Retardation film for va, method for producing retardation film for va, polarizing plate, and vertical alignment type liquid crystal display device

A technology of retardation film and manufacturing method, applied in polarizing elements, instruments, optical elements, etc., can solve problems such as color tone change, and achieve the effect of improving the durability of damp heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example

[0239]

[0240] Hereinafter, synthesis examples of sugar esters are shown.

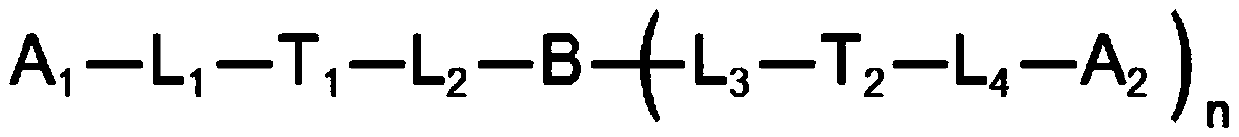

[0241] [chemical formula 15]

[0242]

[0243] 34.2g (0.1 moles) of sucrose, 180.8g (0.8 moles) of benzoic anhydride, and 379.7g (4.8 moles) of pyridine were respectively charged into a four-necked flask equipped with a stirring device, a reflux cooler, a thermometer and a nitrogen inlet pipe, and While bubbling nitrogen gas from a nitrogen gas introduction tube with stirring, esterification reaction was performed at 70 degreeC for 5 hours, raising temperature. Next, reduce the pressure in the flask to 4×10 2 After distilling off excess pyridine at 60° C. below Pa, the pressure in the flask was reduced to below 1.3×10 Pa, and the temperature was raised to 120° C. to distill off most of benzoic anhydride and generated benzoic acid. Then, 1 L of toluene and 300 g of a 0.5% by mass sodium carbonate aqueous solution were added, and after stirring at 50° C. for 30 minutes, the mixture was left still...

Embodiment

[0413] Hereinafter, although an Example is given and this invention is demonstrated concretely, this invention is not limited to these Examples. In addition, in an Example, the expression of "part" or "%" is used, and unless otherwise specified, it means "part by mass" or "% by mass".

[0414]

[0415]

[0416] Particles (manufactured by AEROSIL R812 Japan Aerosil Co., Ltd.) 11 parts by mass

[0417] 89 parts by mass of ethanol

[0418] The above substances were stirred and mixed with a dissolving bar for 50 minutes, and then dispersed with Manton-Gaulin to prepare fine particle dispersion 1.

[0419]

[0420] The microparticle dispersion 1 was slowly added to the dissolving tank containing dichloromethane while fully stirring. Further, disperse with an Attritor to make the particle size of the secondary particle a specified size. This was filtered through Fine Met NF manufactured by Nippon Seisen Co., Ltd., to prepare fine particle addition liquid 1.

[0421] Dichlor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com