A multi-shaft synchronous transmission device for non-parallel shaft transmission

A multi-axis synchronization and transmission technology, which is applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve problems such as the inability to apply multi-point transmission alone, large space production costs, and only one-to-one transmission. Achieve the effect of ingenious structure, less space occupation and smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

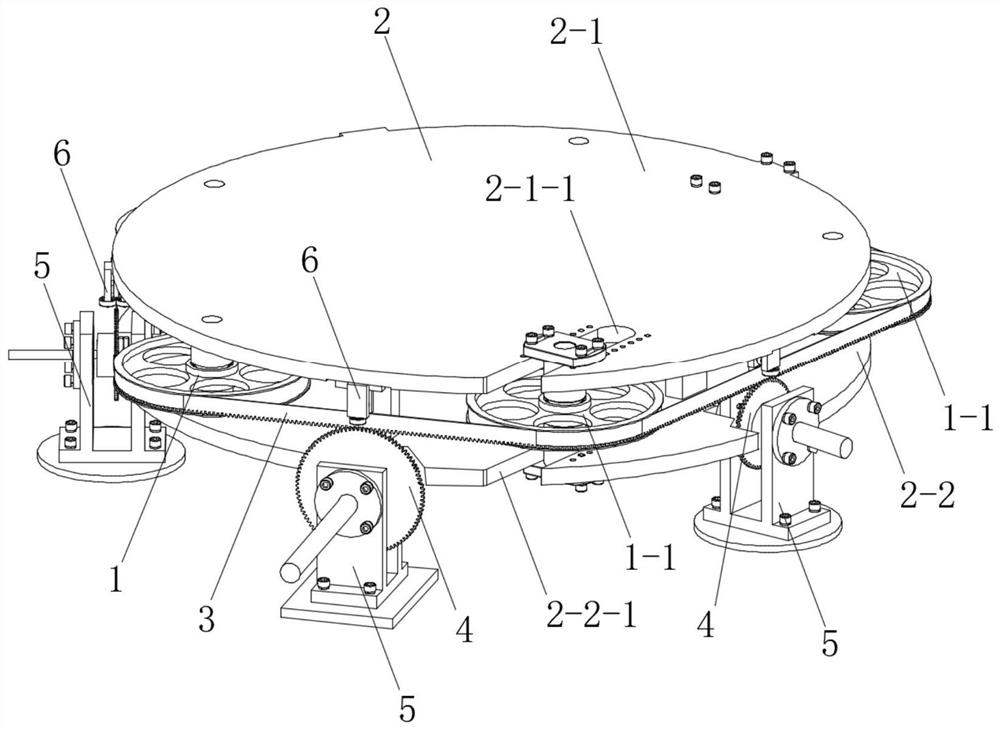

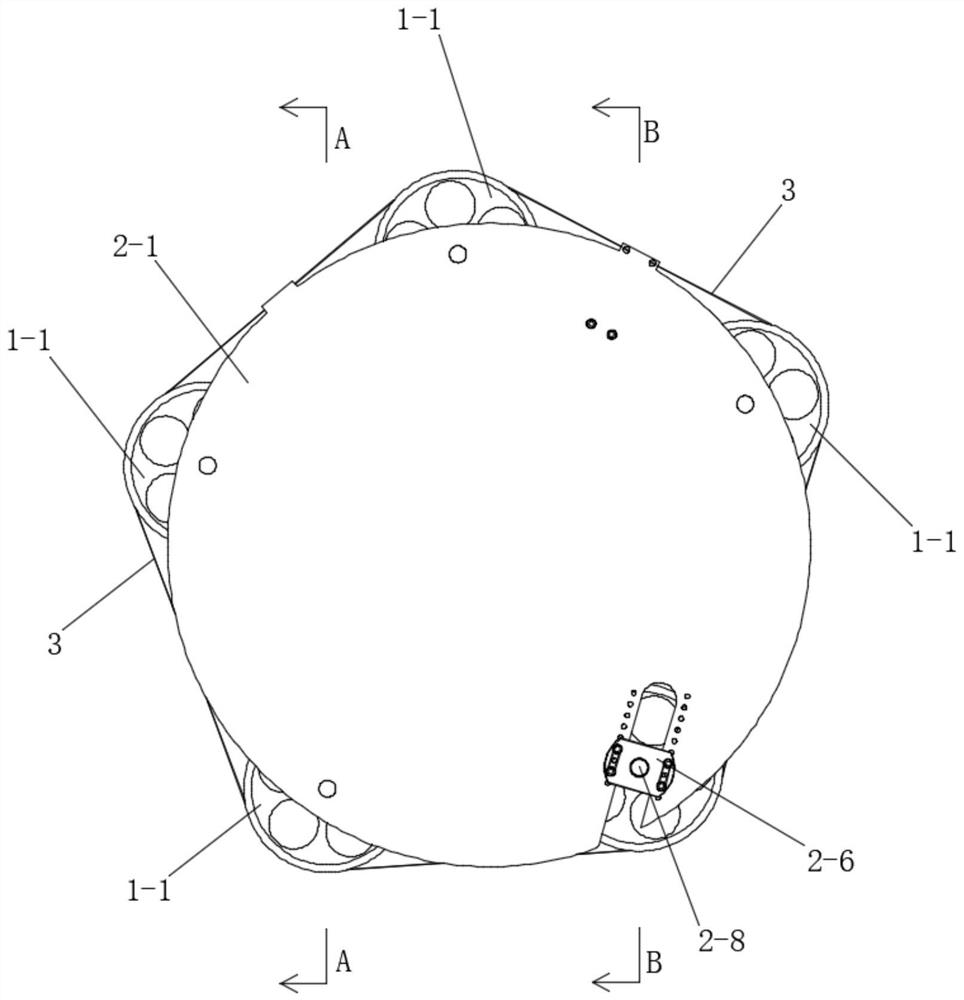

[0034] See Figure 1 to Figure 6 , the multi-axis synchronous transmission device for non-parallel shaft transmission in this embodiment includes a transmission wheel assembly 1 , a transmission wheel mounting base 2 , a flexible rack ring 3 , a pinion shaft assembly 4 and a base 5 . The transmission wheel assembly 1 is arranged on the transmission wheel mounting base 2 . The transmission wheel assembly 1 includes a plurality of transmission wheels 1 - 1 supporting the flexible rack ring 3 from the inside of the flexible rack ring 3 and cooperating with the flexible rack ring 3 . The bottom of the flexible rack ring 3 is provided with teeth. A plurality of bases 5 are evenly distributed along the bottom edge of the transmission wheel mounting base 2 . There are multiple gear shaft assemblies 4 and they are mounted on multiple bases 5 respectively. The pinion shaft assembly 4 meshes with the flexible rack gear 3 .

