Heating device for textile machinery

A heating device and textile machinery technology, applied in the field of textile machinery, can solve the problems of operator influence, temperature rise, cloth quality influence, etc., and achieve the effect of ensuring normal work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

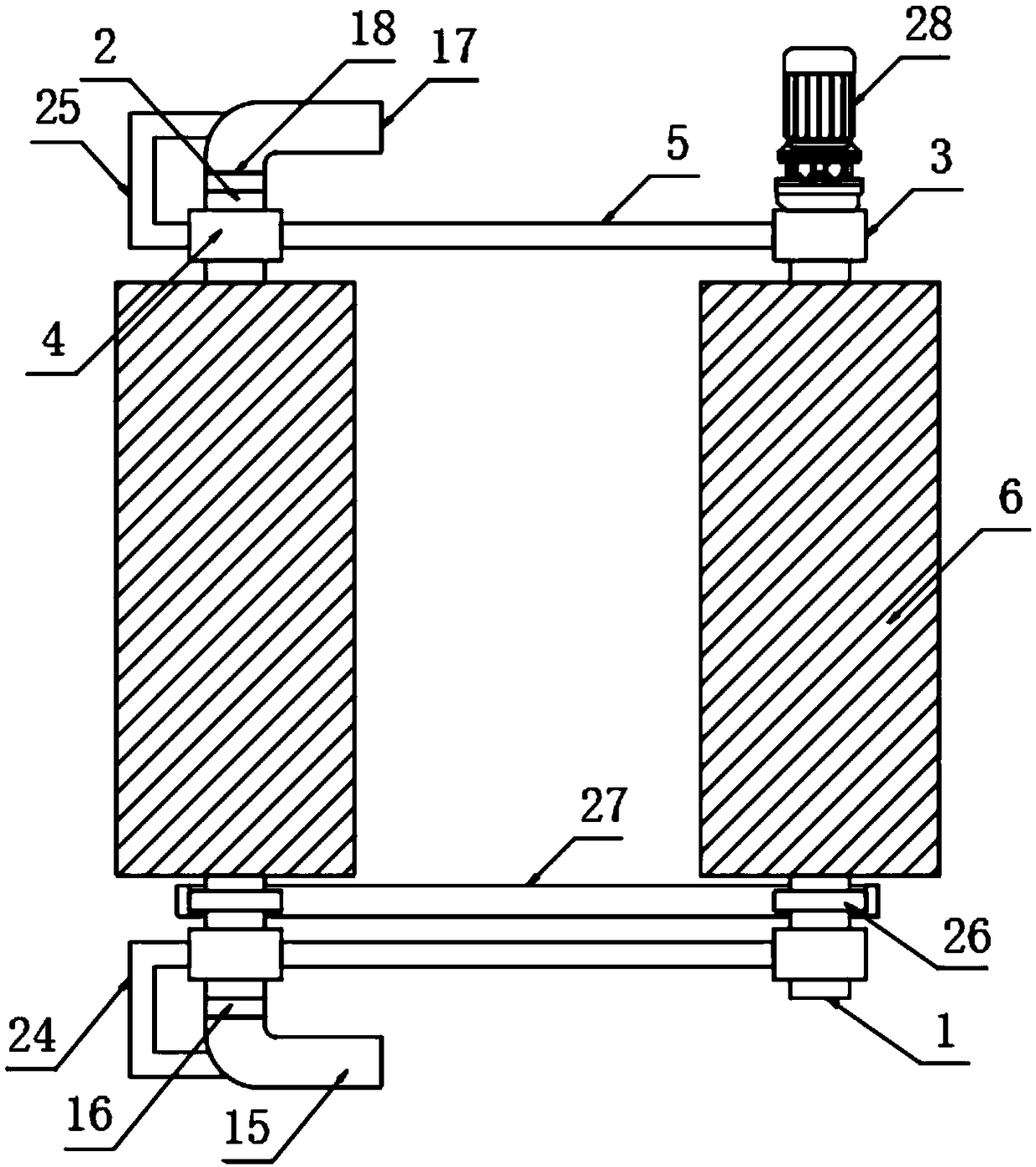

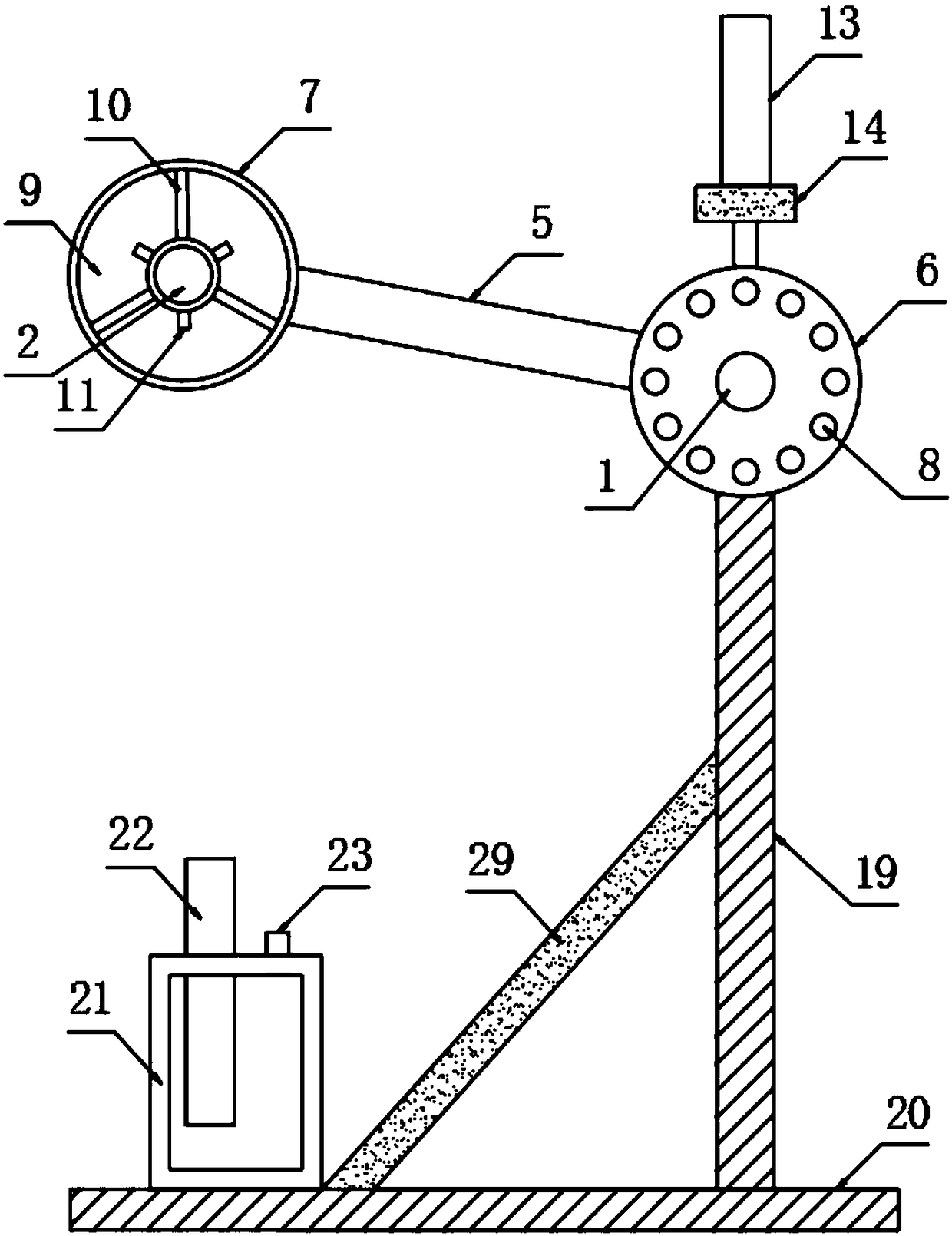

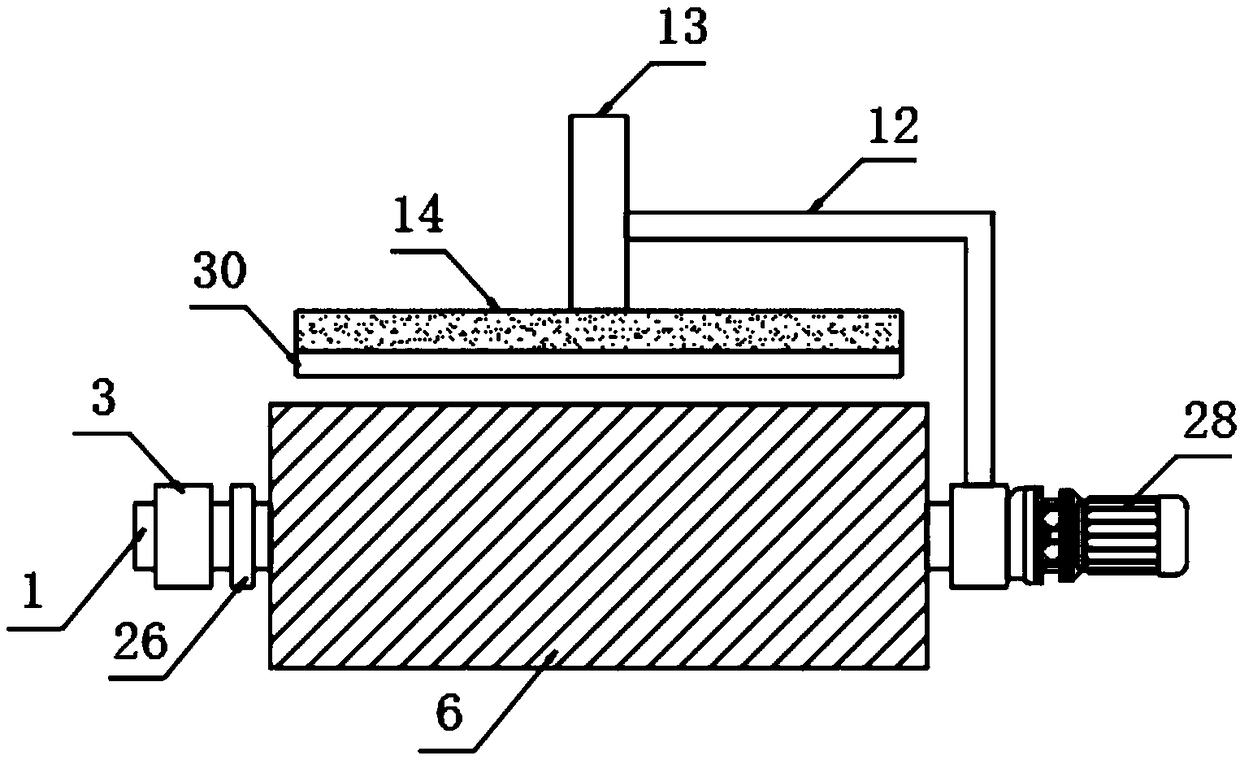

[0023] The present invention provides such Figure 1-3 The shown heating device for textile machinery includes a first rotating rod 1 and a second rotating rod 2, the second rotating rod 2 is arranged on one side of the first rotating rod 1, and the outer cover of the first rotating rod 1 The first heating roller 6 and the first fixing ring 3 are connected, and the heating resistor 