Ink-jet recording method

An inkjet recording method and ink technology, applied in the direction of copying/marking method, ink, nanotechnology, etc., can solve the problems that have not been mentioned in the recording method of the fine aperture of the receiving layer, and achieve the effect of suppressing the change of color tone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

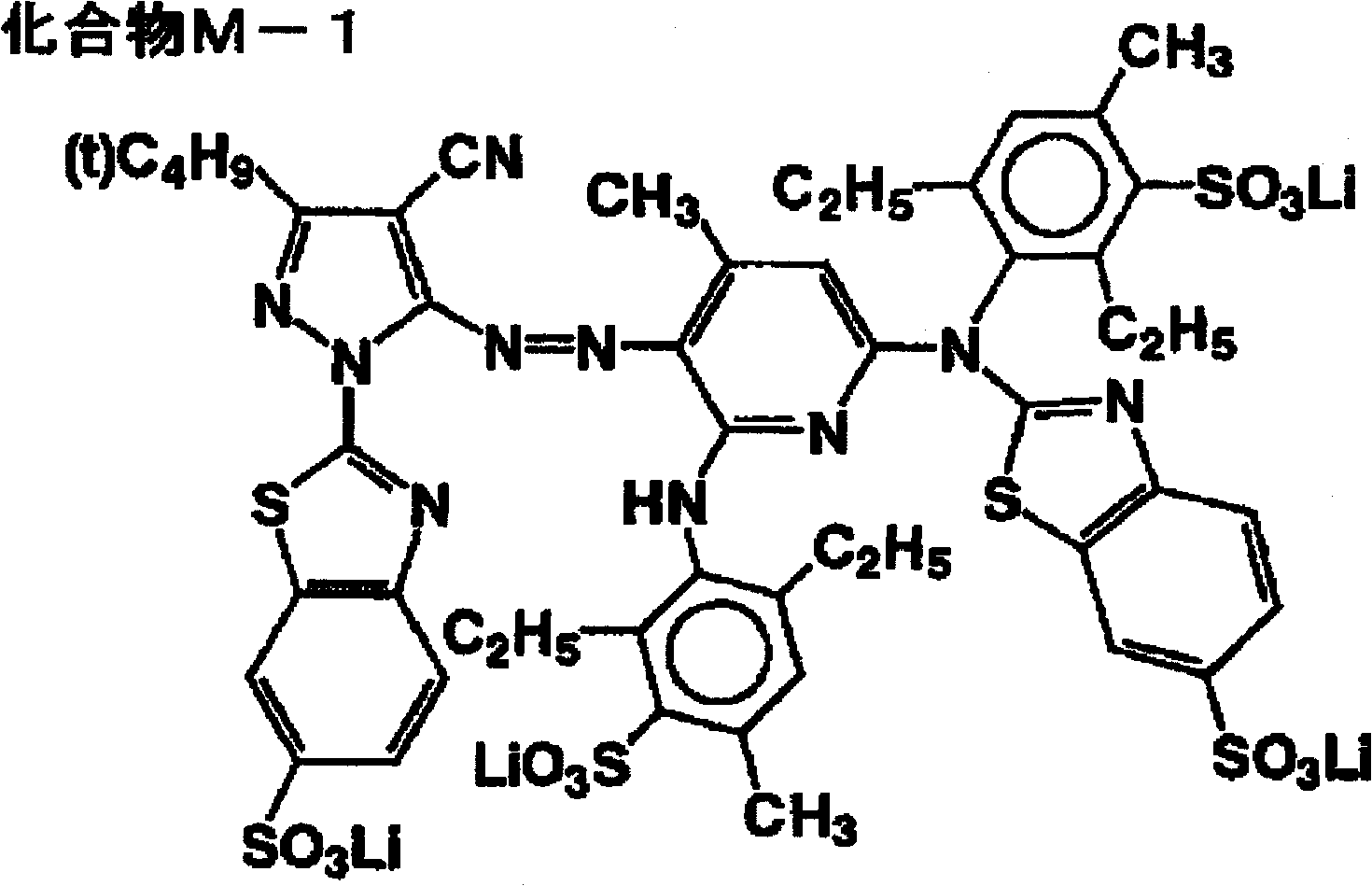

Examples

Embodiment 1

[0275] (production of support body)

[0276] 50 parts of LBKP derived from acacia and 50 parts of LBKP derived from aspen were beaten with a disc refiner to 300 ml in Canadian standard freeness to prepare paper slurry.

[0277] Next, to the pulp slurry obtained above, 1.3% of cationic modified starch (CAT0304L manufactured by NSC Japan), 0.15% of anionic polyacrylamide (DA4104 manufactured by Starlight PMC), and alkylketene dimer (Arakawa Chemical Co., Ltd. SIZEPINE K) 0.29%, epoxidized behenamide 0.29%, polyamide polyamine epichlorohydrin (Arakawa Chemical Co., Ltd.: ARAFIX 100) 0.32%, and then added 0.12% of an antifoaming agent.

