After burning co 2 Coordinated predictive control method for capture coal-fired power generation system

A technology for predictive control and power generation systems, applied in control/regulation systems, adaptive control, general control systems, etc., and can solve problems such as rare control research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

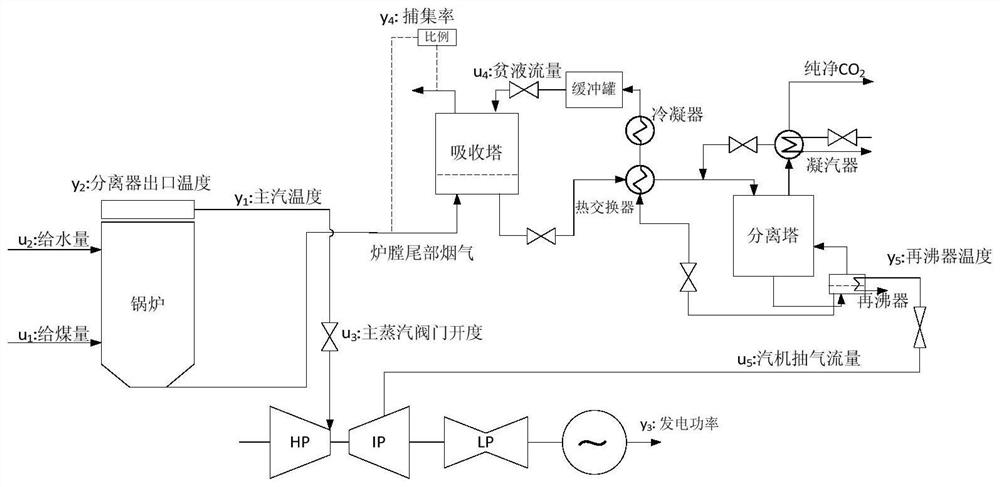

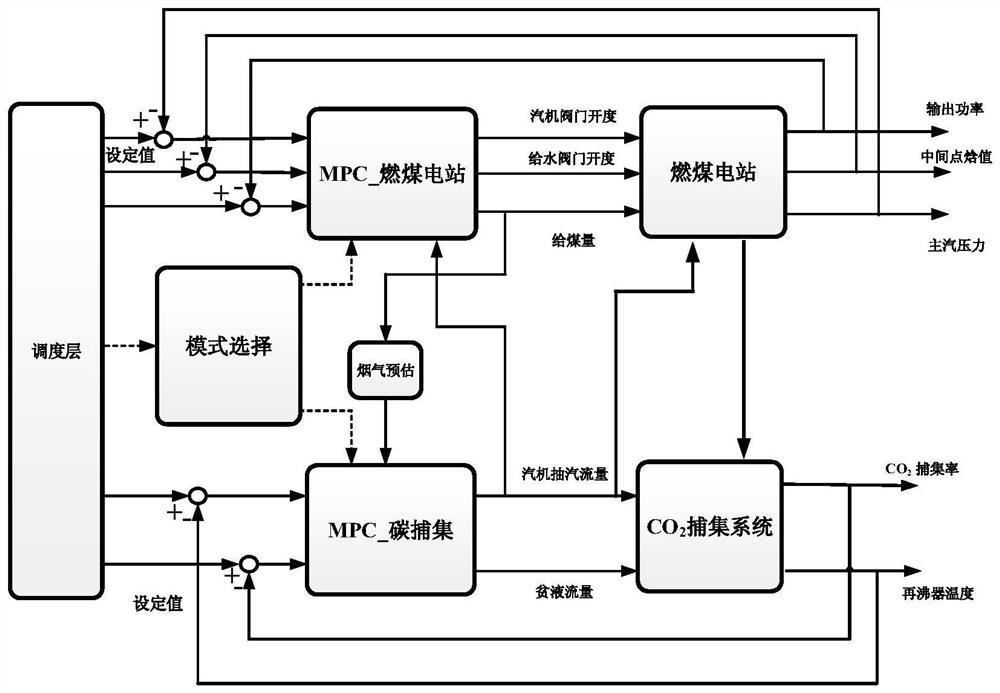

[0045] like figure 2 As shown, a post-combustion CO 2 The coordinated predictive control method for capturing coal-fired power generation system includes the following steps:

[0046] (1) The coal-fired generating unit furnace system is constructed with the command of coal feed, steam turbine valve opening and water supply valve opening as the operating variables, and the values of power generation, main steam pressure and intermediate point enthalpy are 3×3 of the controlled variables Multivariable Predictive Control Systems. Consider CO during the design process 2 The steam extraction flow of the capture system from the connection between the medium and low pressure cylinders of the turbine is used as a disturbance signal;

[0047] (2) is post-combustion CO based on chemisorption 2 The structure of the capture system takes lean liquid flow and turbine extraction flow as operating variables, and the CO 2 A 2×2 multivariable predictive control system with capture rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com