A structure for self-controlled low pressure normally open decompression

A low-pressure, pressure-reducing valve technology, applied in separation methods, filtration separation, functional valve types, etc., can solve problems such as difficulty in ensuring water output, affecting life and production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the following examples are combined with the appended figure 1 To attach Figure 4 The technical solutions provided by the present invention are described in detail, but the following content is not intended as a limitation of the present invention.

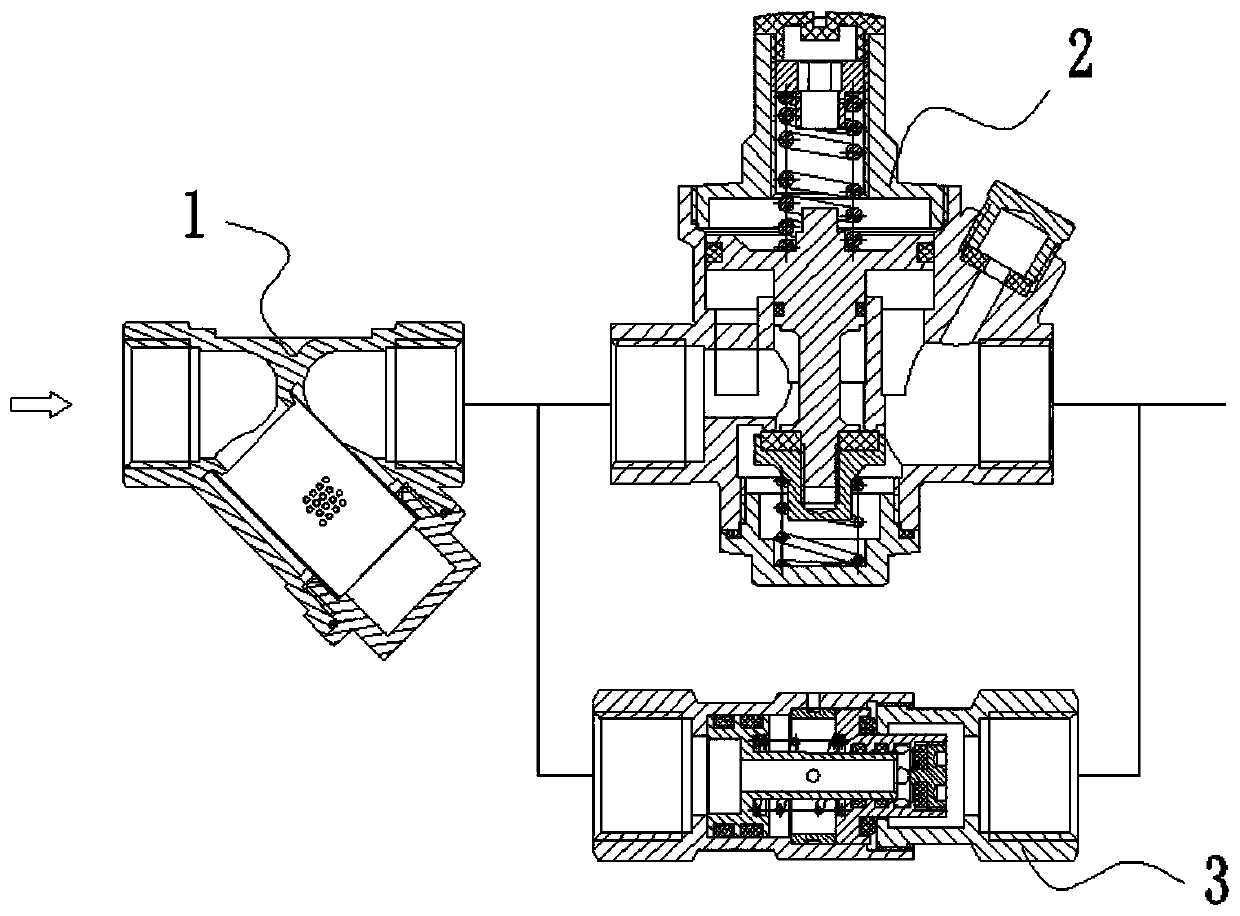

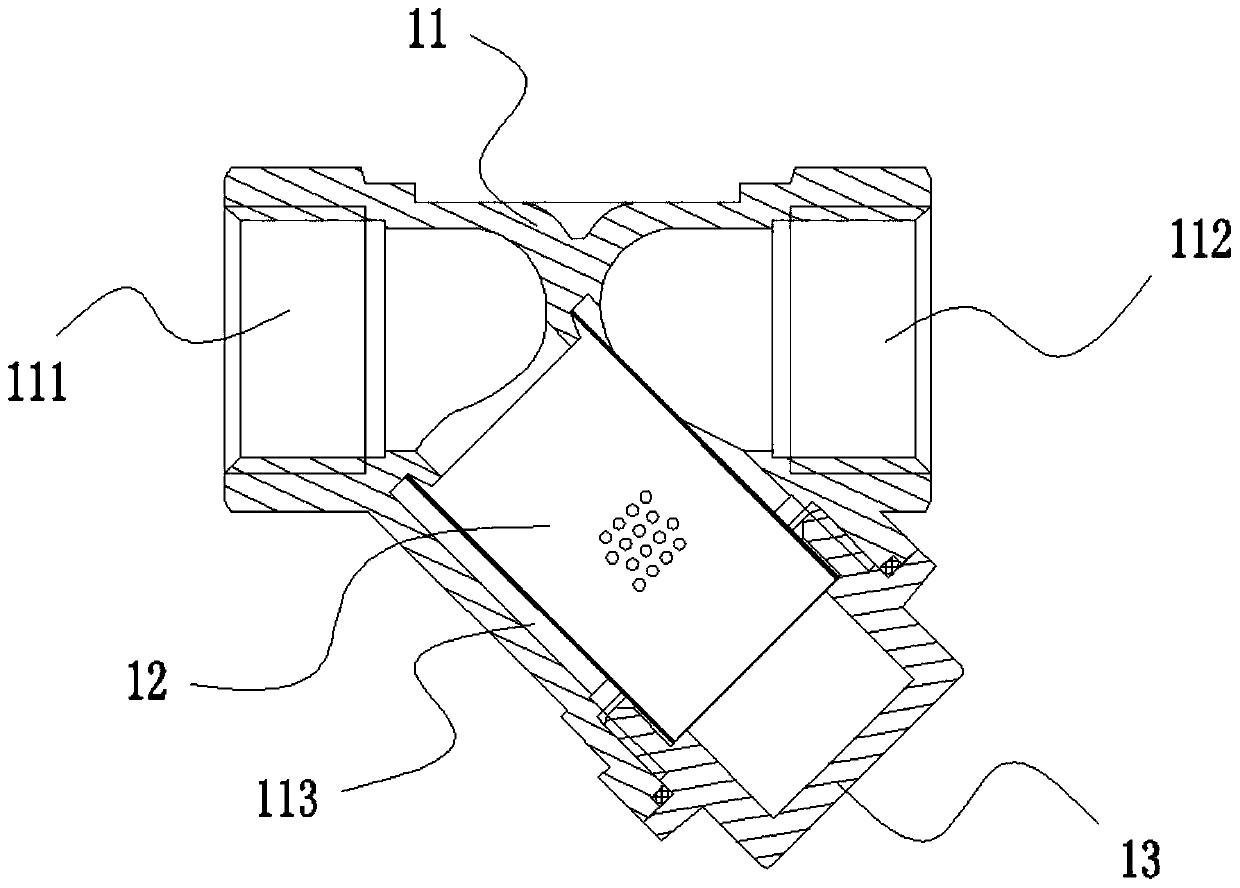

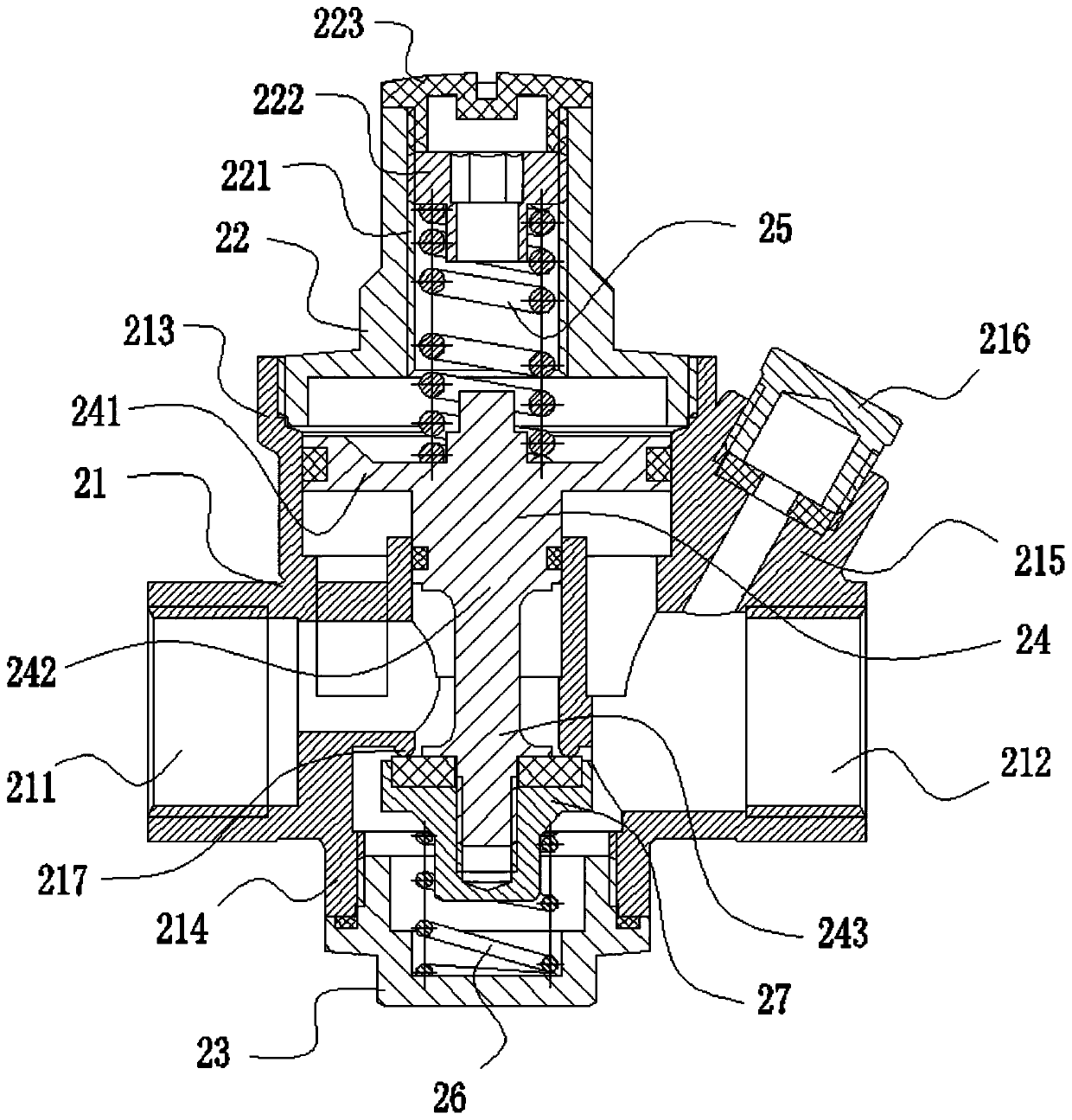

[0032] figure 1 It is a structural diagram of an embodiment of a self-controlled low-pressure normally-open decompression structure of the present invention. Such as figure 1 As shown, the structure of the self-controlled low pressure normally open decompression provided by this embodiment includes: a filter 1 and a pressure regulating structure, the filter 1 and the pressure regulating structure are connected in series, the filter 1 is arranged on the installation pipeline, and the filter 1 The outlet is connected to the inlet of the pressure regulating structure, and the outlet of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com