A flexible rack

A kind of rack and flexible technology, applied in the direction of elements with teeth, belts/chains/gears, hoisting devices, etc., can solve the problems of narrow application range of a single specification rack, high cost, and the rack can no longer be used. , to achieve the effect of ingenious structure, convenient assembly and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

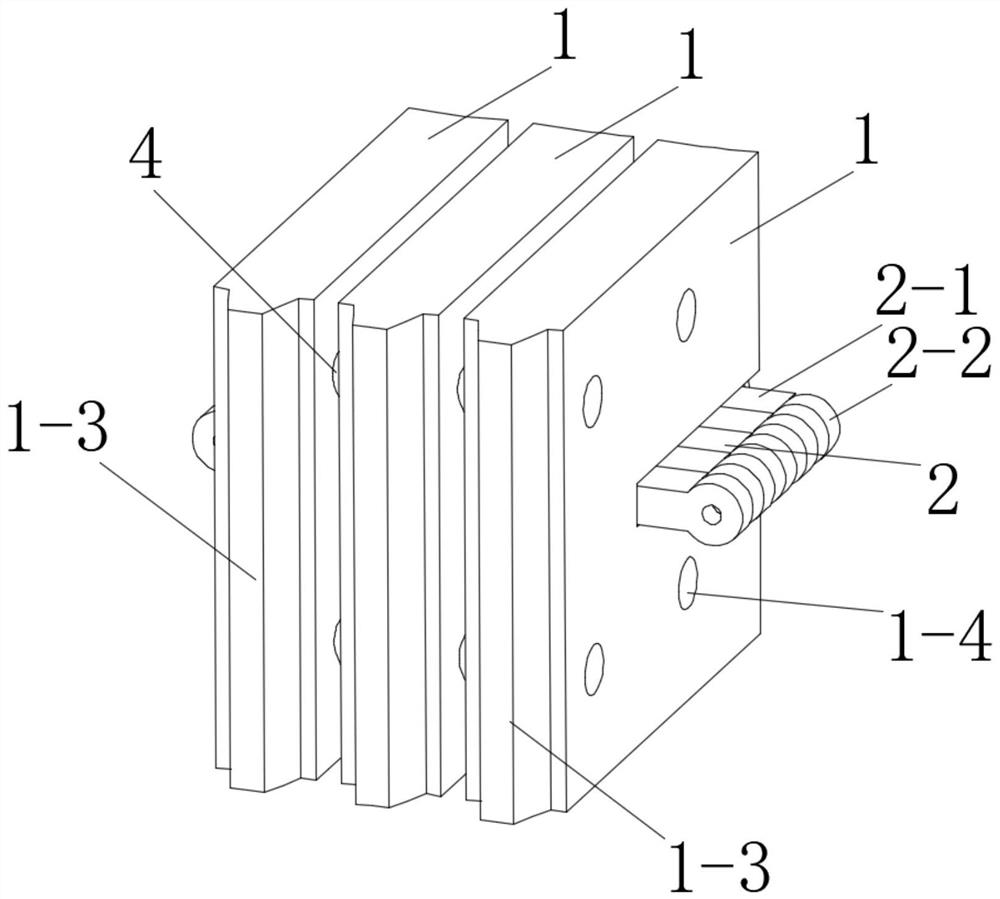

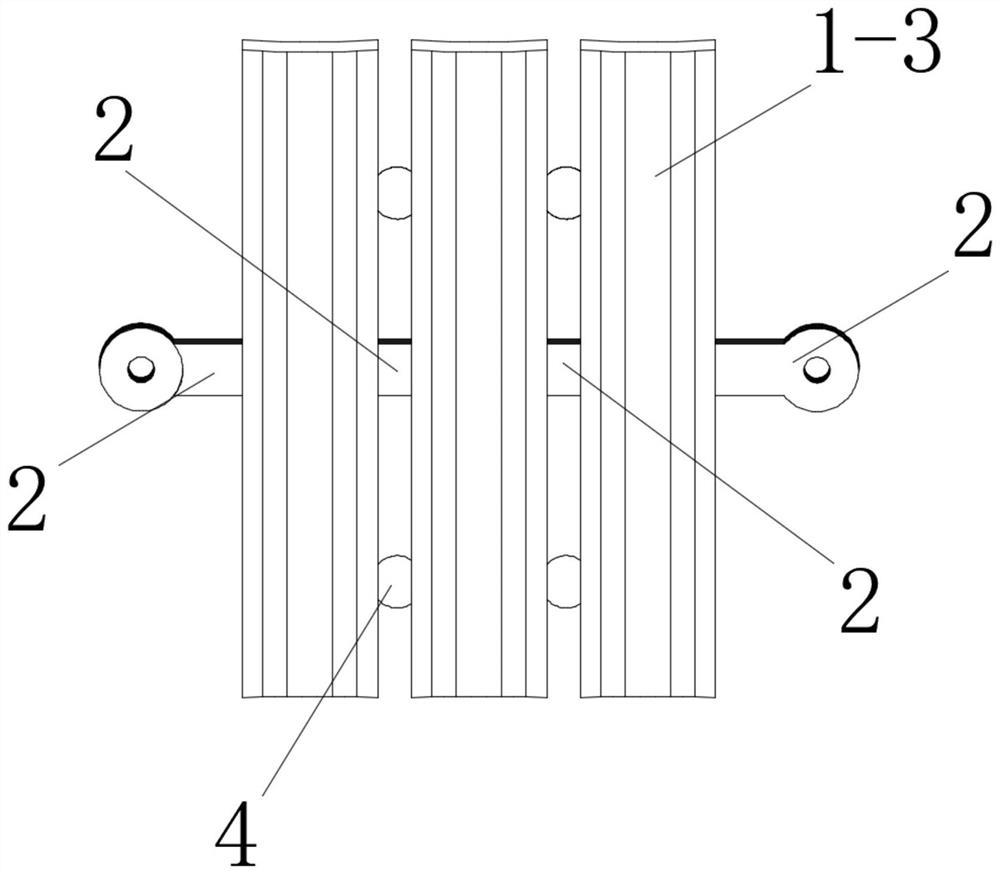

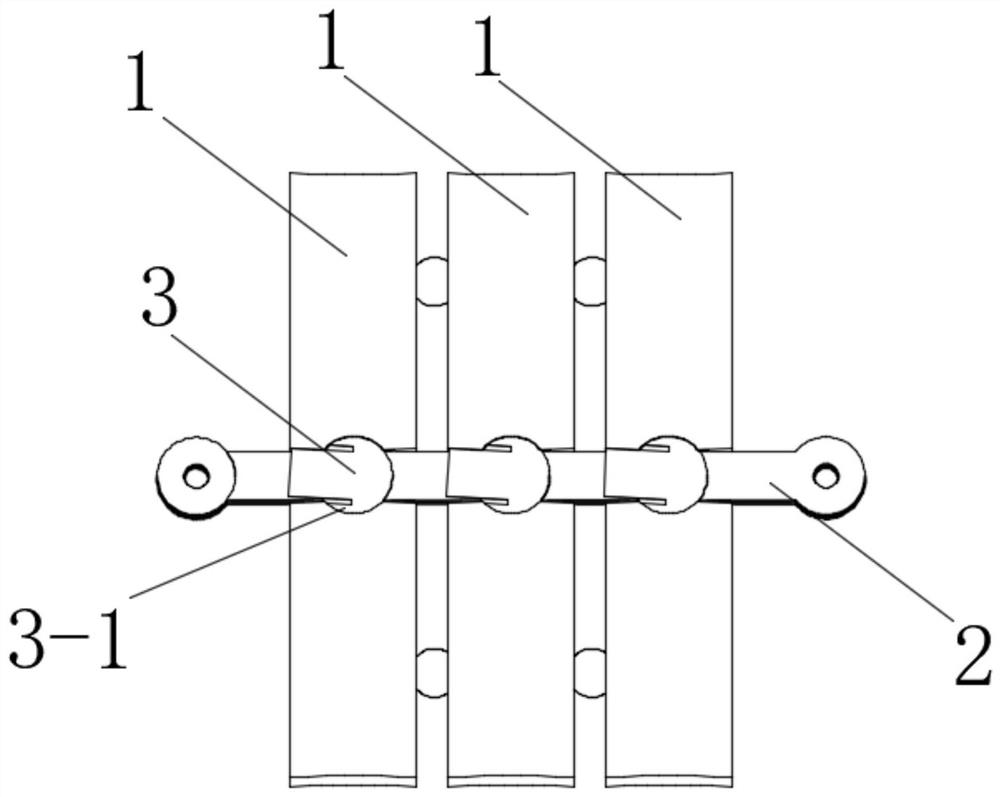

[0045] See Figure 1 to Figure 7 , the flexible rack of this embodiment includes a tooth body 1 and a tooth body connection assembly 2 . Both the tooth body 1 and the tooth body connecting assembly 2 are provided in plurality. Each tooth body 1 is arranged in sequence. Both sides of each tooth body connecting assembly 2 are respectively rotatably connected in the limiting spaces of two adjacent tooth bodies 1 . A stop piece 3 is provided in the limiting space of the tooth body 1 to prevent the tooth body connection assembly 2 from leaving the limiting space.

[0046] In order to cooperate more stably with the tooth body connection components, the limit effect is excellent, and the overall stability after assembly is improved, the limit space of the tooth body 1 includes the blind hole 1-1 on the back of the tooth body 1, and the On both sides of the body 1, and communicate with the notch 1-2 of the blind hole 1-1.

[0047] In order to provide a rotating space for the tooth...

Embodiment 2

[0062] See Figure 8 , this embodiment is basically the same as Embodiment 1, the difference is:

