Flexible printed substrate for mounting light emitting component, and flexible printed substrate mounted with light emitting component

A flexible printed circuit board and light-emitting component technology, which is applied in the directions of circuit optical components, lighting device components, printed circuits, etc., to achieve the effect of suppressing the change of light tone, suppressing the change of color tone, and suppressing the transmission of light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

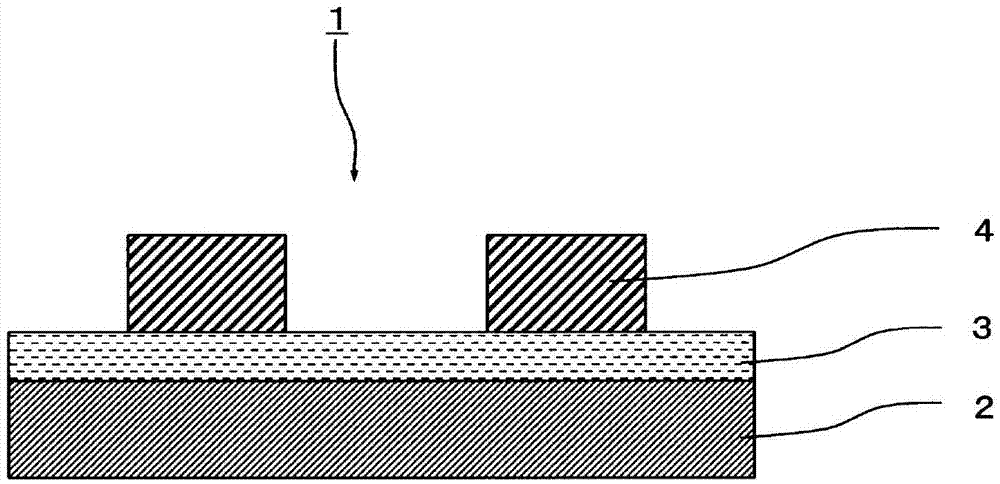

Image

Examples

Embodiment 1

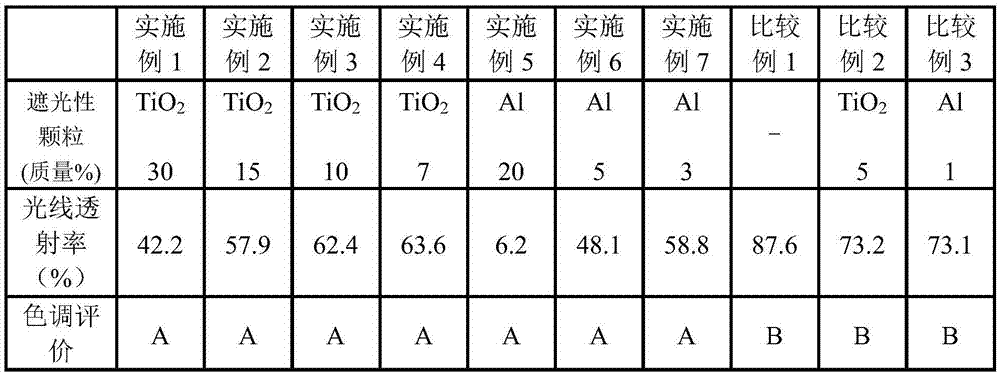

[0068] The 35-micrometer-thick electrolytic copper foil and the 38-micrometer-thick polyethylene terephthalate film were bonded together using the adhesive resin composition, and the laminated body was produced. The adhesive resin composition is prepared by mixing 100 parts by mass of DIC Co., Ltd. trade name: LX500 with 10 mass parts of DIC Co., Ltd. trade name KW75, and diluting with ethyl acetate. It was prepared by adding titanium dioxide with an average particle diameter of 0.24 μm.

[0069] An adhesive resin layer was produced by incubating the produced laminate at 60° C. for 5 days, and heating and curing the adhesive resin composition. The thickness of the adhesive resin layer was 15 μm, and the content of titanium dioxide in the adhesive resin layer was 30% by mass relative to 100% by mass of the adhesive resin layer. Moreover, the light transmittance of the wavelength 380-750nm of an adhesive resin layer was 42.2%. In addition, the light transmittance of the adhesi...

Embodiment 2

[0076] The light transmittance of the adhesive resin layer was measured in the same manner as in Example 1, except that the content of titanium dioxide in the adhesive resin layer was 15% by mass, and the color tone of the light was evaluated.

Embodiment 3

[0078] The light transmittance of the adhesive resin layer was measured in the same manner as in Example 1, except that the content of titanium dioxide in the adhesive resin layer was 10% by mass, and the color tone of the light was evaluated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com