Patents

Literature

37results about How to "Suppresses color change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

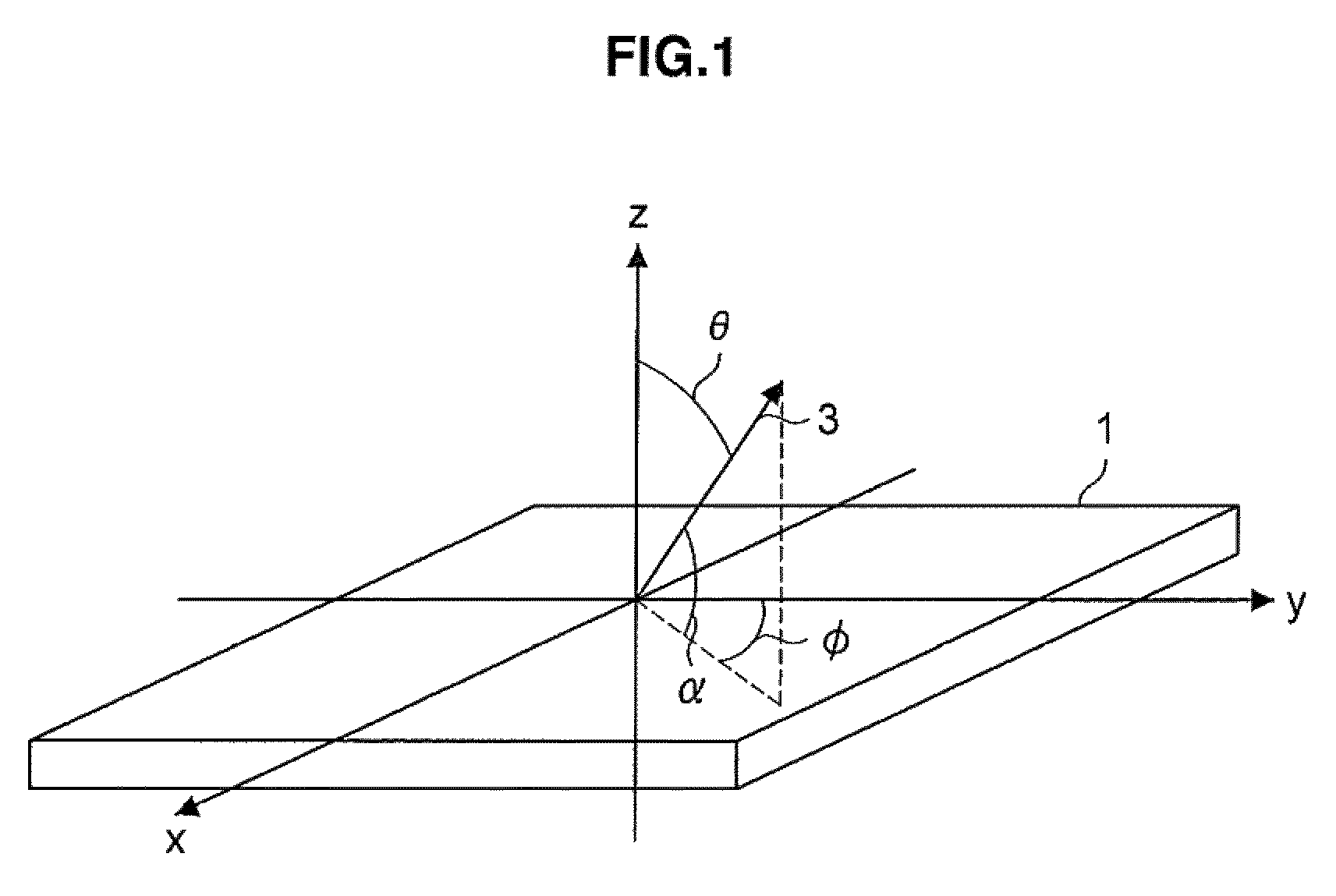

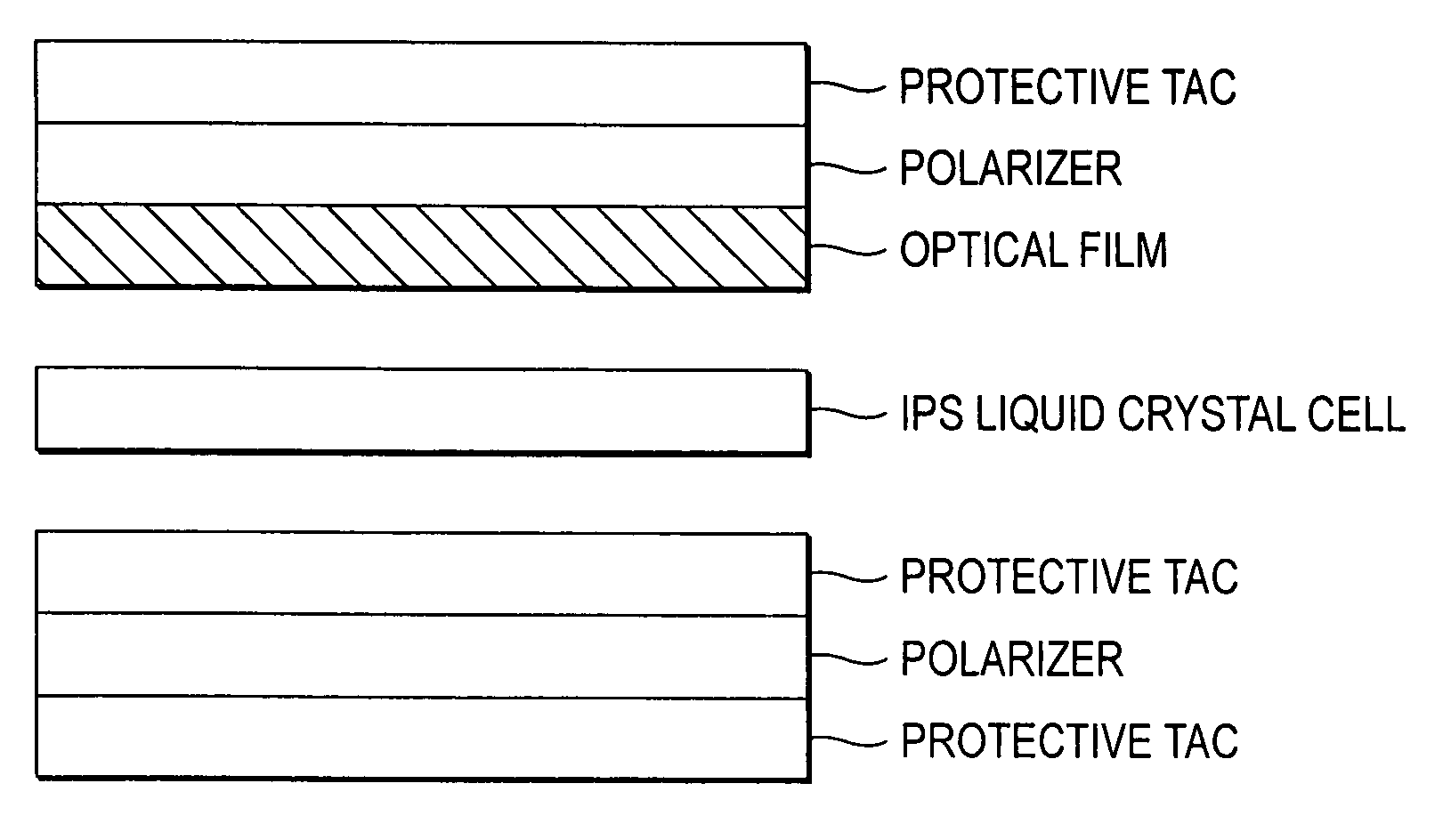

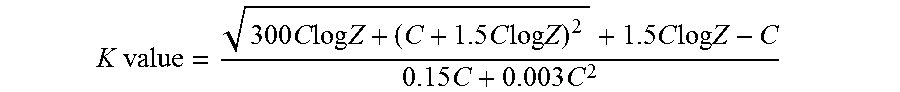

Optical film, production method of optical film, optically-compensatory film, polarizing plate and liquid crystal display device

InactiveUS20080158490A1Suppresses color changeSignificant differenceGlass making apparatusPolarising elementsIn planeLiquid-crystal display

An optical film satisfies the following formulae (1) to (6):150≦Re(550)≦400 (1)−100≦Rth(550)≦100 (2)0.1<Re(450) / Re(550)<0.95 (3)1.03<Re(650) / Re(550)<1.93 (4)0.4<(Re(450) / Rth(450)) / (Re(550) / Rth(550))<0.95 (5)1.05<(Re(650) / Rth(650)) / (Re(550) / Rth(550))<1.90, (6)wherein Re(450), Re(550) and Re(650) are an in-plane retardation value (unit: nm) measured with light at a wavelength of 450 nm, 550 nm and 650 nm, respectively, and Rth(450), Rth(550) and Rth(650) are a retardation value in a thickness-direction (unit: nm) measured with light at a wavelength of 450 nm, 550 nm and 650 nm, respectively.

Owner:FUJIFILM CORP

Polyester resin composition

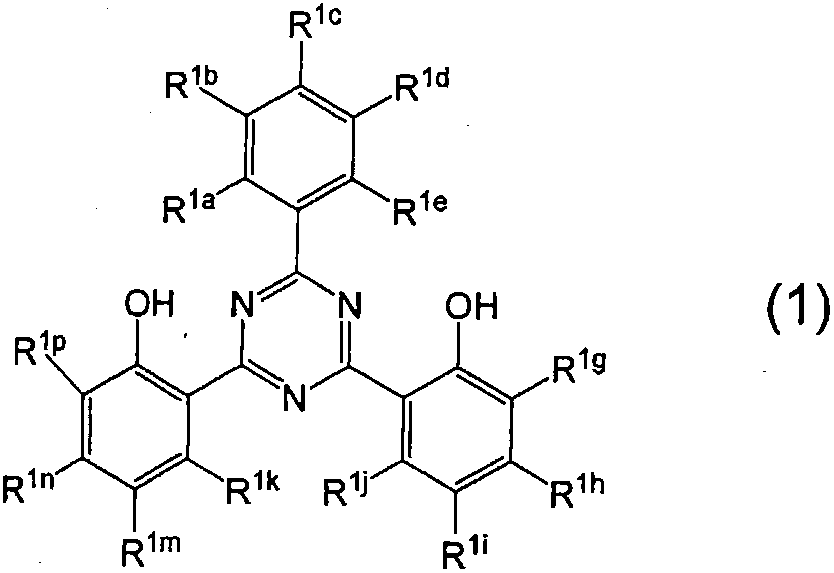

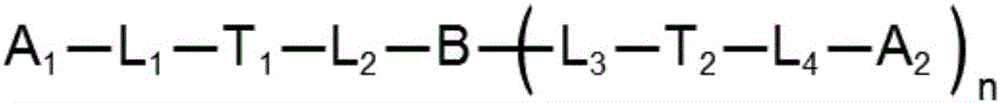

ActiveCN102712799AImprove solubilityHue changes rarely occurPhotovoltaic energy generationMonocomponent polyesters artificial filamentSolubilityHydrogen atom

Disclosed is a polyester resin composition which maintains long wave ultraviolet shielding effect for a long period of time, while having high solubility in a solvent and excellent light resistance. Specifically disclosed is a polyester resin composition which is characterized by containing a compound represented by general formula (1) and a polyester resin. (In general formula (1), R1a, R1b, R1c, R1d and R1e each independently represents a monovalent substituent other than a hydrogen atom and an OH group, with at least one of the substituents being a substituent that has a positive Hammett substituent constant (sigma p), and the substituents may combine together to form a ring; and R1g, R1h, R1i, R1j, R1k, R1m, R1n and R1p each independently represents a hydrogen atom or a monovalent substituent, and the substituents may combine together to form a ring.).

Owner:FUJIFILM CORP

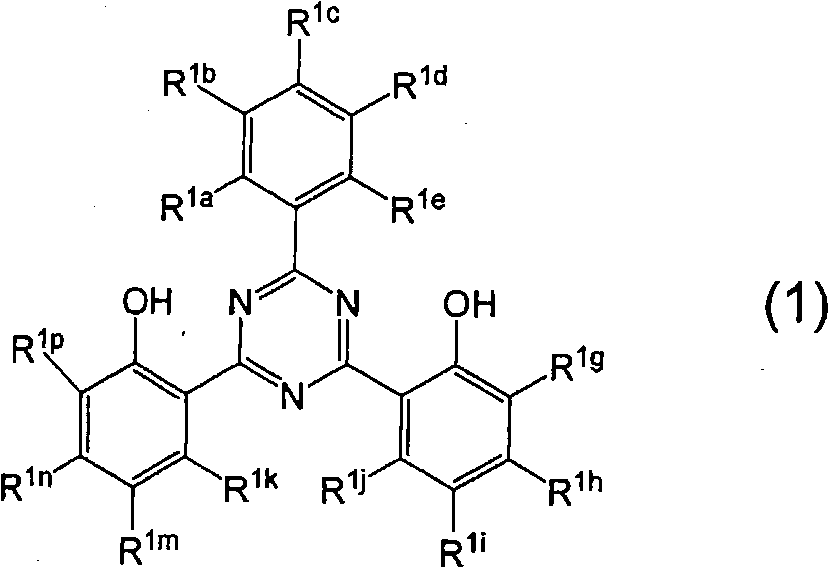

Display device, method, and terminal device having switchable viewing angle

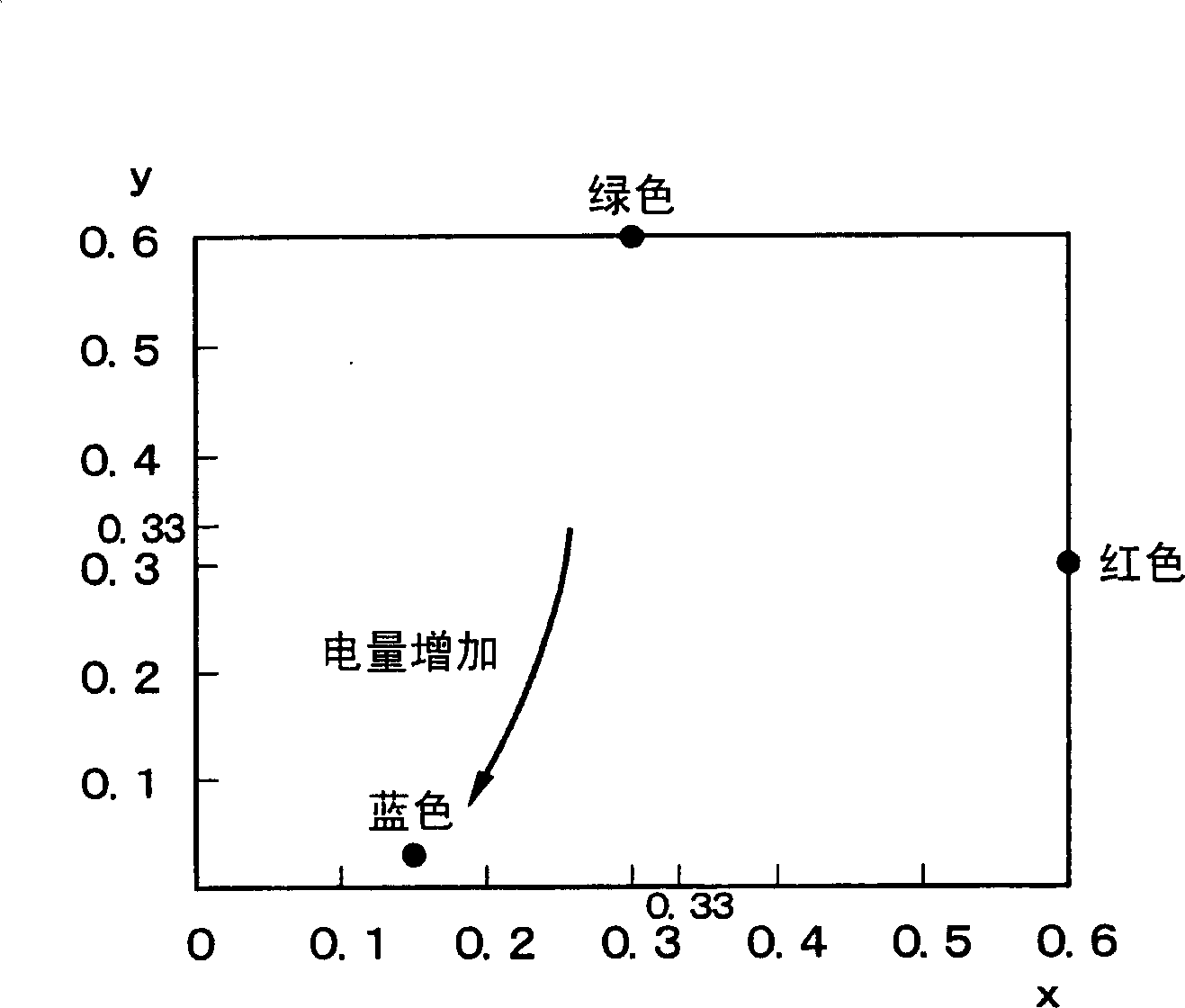

ActiveCN1908746ASuppress brightnessSuppresses color changeStatic indicating devicesNon-linear opticsTerminal equipmentDisplay device

After light from a planar light source is switched to scattered light or collimated light by a switching element, the light is incident on a display panel, and an image is displayed. At this time, the luminance of the planar light source is adjusted, the contrast voltage of the display panel is reset, and adjustment is performed so that the luminance and hue of the frontal image does not vary before and after switching.

Owner:NEC LCD TECH CORP

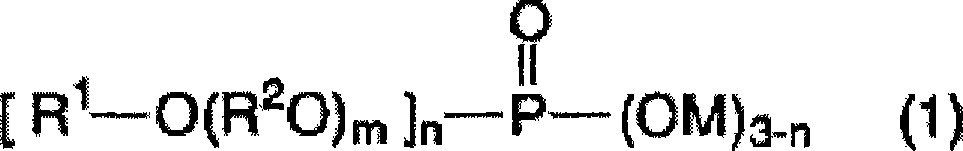

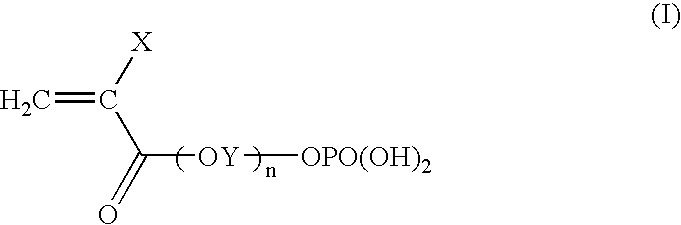

Polymer particle, resin composition containing same, and molded body

ActiveCN101133088ASuppresses color changeReduced thermal stabilityAlkaline earth metalHeat resistance

Disclosed is a polymer particle obtained by polymerizing a monomer in the presence of a phosphate salt represented by the formula (1) below. The polymer particle is characterized by containing 0.01-1.0 part by mass of the phosphate salt per 100 parts by mass of the polymer particle. When such a polymer particle is blended in a resin, change in the color tone of the resin is suppressed without decreasing thermal stability or wet heat resistance of a molded body. A resin composition and molded body using such a polymer particle are excellent in thermal stability and wet heat resistance, and the color tone of the resin does not change very much before and after the blending of the polymer particle. (1) (In the formula, R<1> represents an alkyl group having 10-18 carbon atoms; R<2> represents an alkylene group having 2 or 3 carbon atoms; M represents an alkali metal or an alkaline earth metal; m represents a number of 1-20; and n represents 1 or 2.

