Winding device

A winding device and winding core technology, applied in the direction of sustainable manufacturing/processing, electrochemical generators, electrical components, etc., can solve problems such as uneven thickness of electrode sheets, defective winding components, etc., and achieve high productivity , the effect of suppressing enlargement and preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

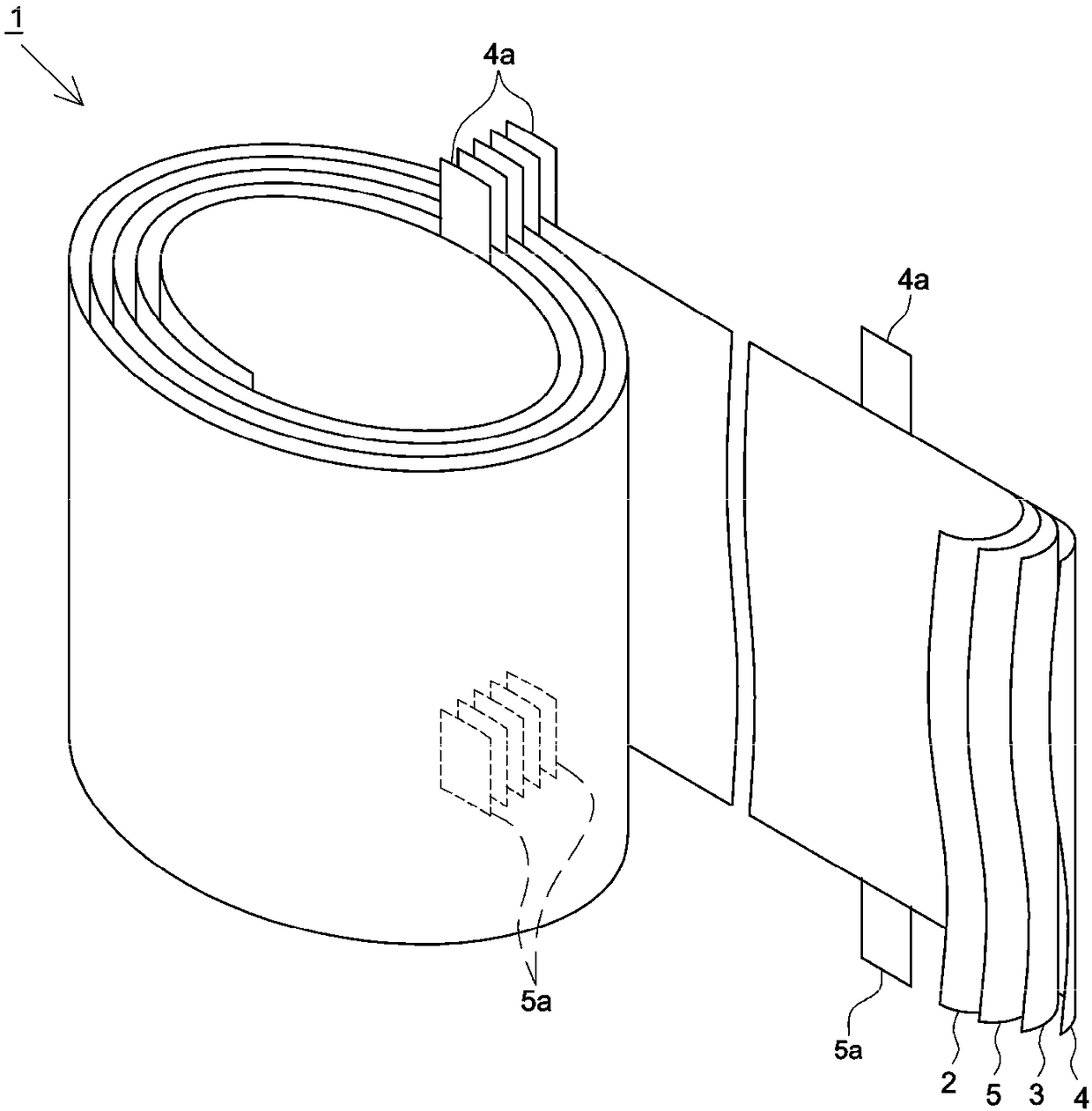

[0092] One embodiment will be described below with reference to the drawings. First, the structure of a lithium ion battery element as a wound element obtained by a winding device will be described.

[0093] picture figure 1 As shown, a lithium ion battery element 1 (hereinafter simply referred to as "battery element 1") is manufactured by interposing two separator sheets 2, 3, a positive electrode sheet 4 and a negative electrode sheet 5. I wind it up in a superimposed state. In addition, instead of the two separator sheets 2 and 3, one folded separator sheet may be used. In addition, below, the separator sheets 2 and 3 and the electrode sheets 4 and 5 are referred to as "various sheets 2 to 5" for convenience of description.

