Colorful fabric distribution device and method

A fabric cloth, magic color technology, applied in the direction of supply device, auxiliary molding equipment, ceramic molding machine, etc., can solve the problem of difficult to meet the needs of various styles, colors, and individuality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

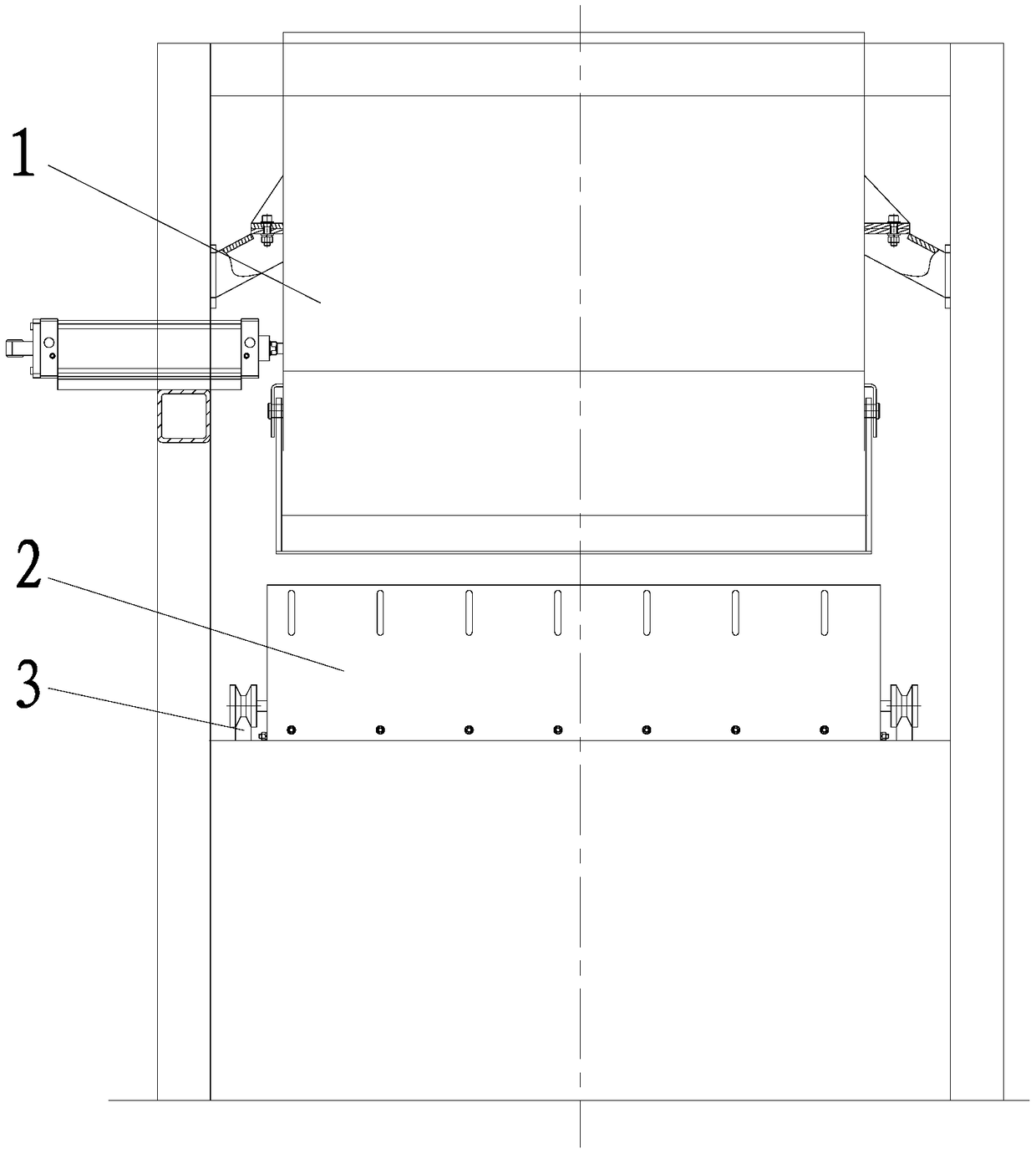

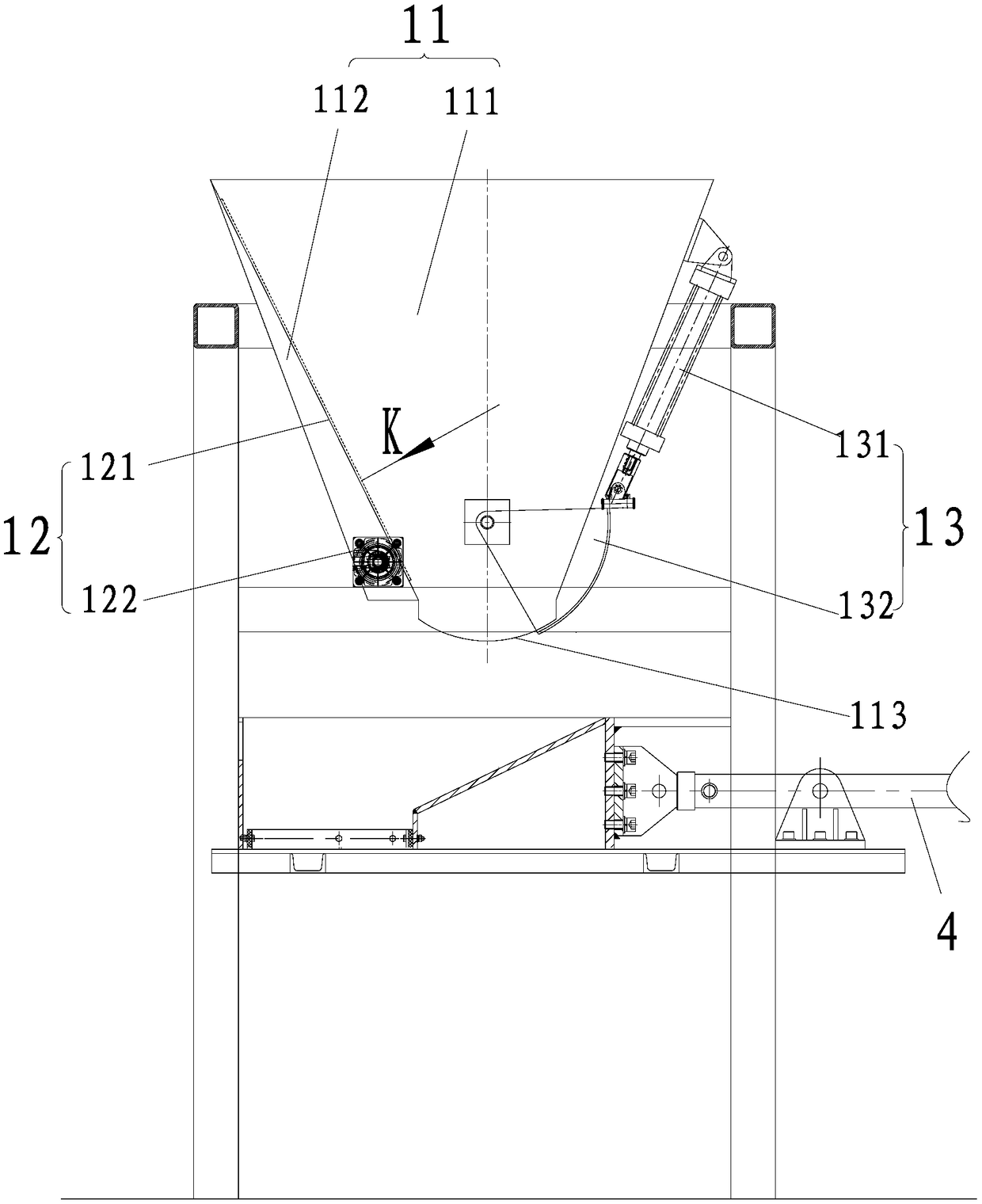

[0029] Such as Figures 1 to 6 As shown, in this embodiment, the magic color fabric distributing device 1 mainly includes a hopper 11 and a material distributing mechanism 12 .

[0030] The hopper 11 has a hopper inlet and a hopper outlet 113. The hopper 11 can be in any shape. Preferably, the hopper 11 is in the shape of a bucket, which is convenient for receiving and discharging materials.