Owner:MITSUBISHI CHEM CORP

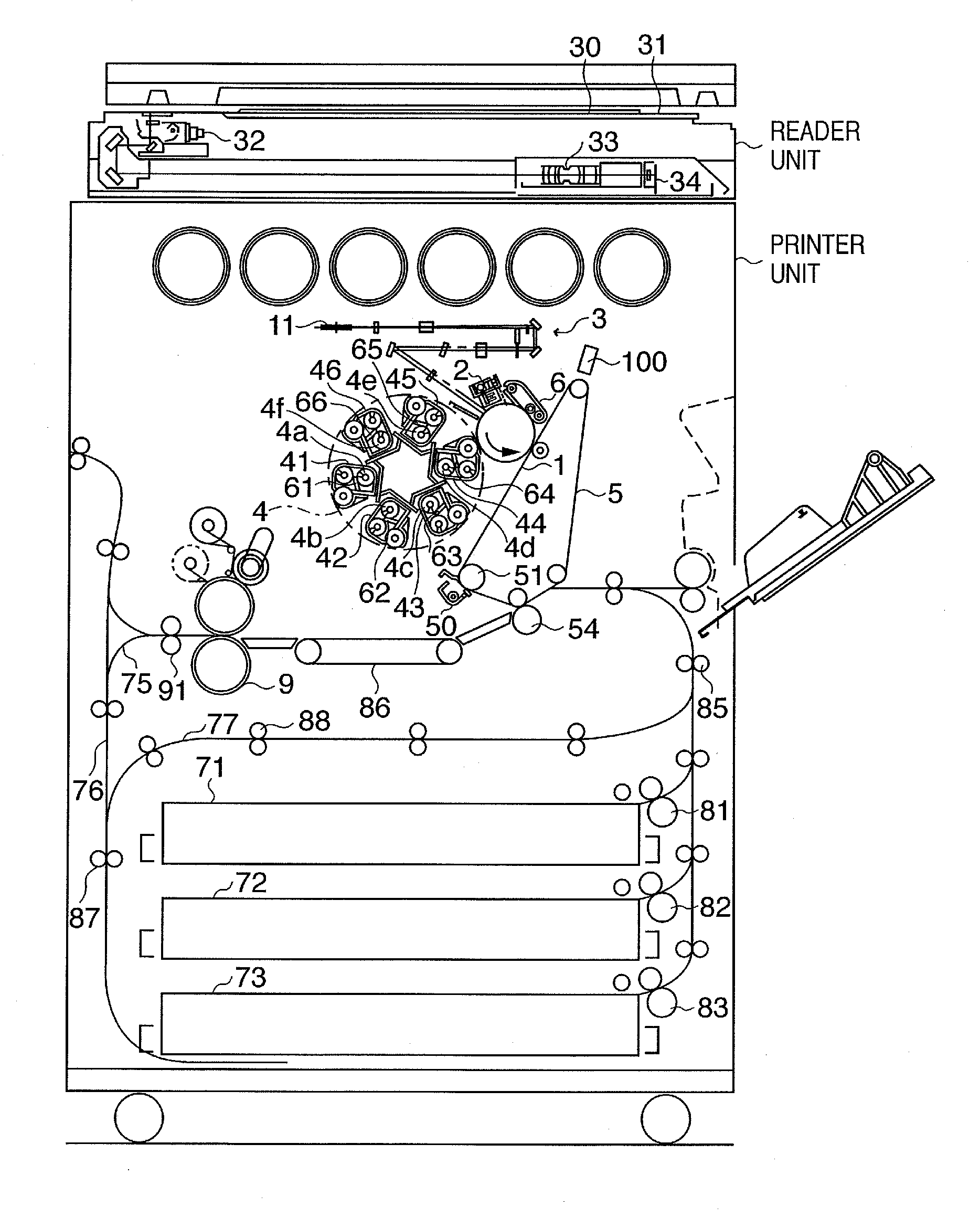

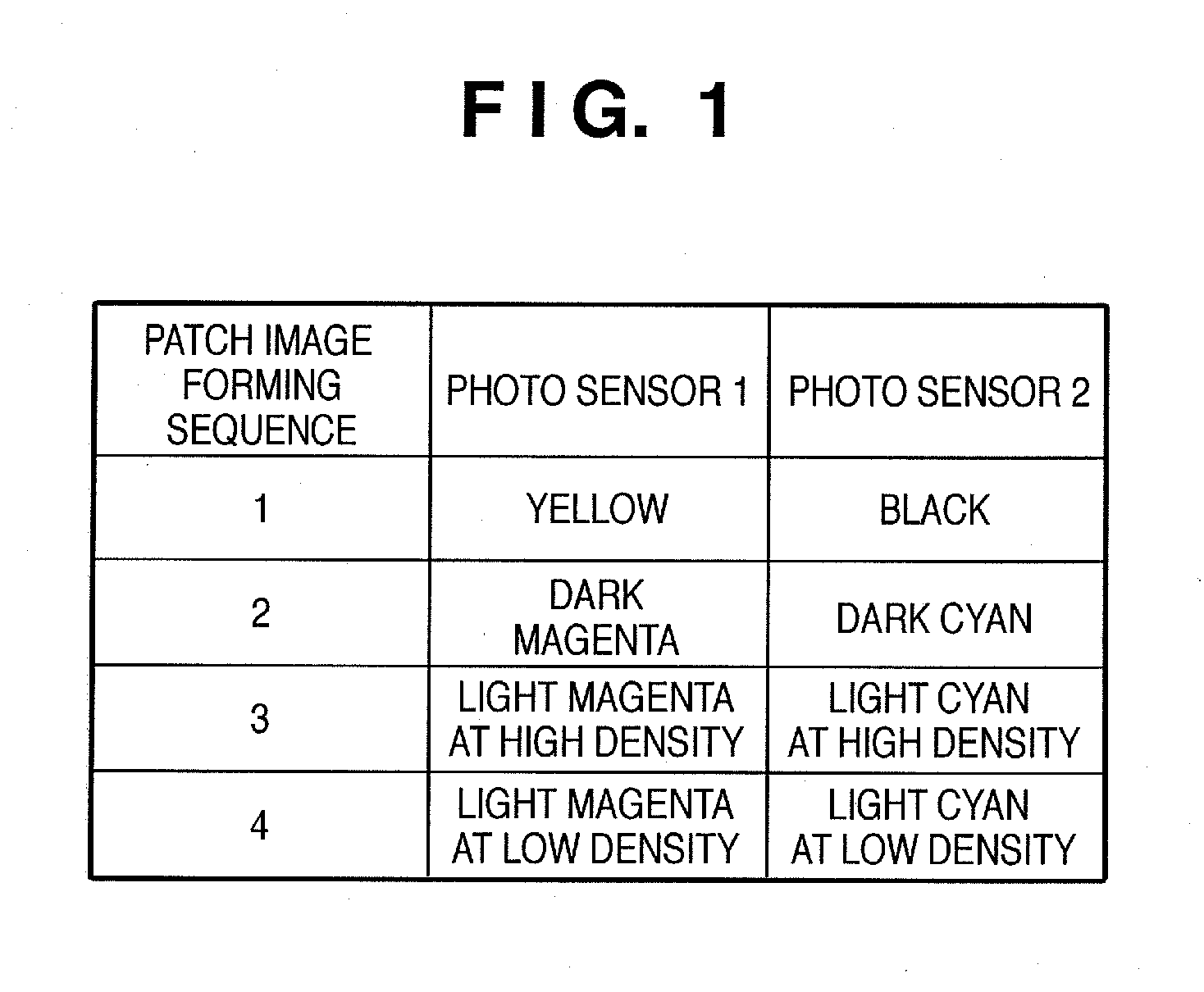

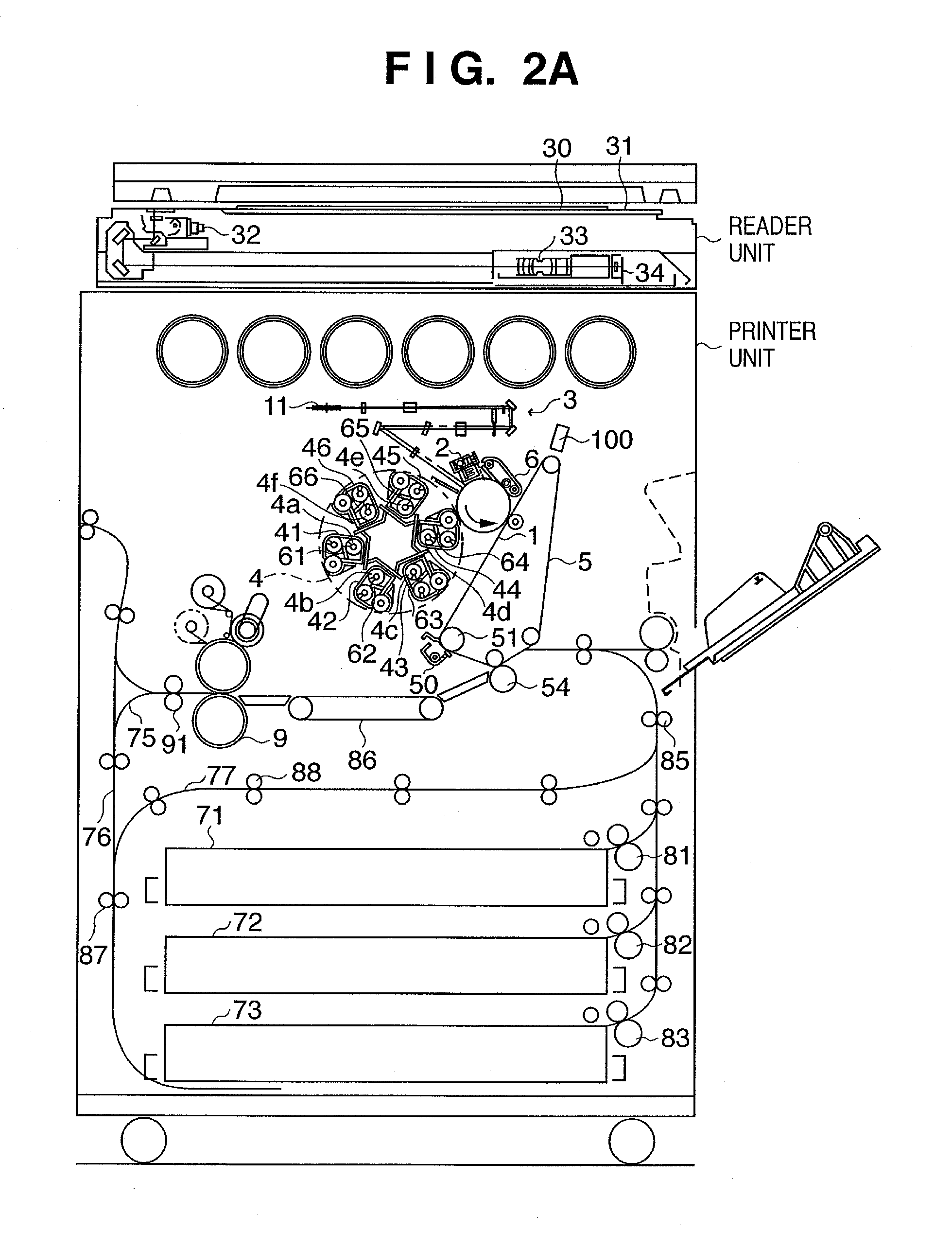

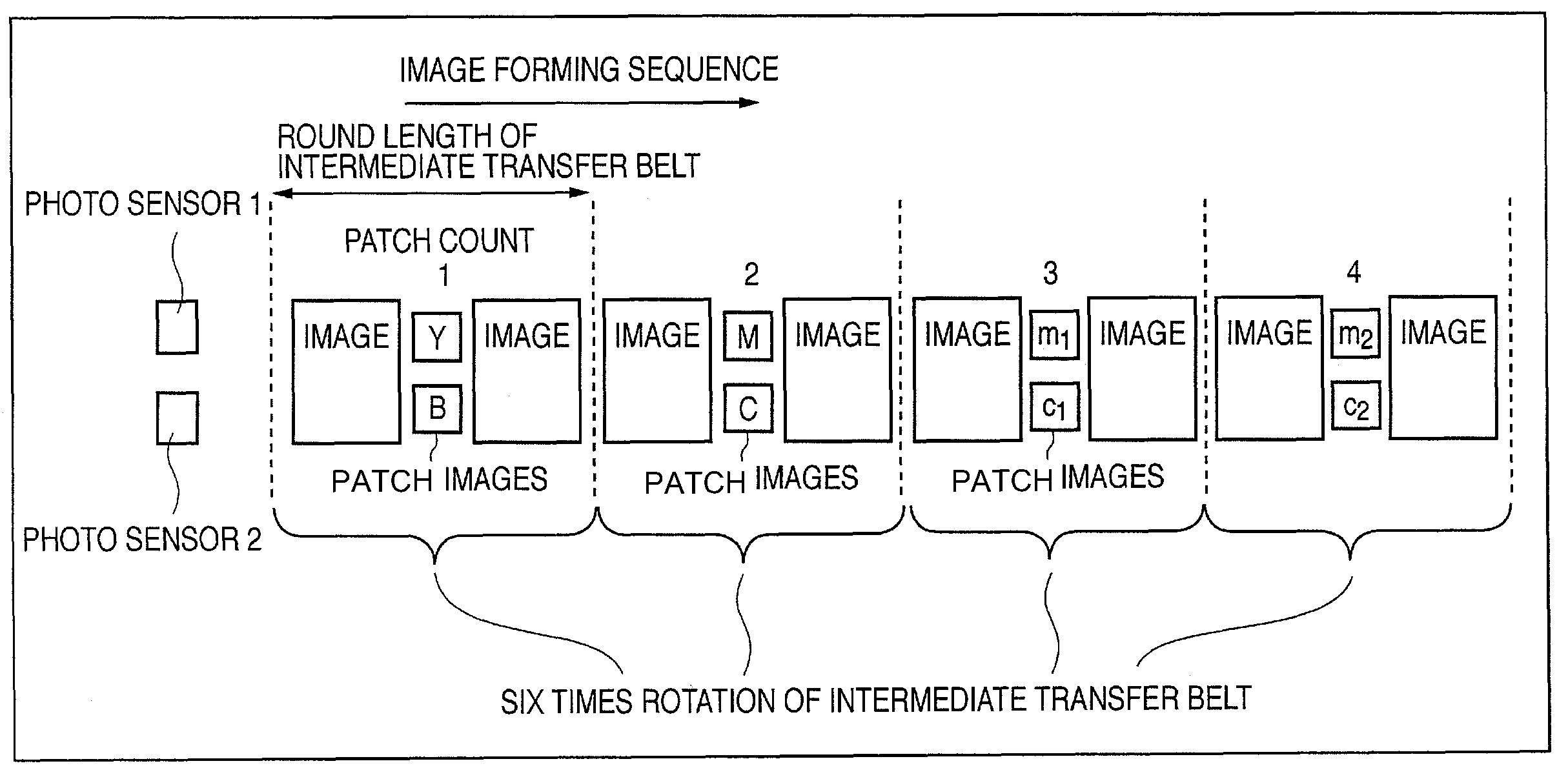

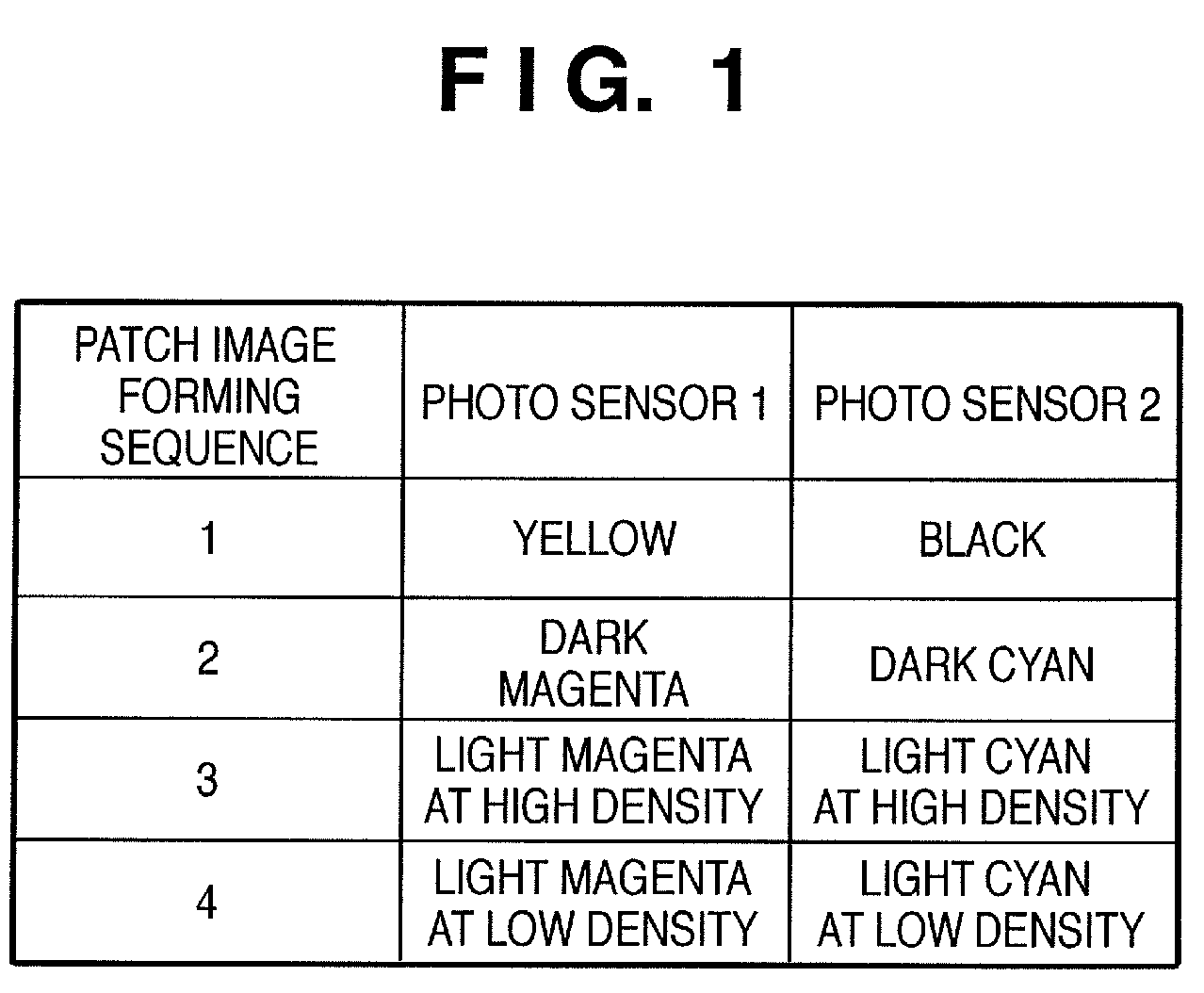

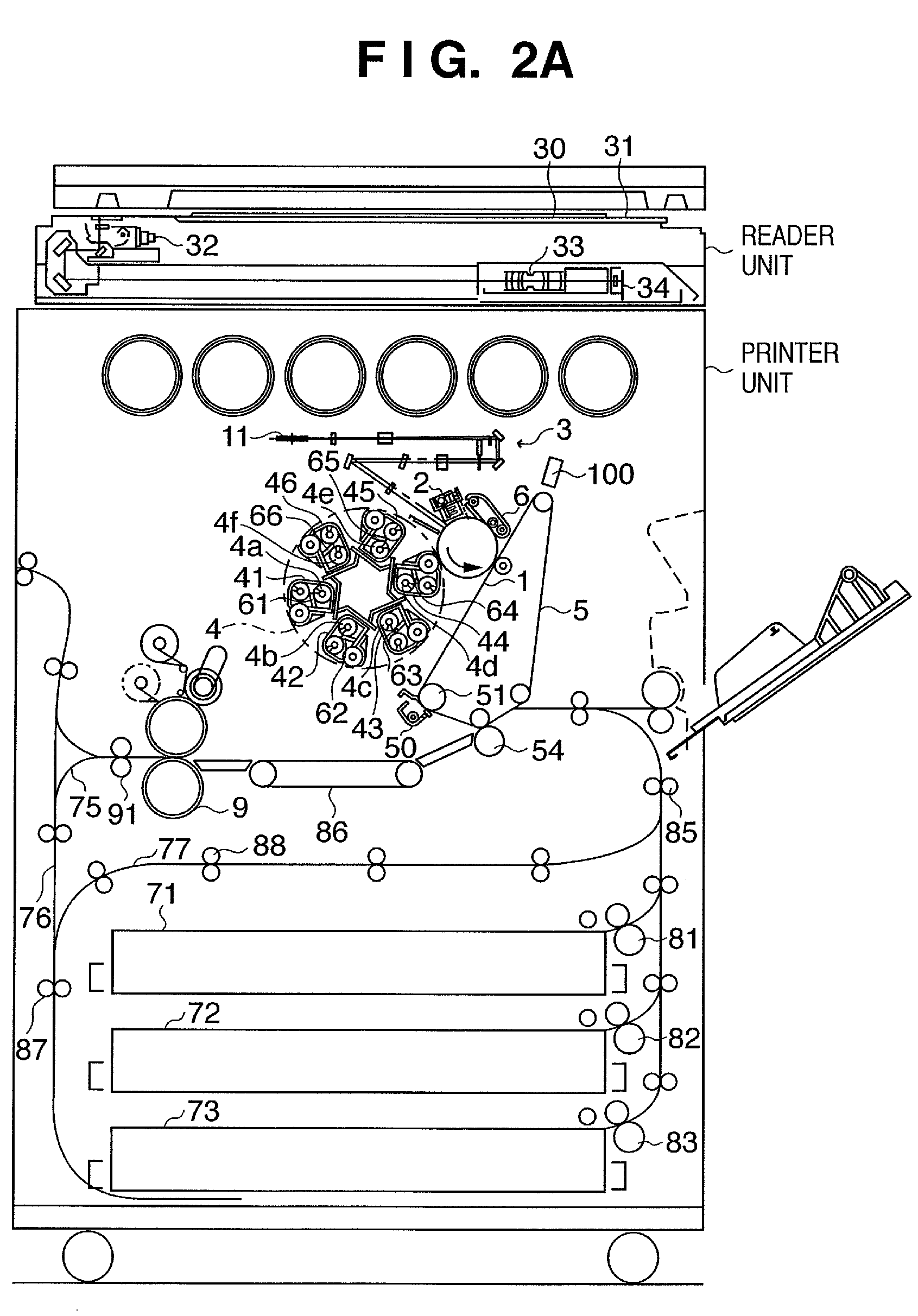

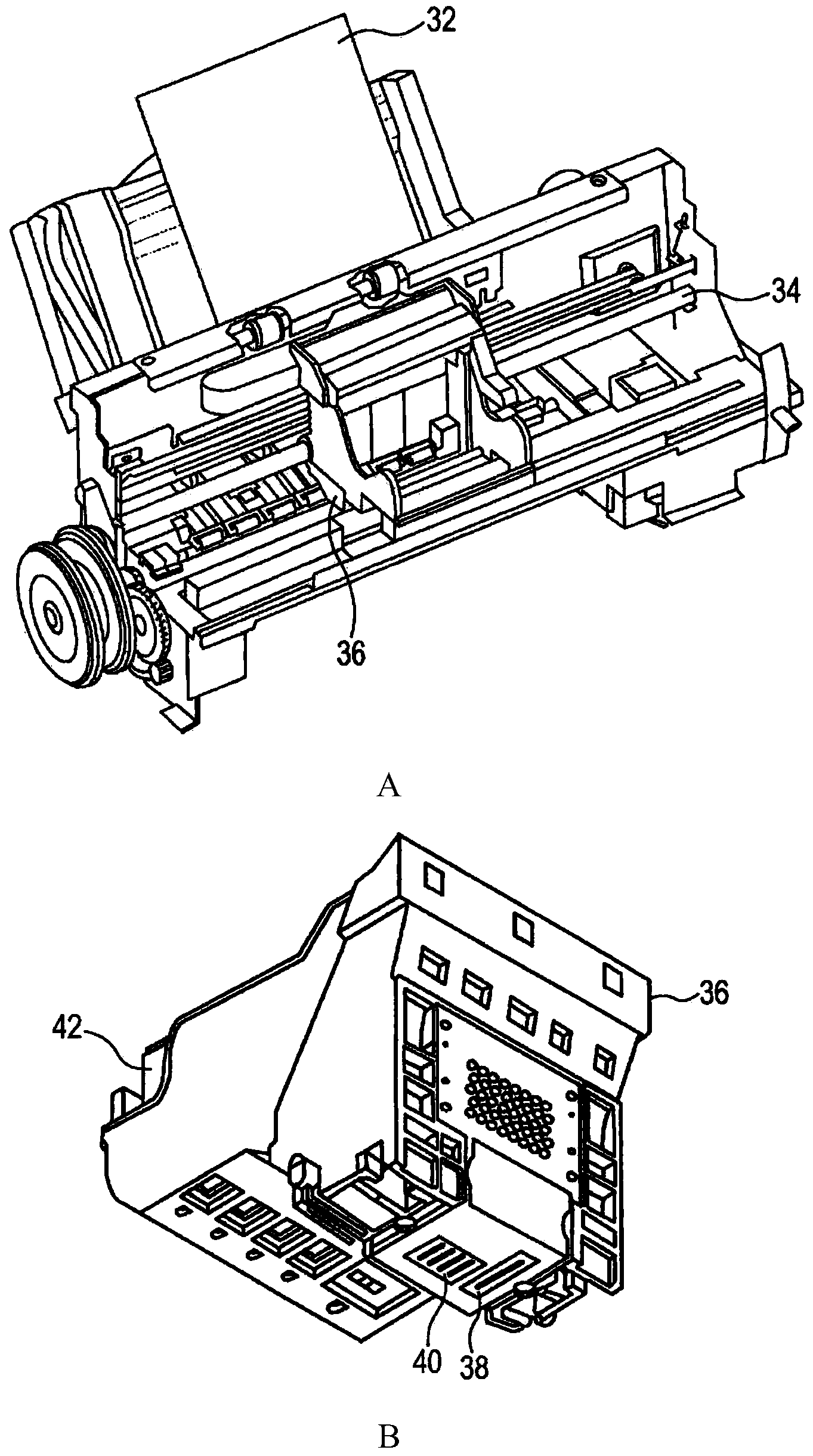

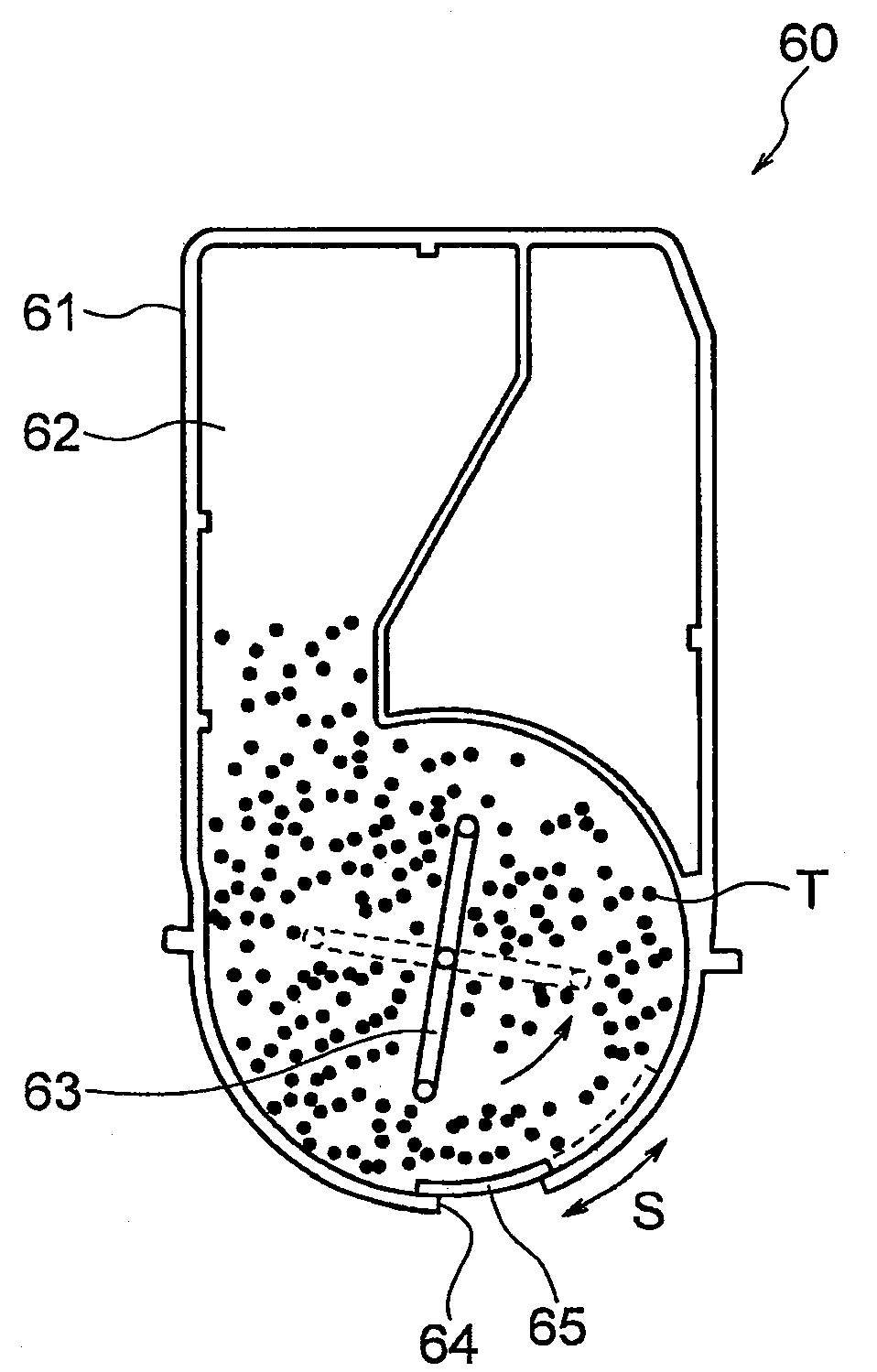

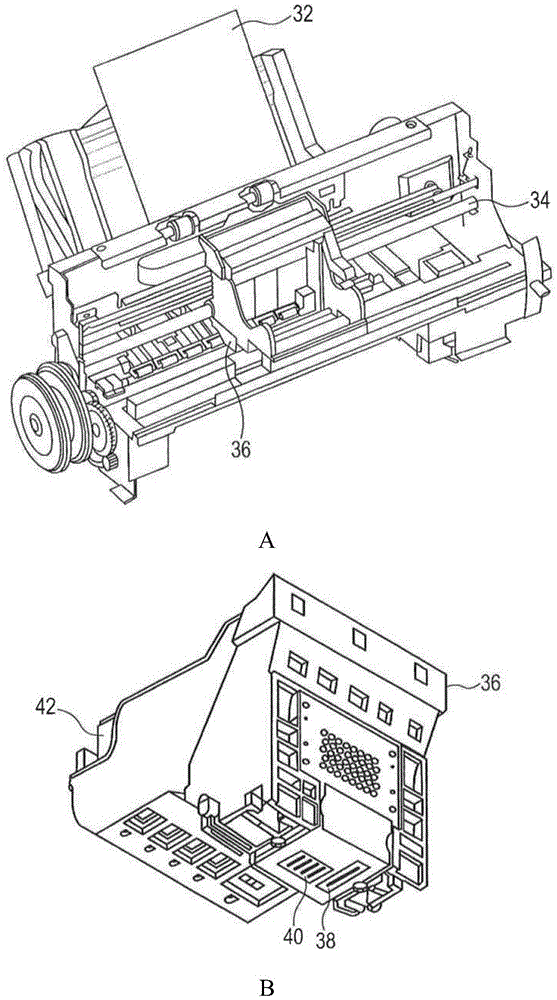

Image forming apparatus and control method thereof

InactiveUS20080107434A1Improve image qualityAvoid changeElectrographic process apparatusImaging qualityImage formation

An image forming apparatus is provided that forms an image using developers of different tone and the same hue. When forming images for measurement for density control, the apparatus performs density control by forming a greater number of density levels of an image for measurement developed using a light developer than the number of density levels of an image for measurement developed using a dark developer. Thus, even if the amount of applied light developer may fluctuate, the fluctuation can be compensated to prevent the occurrence of pseudo-contours that lower image quality.

