Double steel wheel axle and its road roller

A dual-drum, road roller technology, applied in the directions of roads, roads, vehicle components, etc., can solve the problems of large turning range, unfavorable work efficiency, difficult adjustment, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

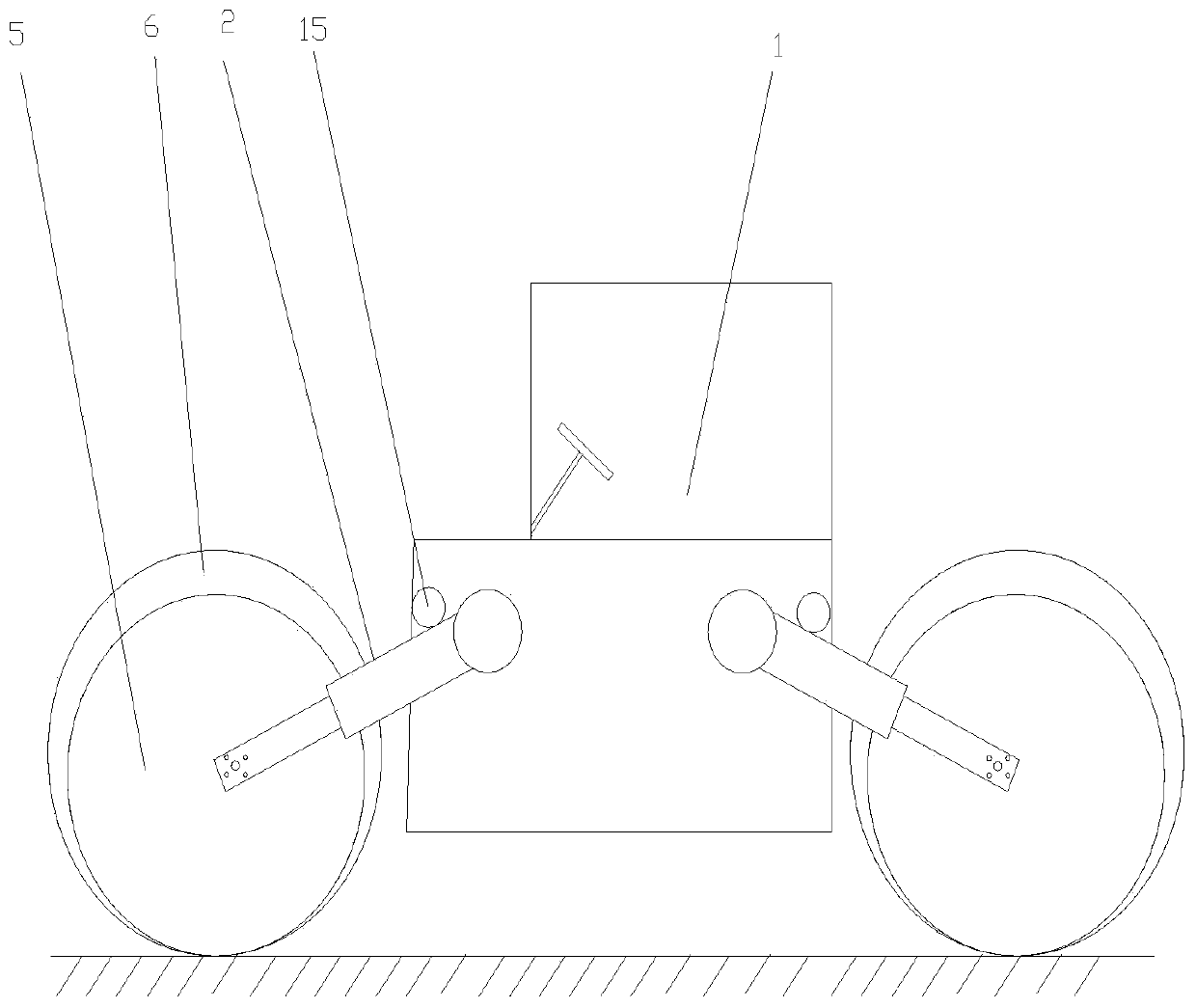

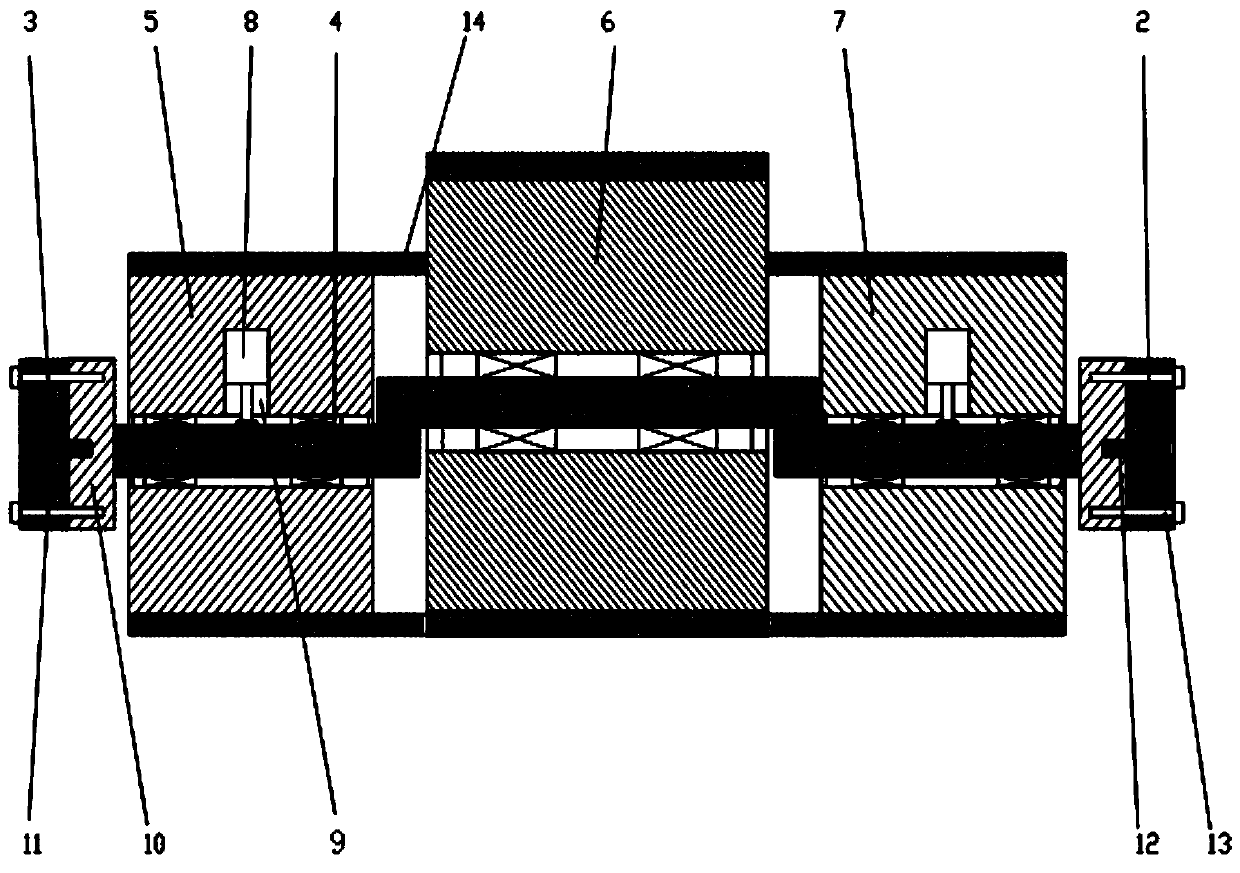

[0017] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a structural schematic diagram of the steel drum in the present invention. As shown in the figure, the road roller in this embodiment includes a car body 1, a front steel drum arranged on the front side of the car body, and a rear steel drum arranged on the rear side of the car body. 1. The double steel wheel axle between the rear cylinder and the car body, the double steel wheel axle includes the front axle connected between the front steel cylinder and the front end of the car body and the front axle connected between the rear steel cylinder and the rear end of the car body The rear axle; the front and rear axles all include left longitudinal beam 2, right longitudinal beam 3 and crossbeam 4, and the inner end of the left longitudinal beam and the inner end of the right longitudinal beam are connected to the vehicle body through a ball joint structure end; the left longitudinal be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com