Continuous hydraulic traction device

A traction device and continuous technology, which is applied in the field of continuous hydraulic traction devices, can solve the problems of multiple traction times, limited oil cylinder stroke, waste of time, etc., and achieve the effect of reducing time and shortening the number of traction times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described:

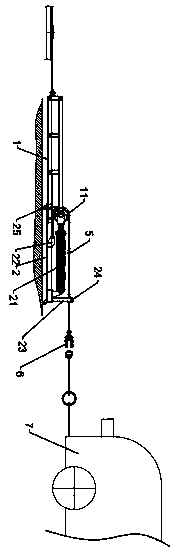

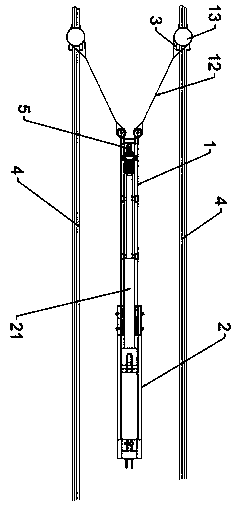

[0012] refer to Figure 1 to Figure 2 , a continuous hydraulic traction device, including a guide bracket 1 and an oil cylinder support frame 2 that can be close to or separated from each other in the horizontal direction, so that it is easy to store and transport, and one end of the guide bracket 1 is connected to two steel cables 12. The other end of the steel cable 12 is fixed on the steel cable reel 13, and the two steel cable reels 13 are respectively fixed on the two steel rails 4 through wedge blocks 3, and the oil cylinder support frame 2 is provided with an oil cylinder 21, and one end of the oil cylinder 21 is fixed On the cylinder support frame 2, a guide wheel 11 is installed at the other end, a wire rope fixed end 22 is fixed on the top of the cylinder support frame 2, and a suspension wheel support seat 23 is fixed on the end of the cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com