Owner:CANON KK

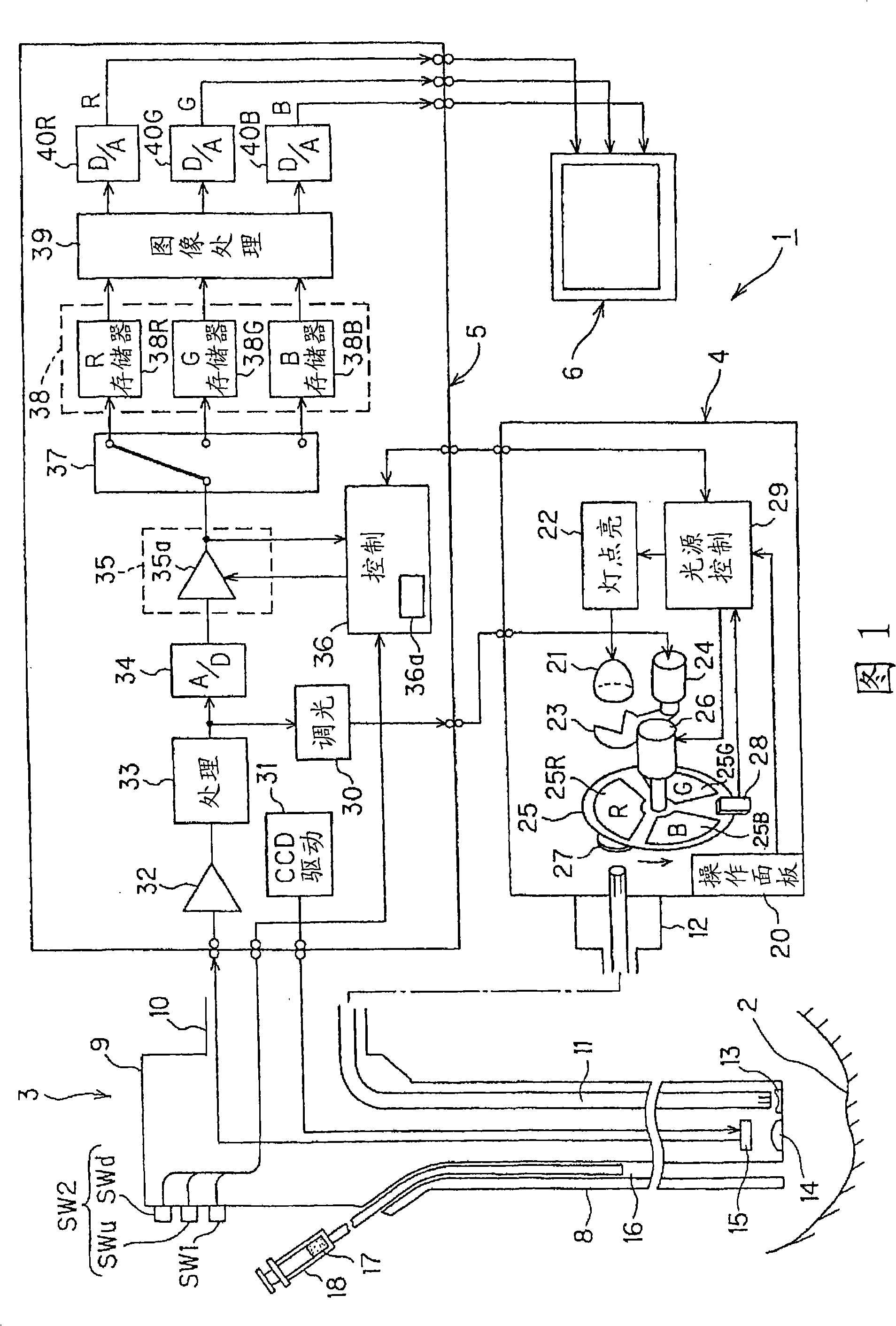

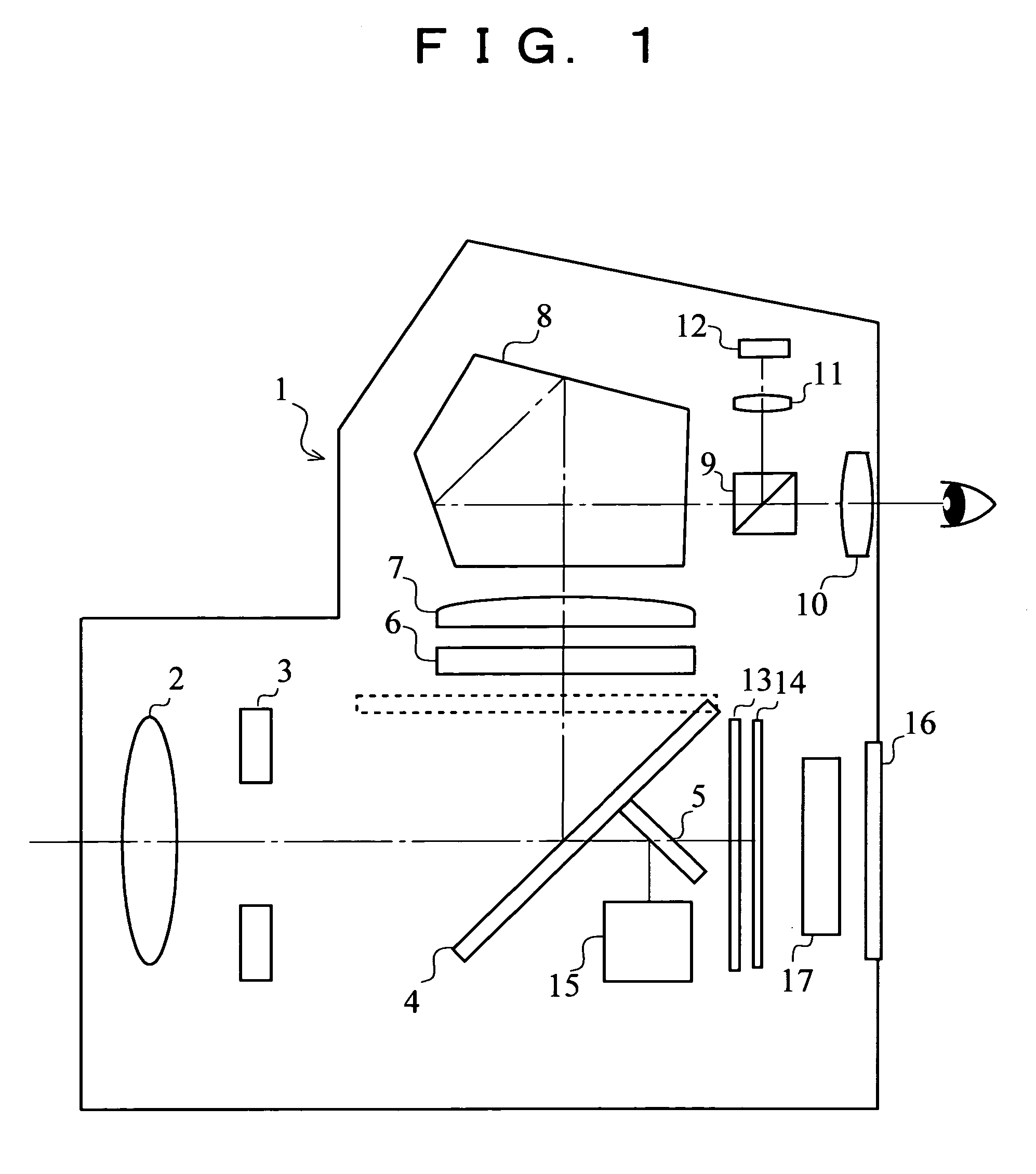

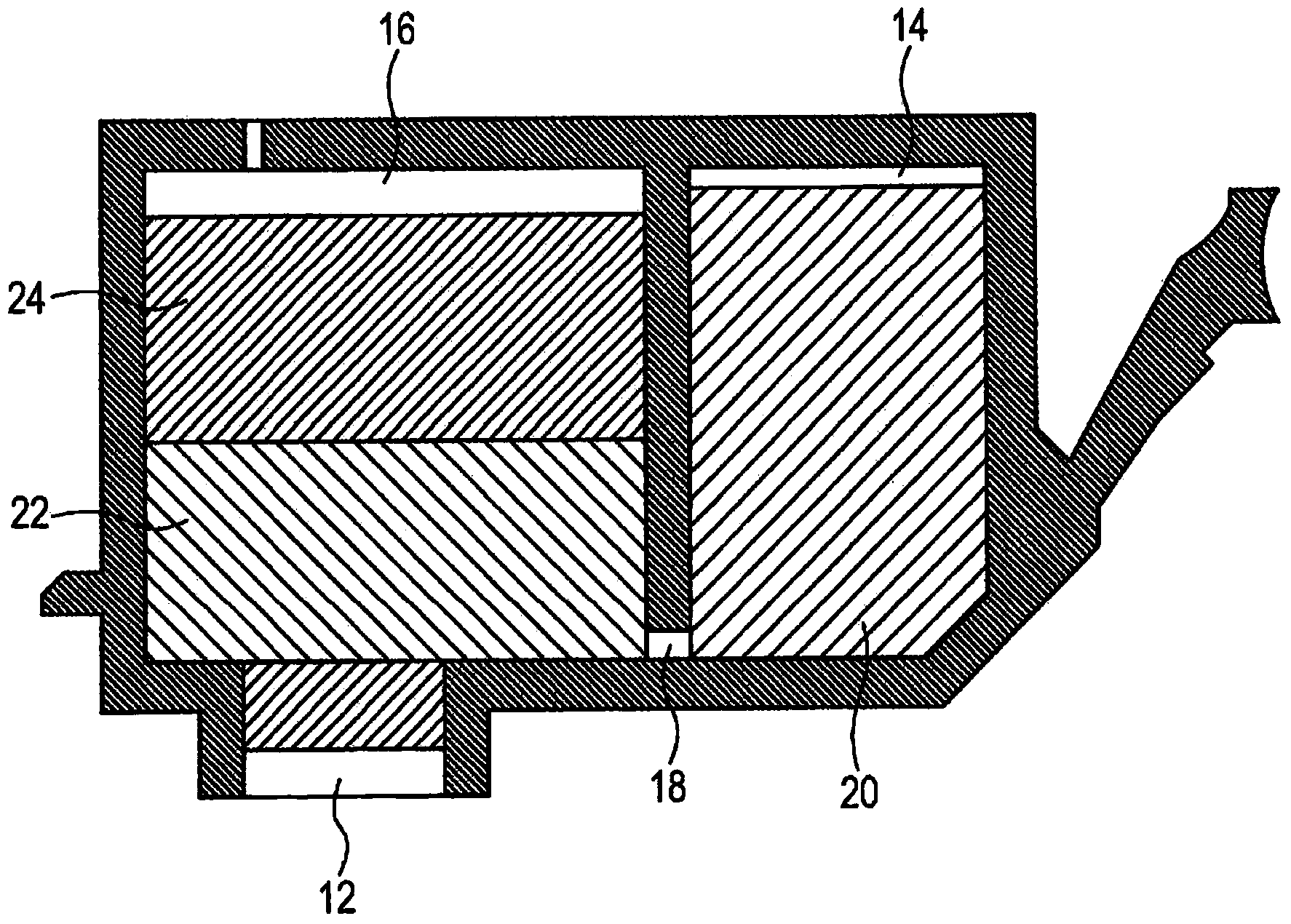

Endoscopic device

An endoscopic device comprises an endoscope having an insertion part insertable into an organism, an illumination part for emitting illumination light to the side of a portion to be observed in the organism, a light quantity control part for controlling the light quantity so that the light quantity of the red wavelength range exciting a light sensitizer given to the portion to be observed and illuminated with the illumination light is at least reduced, and a signal processing part for performing a signal processing to increase the luminance level of a red color signal corresponding to the red wavelength range in taking an image under the illumination light in response to the light quantity control.

Owner:OLYMPUS CORP

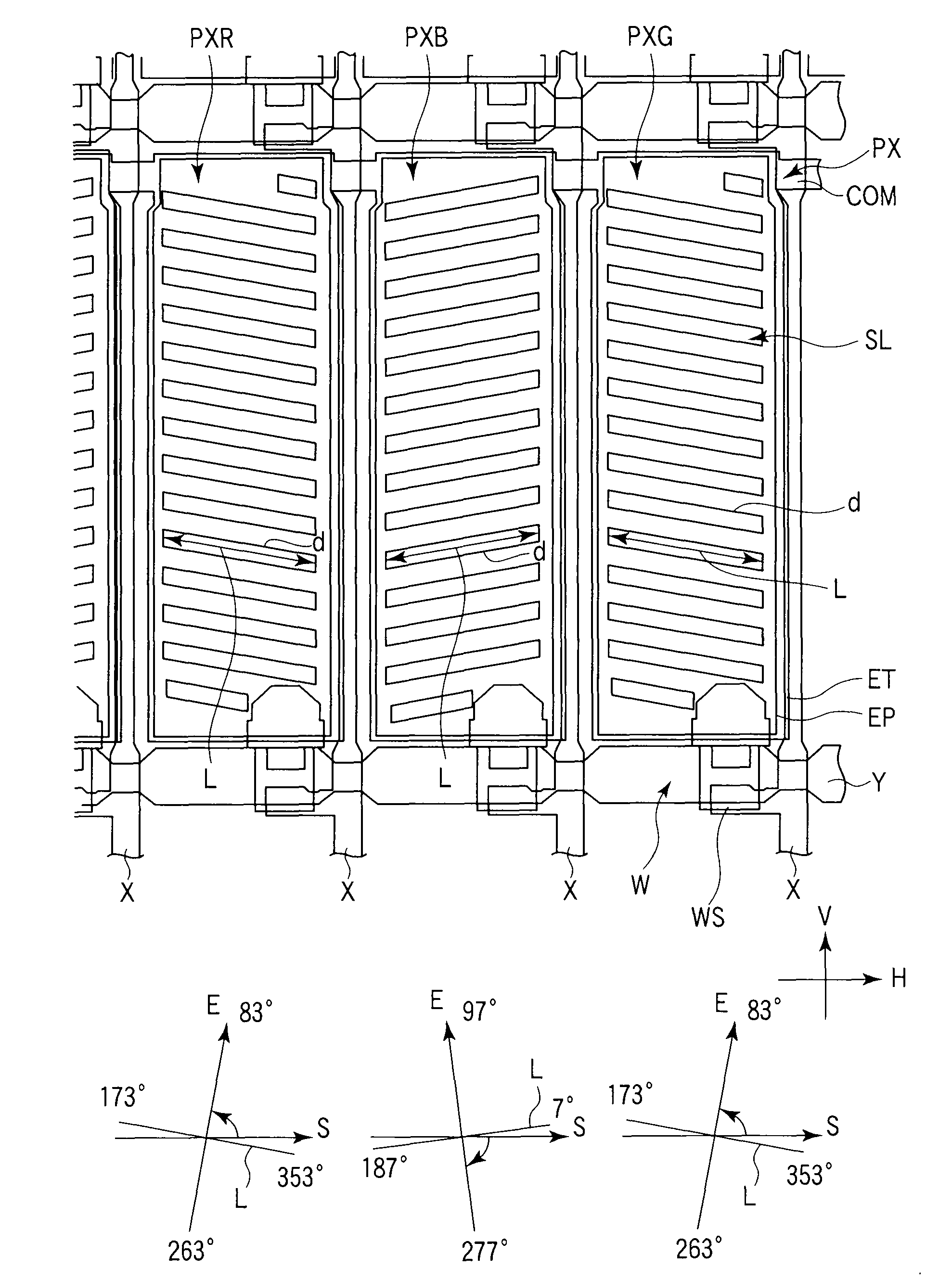

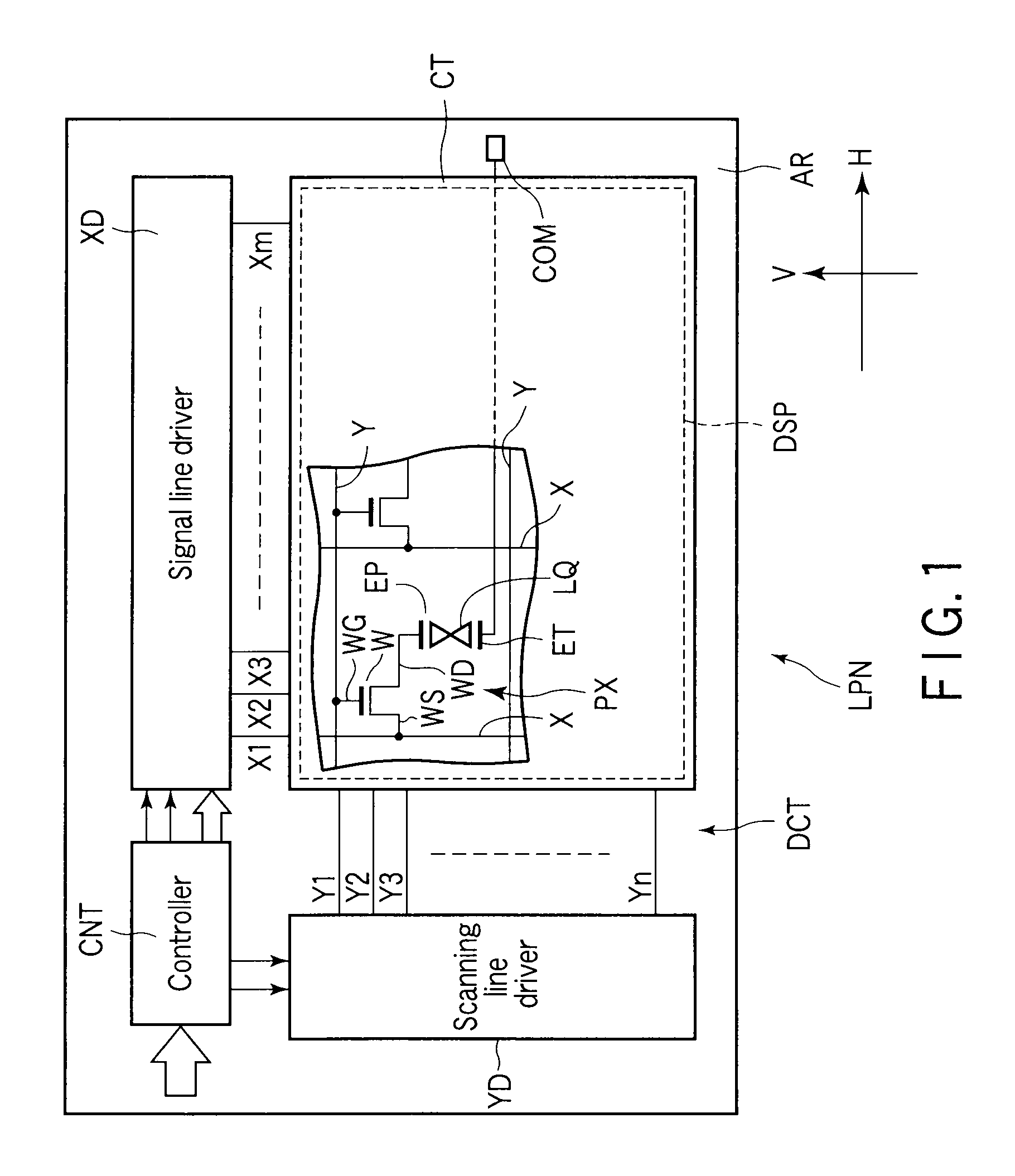

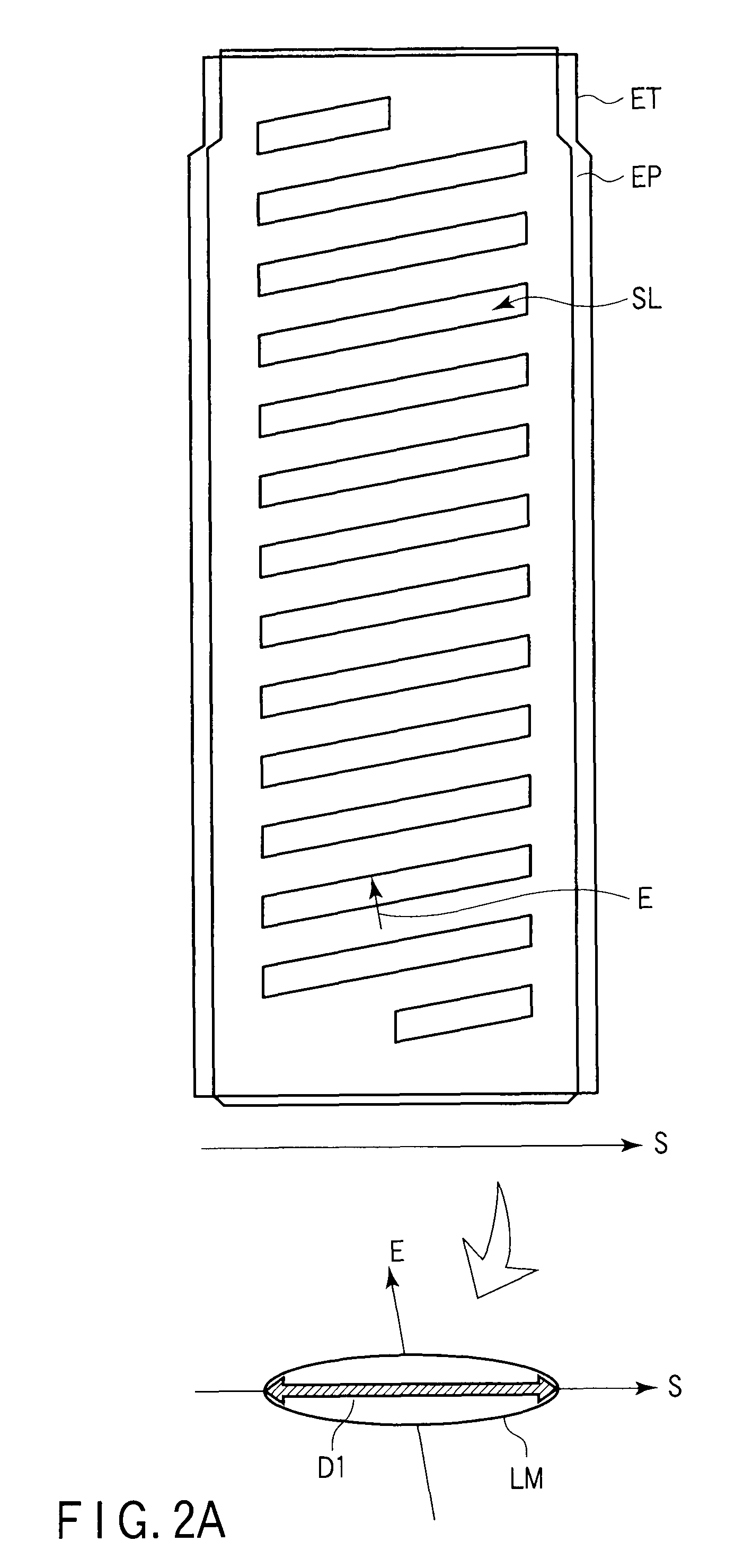

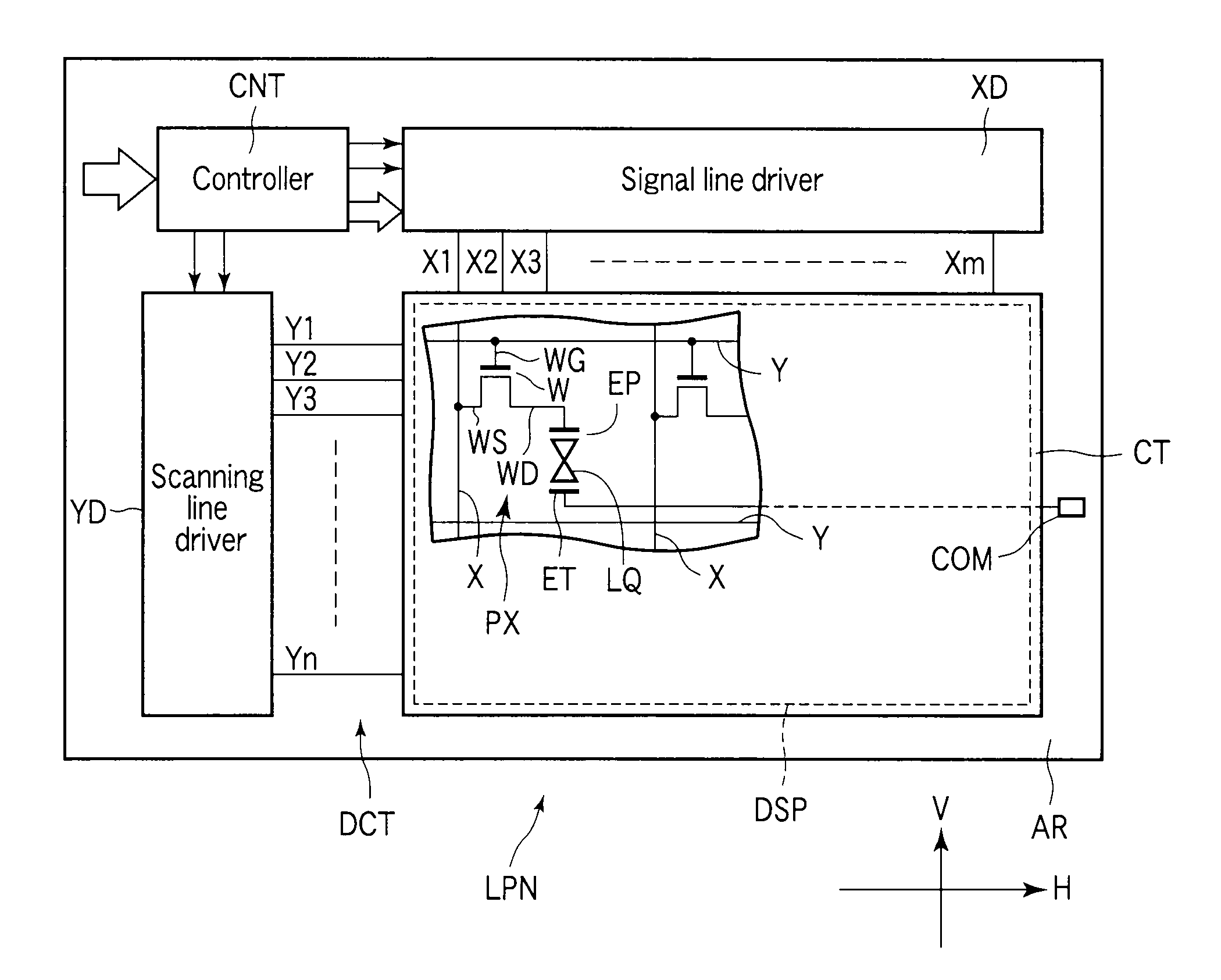

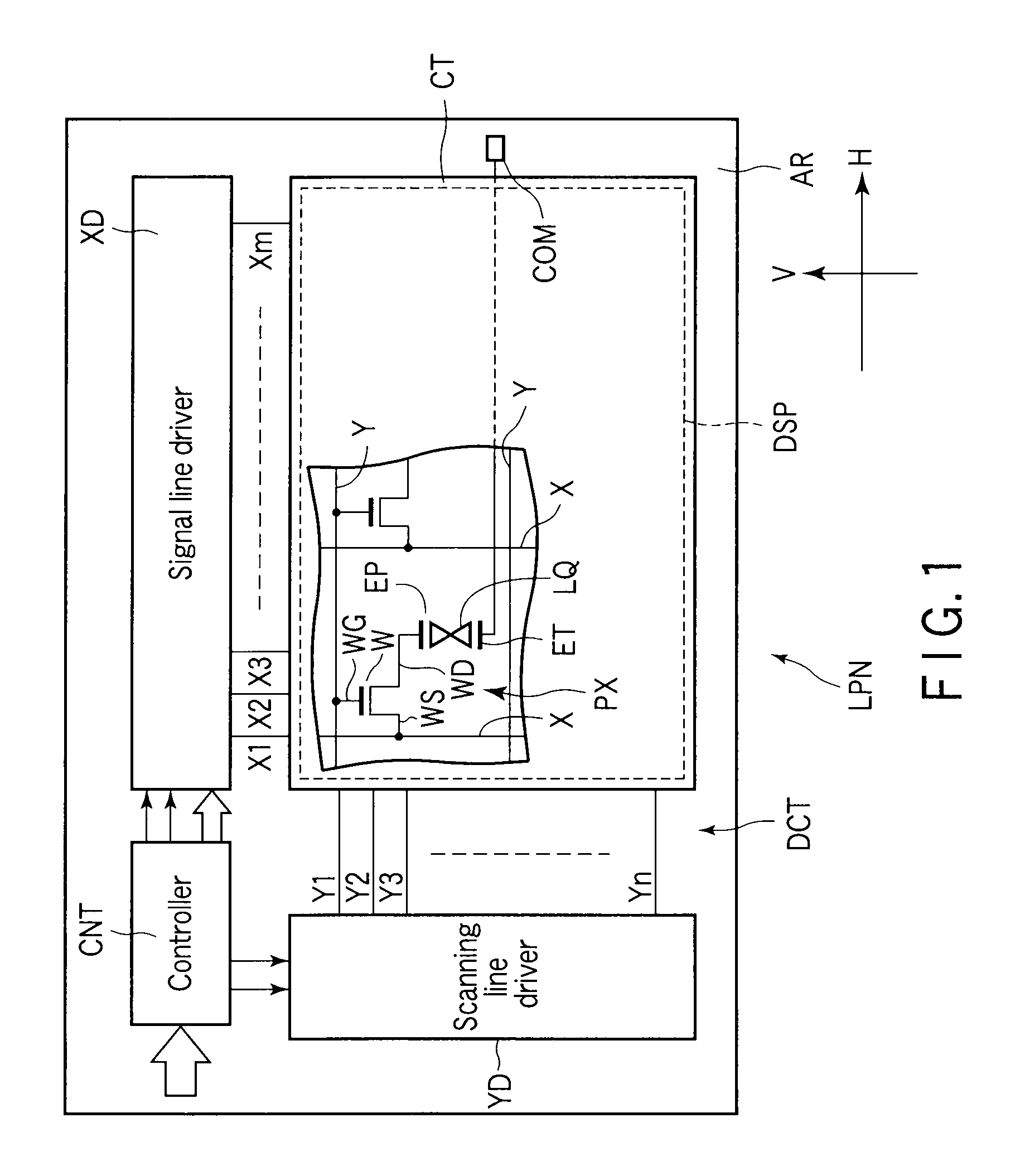

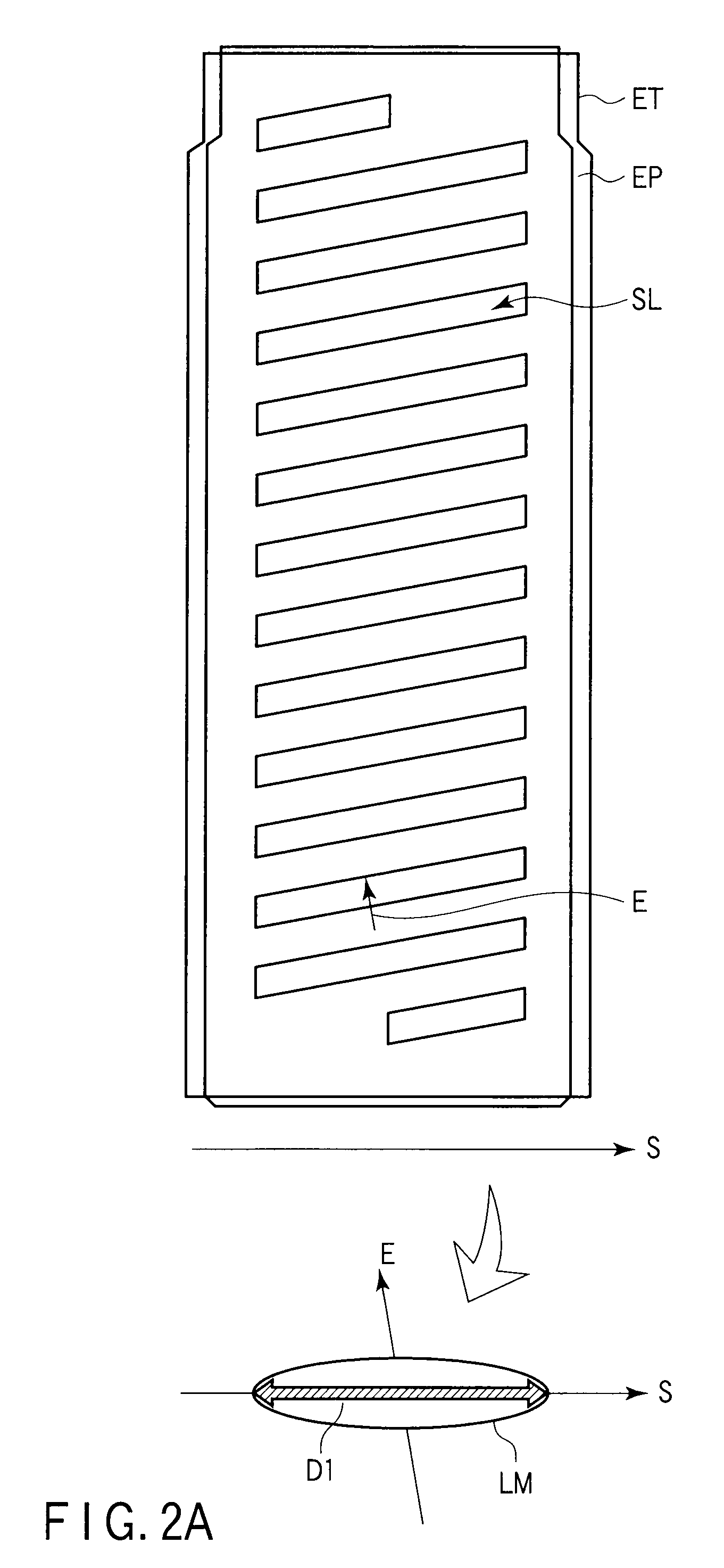

Liquid crystal display device

A liquid crystal display device, which is configured to have a liquid crystal layer held between a pair of substrates, includes a display area including a red color pixel, a green color pixel and a blue color pixel, a pixel electrode which is disposed in each of the color pixels, a counter-electrode which is opposed to the pixel electrode via an interlayer insulation film, and an alignment film which is disposed in contact with the liquid crystal layer and is subjected to such rubbing treatment as to restrict alignment of liquid crystal molecules included in the liquid crystal layer. The pixel electrode has a slit which is formed to be inclined with respect to a direction of rubbing of the alignment film, and the slit of the red pixel and the slit of the blue pixel are formed to be inclined in different directions.

