Method for calculating critical flowback velocity of fracturing fluid

A technology of speed calculation and speed calculation formula, which is applied in calculation, earthwork drilling, mining fluid, etc., can solve problems such as fracture sand spit, and achieve the effect of solving formation sand spit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the above and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments are listed below and shown in the accompanying drawings in detail as follows.

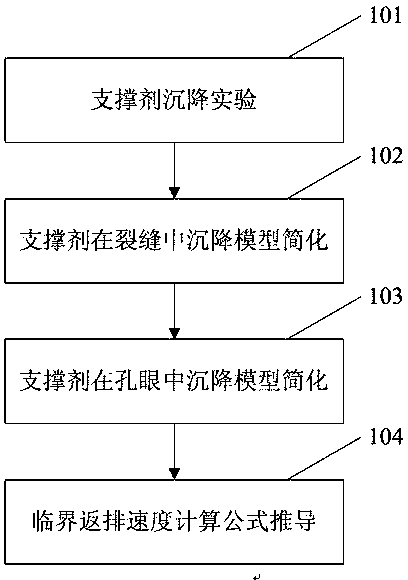

[0038] Such as figure 1 as shown, figure 1 It is a flow chart of the method for calculating critical flowback velocity of fracturing fluid in the present invention.

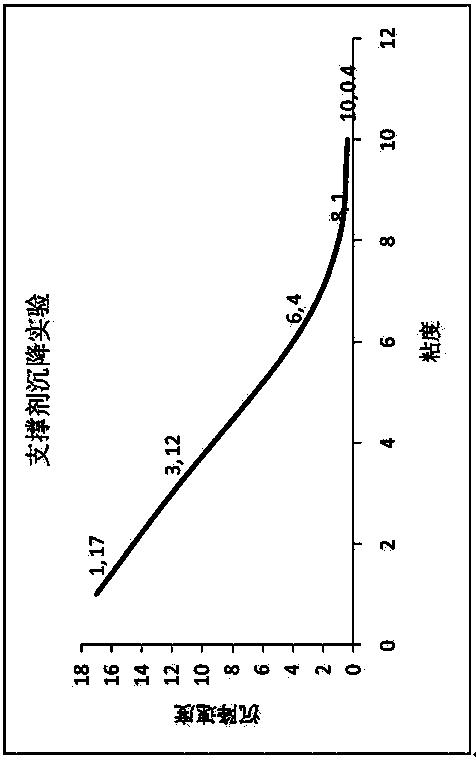

[0039] Step 101, proppant settlement experiment. The settling velocity experiment of proppant in gel-breaking fluid to determine the settling velocity of proppant.

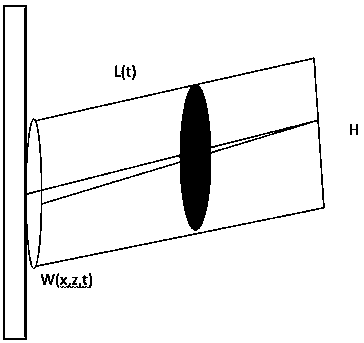

[0040] The movement of the proppant in the fracture is free-settling in the vertical direction, and moves in the horizontal direction due to the stagnation effect of the fracturing fluid, so it can be regarded as the synthesis of the subsidence and the stagnation of the fracturing fluid. Regardless of the influence of sand concentration and fracture wall, the velocity of a single proppant in the horizontal direction should...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com