[0278] The paper slurry prepared as above is made with a fourdrinier paper machine, and the suede surface of the web is pressed to a drum drying drum through a dry wire to dry. After setting the tension to 1.6kg / cm and drying, apply polyvinyl alcohol (manufactured by Kuraray: KL-118) 1g / m on both sides of the base paper with a size machine 2 , d...

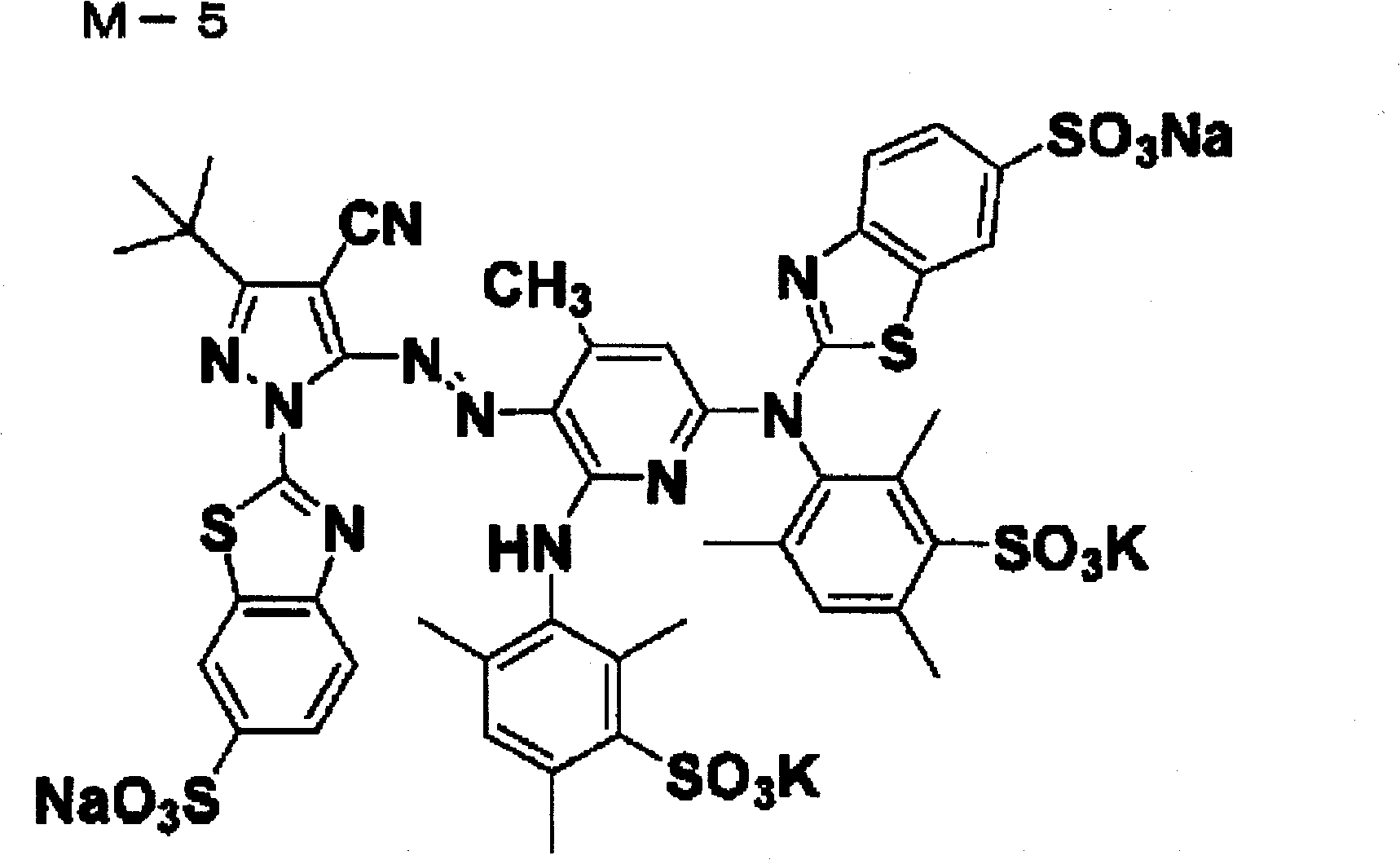

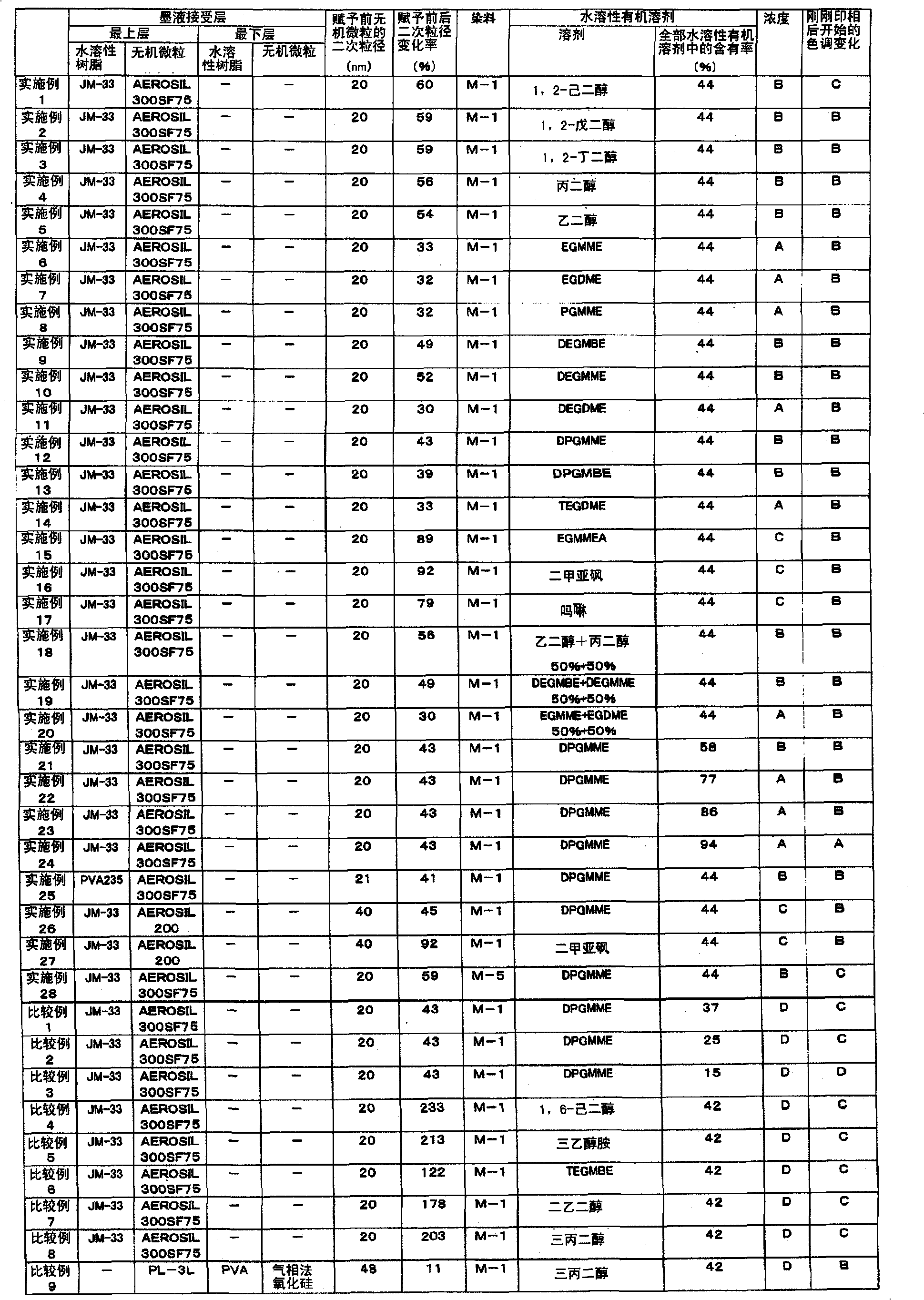

Embodiment 2~20

[0356] In Example 1, except that 1,2-hexanediol was replaced with the water-soluble organic solvent shown in Table 1, magenta ink was produced in the same manner as in Example 1, and printed and evaluated.

[0357] Here, the abbreviations of the water-soluble organic solvent columns in Table 1 and Table 2 are as follows.

[0358] EGMME: Ethylene glycol monomethyl ether

[0359] EGDME: Ethylene glycol dimethyl ether

[0360] PGMME: Propylene Glycol Monomethyl Ether

[0361] DEGMME: Diethylene glycol monomethyl ether

[0362] DEGMBE: Diethylene glycol monobutyl ether

[0363] DEGDME: Diethylene glycol dimethyl ether

[0364] DPGMME: Propylene Glycol Monomethyl Ether

[0365] DPGMBE: Dipropylene Glycol Monobutyl Ether

[0366] EGMMEA: Ethylene glycol monomethyl ether acetate

[0367] TEGMBE: Triethylene glycol monobutyl ether

[0368] TEGDME: Triethylene glycol dimethyl ether

Embodiment 21

[0370] In Example 1, except that the composition of the magenta ink was changed as follows, in the same manner as in Example 1, a magenta ink was prepared, printed, and evaluated.

[0371] ・Dye M-1 (see above) 35.0g

[0372] ·Glycerin 37.5g

[0373] 1,5-pentanediol 18.8g

[0374] 2-Pyrrolidone 18.8g

[0375] DPGMME 103.6g

[0376] ·Urea 19.0g

[0377] ・PROXEL XL2 (manufactured by Avecia Co., Ltd.) 1.1g

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com