Owner:JAPAN DISPLAY CENTRAL CO LTD

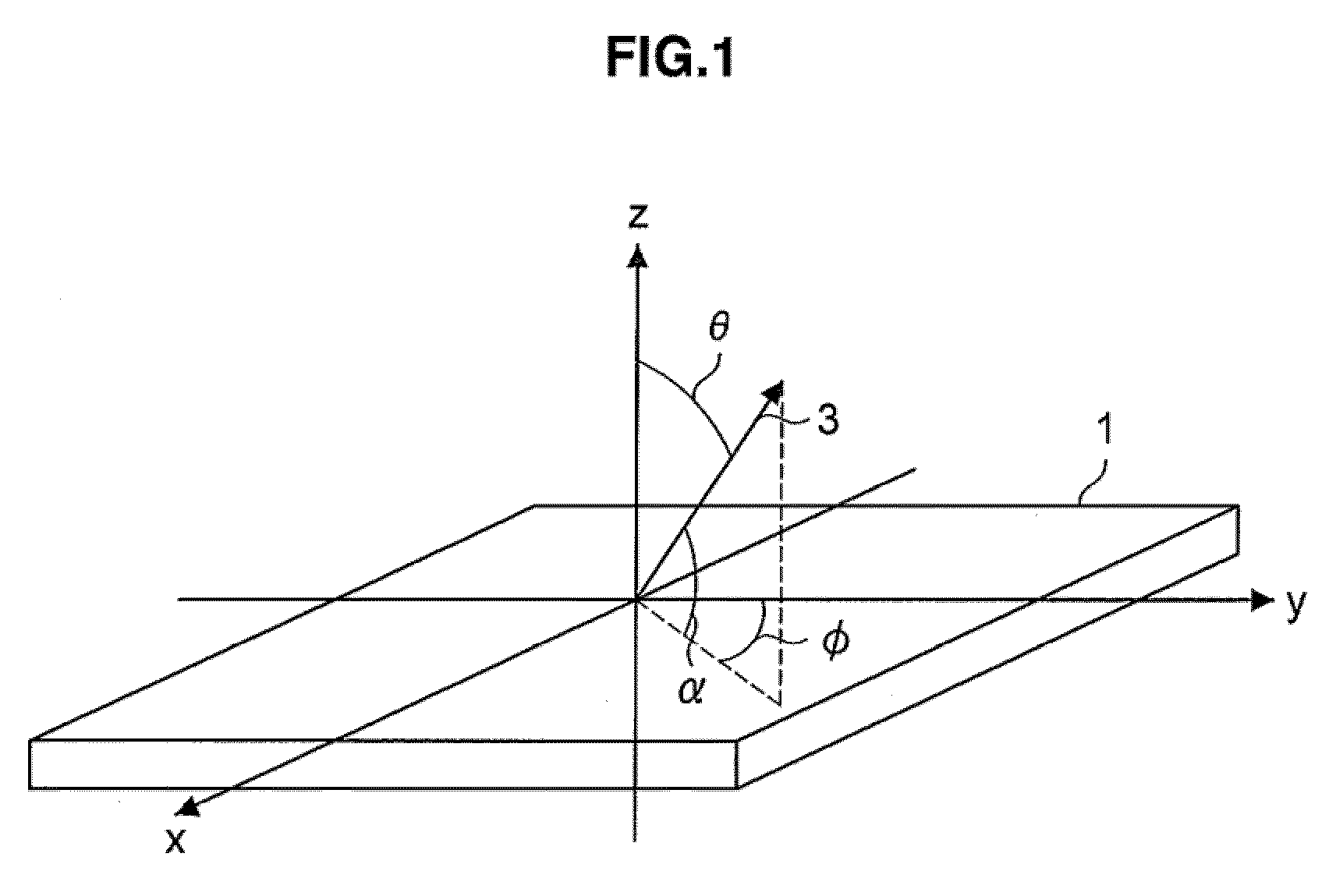

Optical element, window material, fitting, and insolation shielding device

ActiveCN102193129ASuppresses color changeSunshadesLight protection screensRefractive indexReflective layer

The invention provides an optical element, a window material, a fitting, and an insolation shielding device. The optical element has a first optical layer; a reflective layer; and a second optical layer. The reflective layer includes at least five layers of high refractive-index layers and metal layers alternately laminated. When a thickness L of the entire reflective layer is 80 nm, a ratio [alpha] of an optical thickness of the entire metal layers to that of the entire high refractive-index layers and a ratio [beta] of an optical thickness of a third high refractive-index layer to that of a first high refractive-index layer are included in a first region, when the thickness L is 90 nm, the ratios [alpha] and [beta] are included in a second region, and when the thickness L is 80 to 90 nm, the ratios [alpha] and [beta] are included in a space enclosed by the first region, the second region, and straight lines derived from these regions.

Owner:DEXERIALS CORP

Image forming apparatus including density control and control method thereof

InactiveUS7945178B2Improve image qualityAvoid changeElectrographic process apparatusImaging qualityImage formation

An image forming apparatus is provided that forms an image using developers of different tone and the same hue. When forming images for measurement for density control, the apparatus performs density control by forming a greater number of density levels of an image for measurement developed using a light developer than the number of density levels of an image for measurement developed using a dark developer. Thus, even if the amount of applied light developer may fluctuate, the fluctuation can be compensated to prevent the occurrence of pseudo-contours that lower image quality.

