an unloading trailer

A trailer and wheel assembly technology, applied in the field of unloading trailers, can solve the problems of labor-consuming, dangerous production, complex shock-absorbing structure, etc., and achieve the effect of stable shock absorption and convenient unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

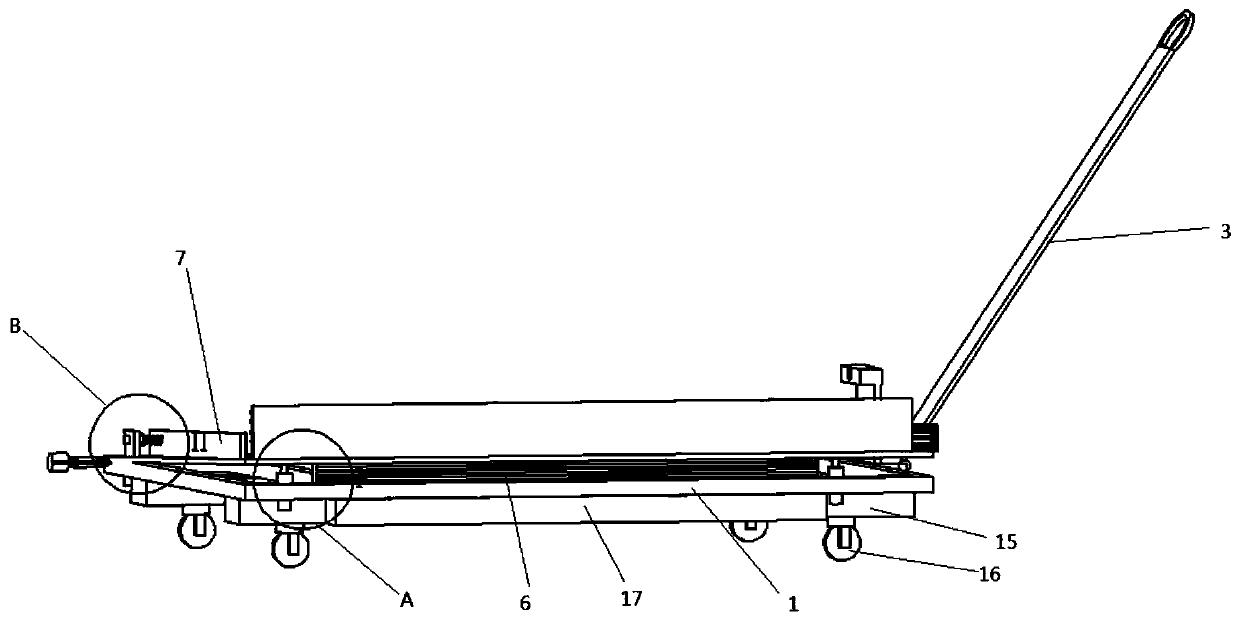

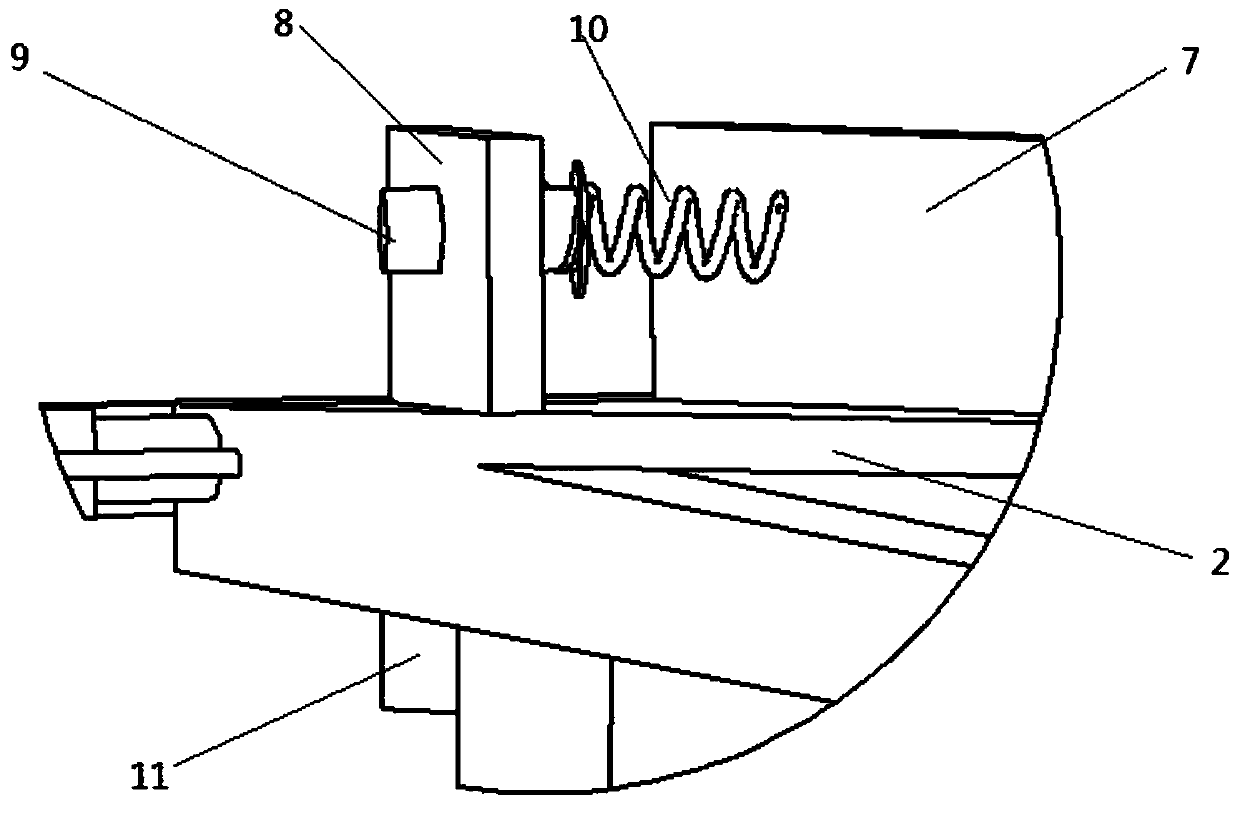

[0023] as attached Figure 1 to Figure 5 As shown, a kind of unloading trailer comprises a base plate 1, a wheel assembly, a loading platform 2, a jacking assembly, a buffer assembly and a drawbar 3, the bottom end of the base plate 1 is equipped with a wheel assembly, and the