A line-drawing auxiliary device for clothing production

An auxiliary device and line-drawing technology, which is applied in the direction of sewing tools, etc., can solve the problems of low line-drawing efficiency, fabric wrinkles, etc., and achieve the effect of alleviating work fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

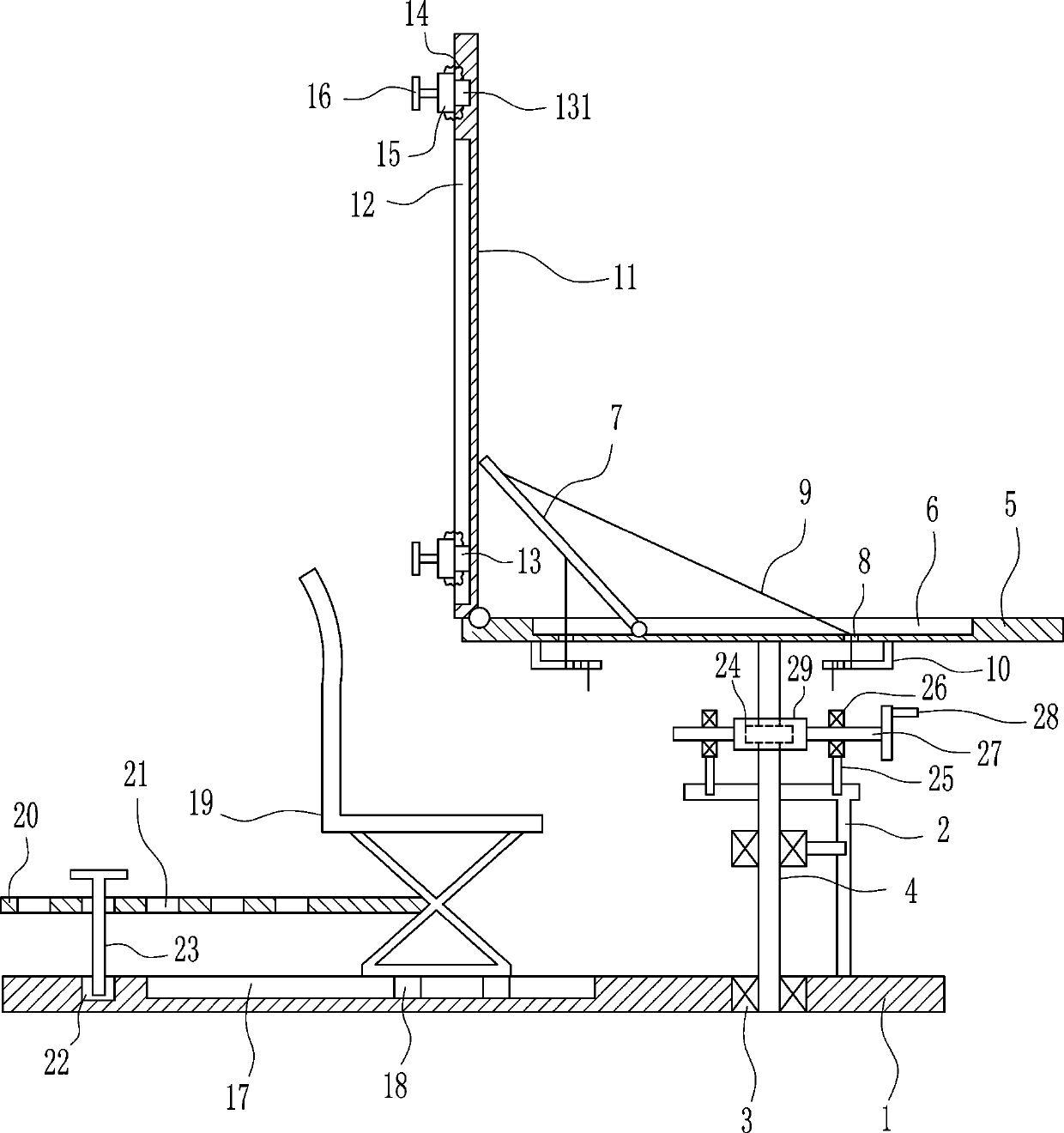

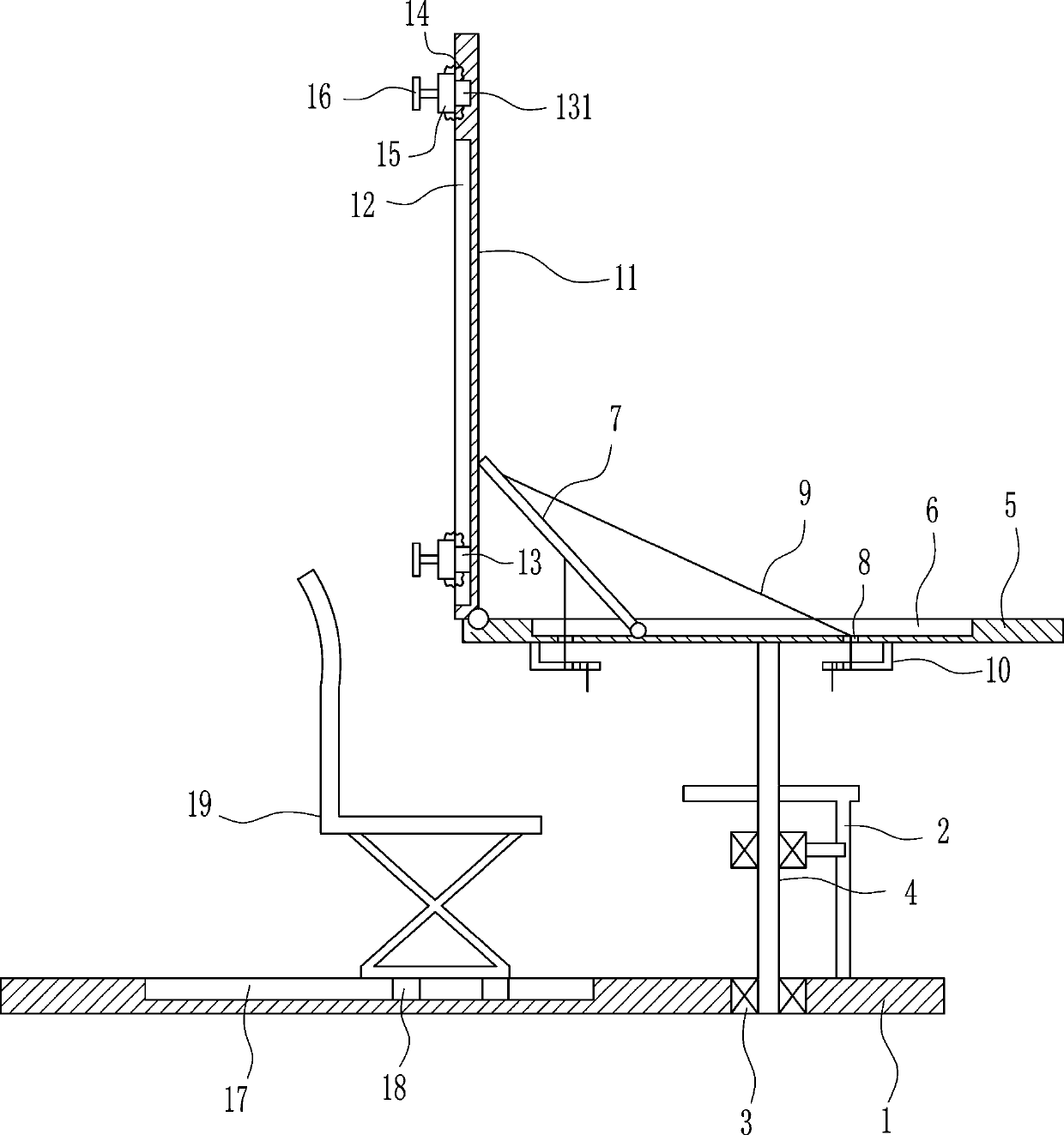

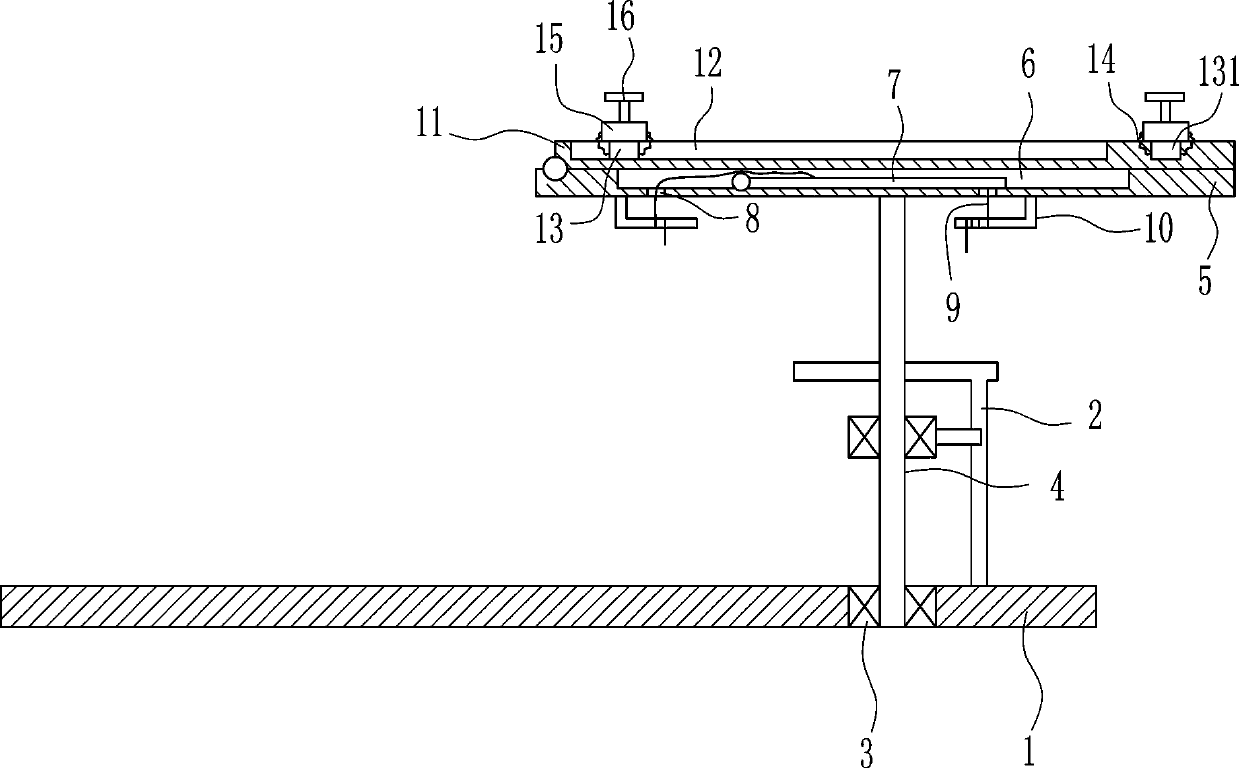

[0024]A line-drawing auxiliary device for clothing production, such as Figure 1-5 As shown, it includes a base 1, a pole 2, a first bearing seat 3, a first rotating rod 4, a mounting plate 5, a supporting rod 7, a steel wire rope 9, a fixed rod 10, a rotating plate 11, a first slide rail 12, a A slider 13, a mounting block 131, a spring 14, a strip-shaped pressing plate 15 and a pull rod 16, the upper right part of the base 1 is provided with a pole 2, and the upper part of the front wall of the pole 2 and the right part of the base 1 are provided with a first bearing Seat 3, the upper and lower two first bearing seats 3 are located on the same vertical line, the first rotating rod 4 is connected