Owner:CANON KK

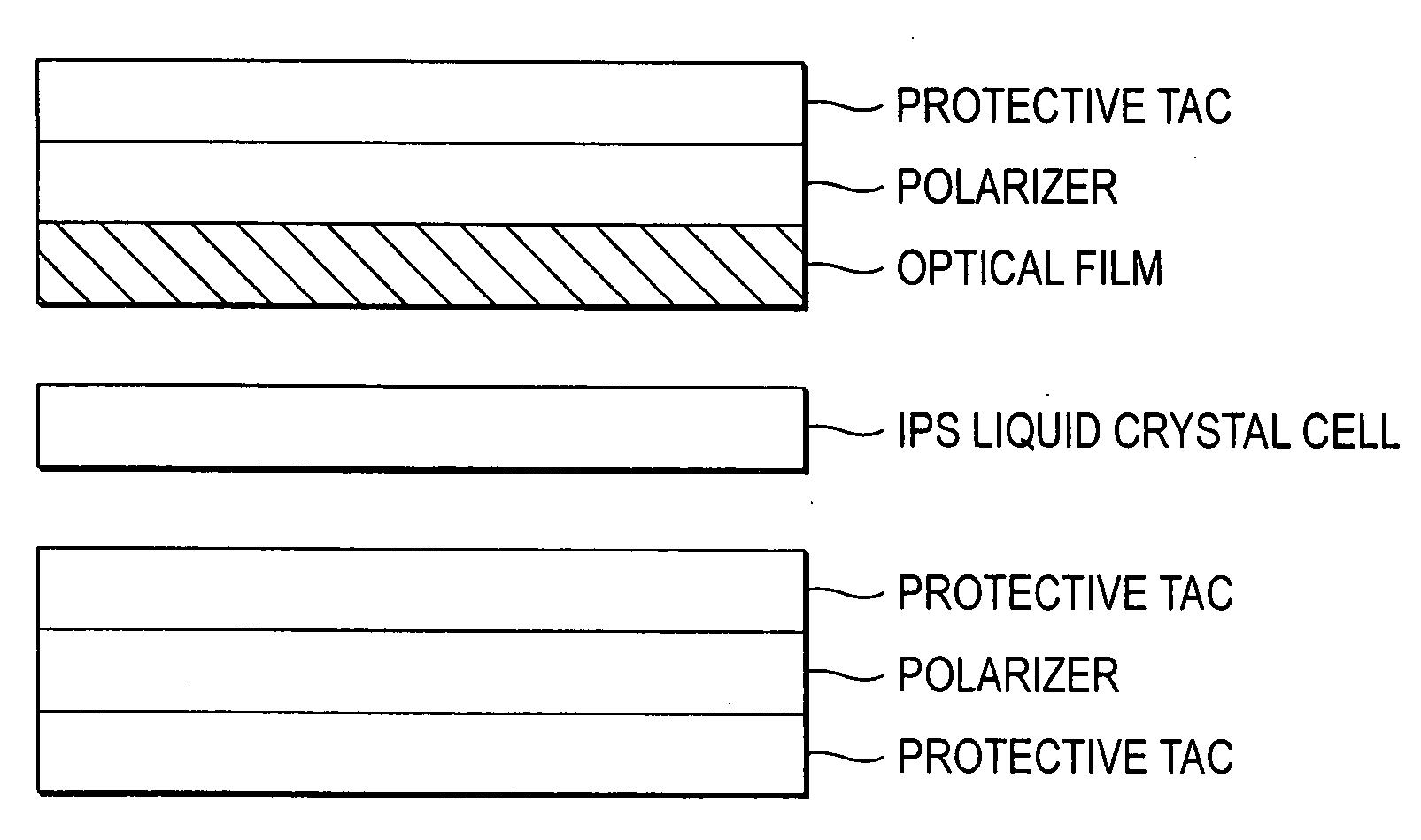

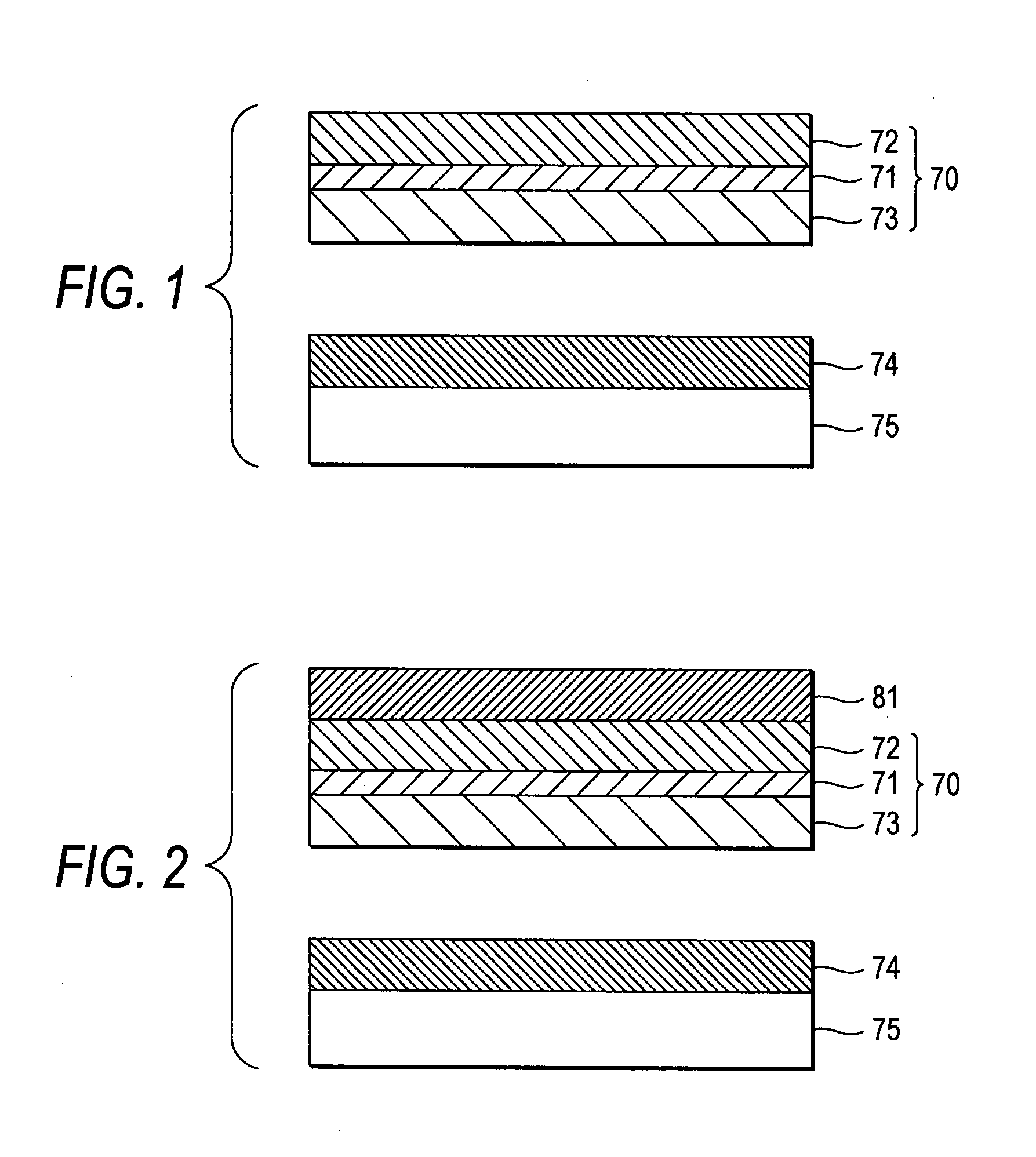

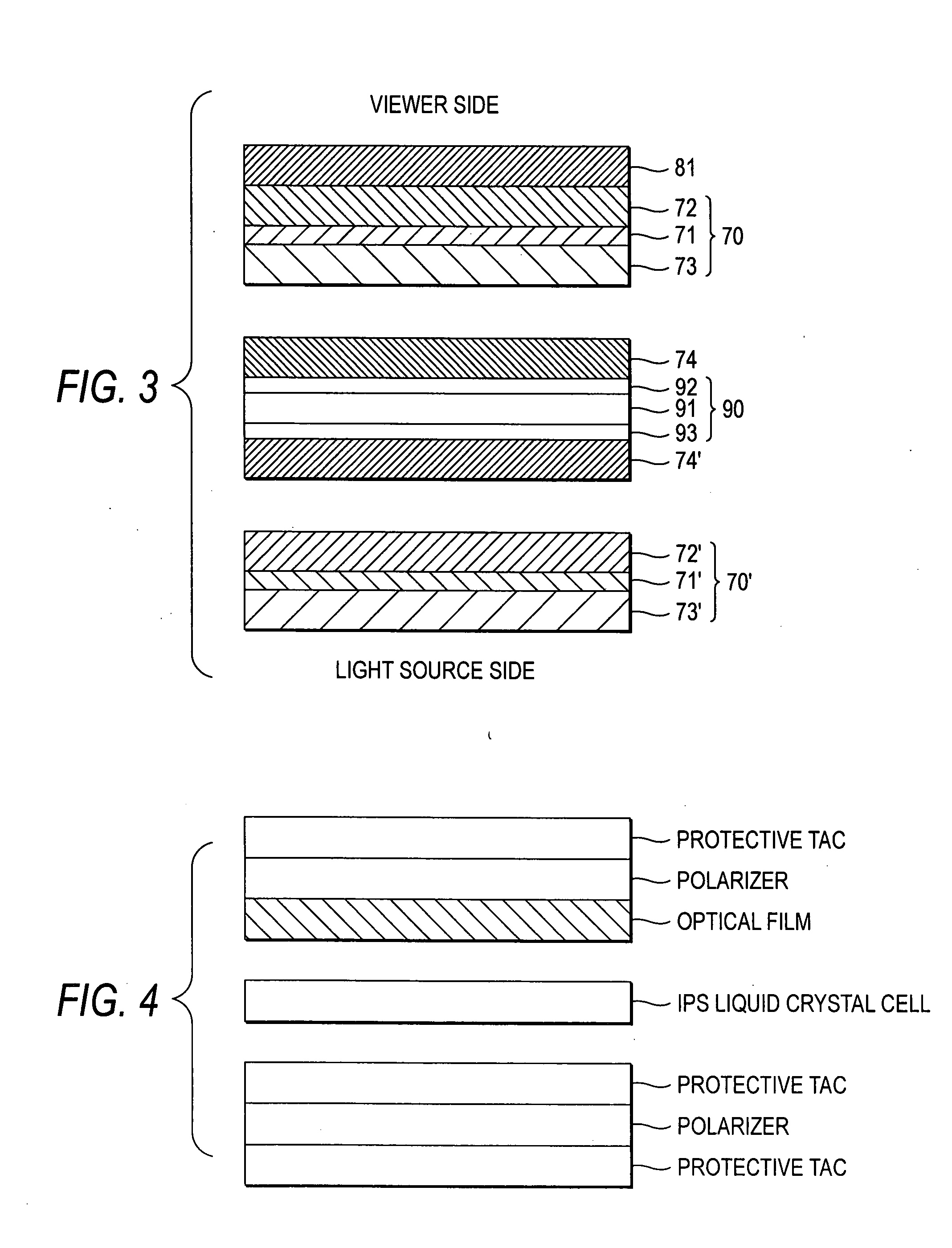

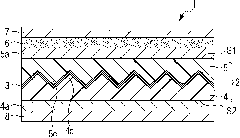

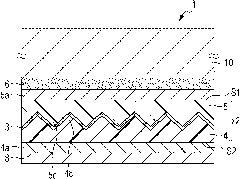

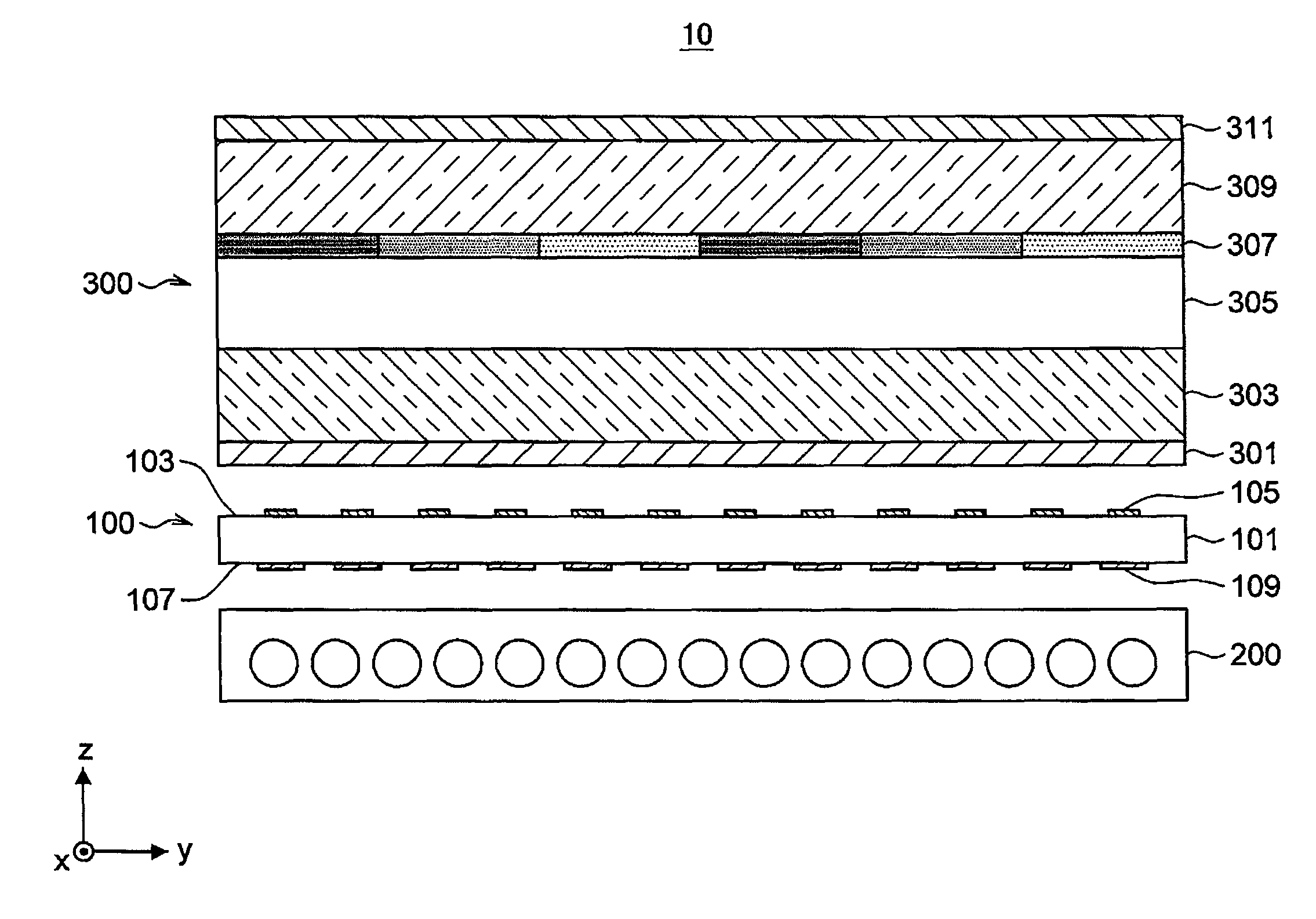

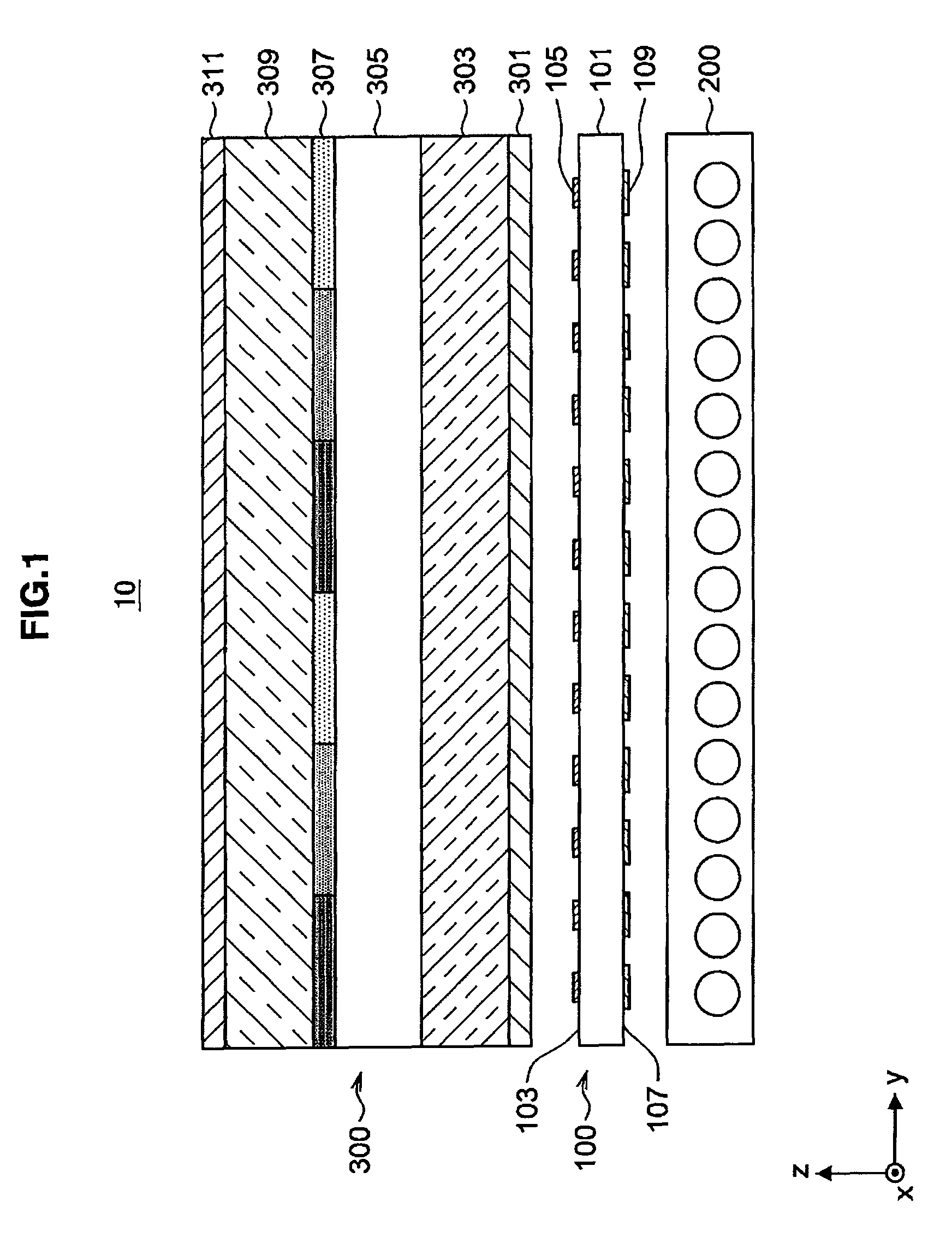

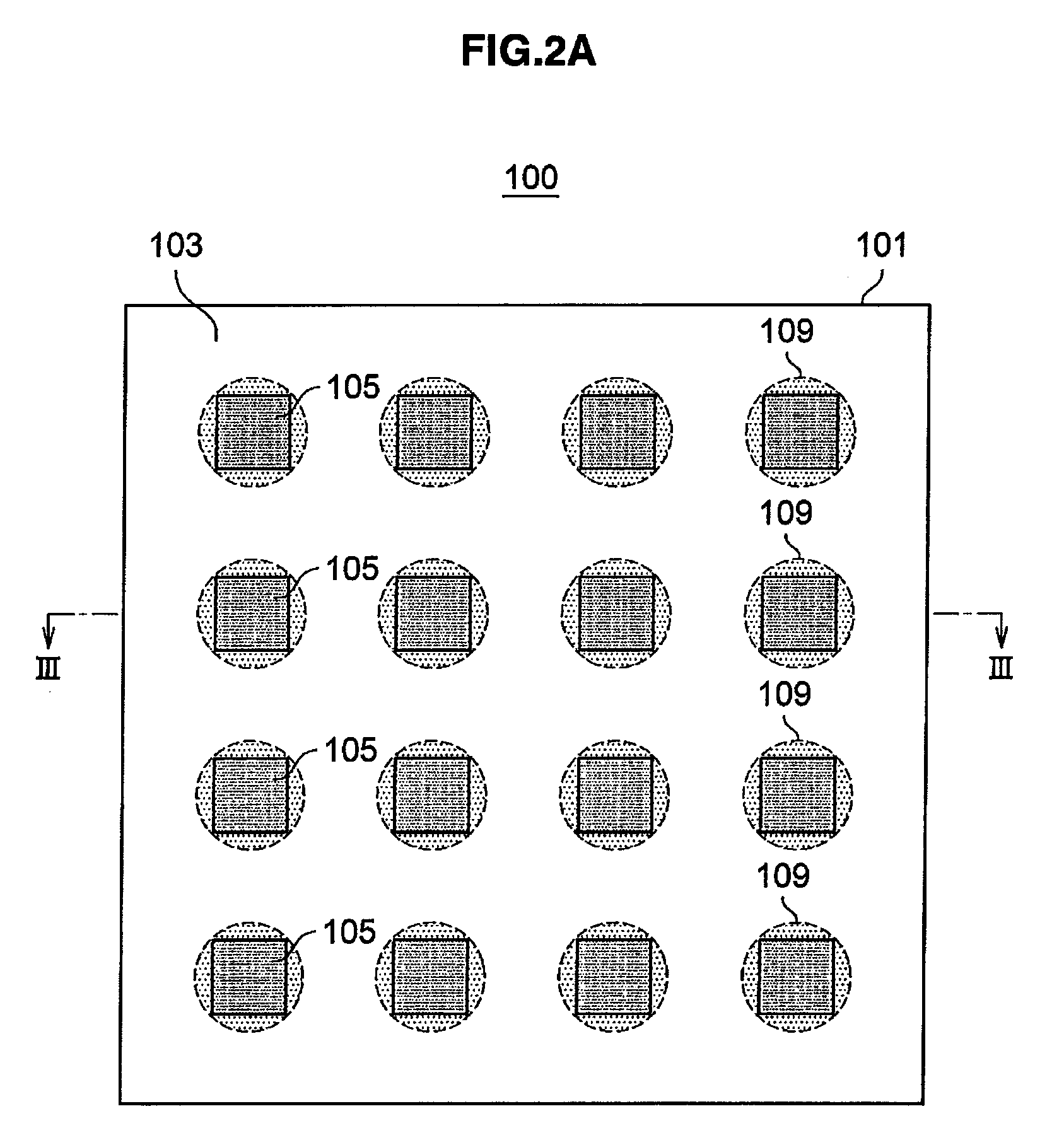

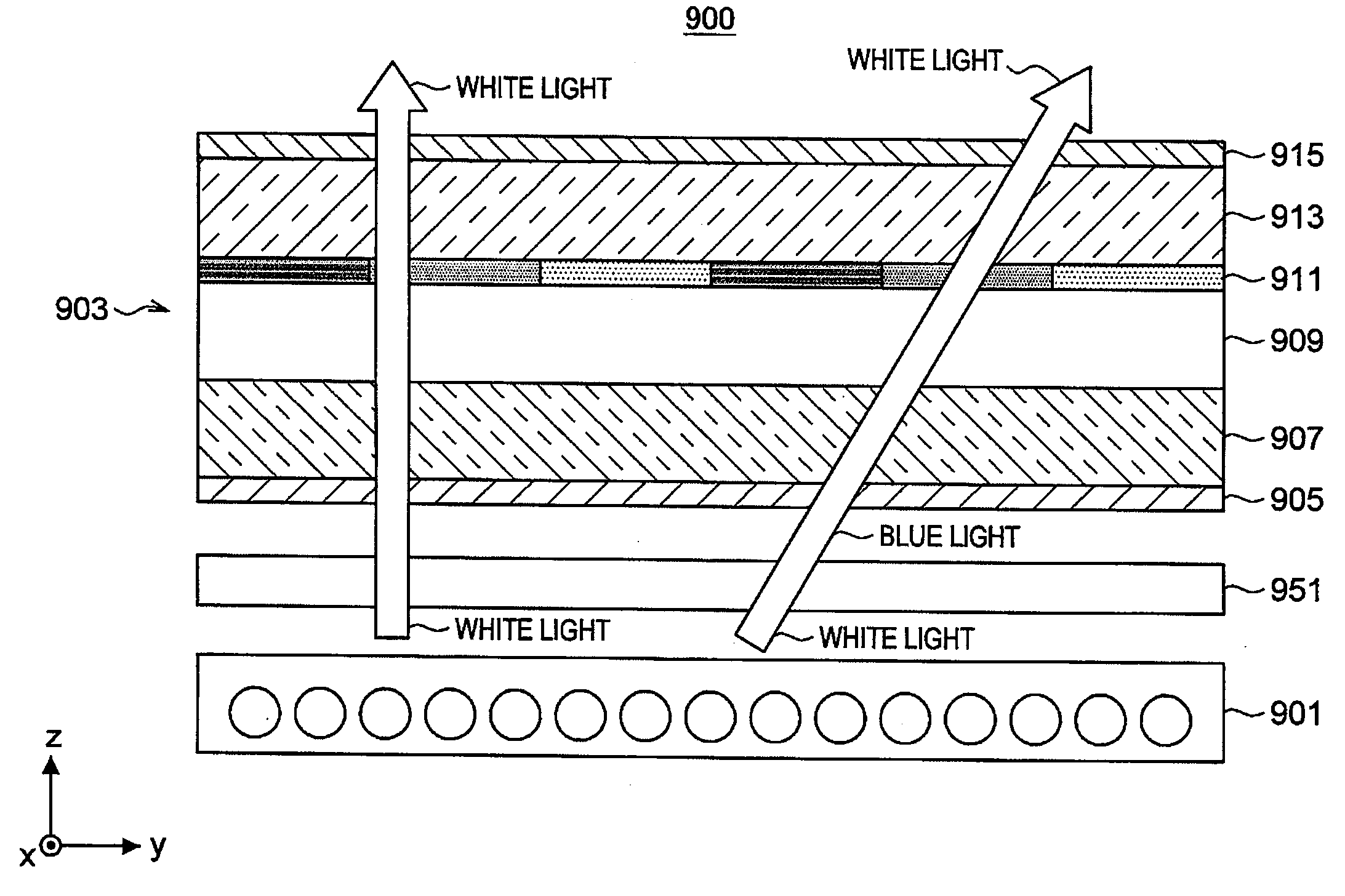

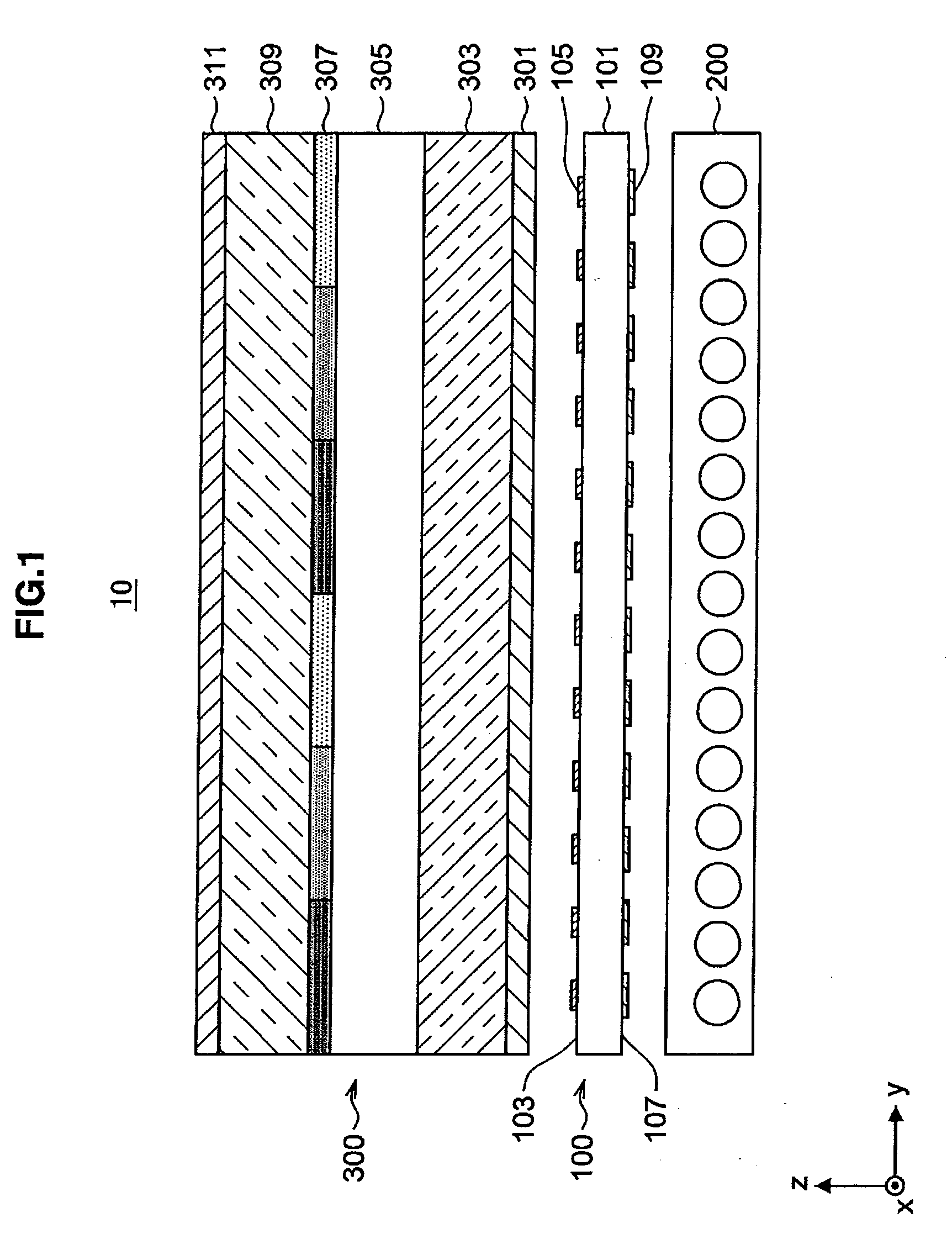

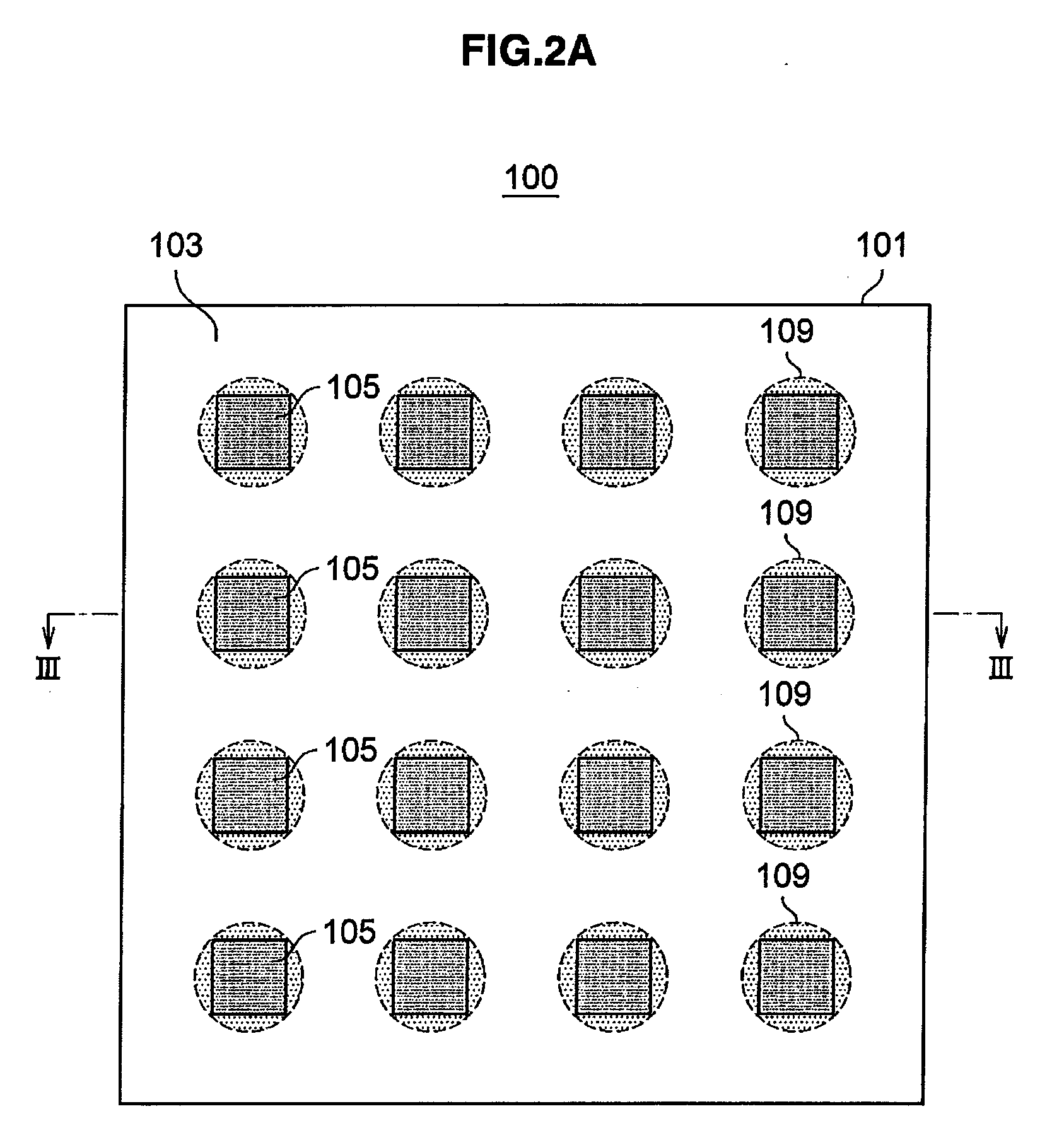

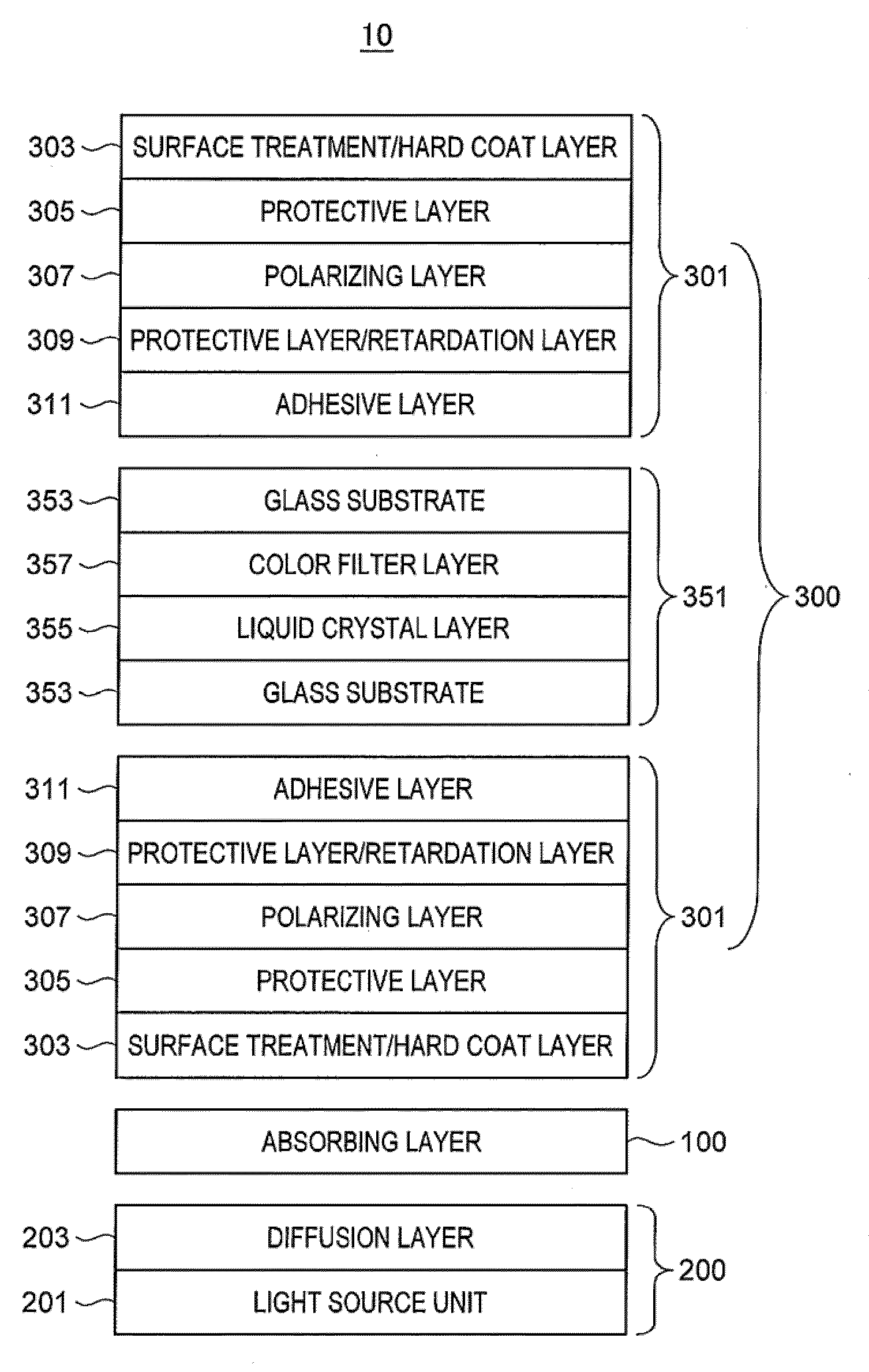

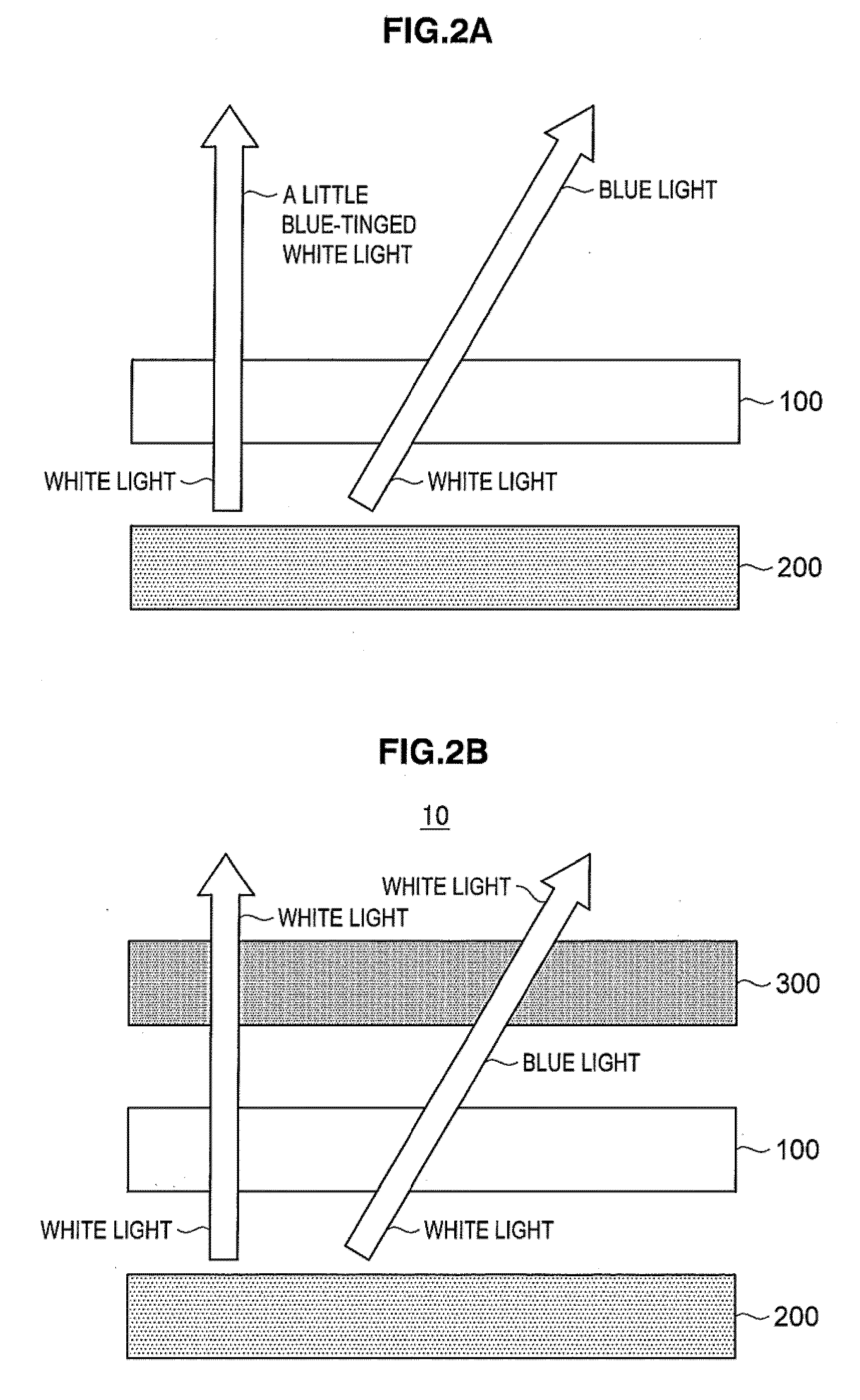

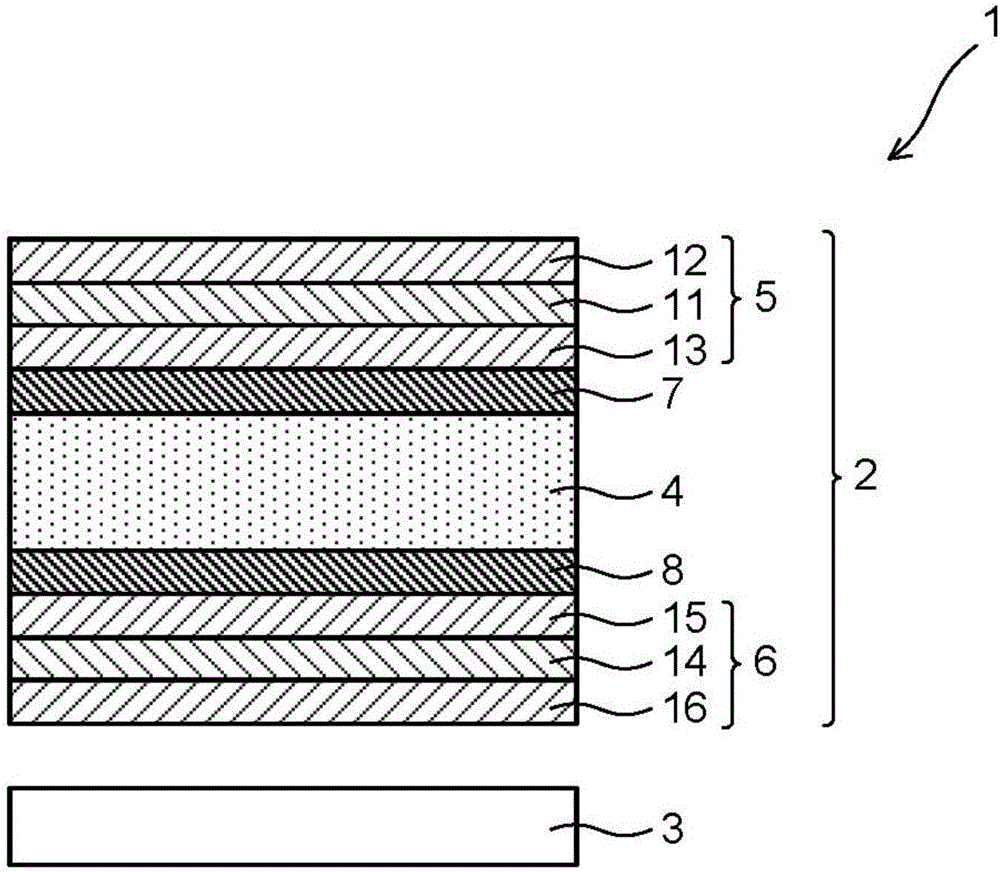

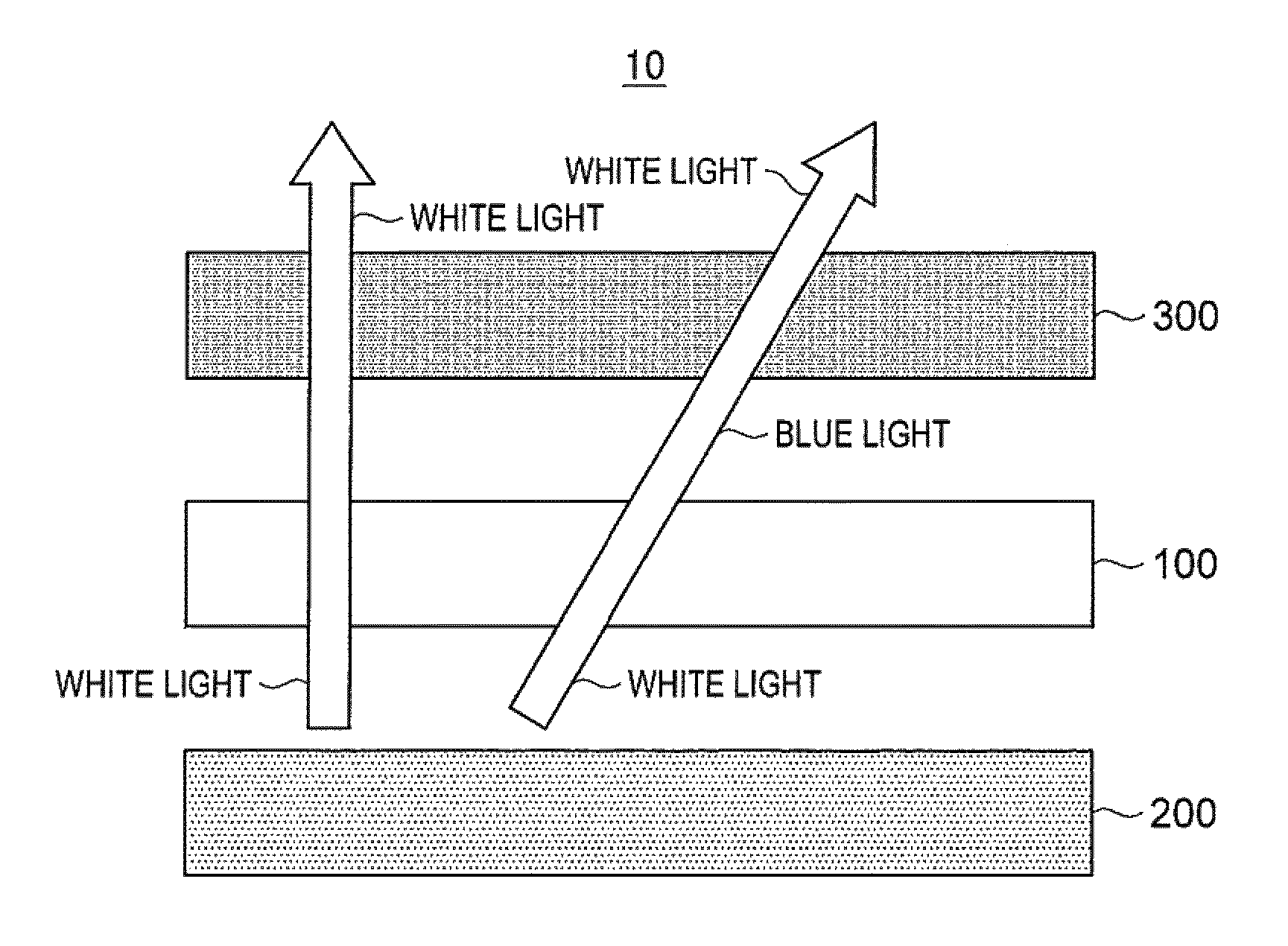

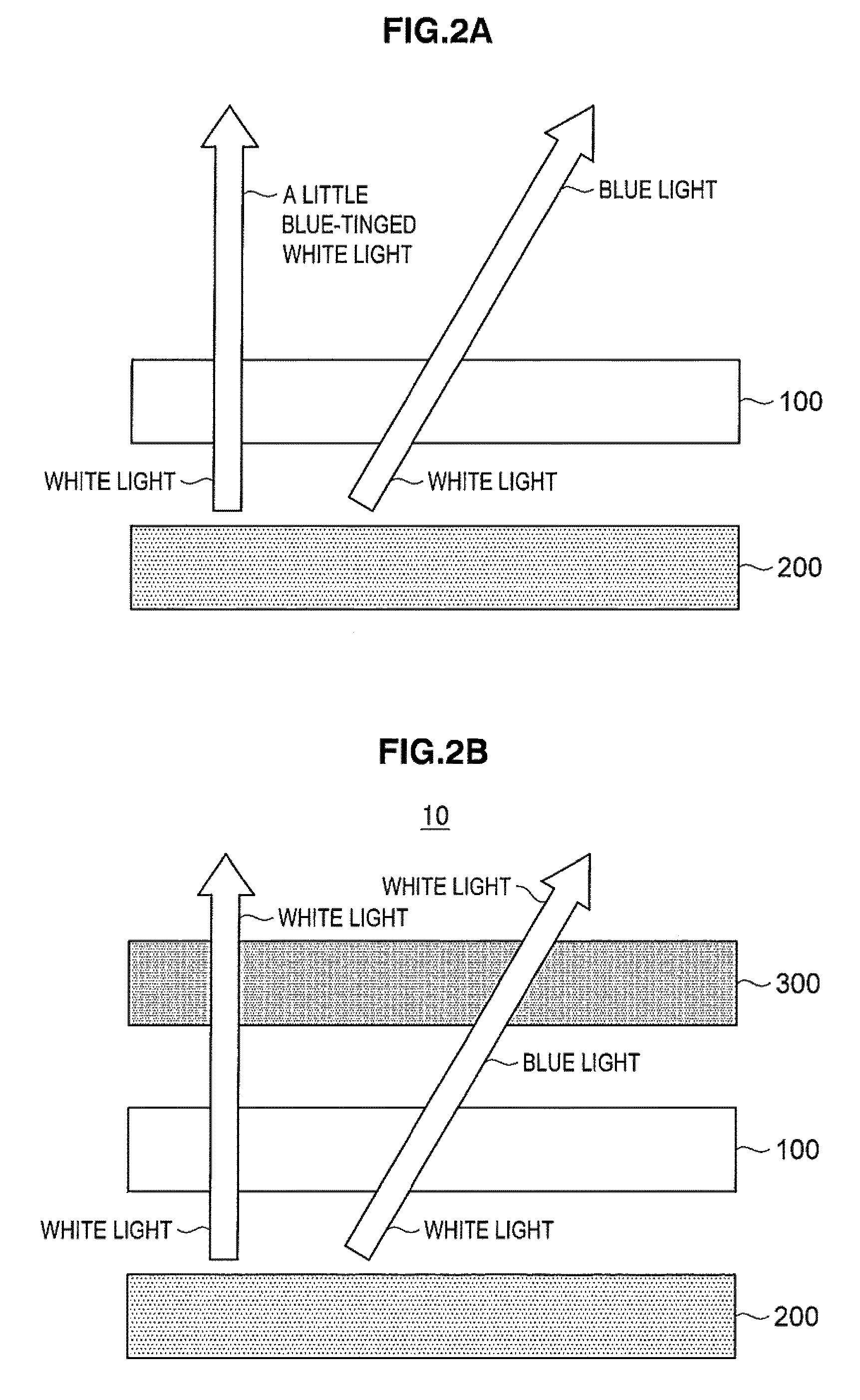

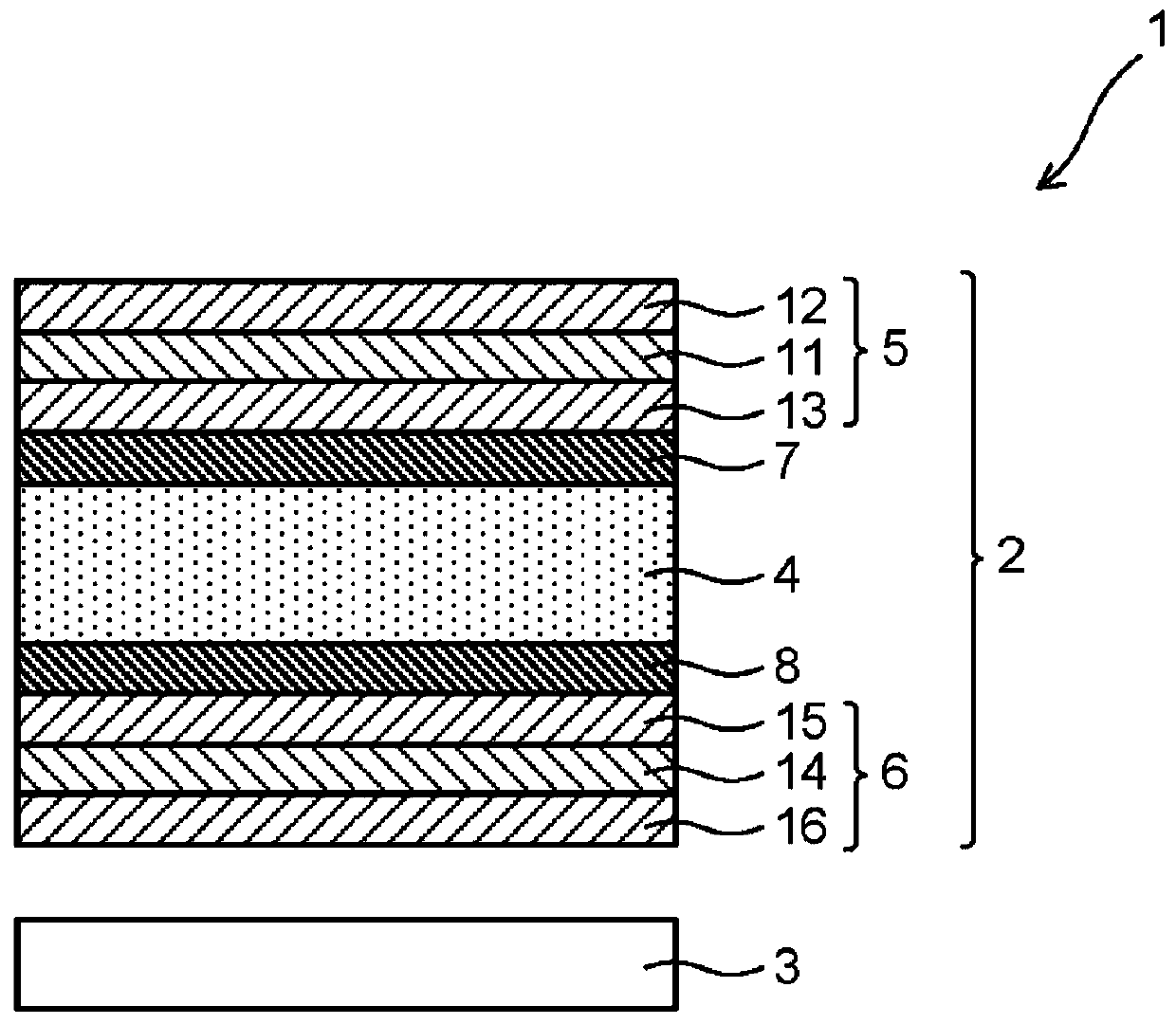

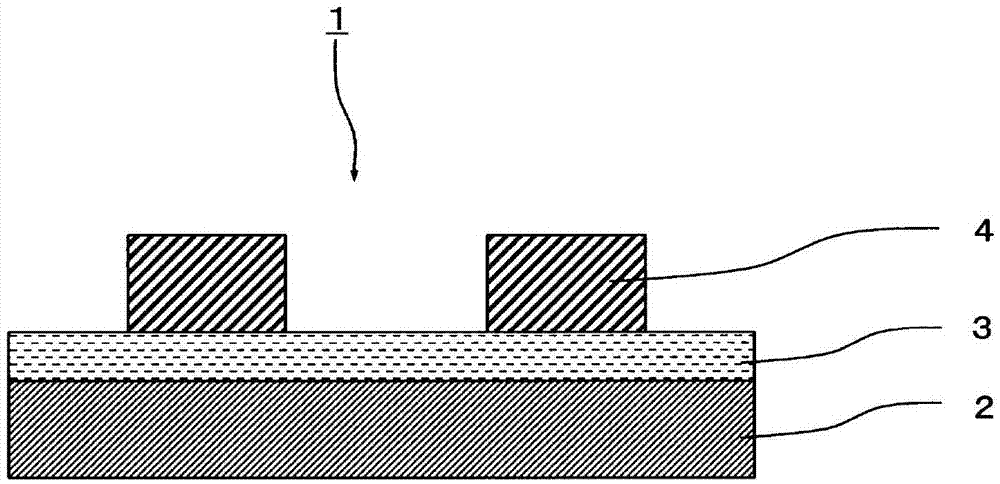

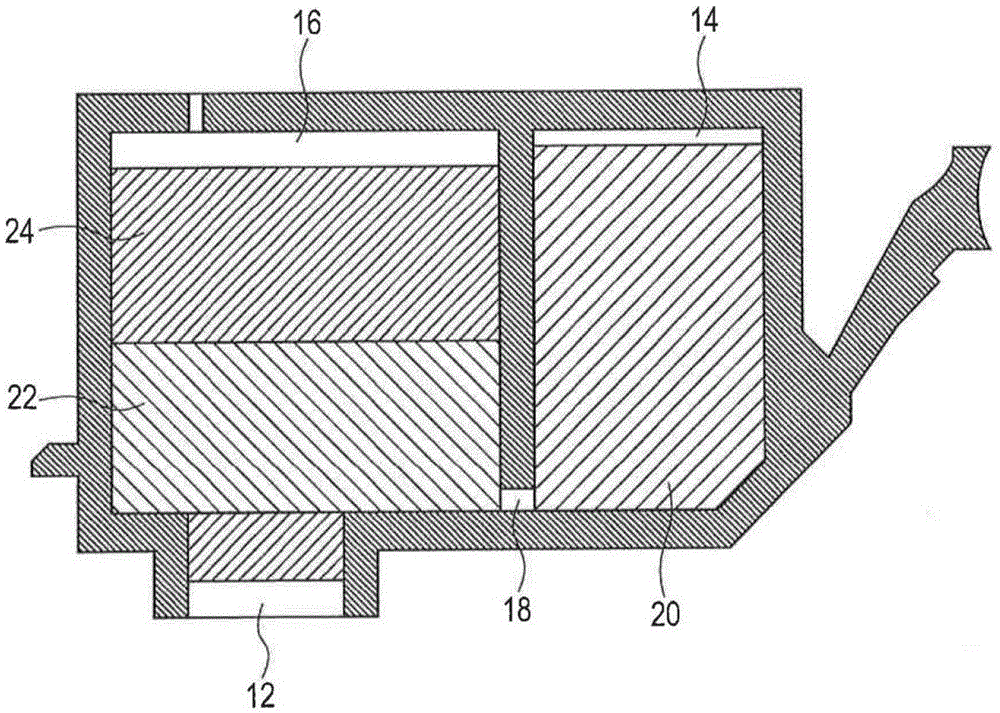

Liquid crystal display device, backlight source and optical film

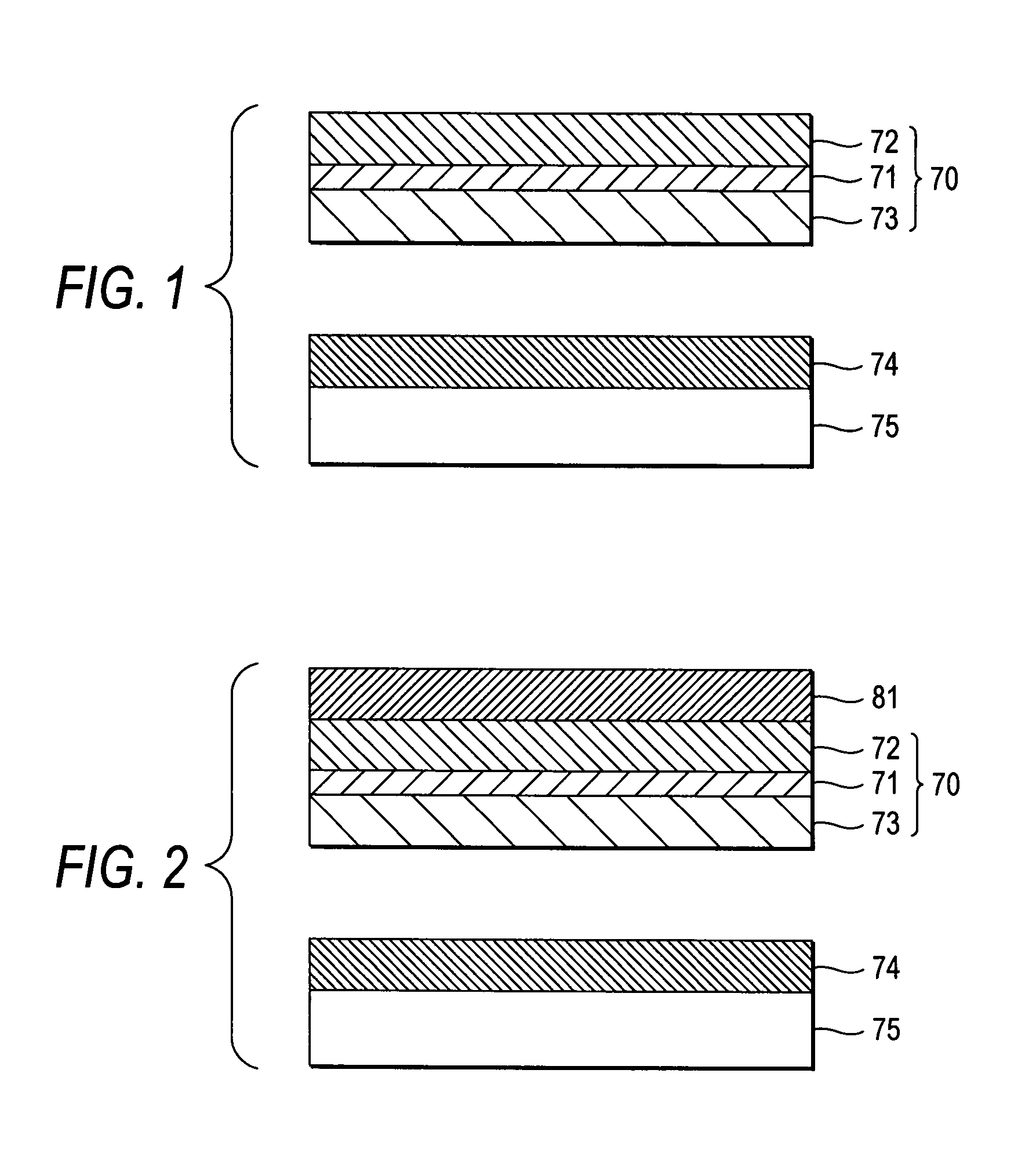

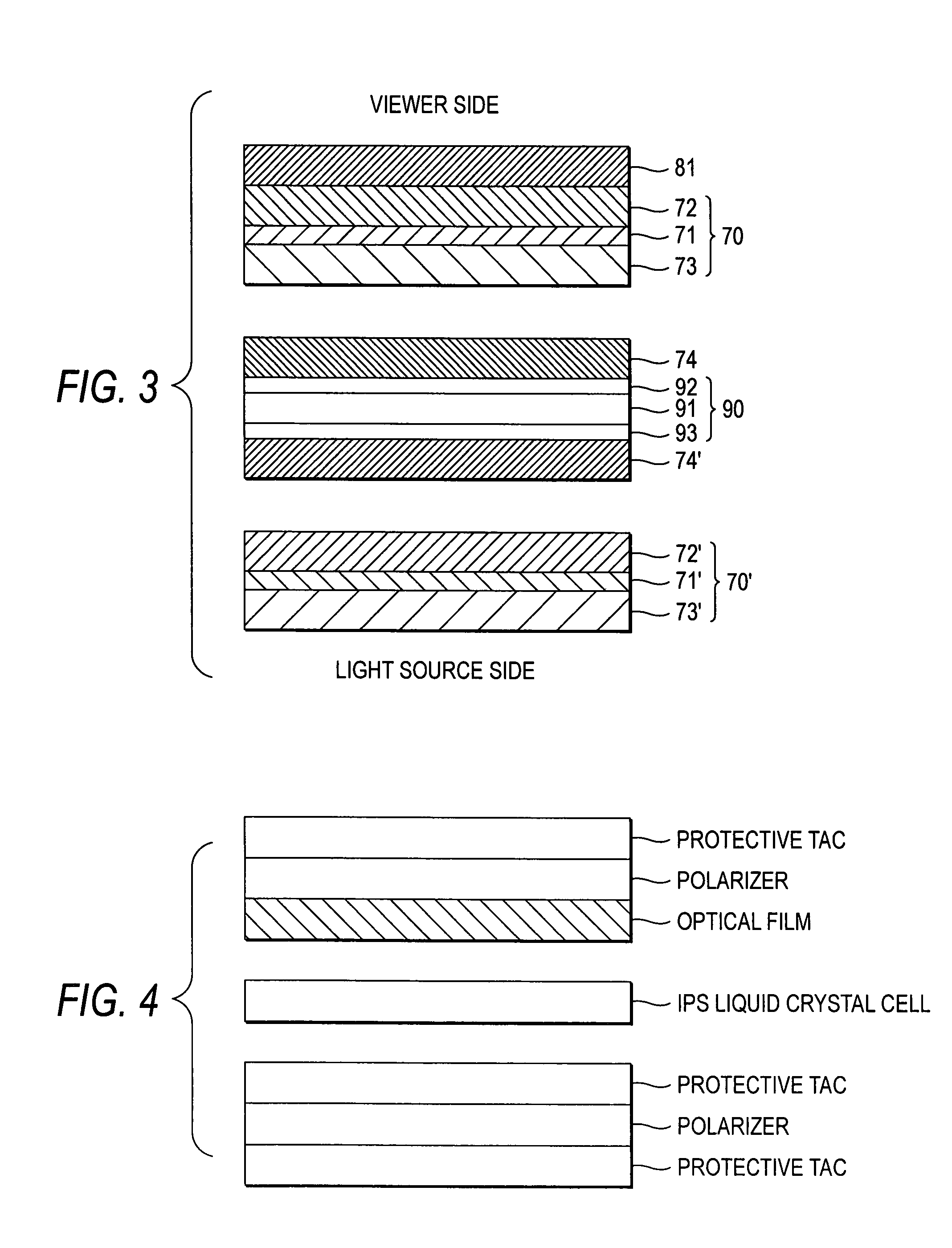

InactiveUS8253885B2Suppresses color changeEasy to manufactureShow cabinetsImpedence networksLiquid-crystal displayReflective layer

A liquid crystal display device according to the present invention includes a liquid crystal panel, a backlight source provided on a rear surface of the liquid crystal panel, for irradiating the liquid crystal panel with white light, and an optical film provided between the liquid crystal panel and the backlight source, in which the optical film includes a base material which passes the white light irradiated from the backlight source, a colored layer partially provided on one surface of the base material at the side of the liquid crystal, panel, and a reflective layer provided on another surface of the base material at the side of the backlight source opposite to the colored layer, for reflecting the white light.

Owner:SONY CORP

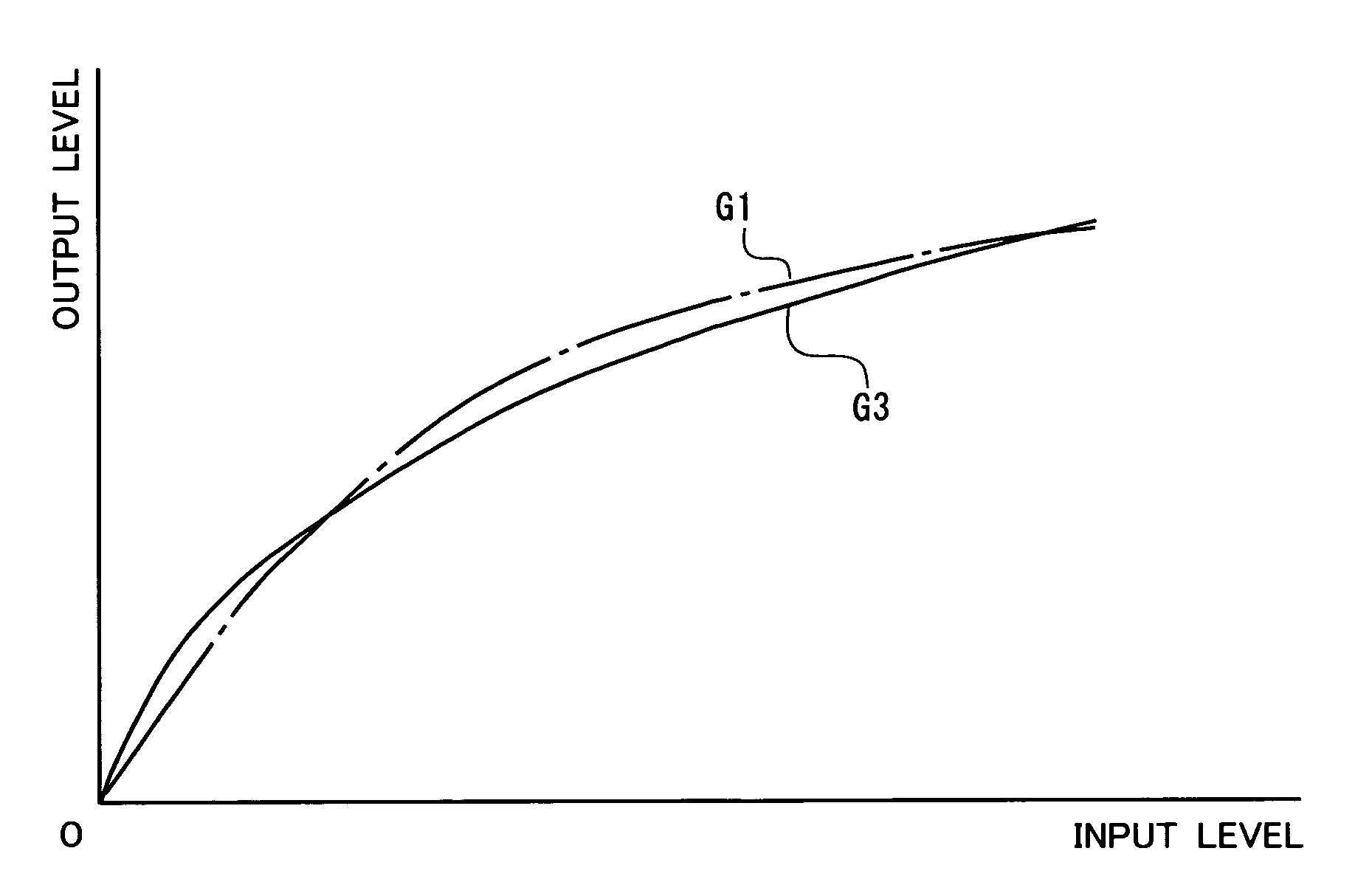

Medium storing image processing program, image processing device, and image processing method

ActiveUS20110286680A1Improving bright part gradation partImproving part gradation dark partTelevision system detailsImage enhancementImaging processingColor saturation

A non-transitory computer-readable storage medium storing an image processing program causing a computer to execute an image processing on image data to be processed, the image processing program including an obtaining step obtaining the image data, a gradation conversion processing step performing gradation conversion processing on the image data at an intermediate part of gradation according to input / output characteristics having characteristics to which characteristics to reduce a contrast are added, and a correcting step making a correction to enhance a local contrast indicative of contrast at a local part of an image for the image data subjected to the gradation conversion processing by using a gain curve in which a degree of enhancement changes in accordance with luminance information of a pixel to be processed, and thus, bright and dark part gradations are improved while suppressing a change in a hue and color saturation as well as maintaining an apparent contrast.

Owner:NIKON CORP

Method for Forming Coating Film

