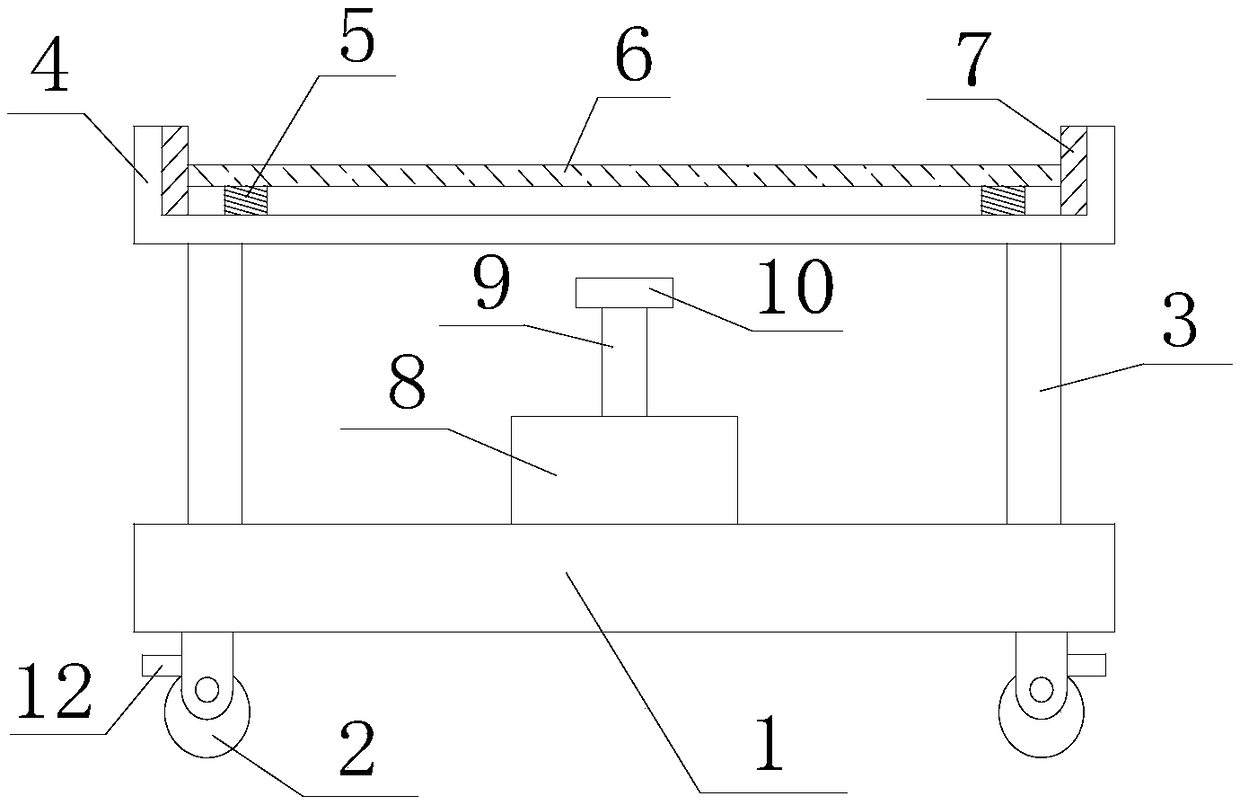

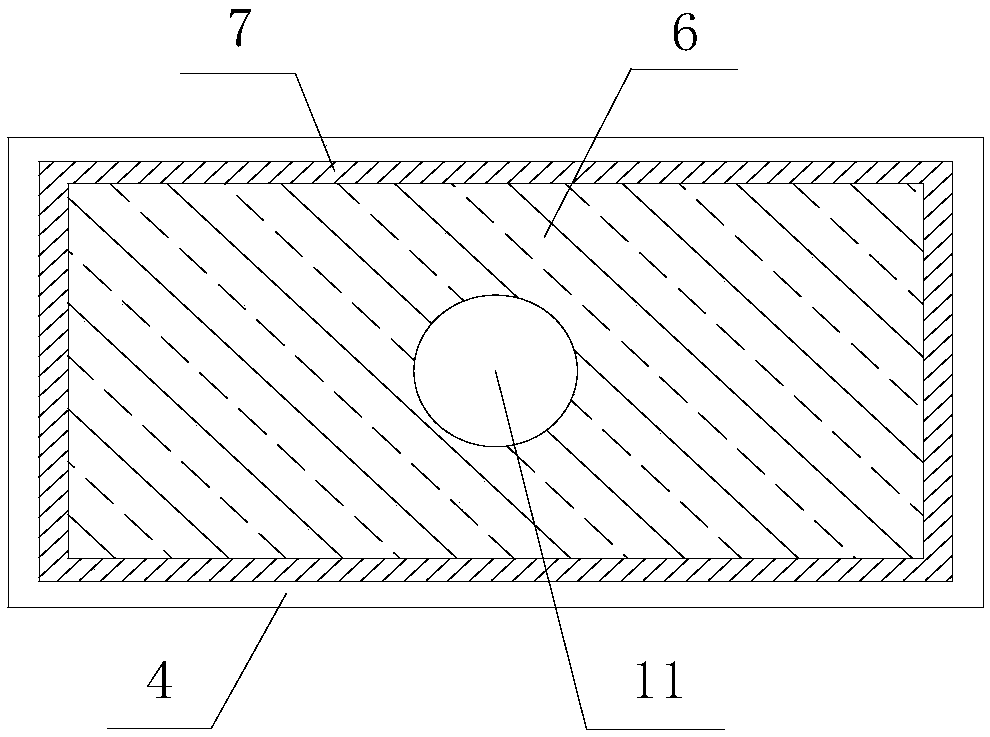

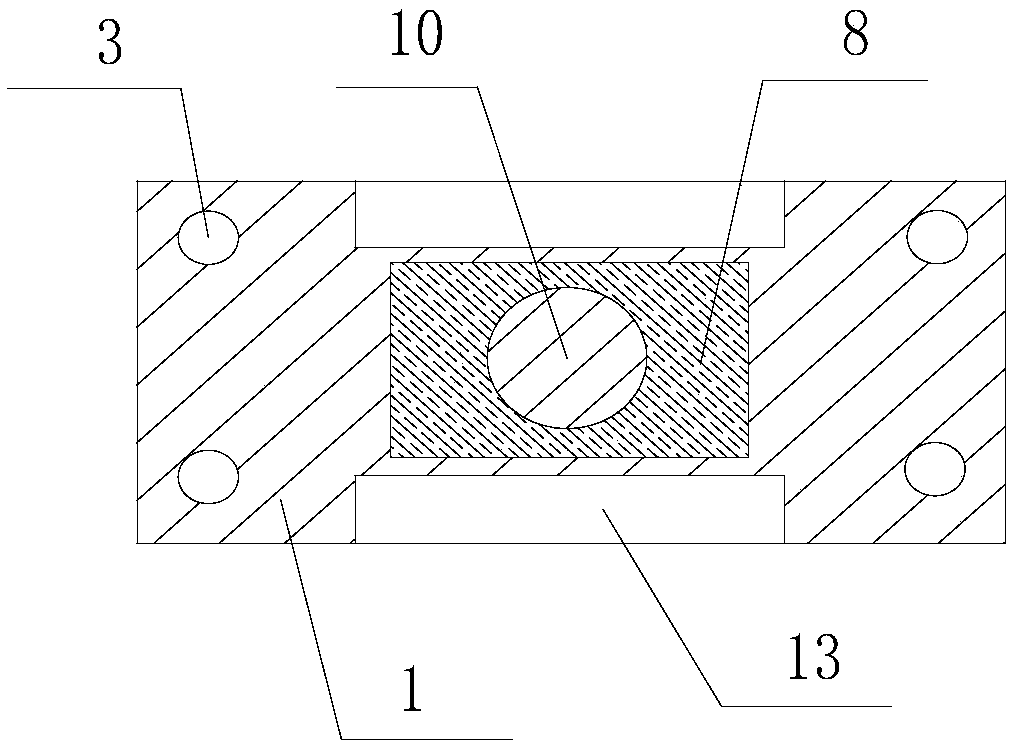

[0024] Such as Figure 1-3 As shown, the door panel carrying device based on the anti-collision and shock absorption design includes a base plate 1, a universal wheel 2 arranged at the bottom of the base plate 1, and a support frame 3 arranged at the top of the base plate 1, and a lifting device is provided at the middle position of the top of the base plate 1 8. The lifting device 8 is provided with a lifting shaft 9, the top of the lifting shaft 9 is provided with a top plate 10, and the top of the support frame 3 is provided with a loading tank 4, the opening of the loading tank 4 is upward, and the inner wall of the loading tank 4 An anti-collision layer 7 is provided, and a load-bearing plate 6 is placed in the loading tank 4. Both are provided with through holes 11 , and the through holes 11 are facing the top plate 10 below.

Embodiment 2

[0026] As an optimization of the above embodiment, the anti-collision layer 7 is a foam layer, which can slow down the direct collision between the corners of the door panel and the loading slot 4; the universal wheel 2 is provided with brake pads 12, which can be braked at any time Fixed; there is a component groove 13 on the bottom plate 1, which can be used to place the supporting processing profiles of the door panel; the surfaces of the load-bearing plate 6 and the top plate 10 are made of rubber, which can prevent the door panel from being picked up and moved during the application. Abrasion occurs in the middle; the lifting device 8 is a hydraulic lifting device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com