loading platform 2- One side is hinged to the bottom plate 1, the other side of the loading table 2 is installed on the bottom plate 1 through a jacking assembly, the buffer assembly is installed on the opposite side of the loading table 2, and the traction rod 3 is hinged to the bottom plate 1;

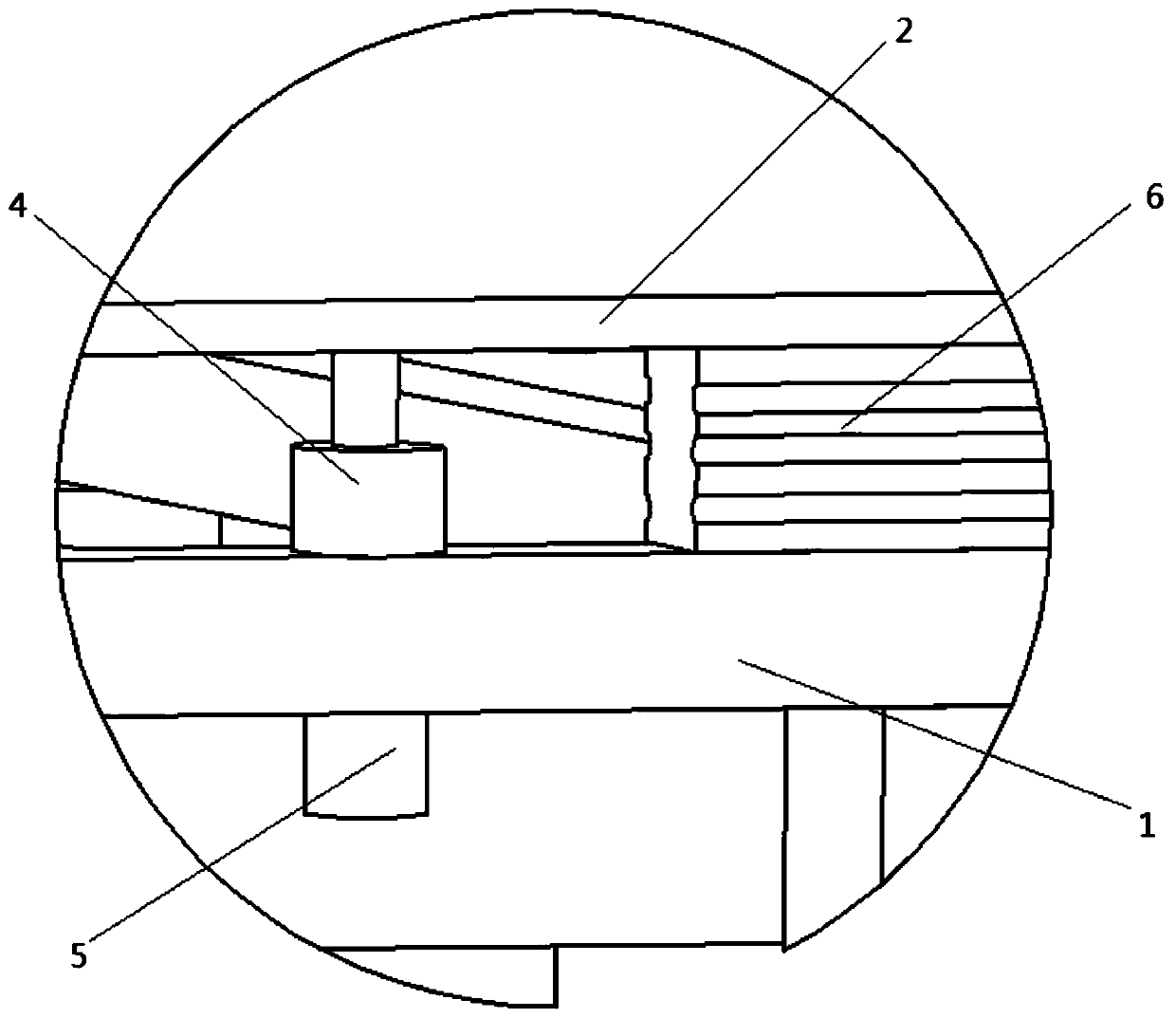

[0024] The jacking assembly includes a servo electric cylinder 4, a threaded cylinder 5 and an elastic buffer 6. The bottom plate 1 is provided with a threaded hole matching the cylinder 5, and the two threaded holes are located on the bottom of the bottom plate 1. At both ends of the edge, the servo el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com