[0094] The separators 2 and 3 are strip-shaped with the same width and are made of an insulator such as polypropylene (PP) to prevent short-circuiting caused by contact between different electrodes 4 and 5 .

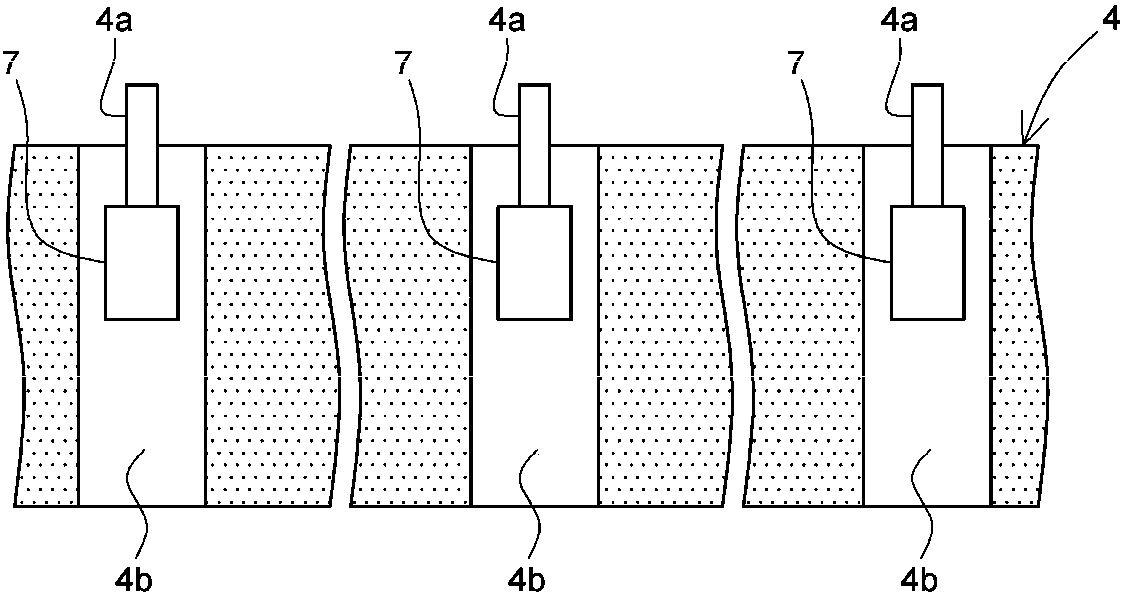

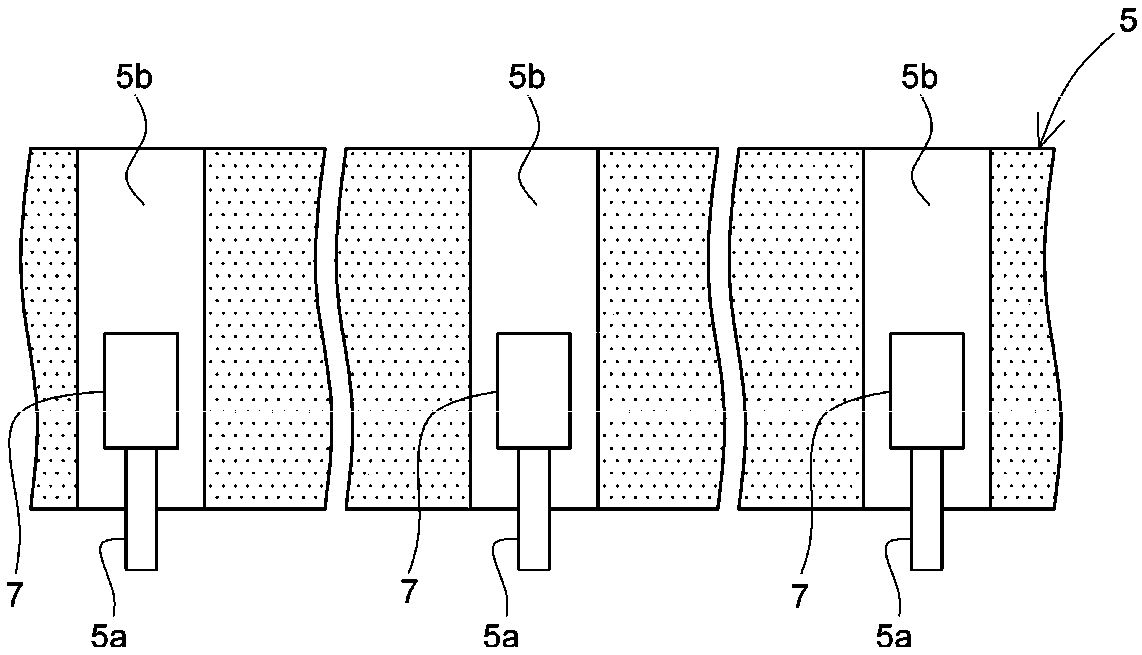

[0095]The electrode sheets 4 and 5 are...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap