Multifunctional vacuum homogenization emulsifying machine

A vacuum homogenizer and emulsifier technology, applied in mixers, mixer accessories, chemical instruments and methods, etc., can solve the problems of increasing the labor force and labor time of users, unable to use personnel to provide entertainment activities, and not having all-round music playback. , to relieve work fatigue, improve labor efficiency, and increase the effect of fun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

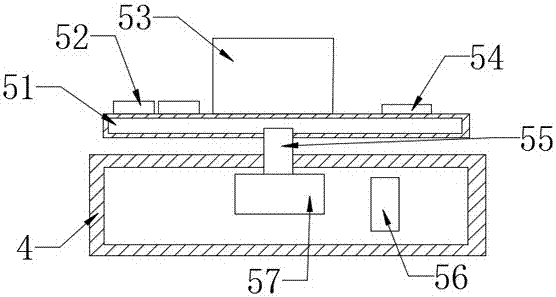

[0025] Specific implementation method: when the emulsifying machine is working, the user turns on the play switch 54, and the play switch 54 is switched to an on state, and the storage battery 56 transmits electric energy to the speaker 53 through a wire, and the speaker 53 starts to play music, and the battery 56 passes the wire to the speaker 53 at the same time. The electric energy is transmitted to the rotating motor 57, and the rotating motor 57 converts the electric energy into mechanical energy, and the rotating motor 57 starts to work, and the rotating motor 57 drives the fixed plate 51 to rotate through the rotating shaft 55, and the fixed plate 51 drives the sound box 53 to rotate, so that the full play of the sound box 53 is realized. Effect, because the speaker 53 is equipped with a Bluetooth receiving module, the user can connect the speaker 53 to an external mobile phone through Bluetooth, and the speaker 53 can play the built-in music of the mobile phone, which im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com