between the two first bearing seats 3, the top of the first rotating rod 4 is provided with a mounting plate 5, the mounting plate 5 There is a first groove 6 in the middle, and a support rod 7 is connected to the middle of the top of the mounting plate 5 in a rotating manner. The f...

Embodiment 2

[0026] A line-drawing auxiliary device for clothing production, such as Figure 1-5 As shown, it includes a base 1, a pole 2, a first bearing seat 3, a first rotating rod 4, a mounting plate 5, a supporting rod 7, a steel wire rope 9, a fixed rod 10, a rotating plate 11, a first slide rail 12, a A slider 13, a mounting block 131, a spring 14, a strip-shaped pressing plate 15 and a pull rod 16, the upper right part of the base 1 is provided with a pole 2, and the upper part of the front wall of the pole 2 and the right part of the base 1 are provided with a first bearing Seat 3, the upper and lower two first bearing seats 3 are located on the same vertical line, the first rotating rod 4 is connected between the two first bearing seats 3, the top of the first rotating rod 4 is provided with a mounting plate 5, the mounting plate 5 There is a first groove 6 in the middle, and a support rod 7 is connected to the middle of the top of the mounting plate 5 in a rotating manner. The ...

Embodiment 3

[0029] A line-drawing auxiliary device for clothing production, such as Figure 1-5 As shown, it includes a base 1, a pole 2, a first bearing seat 3, a first rotating rod 4, a mounting plate 5, a supporting rod 7, a steel wire rope 9, a fixed rod 10, a rotating plate 11, a first slide rail 12, a A slider 13, a mounting block 131, a spring 14, a strip-shaped pressing plate 15 and a pull rod 16, the upper right part of the base 1 is provided with a pole 2, and the upper part of the front wall of the pole 2 and the right part of the base 1 are provided with a first bearing Seat 3, the upper and lower two first bearing seats 3 are located on the same vertical line, the first rotating rod 4 is connected between the two first bearing seats 3, the top of the first rotating rod 4 is provided with a mounting plate 5, the mounting plate 5 There is a first groove 6 in the middle, and a support rod 7 is connected to the middle of the top of the mounting plate 5 in a rotating manner. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com