Aero-engine flow pass checking multifunctional band rotating machine

An aero-engine and multi-functional belt technology, which is used in engine testing, machine/structural component testing, measuring devices, etc., can solve the problems of laborious, time-consuming, and inconvenient rotating rotors, and achieve easy operation, light weight, and convenience. carry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

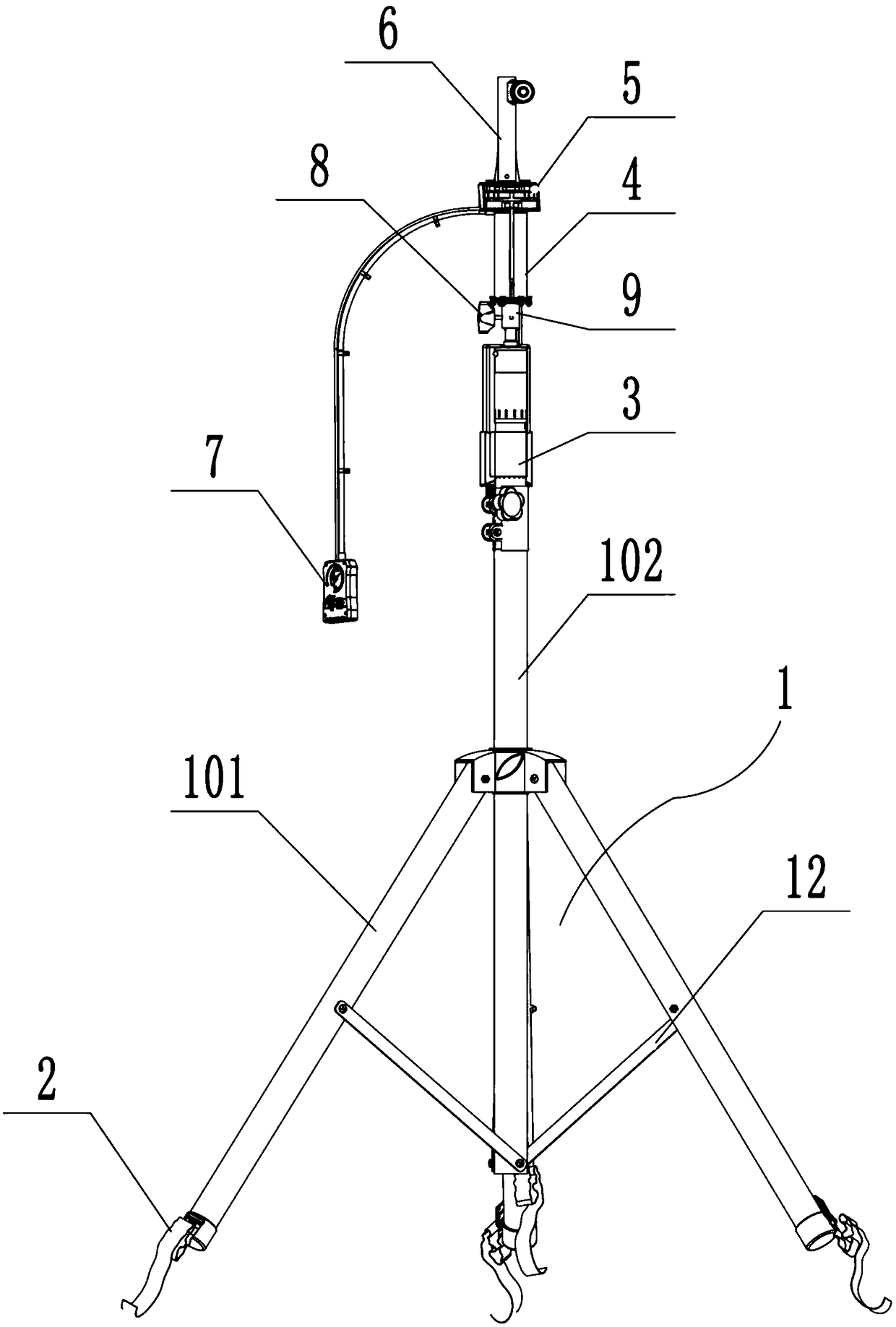

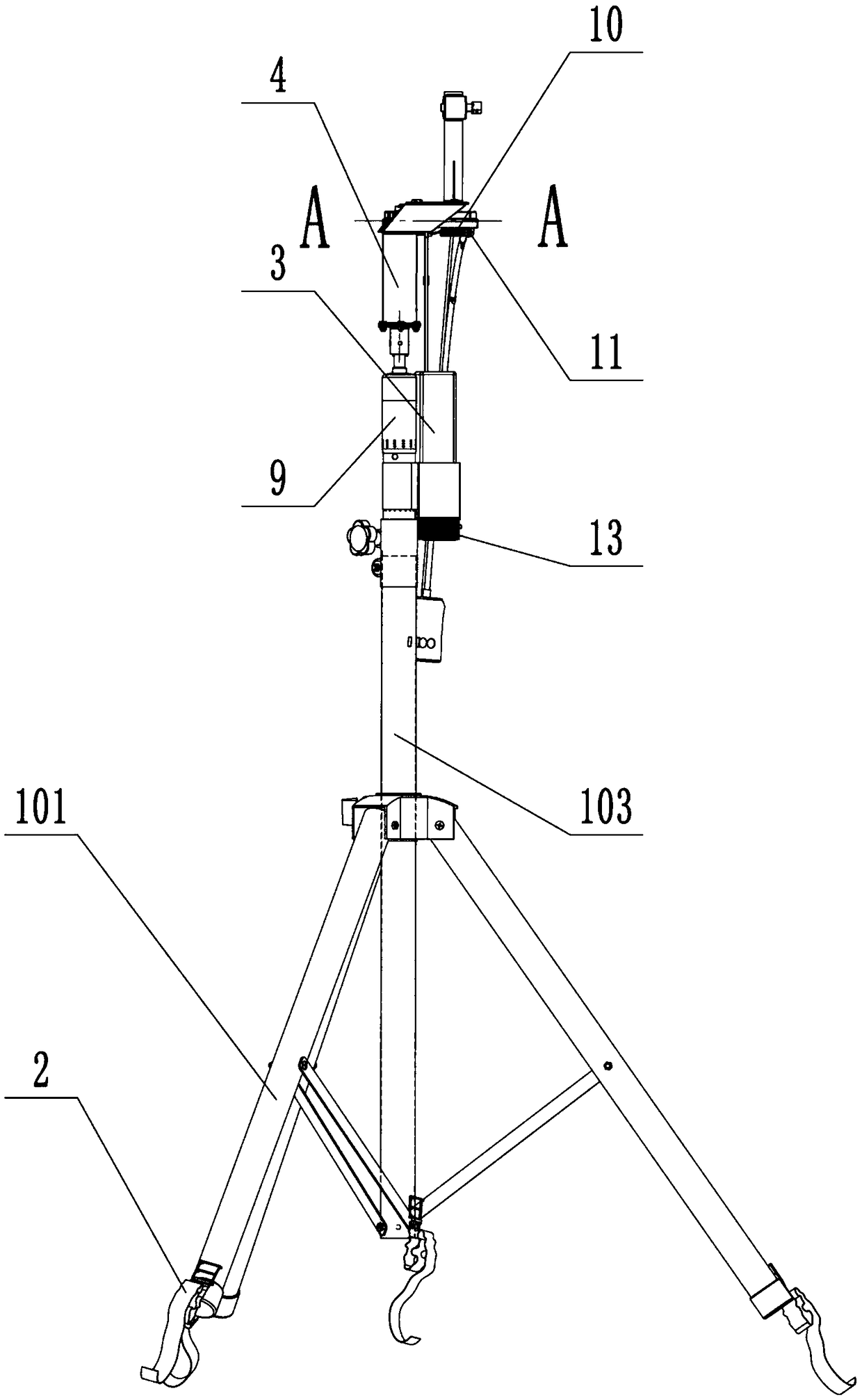