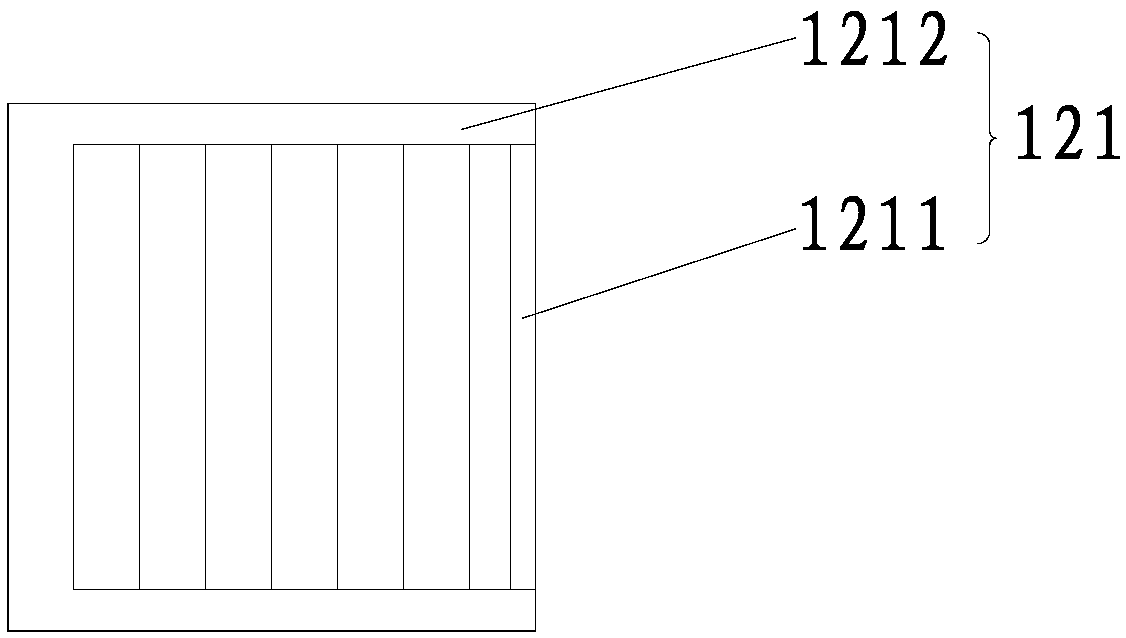

[0031] The material distribution mechanism 12 mainly includes a material distribution plate 121 and a material distribution driving part 122 . The material distribution plate 121 is arranged in the hopper 11, and the material distribution driving part 122 drives the material distribution plate 121 to move, thereby correspondingly conducting or blocking the passage of the material in the hopper 11 entering the hopper outlet 113, that is to say, the material distribution mechanism 12 The material in the hopper 11 can be discharged through the hopper outlet 113 .

[0032] Preferably, the ...

Embodiment 2

[0039] In this embodiment, the fabric machine for the illusion fabric mainly includes a silo, a fabric advancing and retreating track, a fabric driving unit and an illusion fabric fabric distributing device 1 . Wherein, the magic color fabric distributing device 1 adopts the structure as described above, and will not be repeated here.

[0040] The silo has a silo inlet and a silo outlet. The bucket discharge port 113 is set corresponding to the warehouse feed port.

[0041] Adapted pulleys are arranged on the cloth advancing and retreating track, and the pulleys are arranged on the feed bin.

[0042] The cloth driving part drives the material bin to advance and retreat along the cloth advancing and retreating track, and carries out cloth corresponding to the mold of the molding machine. The cloth driving part can adopt an oil cylinder or an air cylinder, and the piston rod of the oil cylinder or the air cylinder is hinged to the feed bin.

[0043] When working, the fabric dri...

Embodiment 3

[0045] In this embodiment, the forming machine of the illusion fabric brick mainly includes a mold and an illusion fabric distributing device 1 . Wherein, the magic color fabric distributing device 1 adopts the structure as described above, and will not be repeated here.

[0046] The mold can adopt any existing structure, and the mold mainly has a mold inlet and a mold outlet, and the bucket outlet 113 is set correspondingly to the mold inlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com