A manual plate bending device

A bending device, manual technology, applied in the field of manual plate bending devices, can solve problems such as affecting the work process, inability to perform operations, and prone to danger, etc., and achieve the goals of increasing the scope of application, improving work efficiency, and reducing energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

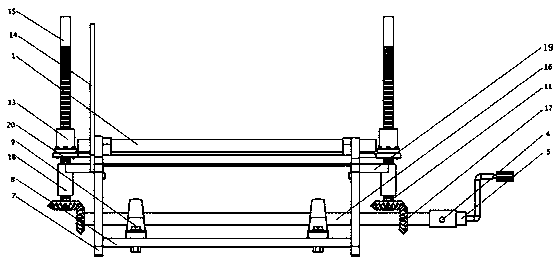

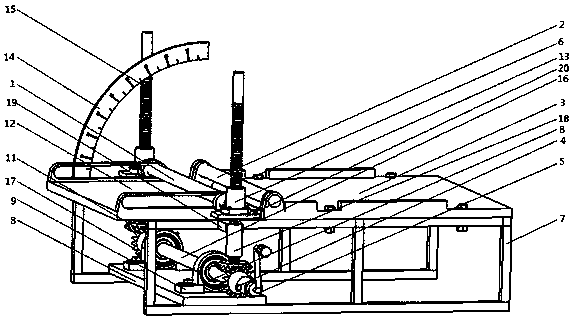

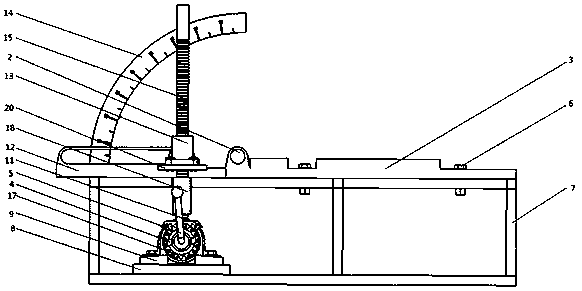

[0021] Embodiment 1: as Figure 1~4 As shown, a manual plate bending device includes a circular shaft I1, a circular shaft II2, a fixed plate 3, a cylindrical pin 4, a rocker 5, 13 bolts 6, a bracket 7, a support plate 8, and two bearing seats 9 , two bearings 10, two bevel gears II 11, movable plate 12, two screw nuts 13, angle scale 14, two lead screws 15, circular shaft III 16, two bevel gears I 17, two sleeves 18, two A cross bar 19, two boards 20;

[0022] The fixed plate 3 is fixedly connected to the top of the bracket 7 through four bolts 6, the movable plate 12 is fixed on the bracket 7 and is located on the side of the fixed plate 3, and one end of the movable plate 12 is connected to the fixed plate 3 through the circular shaft II2. One end is fixedly connected, the circular shaft II2 passes through the two ends of the fixed plate 3 and the movable plate 12 in turn, the two ends of the top of the movable plate 12 have grooves, and the two ends of the circular shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com