InactiveUS20090035540A1Metallic gloss excellent in design propertyImprove Design PerformanceLayered productsPretreated surfacesColloidPolymer chemistry

A method for forming a multi-layer coating film by forming an undercoating film, a glittering material-containing base coating film and a clear coating film in this order on a substrate to be coated, in which a glittering material-containing base coating material for forming the glittering material-containing base coating film contains colloid particles containing a noble metal and / or a metal and a coating film-forming resin, and the undercoating film has a hue in a range of from +35 to +50 and −35 to −50 on a Munsell 100-hue ring with counterclockwise rotation on the hue ring being represented by from 0 to +50 and clockwise rotation being represented by from 0 to −50 where a hue of plasmon coloration of the colloid particles containing a noble metal and / or a metal is 0 on the hue ring, and has a brightness of 9 or less on a Munsell color system, or the undercoating film has an achromatic color having a brightness of 4 or less on a Munsell color system.

Owner:NIPPON PAINT CO LTD

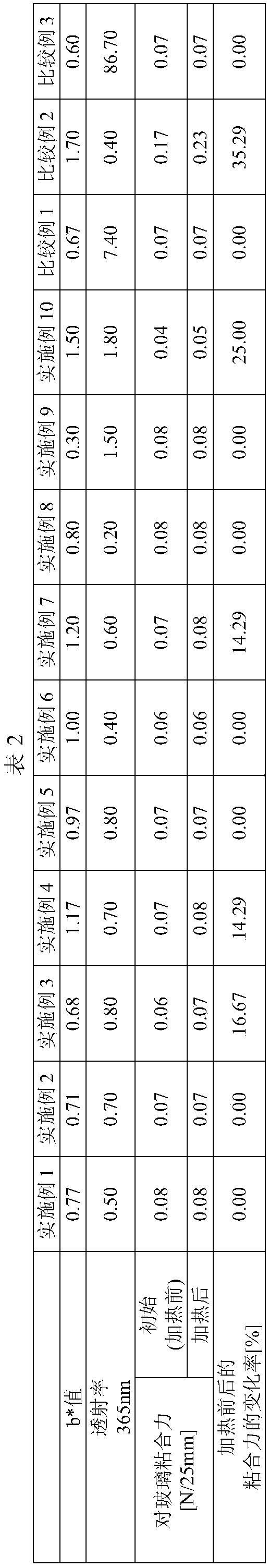

Surface protective film

PendingCN108624252AExcellent adhesion stabilityReduce transmittanceNon-macromolecular adhesive additivesFilm/foil adhesivesTransmittanceUltraviolet

The present invention relates to a surface protective film. The present invention provides an optical surface protective film which has low transmittance of ultraviolet rays, suppresses change in color tone, and is excellent in adhesion stability. The surface protective film for optics of the present invention has a substrate formed of a polyester resin and an adhesive layer formed of an adhesivecomposition provided on one surface of the substrate, wherein the surface protection The b* value of the film is 2 or less, and the transmittance of the surface protective film at a wavelength of 365nm is 2% or less. After the pressure-sensitive adhesive layer is adhered to the glass, the adhesive is heated at 100 DEG C for 30 minutes. The rate of change of the force with respect to the adhesiveforce before heating is +-30% or less.

Owner:NITTO DENKO CORP

Liquid Crystal Display Device, Backlight Source and Optical Film

InactiveUS20090251636A1Suppresses color changeEasy to manufactureShow cabinetsImpedence networksLiquid-crystal displayReflective layer

A liquid crystal display device according to the present invention includes a liquid crystal panel, a backlight source provided on a rear surface of the liquid crystal panel, for irradiating the liquid crystal panel with white light, and an optical film provided between the liquid crystal panel and the backlight source, in which the optical film includes a base material which passes the white light irradiated from the backlight source, a colored layer partially provided on one surface of the base material at the side of the liquid crystal, panel, and a reflective layer provided on another surface of the base material at the side of the backlight source opposite to the colored layer, for reflecting the white light.

