Polymer particle, resin composition containing same, and molded body

A technology of resin composition and polymer, applied in the field of molded body, polymer particle, and resin composition containing it, can solve the problem of lack of optical properties, thermal stability, low humidity and heat resistance, and low industrial application value of the molded body and other problems, to achieve the effect of excellent thermal stability and less color difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0105] Next, the present invention is illustrated by examples.

[0106] (mass average particle size, number average particle size)

[0107] The mass average particle diameter and the number average particle diameter of the polymer particles are measured using a laser diffraction / scattering particle size distribution analyzer (manufactured by Horiba Seisakusho, LA-910).

[0108] (polymerization reactors of synthesis examples 1 to 4)

[0109] A 3-liter glass separable four-necked flask was used as a polymerization reactor equipped with a Fruzen stirring blade, a thermometer, a cooling pipe, and a nitrogen vent pipe. The ratio of the upper blade diameter d1 and the groove diameter D of the stirring blade is d1 / D=0.55, the ratio of the lower end blade diameter d2 and the groove diameter D is d2 / D=0.60, and two baffle plates are installed.

[0110] (measurement of solid content)

[0111] The solid content was measured by drying the sample solution in a hot air dryer at 180° C. f...

Synthetic example 1

[0132] (Preparation of seed latex (a1))

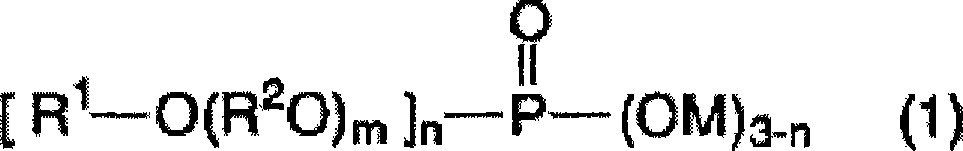

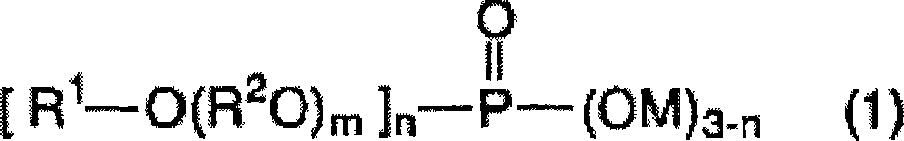

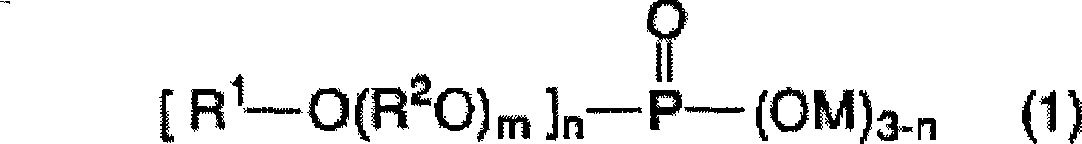

[0133] 360.0 g of pure water, 83.0 g of n-butyl methacrylate, and 55.0 g of styrene were charged into the polymerization reactor. Then, the number of stirring revolutions was set at 110 rpm, the inner temperature of the polymerization reactor was raised to 82° C., and 102.0 g of potassium persulfate aqueous solution (an aqueous solution in which 2.0 g of potassium persulfate was dissolved in 100 g of pure water) was added to start polymerization. After 3 hours from the start of the polymerization, 50.3 g of potassium persulfate aqueous solution (an aqueous solution in which 0.3 g of potassium persulfate was dissolved in 50 g of pure water) was thrown into the polymerization reactor, and 248.0 g of n-butyl methacrylate, 166.0 g of styrene, 1.6 g of polyoxyethylene alkyl ether phosphate sodium salt (trade name: Fosfanol RS-610NA, manufactured by Toho Chemical Co., Ltd.) as a phosphate ester salt represented by the above formula (1), 550...

Synthetic example 2

[0140] (Preparation of polymer particles (A2))

[0141] 60.0 g of seed latex (a1) obtained in Synthesis Example 1 was charged into a polymerization reactor. 0.7 g of polyoxyethylene alkyl ether sodium phosphate containing 12.0 g of 1-chlorododecane, 2.0 g of benzoyl peroxide, 20.0 g of styrene, and 0.7 g of the phosphate ester salt shown in the above formula (1) A mixture of salt (trade name: Foosphano-Lu RS-610NA, manufactured by Toho Chemical Co., Ltd.), 100.0 g of pure water was preliminarily mixed with a mixer made by IKA "Ultratarax T-25" under the condition of 12000rpm for 2 minutes. After emulsification treatment, it was put into a polymerization reactor, and 30.0 g of acetone was further put in, and the temperature in the polymerization reactor was kept at 25° C. and the stirring rotation speed was 120 rpm for 3 hours. After utilizing vacuum evaporation to remove the acetone in the polymerization reactor, 400.0g of n-butyl methacrylate, 250.0g of styrene, 70g of ethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com