Copper foil with resin and process for producing copper foil with resin

A technology of resin copper foil and manufacturing method, which is applied in the direction of circuit substrate materials, printed circuit components, etc., can solve the problems of resin layer becoming brittle and reducing bonding stability, and achieve excellent bonding stability, small thermal expansion coefficient, and good The effect of dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

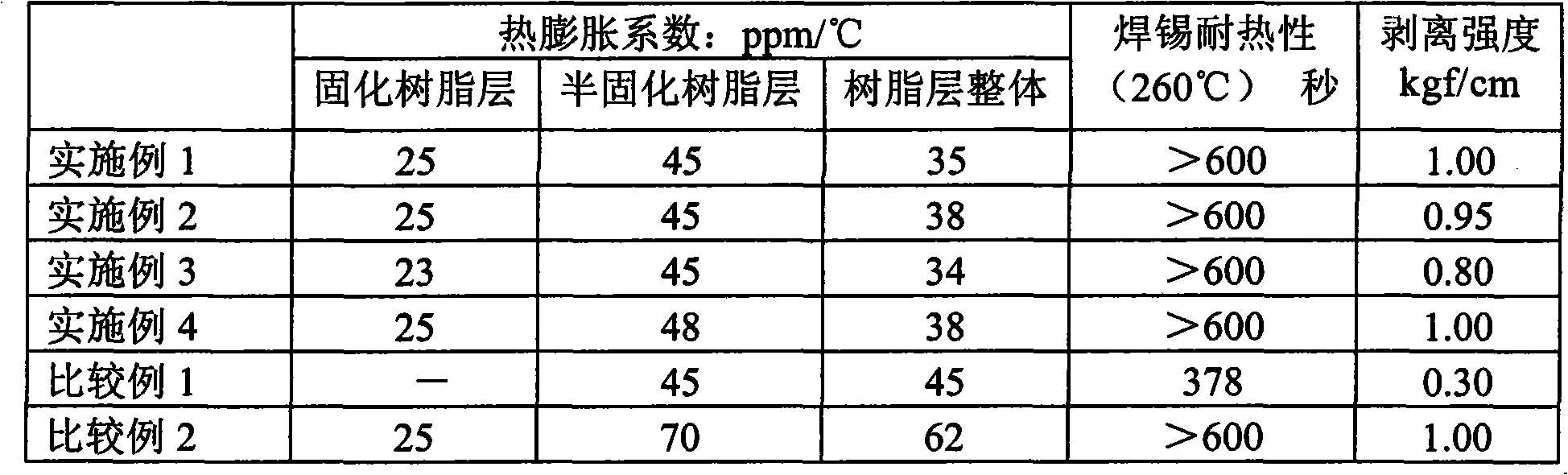

[0078] In Example 1, a copper foil with resin is exemplified in which a polyimide resin layer is formed as a cured resin layer on the surface of an electrolytic copper foil, and a maleimide-based resin is used for the formation of a semi-cured resin layer.

[0079] Electrodeposited copper foil: Electrodeposited copper foil having a glossy surface of surface roughness Rzjis=0.70 and a thickness of 12 μm was used. Using a dilute sulfuric acid solution having a concentration of 100 g / L, this electrolytic copper foil was immersed and washed at a liquid temperature of 30° C. for 30 seconds. Next, nickel-zinc alloy plating treatment, chromate treatment, and silane coupling agent treatment were sequentially performed as antirust treatment on the glossy surface. Among them, nickel-zinc alloy plating is performed in a pyrophosphoric acid bath (nickel 2.5g / L, zinc 0.5g / L, liquid temperature 40°C, current density 0.6A / dm 2 , 8 seconds) under the conditions. In addition, electrolytic ch...

Embodiment 2

[0096]Example 2 is different from Example 1 in thickness of the cured resin layer. That is, in the formation of the cured resin layer in Example 1, the thickness of the resin after drying at 110°C for 6 minutes was 35 μm, whereas in Example 2, the thickness of the resin after drying at 110°C for 6 minutes was adjusted to 8 μm . Other than that, the copper foil with resin was produced by the method similar to Example 1. The cured resin layer of Example 2 has a resin thickness of 5 μm after being dried at 400° C. for 8 minutes, and a residual solvent rate of 0.1 wt %. Furthermore, the coefficient of thermal expansion of the entire resin layer after the semi-cured resin was completely cured was 38 ppm / °C, and the peel strength of the copper foil was 0.95 kgf / cm.

Embodiment 3

[0098] Compared with Example 1, Example 3 has a different composition of the cured resin layer. That is, in the formation of the cured resin layer, the resin used was changed to Bioromax HR16NN (trade name, manufactured by Toyobo Co., Ltd.), the thickness of the cured resin layer after drying at 110° C. for 6 minutes was adjusted to 28 μm, and the subsequent drying conditions were changed to The highest temperature setting is 380°C. Other than that, the copper foil with resin was produced by the method similar to Example 1. At this time, the thickness of the cured resin layer after drying at 380° C. for 8 minutes was 24 μm, the residual solvent rate was 0.8 wt %, and the thermal expansion coefficient of the cured resin layer was 23 ppm / ° C. Furthermore, the coefficient of thermal expansion of the entire resin layer with the resin-coated copper foil after the semi-cured resin was completely cured was 34 ppm / °C, and the peel strength of the copper foil was 0.80 kgf / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com