Owner:SONY CORP

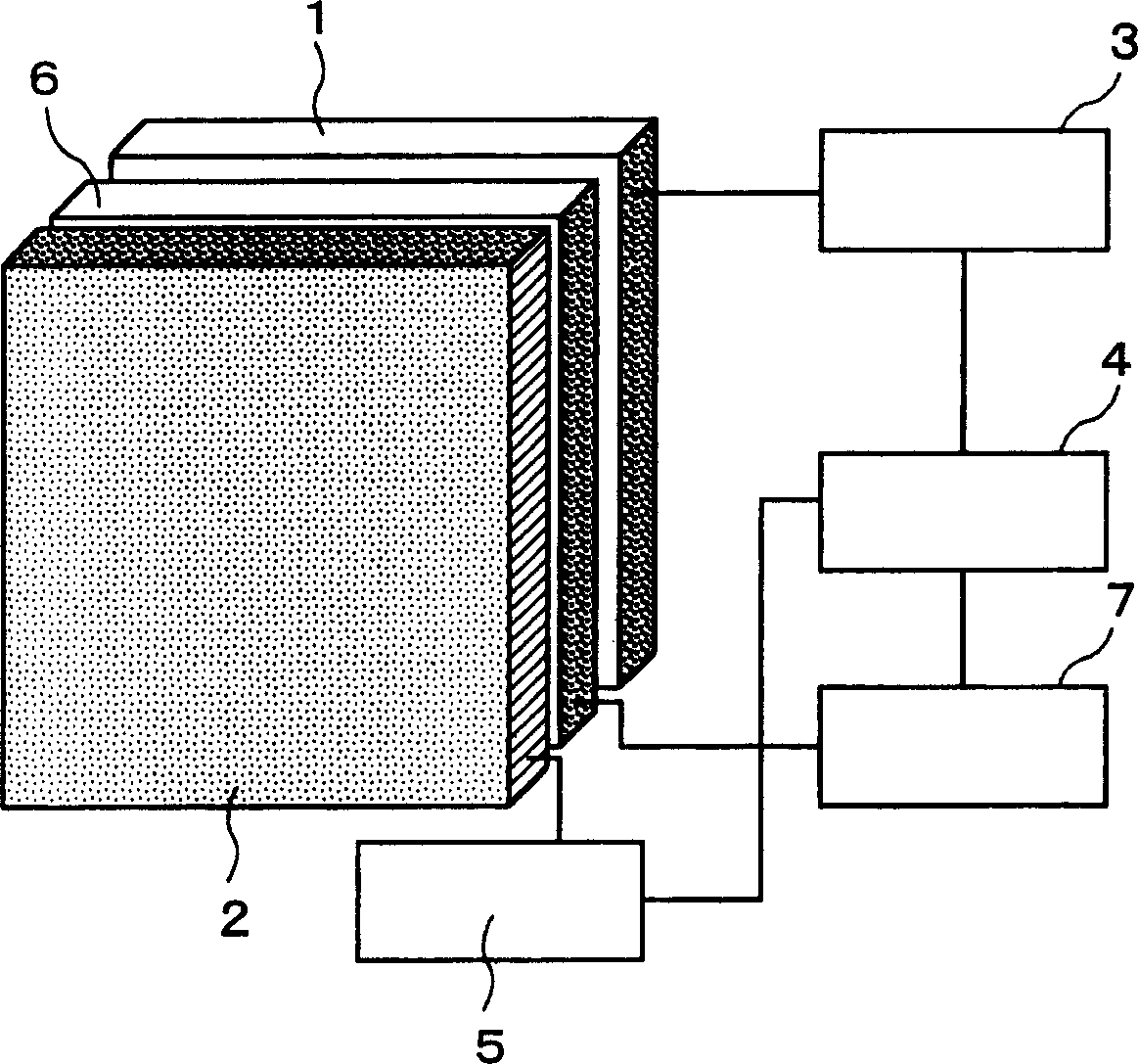

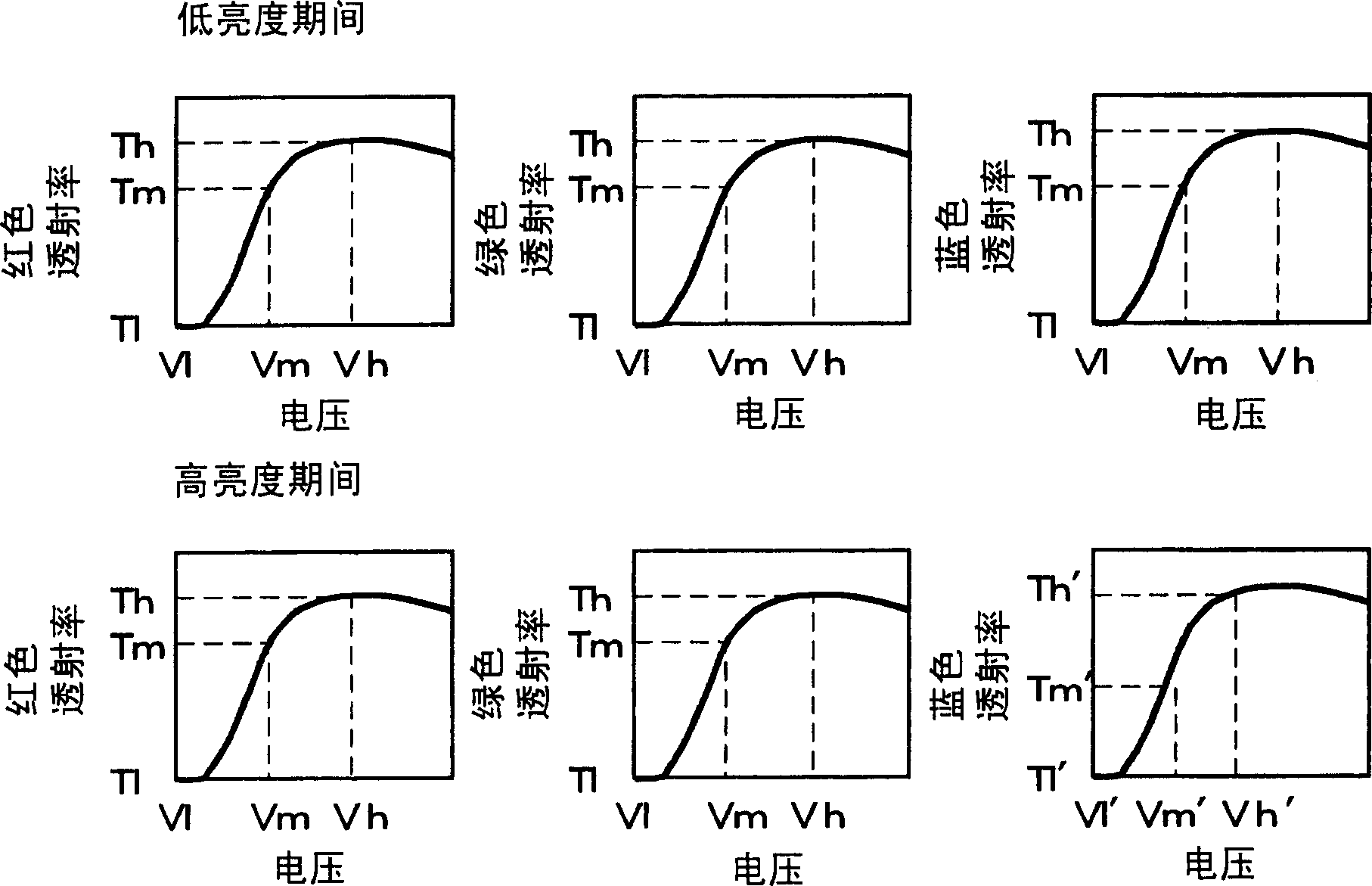

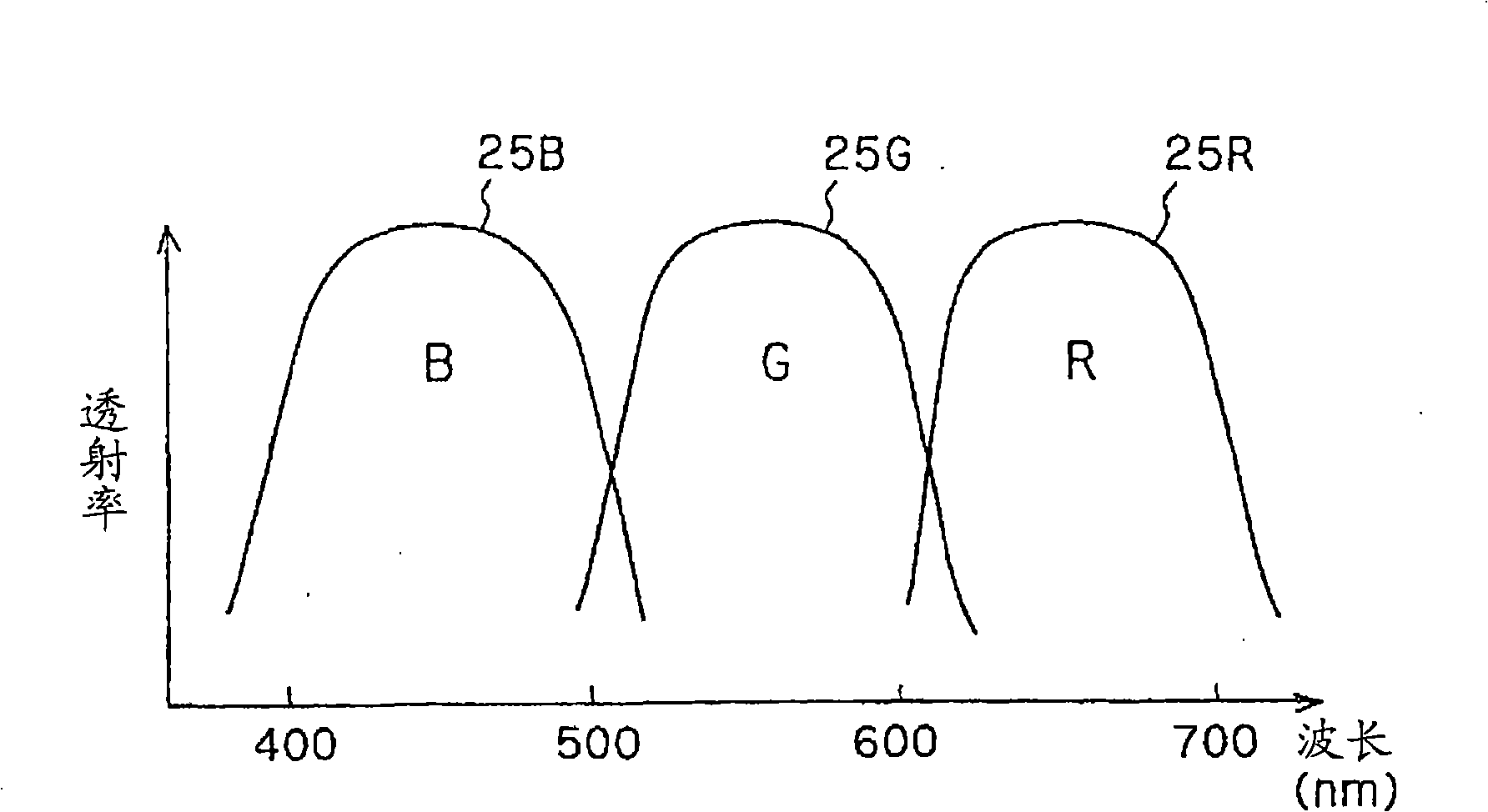

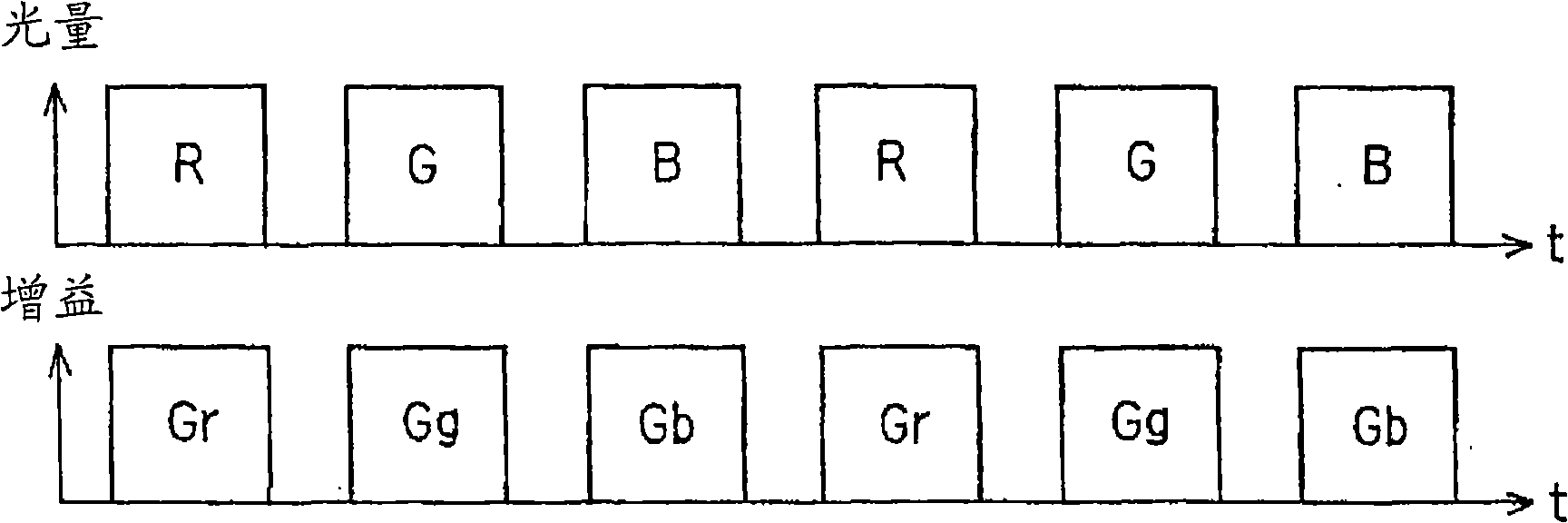

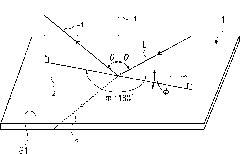

Liquid crystal display device, polarizing plate and backlight source

ActiveUS20090256995A1Suppresses color changeEffective controlNon-linear opticsChange colorWhite light

A liquid crystal display device according to the present invention includes a liquid crystal panel which has a liquid crystal cell including a predetermined liquid crystal layer and polarizing plates for holding the liquid crystal cell, a backlight source which is arranged on the rear side of the liquid crystal panel, for irradiating the liquid crystal panel with white light, and an absorbing layer which is arranged between the backlight source and the liquid crystal cell, for absorbing only the light of the wavelength band corresponding to a changed color of the white light while passing through the liquid crystal panel in the oblique direction with respect to the normal direction of the liquid crystal panel.

Owner:SATURN LICENSING LLC

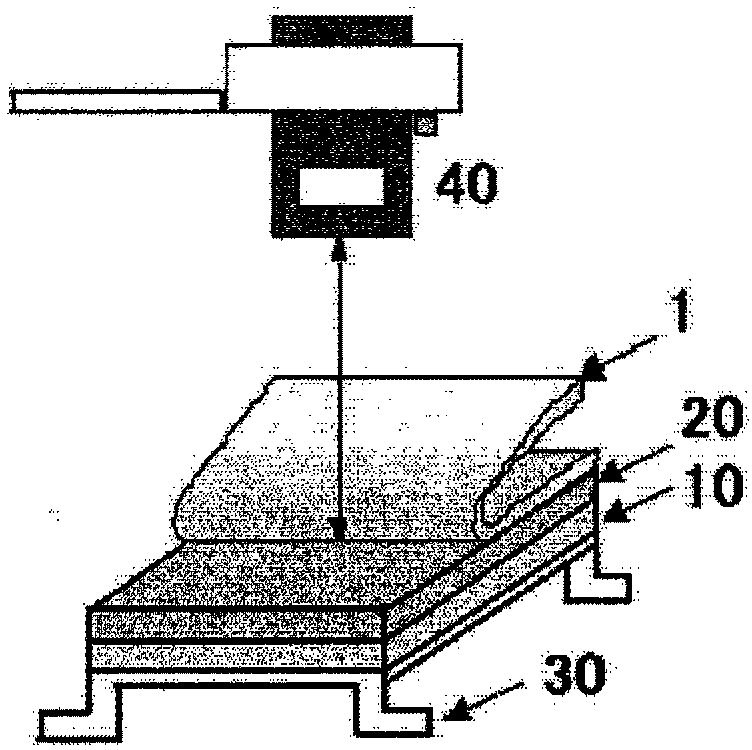

Liquid crystal display device

ActiveUS20090091696A1High display qualityImprove display qualityNon-linear opticsRubbingLiquid crystal molecule

A liquid crystal display device, which is configured to have a liquid crystal layer held between a pair of substrates, includes a display area including a red color pixel, a green color pixel and a blue color pixel, a pixel electrode which is disposed in each of the color pixels, a counter-electrode which is opposed to the pixel electrode via an interlayer insulation film, and an alignment film which is disposed in contact with the liquid crystal layer and is subjected to such rubbing treatment as to restrict alignment of liquid crystal molecules included in the liquid crystal layer. The pixel electrode has a slit which is formed to be inclined with respect to a direction of rubbing of the alignment film, and the slit of the red pixel and the slit of the blue pixel are formed to be inclined in different directions.

Owner:JAPAN DISPLAY CENT INC

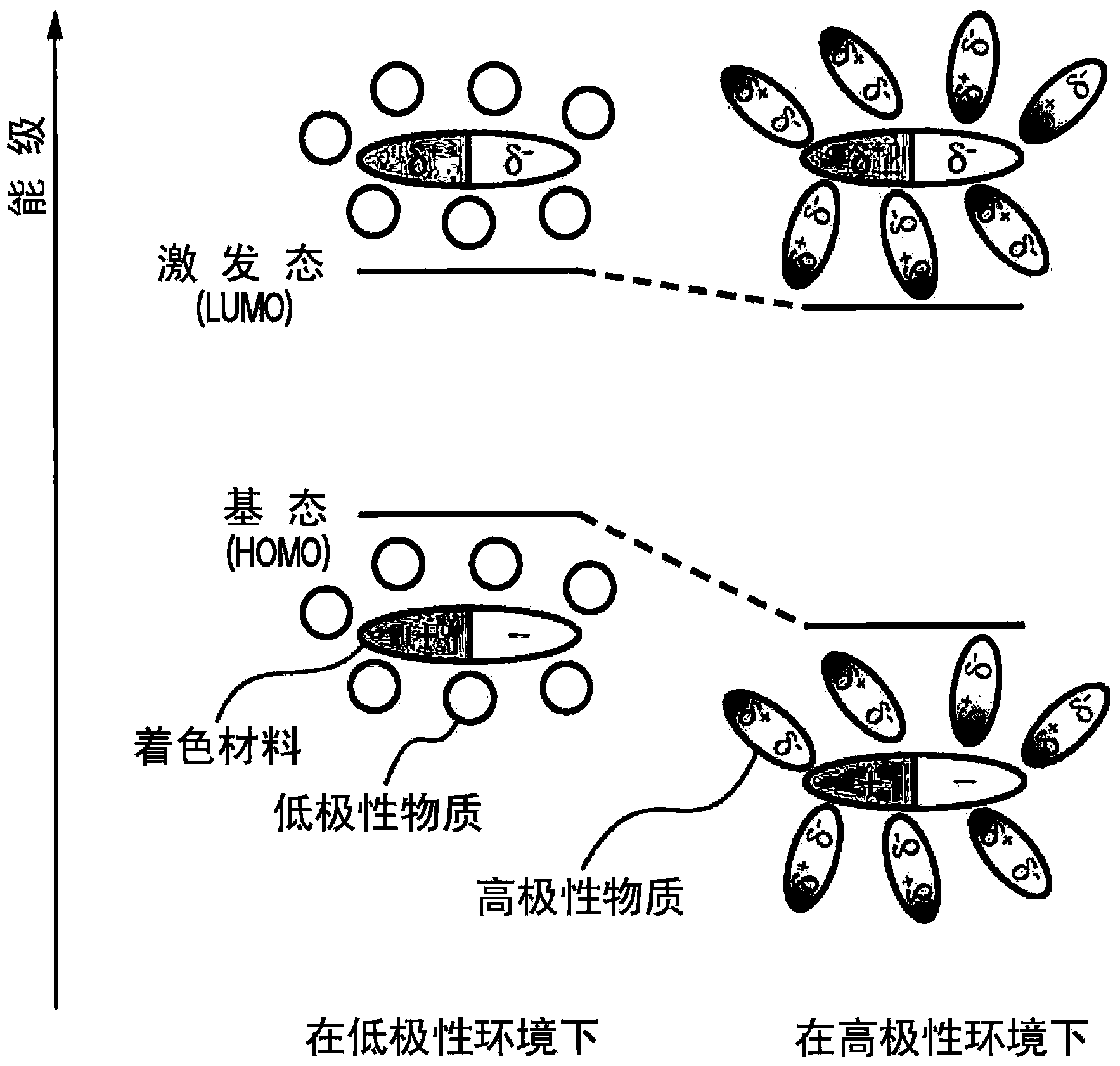

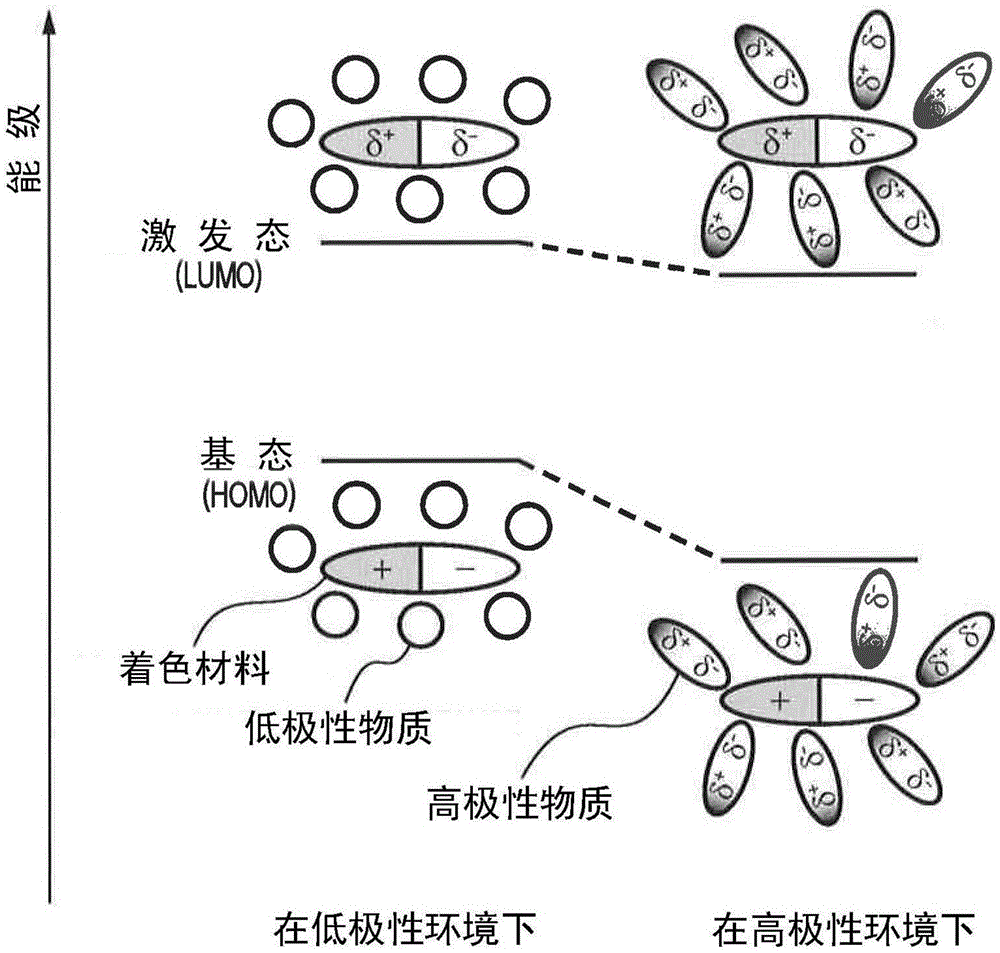

Ink, ink cartridge and ink jet recording method

The invention relates to an ink, an ink cartridge and an ink jet recording method. The ink contains a first coloring material and a second coloring material, the sum total of these contents being 6.0% by mass or less. The first coloring material is a black coloring material exhibiting a difference Delta Lambda max1 of 20.0 or more between a maximum absorption wavelength in a 20.0% by mass aqueous solution of 1,2-hexanediol and a maximum absorption wavelength in water, the second coloring material is a specific coloring material exhibiting a difference Delta Lambda max2 of 12.0 or less between a maximum absorption wavelength in a 20.0% by mass aqueous solution of 1,2-hexanediol and a maximum absorption wavelength in water, and the sum of the Delta Lambda max1 and the Delta Lambda max2 is 35.0 or less.

Owner:CANON KK

Phase difference film used for VA, manufacturing method of phase difference film used for VA, polarizing film, and vertical orientation type liquid crystal display device

ActiveCN106353845AImprove heat and humidity durabilitySuppression of dimensional changesPolarising elementsNon-linear opticsPolarizerChemistry

The invention discloses a phase difference film used for VA comprising cellulose ester resin and satisfying following conditions (1) and (2). According to the condition (1): smd plus std is smaller than or equal to 0.65%, and smd and std respectively represent the size change rates (5) of the film taking the 55% RH state as the reference during the changing from 20% RH to 80% at 23DEG C in the length direction and the width direction. According to the condition (2):rth 2-rth1 is smaller than or equal to 9nm, and rth 1 represents the measured delay (nm) of the thickness direction, when two transparent substrates are used to clamp the film without using adhesive agent, and rth 2 represents the measured delay (nm) of the thickness direction, when the two transparent substrates are used to clamp the film, and the adhesive agent exists between the film and one of the transparent substrates.

Owner:KONICA MINOLTA INC

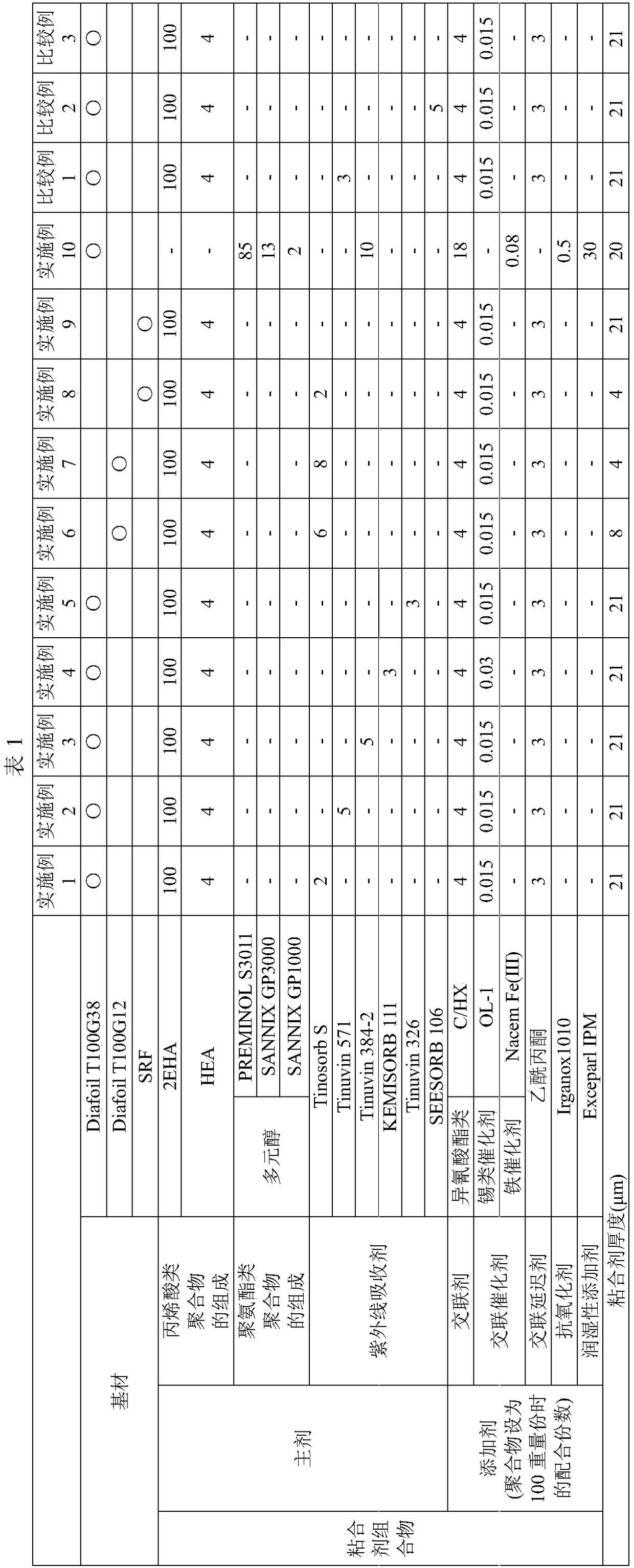

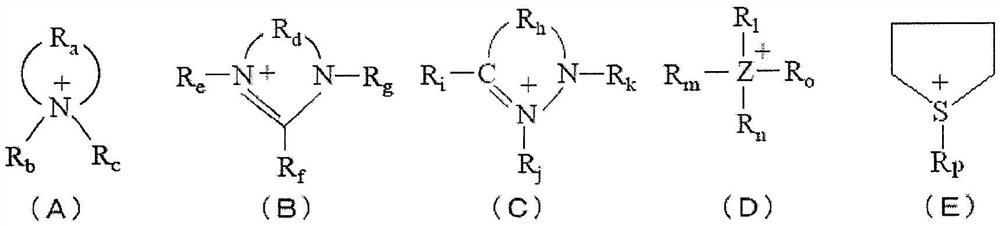

Adhesive composition, adhesive layer, surface protecting film and optical member

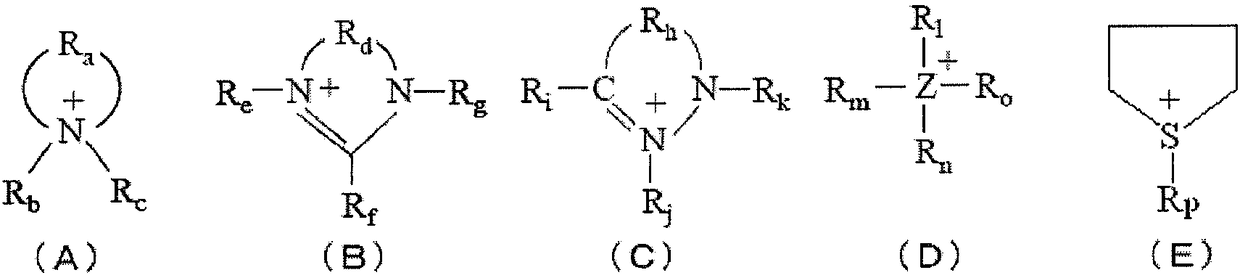

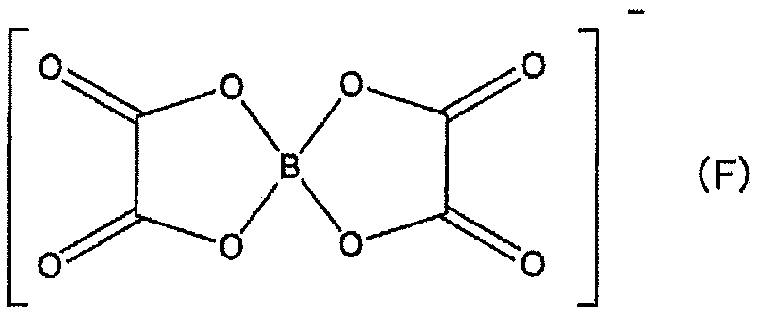

ActiveCN108384474ASuppresses color changeLong application periodWax coatingsNon-macromolecular adhesive additivesIsocyanateActive center

The invention relates to an adhesive composition, an adhesive layer, a surface protecting film and an optical member. The invention provides an adhesive composition capable of suppressing tonal variation of an adhesive layer and having long service lifetime and excellent anti-static property, an adhesive layer obtained by cross-linking of the adhesive composition, a surface protecting film obtained by forming the adhesive layer on a support body, and an optical member protected by the surface protecting film. The adhesive composition is characterized in that relative to 100 parts by mass of apolymer (A) containing an active hydrogen functional group, the adhesive composition includes an isocyanate-containing cross-linking agent (B), 0.001-0.4 part by mass of a compound (C) regarding tin as the active center, 0.001-0.4 part by mass of a compound (D) regarding iron as the active center, and an antistatic agent (E).

