Motorbike hub surface deburring device convenient to open and close

A technology for wheel hub surface and deburring, which is used in grinding drive devices, grinding/polishing safety devices, machine tools suitable for grinding workpiece edges, etc. problems, to achieve the effect of quick installation and removal of the hub, easy installation and removal of the hub, and improved deburring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

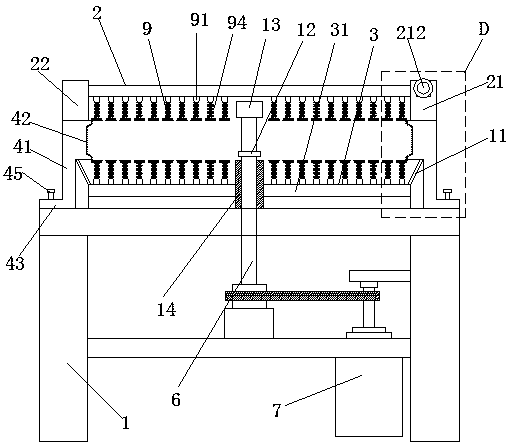

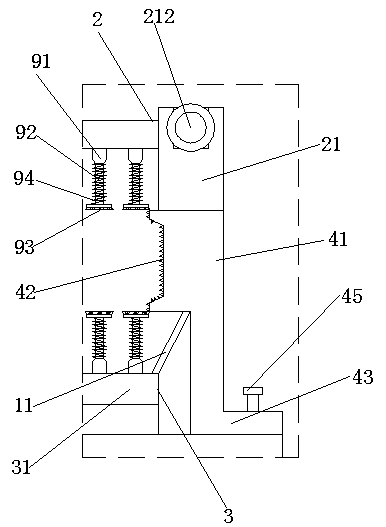

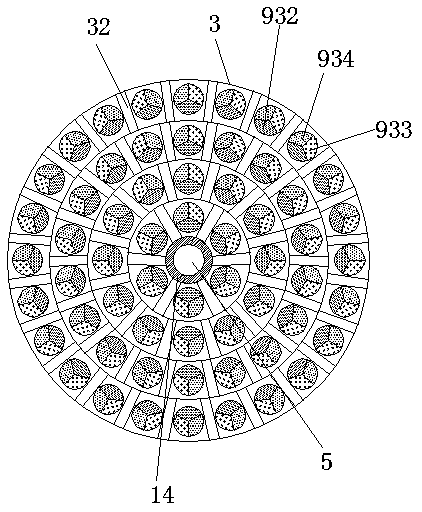

[0026] Refer to attached Figure 1-6 A motorcycle wheel hub surface deburring device that is easy to open and close is shown, including an operation console 1, and also includes an upper deburring disk 2, a deburring disk 3, and an adjustable side deburring mechanism 4, and the operation console 1 is fixed. The deburring disk 3 is provided with a rotating hole 5 at the central position of the deburring disk 3, a bearing 14 is arranged in the rotating hole 5, and a rotating shaft 6 is vertically arranged in the bearing 14 of the rotating hole 5, so that The lower end of the rotating shaft 6 passes through the operating table 1 and is connected with the drive motor 7 fixed on the support of the operating table 1. Unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com