8 is nested inside the first heating roller 6, and the second heating roller 7 and the second heating roller 7 are nested on the outside of the second rotating rod 2. Two fixed rings 4, the inside of the second heating roller 7 is provided with a gas storage chamber 9, the inside of the gas storage chamber 9 is provided with a support rod 10 and a gas transmission connection pipe 11, and the support rod 10 and the gas transmission connection pipe 11 Arranged in a staggered manner, the top of the first fixing ring 3 is provided with a first support frame 12 and the bottom is provided with a vertical ...

Embodiment 2

[0026] Further, in the above-mentioned embodiment 1, the first fixing ring 3 is arranged on both sides of the first heating roller 6, the second fixing ring 4 is arranged on both sides of the second heating roller 7, and the first fixing ring 3 and the second fixed ring 4 are fixedly provided with a connecting cross bar 5 .

[0027] Further, in the above-mentioned embodiment 1, a first bearing 16 is provided between the second air collecting pipe 15 and the second rotating rod 2, and a bearing 16 is provided between the second exhaust pipe 17 and the second rotating rod 2. The second bearing 18 .

[0028] Further, in the first embodiment above, the second air collecting pipe 15 is connected to the first air collecting pipe 13 through a pipe, and the second exhaust pipe 17 is connected to the first exhaust pipe 22 through a pipe.

[0029] Further, in the above-mentioned embodiment 1, the second support frame 24 and the third support frame 25 are fixedly provided on the side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com