Surface protective film

A surface protection film, optical technology, applied in the direction of film/sheet adhesive, adhesive type, adhesive additive, etc., can solve the problem of protective glass breakage, etc., to inhibit the color change and adhesion stability Excellent, low transmittance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0185] [Preparation of Acrylic Polymer]

[0186] Put 200 parts by weight of 2-ethylhexyl acrylate (2EHA) and 8 parts by weight of 2-hydroxyethyl acrylate (HEA) into a four-necked flask with a stirring blade, a thermometer, a nitrogen gas inlet tube, and a condenser, as a polymerization initiator 0.4 parts by weight of 2,2'-azobisisobutyronitrile, 312 parts by weight of ethyl acetate as a solvent, introducing nitrogen gas while stirring slowly, keeping the liquid temperature in the flask at about 65°C, and performing 6 Polymerization was carried out for 1 hour to prepare an acrylic polymer solution (40% by weight). The weight average molecular weight (Mw) of the said acrylic polymer was 540,000, and the glass transition temperature (Tg) was -68 degreeC.

[0187] [Preparation of Acrylic Binder Solution]

[0188] The above-mentioned acrylic polymer solution (40% by weight) was diluted to 29% by weight with ethyl acetate, and isocyanurate of hexamethylene diisocyanate was added ...

Embodiment 2~5、 comparative example 1~3

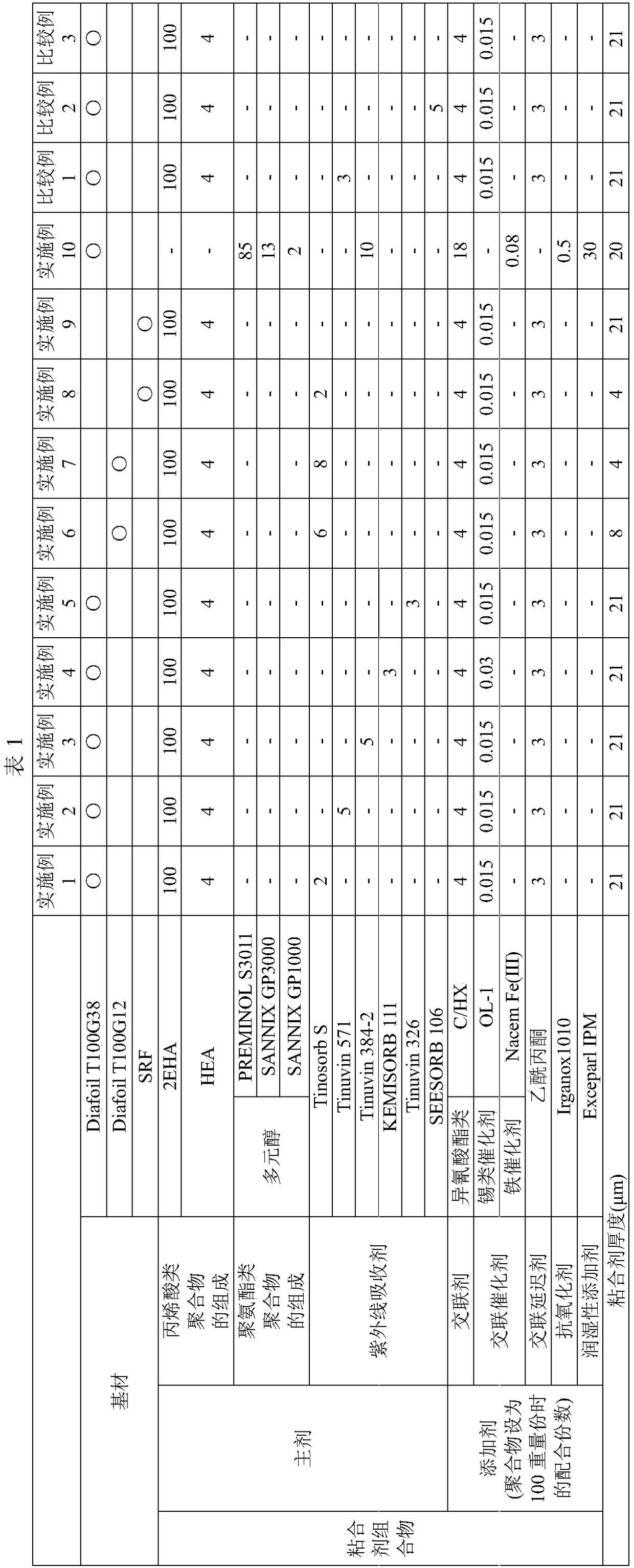

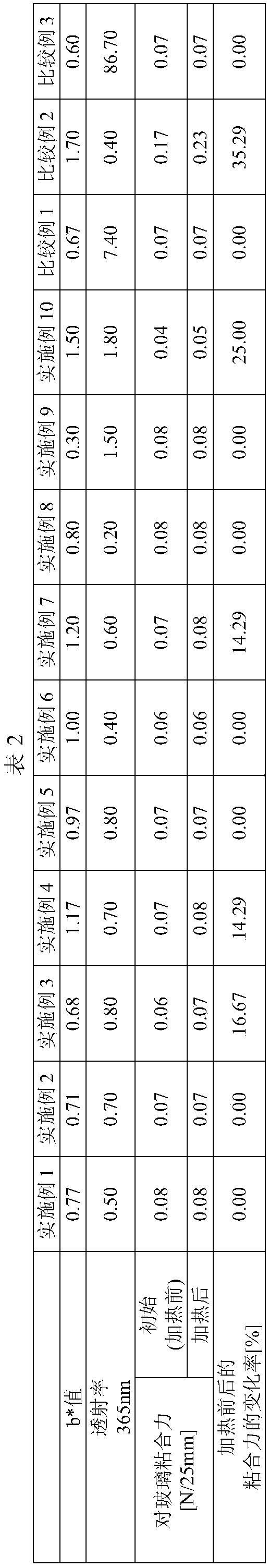

[0192] Based on the compounding content shown in Table 1, the surface protection film for optics was produced by the method similar to Example 1.

Embodiment 6 and 7

[0194] Using a polyester film with a thickness of 12 μm (manufactured by Mitsubishi Plastics Corporation, trade name: Diafoil T100G12) instead of the base material used in Example 1, an optical film was produced in the same manner as in Example 1 based on the composition shown in Table 1. Surface protection film.

[0195]

[0196] Using a polyester film with a thickness of 80 μm (manufactured by Toyobo Co., Ltd., trade name: SRF) instead of the base material used in Example 1, an optical surface was produced by the same method as in Example 1 based on the composition shown in Table 1. protective film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com