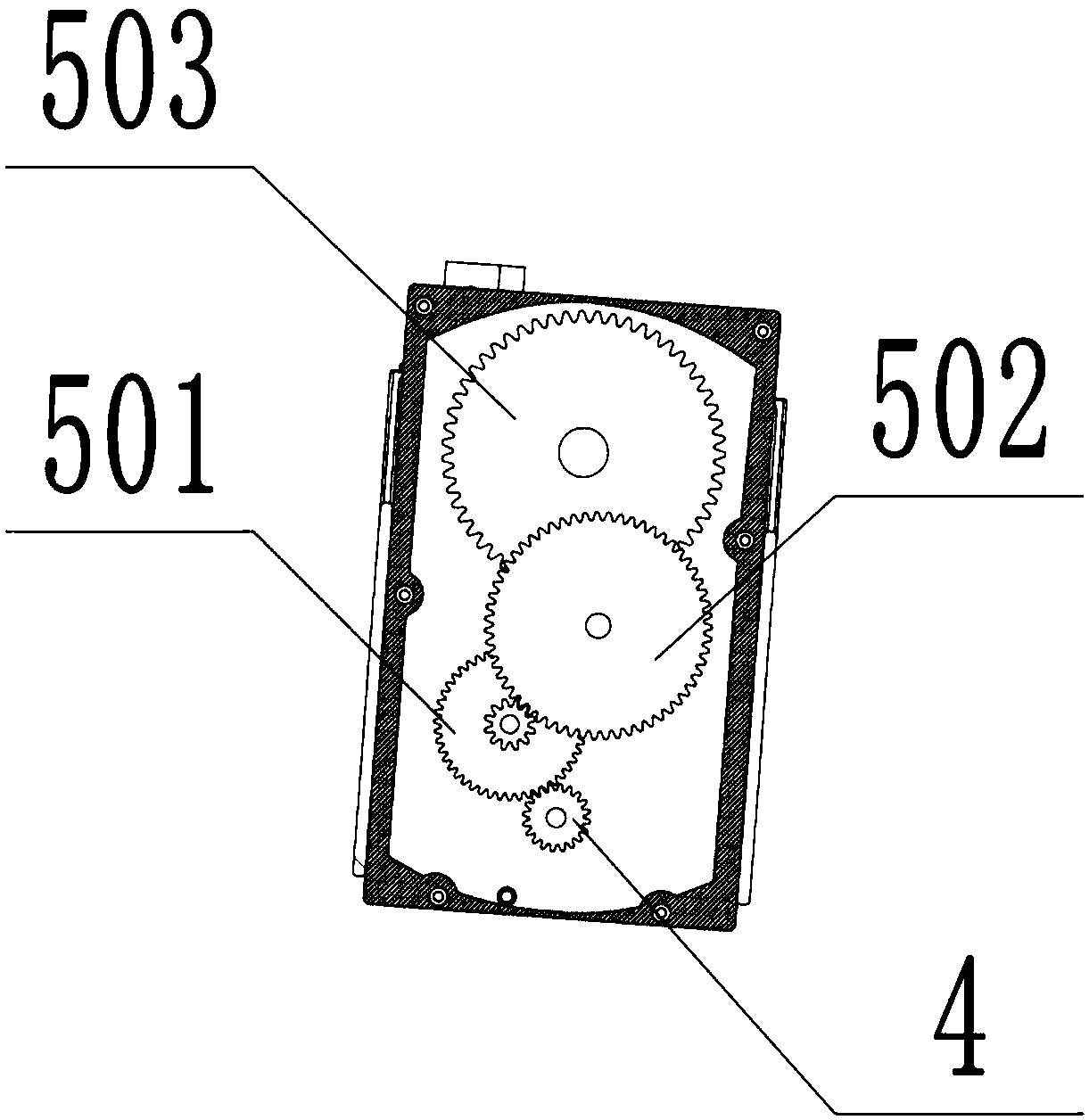

[0025] Please see attached figure 1 and attached image 3 Shown, a kind of aero-engine flow channel checks multi-functional belt turning machine, comprises tripod 1, fixed strap 2, battery 3, drive motor 4, three-stage reducer 5 and worm gear reducer 6 and controller 7; Said tripod 1 includes a leg 101 and a pole 102, the pole 102 is a telescopic pole, and the three legs 101 are evenly arranged along the circumference of the pole 102; the fixing strap 2 is arranged on the leg 101 bottom, the battery 3 is installed in the pole 102, the driving motor 4 is arranged on the upper part of the battery 3, and is electrically connected with the battery 3; the three-stage reducer 5 is arranged on the driving The upper part of the motor 4, and the output end of the driving motor 4 is connected to the input end of the three-stage reducer 5; the worm gear reducer 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com