Owner:NITTO DENKO CORP

Liquid crystal display device, polarizing plate and backlight source

Owner:SATURN LICENSING LLC

N-vinyl lactam polymer and method for producing same

The present invention provides an N-vinyl lactam polymer that is less likely to be colored (yellowing) even at high temperatures to maintain its color tone. The present invention provides an N-vinyl lactam polymer comprising a structural unit derived from an N-vinyl lactam monomer, the N-vinyl lactam polymer including a structural unit that has at least one of a hypophosphorous group and a group of hypophosphorous acid metal salt at a main chain terminal.

Owner:NIPPON SHOKUBAI CO LTD

Retardation film for va, method for producing retardation film for va, polarizing plate, and vertical alignment type liquid crystal display device

ActiveCN106353845BSuppression of dimensional changesSuppress changesPolarising elementsNon-linear opticsCellulosePhase difference

The retardation film for VA contains a cellulose ester resin, and satisfies the following conditions (1) and (2) at the same time. Condition (1): Smd+Std≤0.65%, where Smd and Std respectively represent the length direction and Dimensional change rate (%) in film width direction. Condition (2): Rth2‑Rth1≤9nm, where Rth1 refers to the retardation (nm) measured in the thickness direction when the film is sandwiched between two transparent substrates without using an adhesive, and Rth2 refers to the retardation (nm) measured with two transparent substrates. Retardation (nm) in the thickness direction measured when the substrate sandwiches the film and an adhesive is present between the film and a transparent substrate.

Owner:KONICA MINOLTA INC

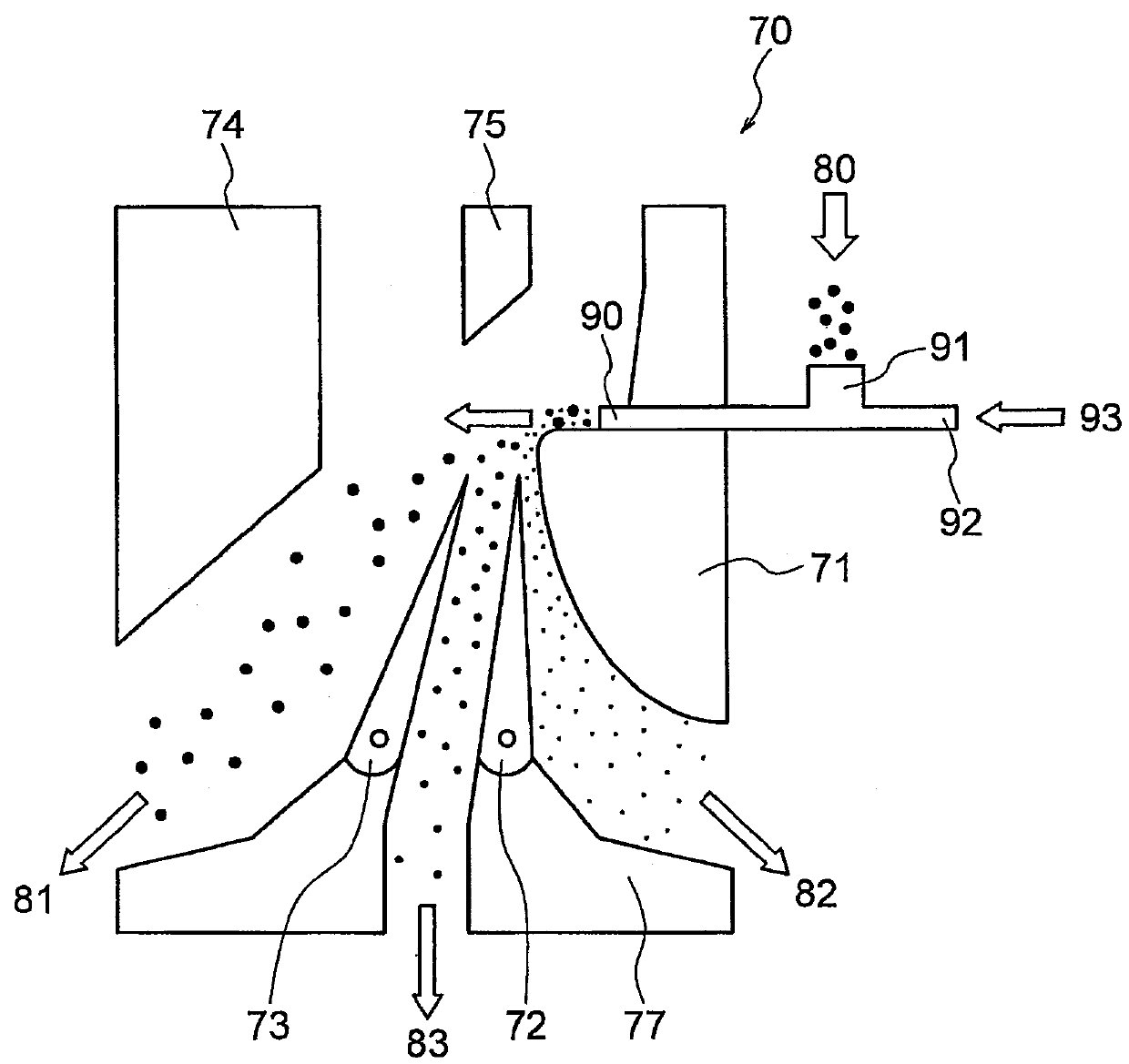

Developer, developer storage body, developing device and image forming apparatus

ActiveCN107664932AReduce the ratioSuppresses color changeDevelopersElectrographic process apparatusSoftware engineeringMagenta

The invention relates to a developer, a developer storage body, a developing device and an image forming apparatus. The developer including developer particles. Each developer particle includes a binder resin, a brilliant pigment whose principal component is aluminum, a yellow pigment, a magenta pigment, a reddish-orange fluorescent dye, and a yellow fluorescent dye. When an average particle diameter of the brilliant pigments included in the developer particles is expressed as D ([mu]m), a number proportion of the developer particles having particle diameters in a range from 4 [mu]m to 1.2*D [mu]m in the whole developer particles is less than or equal to 4%.

Owner:OKI ELECTRIC IND CO LTD

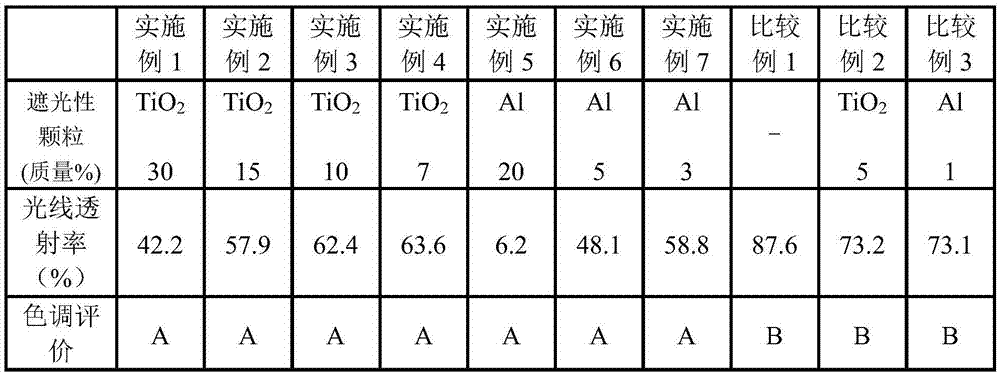

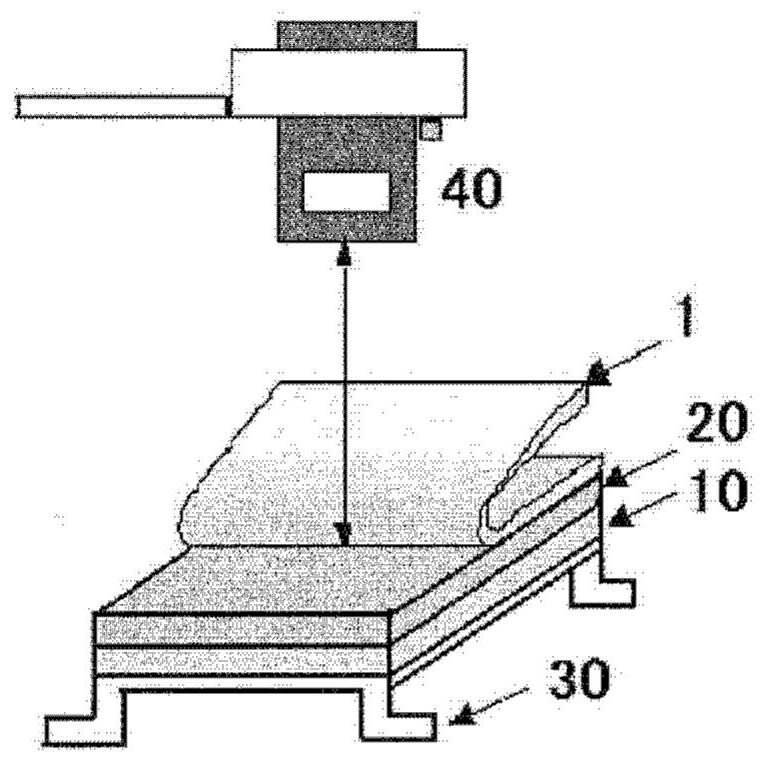

Flexible printed substrate for mounting light emitting component, and flexible printed substrate mounted with light emitting component

InactiveCN105453706ASuppress transmissionAffects changes in light toneNon-macromolecular adhesive additivesCircuit optical detailsMetal foilTransmittance

The present invention provides the following: a flexible printed substrate for mounting a light emitting component with which, even if the substrate is made thin to show flexibility, the transmission of light rays from the mounted light emitting component is suppressed and changes in the color of light due to the impact of light emitting components of different colors are suppressed; and a flexible printed substrate mounted with a light emitting element, in which a light emitting component is mounted on the flexible printed substrate for mounting a light emitting component. The present invention provides a flexible printed substrate for mounting a light emitting component, on which a metal foil is layered in a circuit pattern onto at least one side of an insulative base material with an adhesive resin interposed therebetween, and that is characterized in that the adhesive resin layer contains light-blocking particles and has a light transmission rate of 65% or less for wavelengths in the range 380-750 nm.

Owner:TOYO ALUMINIUM KK

Adhesive composition, adhesive layer, surface protection film, and optical member

ActiveCN108384474BSuppresses color changeLong application periodWax coatingsNon-macromolecular adhesive additivesPolymer scienceCross linker

The present invention relates to an adhesive composition, an adhesive layer, a surface protection film, and an optical member. The present invention provides an adhesive composition capable of obtaining an adhesive layer having a sufficiently long pot life, suppressing color change of the adhesive layer, and excellent antistatic properties, the adhesive A pressure-sensitive adhesive layer obtained by crosslinking the composition, a surface protection film obtained by forming the pressure-sensitive adhesive layer on a support, and an optical member protected by the surface protection film. The adhesive composition of the present invention is characterized in that, relative to 100 parts by mass of the polymer (A) having an active hydrogen functional group, the adhesive composition contains an isocyanate crosslinking agent (B), 0.001 parts by mass to 0.4 parts by mass of the compound (C) having tin as the active center, 0.001 to 0.4 parts by mass of the compound (D) having iron as the active center, and an antistatic agent (E).

Owner:NITTO DENKO CORP

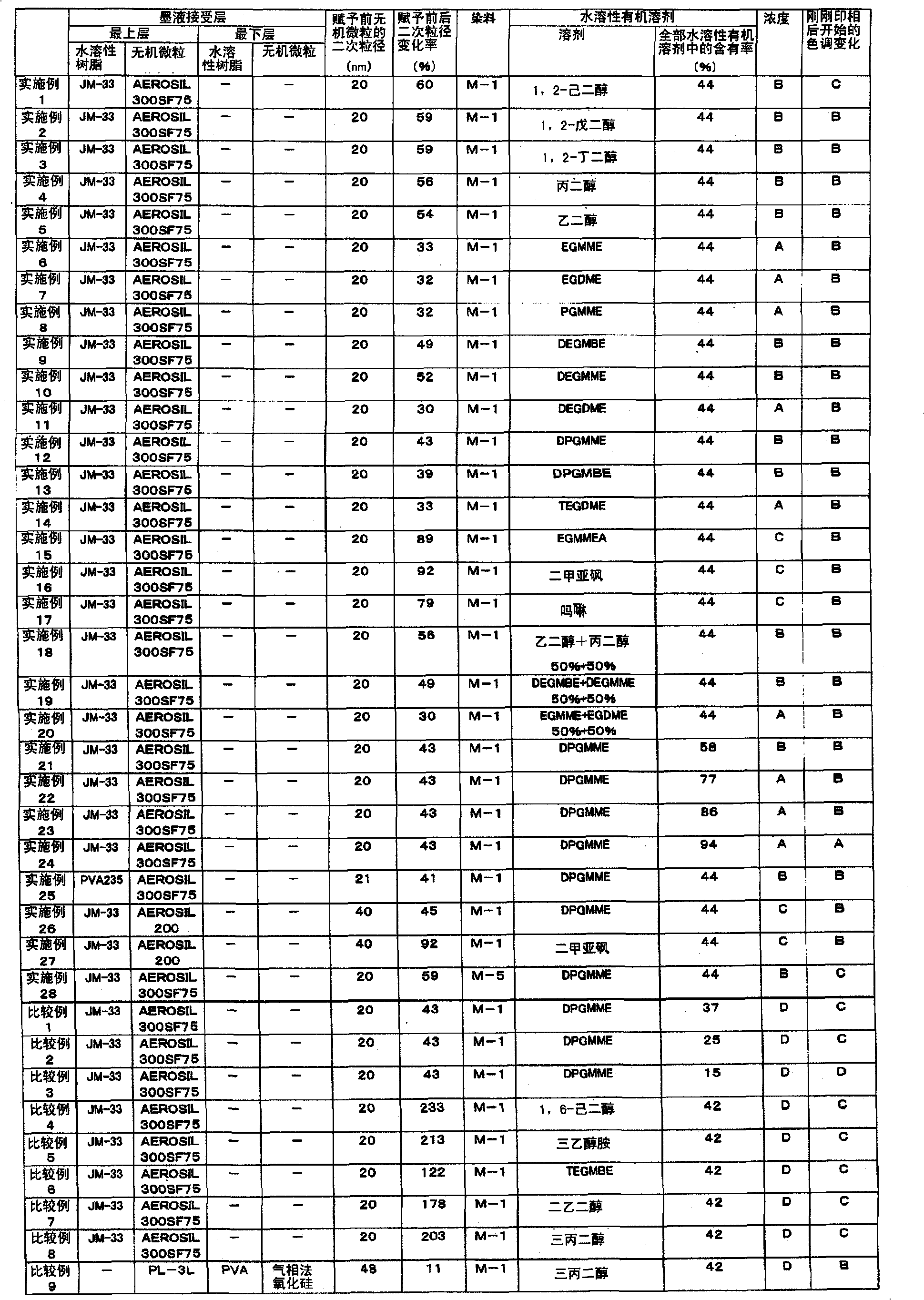

Ink-jet recording method

InactiveCN102112318AIncrease concentrationSuppresses color changeMaterial nanotechnologyDuplicating/marking methodsCross-linkOrganic solvent

Disclosed is an ink-jet recording method. In the method, the recording is carried out on an ink-jet recording medium which comprises a support and an ink-receiving layer arranged over the support as the outermost layer and comprising at least a water-soluble resin, a cross-linking agent and inorganic microparticles having a secondary particle diameter of 45 nm or smaller as measured on an electron microscope. In the method, the recording is carried out by using an ink which comprises at least a dye, water and a water-soluble organic solvent component. In the ink, the water-soluble organic solvent component contains a water-soluble organic solvent at a ratio of 40 mass% or more relative to the total quantity of the water-soluble organic solvent component. The water-soluble organic solvent has such a property that, when applied on the outermost layer at a rate of 6.6 g / m2, the rate of change in secondary particle diameter of the inorganic microparticles in the outermost layer before and after the application on the outermost layers is 100% or less.

Owner:FUJIFILM CORP

Ink, ink cartridge and inkjet recording method

ActiveCN103666111BExcellent ozone resistanceSuppresses color changeInksOrganic chemistryMaterials science

Owner:CANON KK

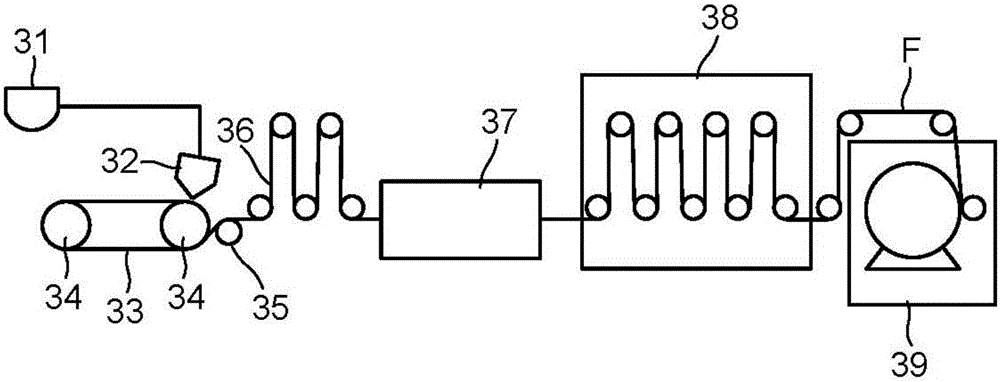

Optical film, production method of optical film, optically-compensatory film, polarizing plate and liquid crystal display device

InactiveUS8350995B2Suppresses color changeSignificant differenceGlass making apparatusPolarising elementsLiquid-crystal displayEngineering

A production method of an optical film, including: a stretching step of stretching a film, wherein the film has a longitudinal direction, a width direction and a thickness direction, wherein the stretching is in either of the longitudinal direction or the width direction of the film; and a shrinking step of shrinking the film in either of the longitudinal direction or the width direction of the film, that is not the direction in which the film is stretched, wherein the film thickness in the thickness direction is increased as compared with the film thickness before at least one of the stretching step and the shrinking step.

Owner:FUJIFILM CORP

N-vinyl lactam polymer and method for producing same

The present invention provides an N-vinyl lactam polymer that is less likely to be colored (yellowing) even at high temperatures to maintain its color tone. The present invention provides an N-vinyl lactam polymer comprising a structural unit derived from an N-vinyl lactam monomer, the N-vinyl lactam polymer including a structural unit that has at least one of a hypophosphorous group and a group of hypophosphorous acid metal salt at a main chain terminal.

Owner:NIPPON SHOKUBAI CO LTD

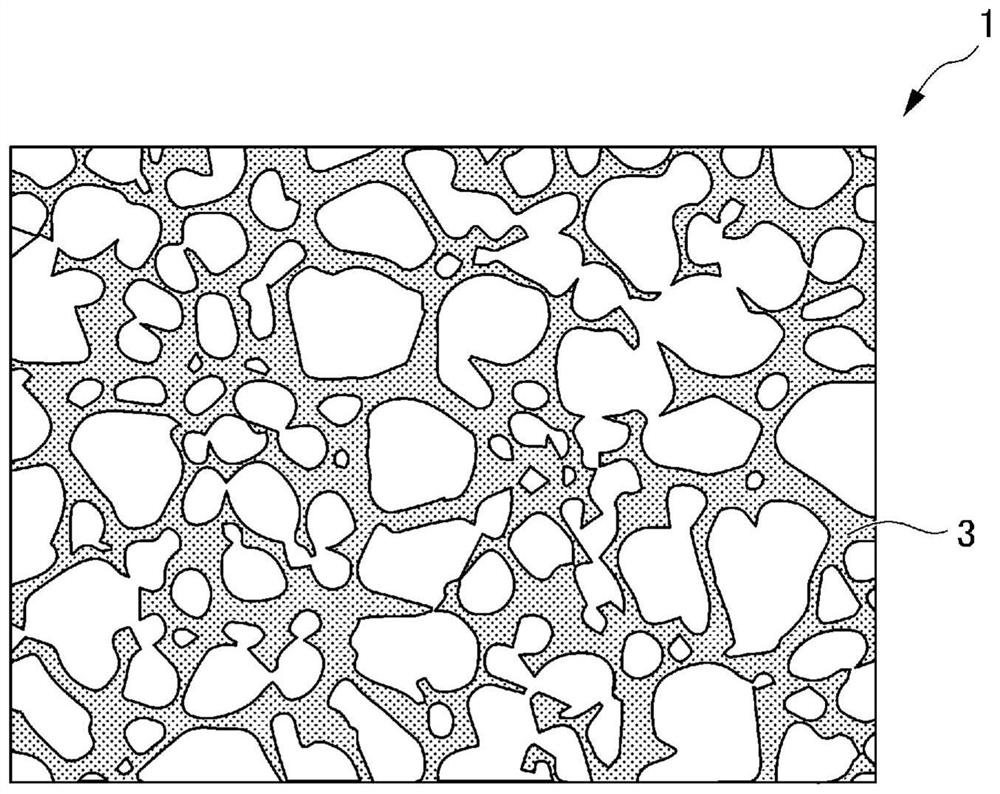

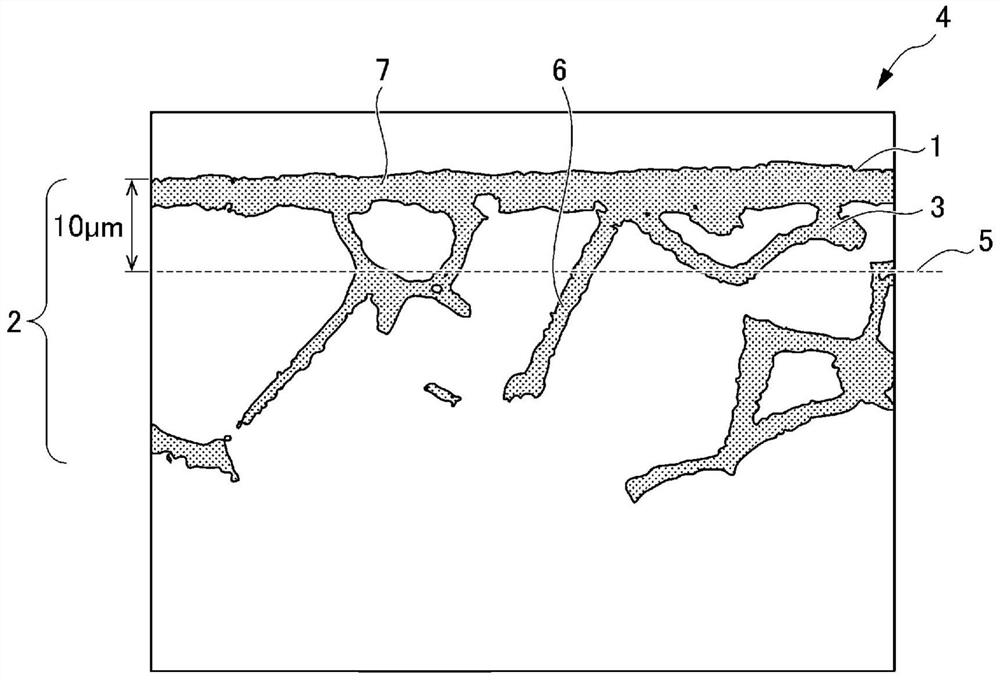

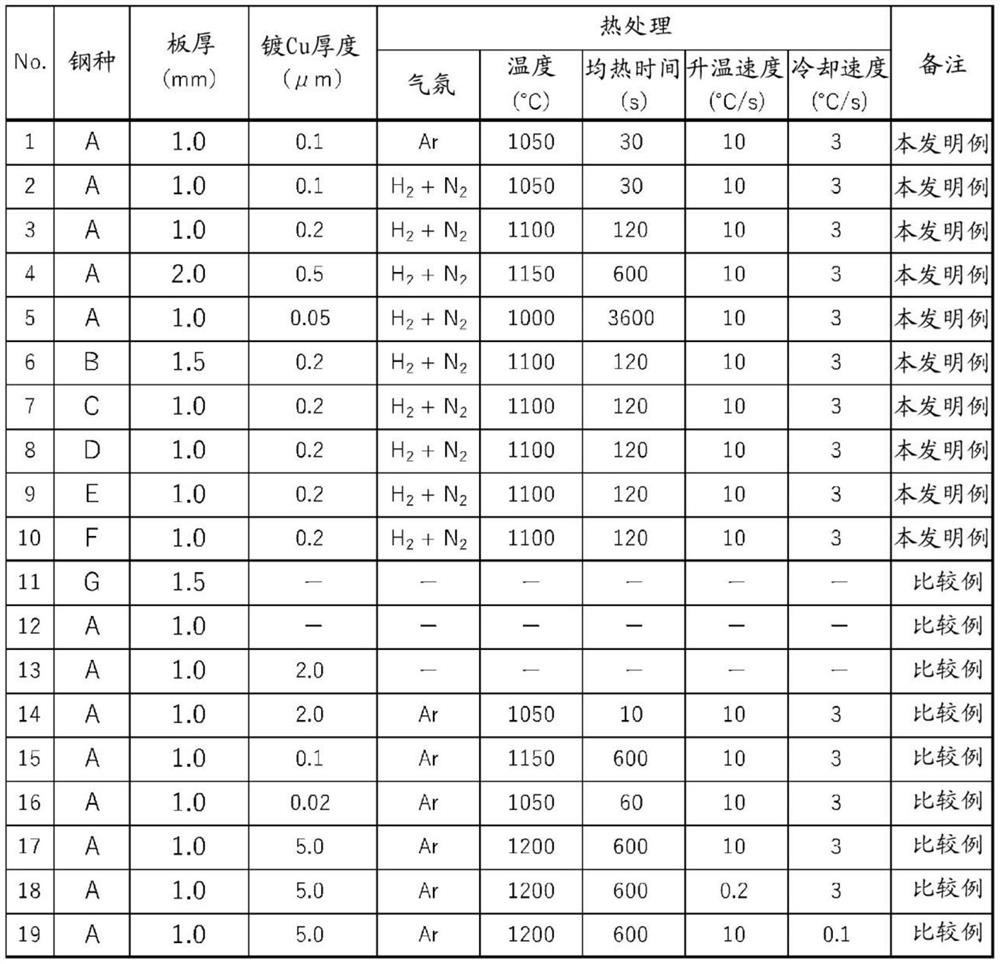

Antibacterial and antiviral stainless steel material and manufacturing method thereof

ActiveCN114364822ANot easy to lose antibacterial propertiesSuppresses color changeLiquid/solution decomposition chemical coatingThin material handlingMetallurgyPhysical chemistry

Provided is a stainless steel material which contains an antibacterial component Cu, has excellent antibacterial and antiviral properties, and has a stainless steel color tone. The present invention is a stainless steel material having antibacterial and antiviral properties, in which a surface (1) and a surface layer (2) directly below the surface of the stainless steel material include a Cu-concentrated region (3) that follows grain boundaries and has a Cu (copper) concentration higher than the average Cu concentration of a base material, and the Cu-concentrated region (3) has a concentration higher than the average Cu concentration by 5 mass% or more. The stainless steel material has Cu grain boundary layers (6) extending continuously from the surface (1) of the stainless steel material at a depth of 10 [mu] m to 200 [mu] m, and the average number of the Cu grain boundary layers (6) is 2.0 or more per 100 [mu] m distance parallel to the surface in a cross-section orthogonal to the surface of the stainless steel material. The chromaticity index a * of the surface in the CIE Lab color space is 0-3.0 (inclusive).

Owner:NIPPON STEEL STAINLESS STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com