Step gauge

A technology of ladder gauges and spacers, which is applied in the field of ladder gauges, can solve problems such as stress changes and size changes of ladder gauges, achieve high-precision calibration processing, and suppress dimensional changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, a step gauge according to one embodiment of the present invention will be described.

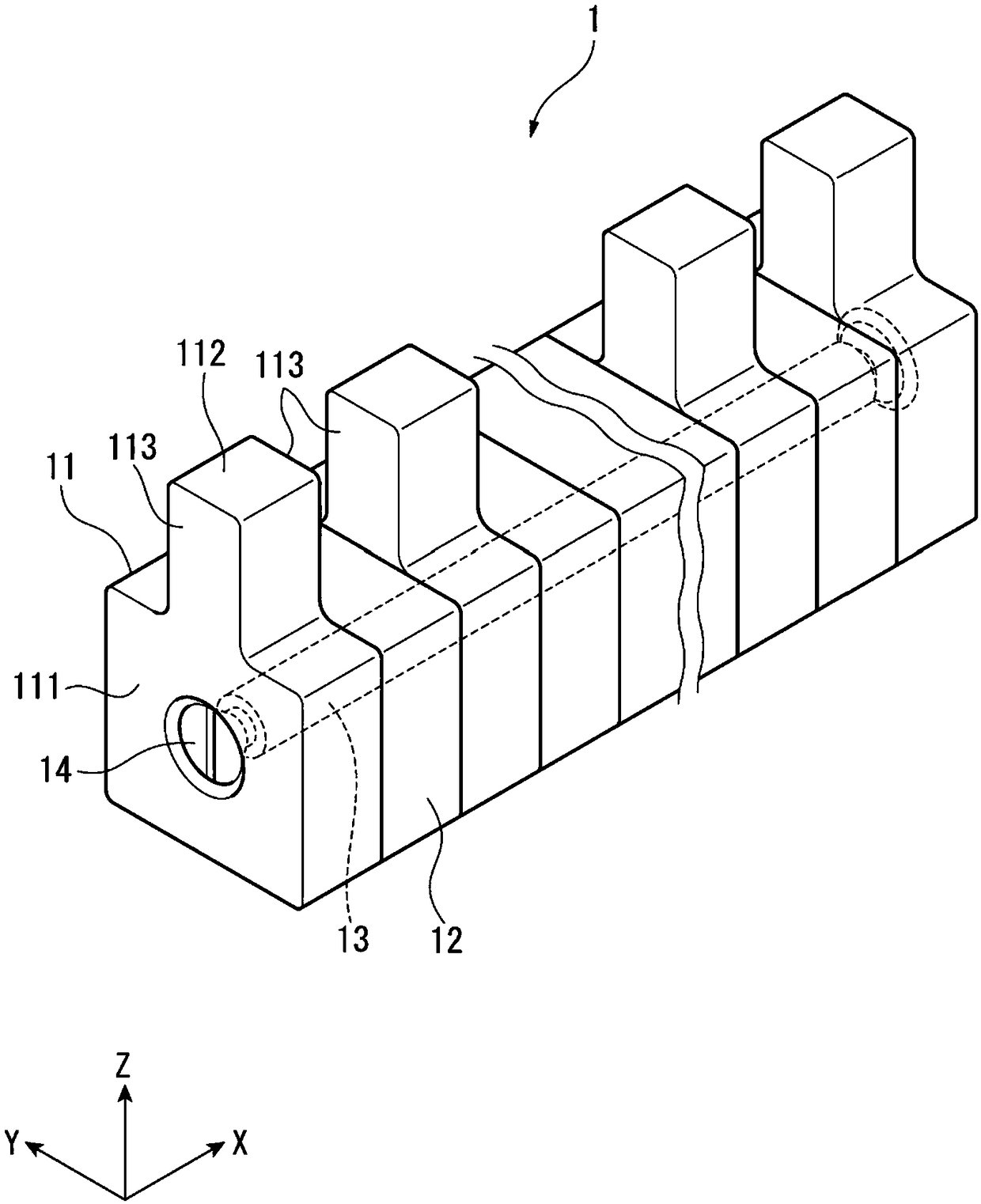

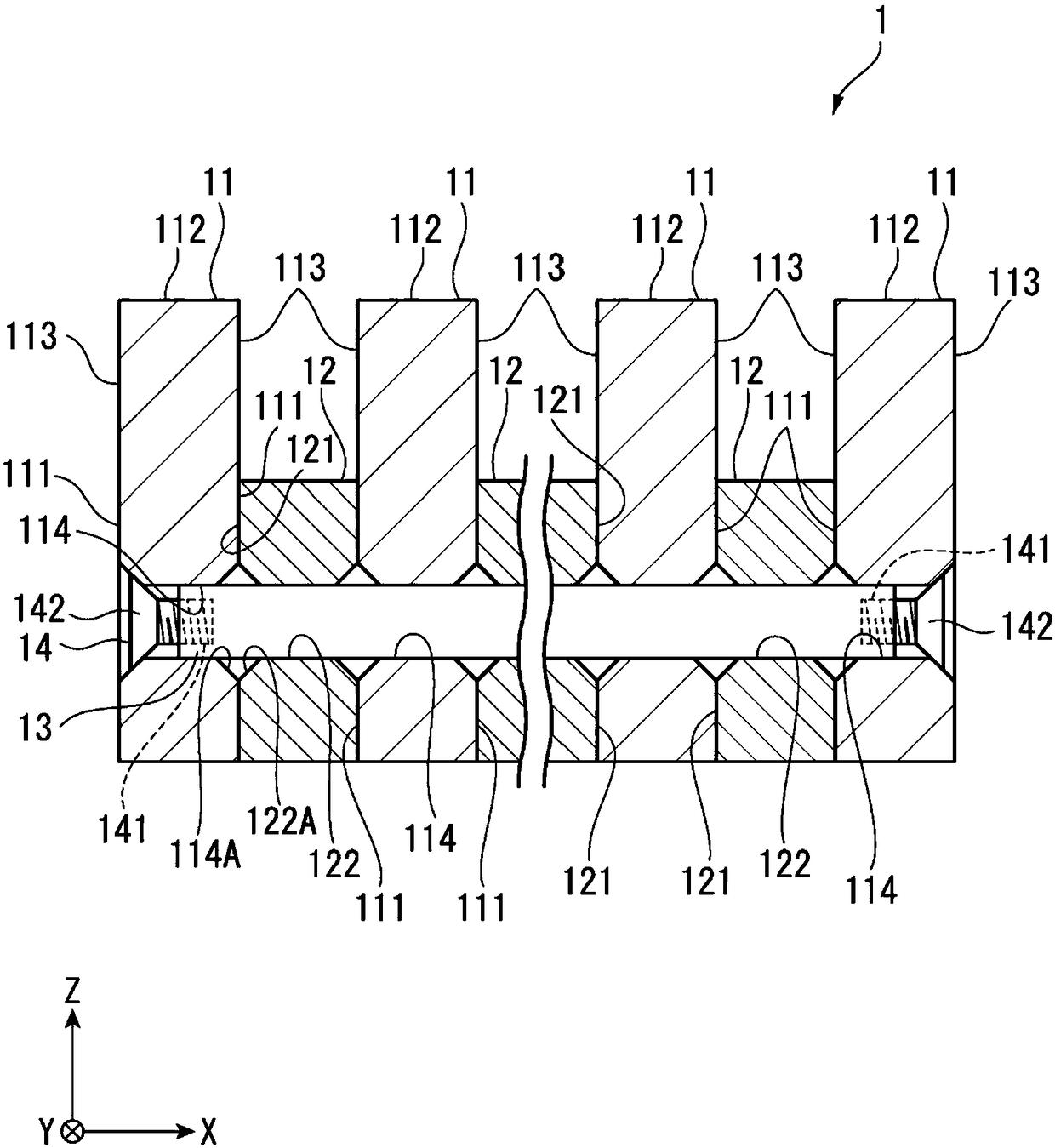

[0022] figure 1 It is a schematic perspective view of the step gauge of this embodiment. figure 2 It is a sectional view along the longitudinal direction of the step gauge of this embodiment.

[0023] The stepped gauge 1 is a standard gauge that becomes long along one direction (X direction). like figure 1 as well as figure 2 As shown, the ladder gauge 1 includes a plurality of gauge blocks 11, a plurality of spacer blocks 12, a pull rod 13 (shaft material) for connecting these gauge blocks 11 and spacer blocks 12, and two ends of the pull rod 13. Countersunk screw 14 (fixed part).

[0024] The gauge block 11 includes a first side 111 extending along a plane intersecting the X direction (orthogonal in this embodiment), and protruding along a Z direction intersecting with the X direction (orthogonal in this embodiment). The measuring part 112.

[0025] The first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com