[0035] A plurality of transmission wheels 1-1 of the trans...

Embodiment 2

[0047] See figure 1 and figure 2 , this embodiment is basically the same as Embodiment 1, the difference is:

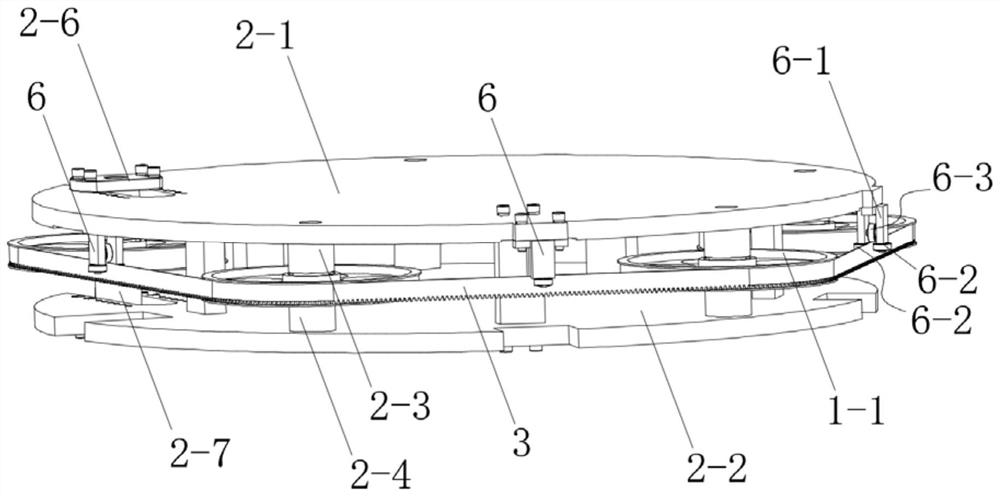

[0048] This embodiment also includes a guide assembly 6 . A plurality of guide assemblies 6 are provided on the drive wheel mount 2 . Each guide assembly 6 is respectively located above each pinion shaft assembly 4, and is used to limit the shaking of the flexible rack ring 3.

[0049] The guide assembly 6 includes a fixing part 6-1 and side guide wheels 6-2. The fixing part 6-1 is fixed on the drive wheel mounting seat 2. Two side guide wheels 6-2 are rotatably connected to the fixing member 6-1, and the peripheral surfaces of the two side guide wheels 6-2 are attached to the two sides of the flexible rack ring 3 respectively.

[0050] The guide assembly 6 also includes a top guide wheel 6-3. The top guide wheel 6-3 is rotatably connected to the fixing member 6-1, and the peripheral surface of the top guide wheel 6-3 is attached to the top surface of the flexi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com