[0063] The tooth connection assembly 2 includes a second connection block 2-3. Both sides of the second connecting block 2-3 are provided with a plurality of second connecting rings 2-4 that fit into the limiting space of the tooth body 1, and the second connecting rings located on the same side of the second connecting block 2-3 2-4 are coaxial settings.

[0064] The second connection rings 2-4 on one side of the second connection block 2-3 of the tooth body connection assembly 2 and the second connection rings 2-4 on the other side are arranged alternately on the projection of the horizontal plane.

[0065] installation method:

[0066] Step 1: first connect two adjacent tooth body connection assemblies 2 by plugging, and the second connection rings 2-4 of the two tooth body connection assemblies 2 are coaxial to form corresponding connection shafts.

[0067] Step 2: Insert...

Embodiment 3

[0069] See figure 1 and figure 2 , the remainder of this embodiment is the same as in Embodiment 1, the difference being:

[0070] In order to provide elasticity between two adjacent tooth bodies and improve overall flexibility, a number of positioning balls 4 with elastic distances are arranged between every two adjacent tooth bodies 1 . Elastic pitch positioning ball 4 is made of rubber. Preferably, there are four elastic spacing positioning balls 4 arranged in a square shape.

[0071] In order to stably install the positioning balls 4 with elastic spacing, a plurality of spherical grooves 1-4 cooperating with the positioning balls 4 at elastic spacings are evenly distributed on both sides of the tooth body 1 .

[0072] To prevent the elastic distance positioning ball 4 from falling, the distance between every two adjacent tooth bodies 1 is smaller than the diameter of the elastic distance positioning ball 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com