Full-automatic goods shelf stacking-and-unstacking feeding equipment

A feeding equipment, fully automatic technology, applied in the direction of stacking, transportation and packaging of objects, can solve the problems of single piece extraction, unable to meet the feeding method, unable to meet the continuous feeding of the automatic production line, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

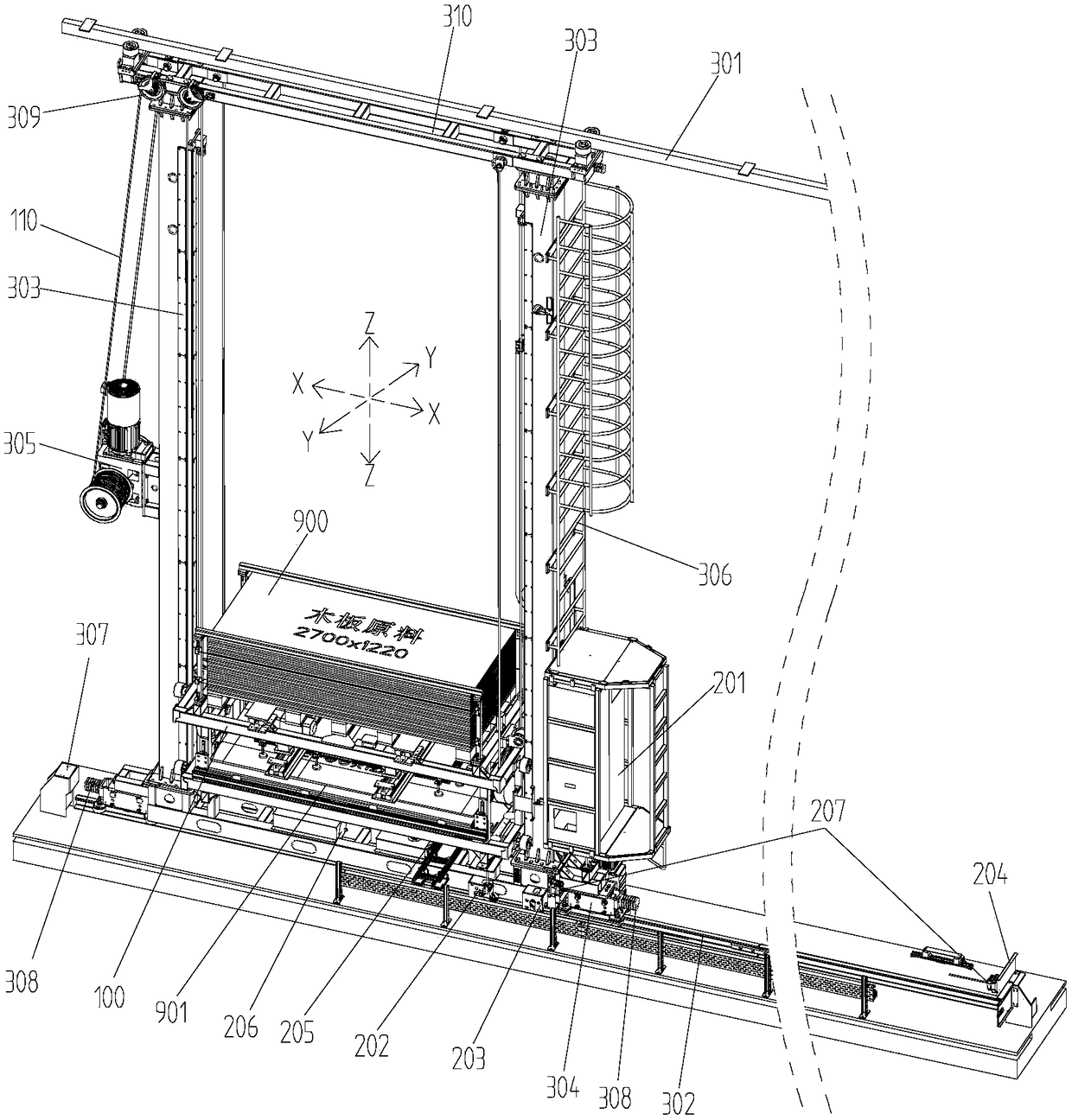

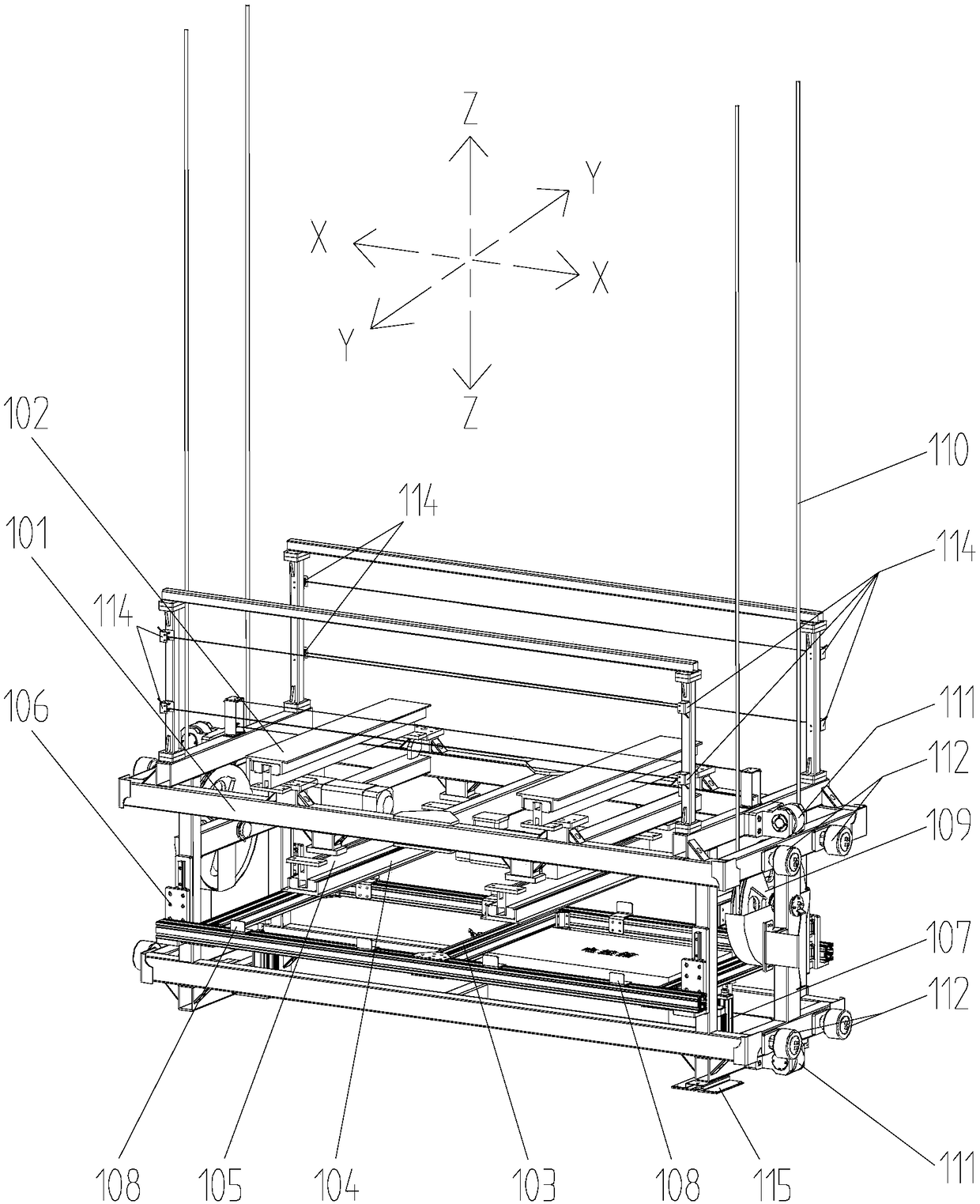

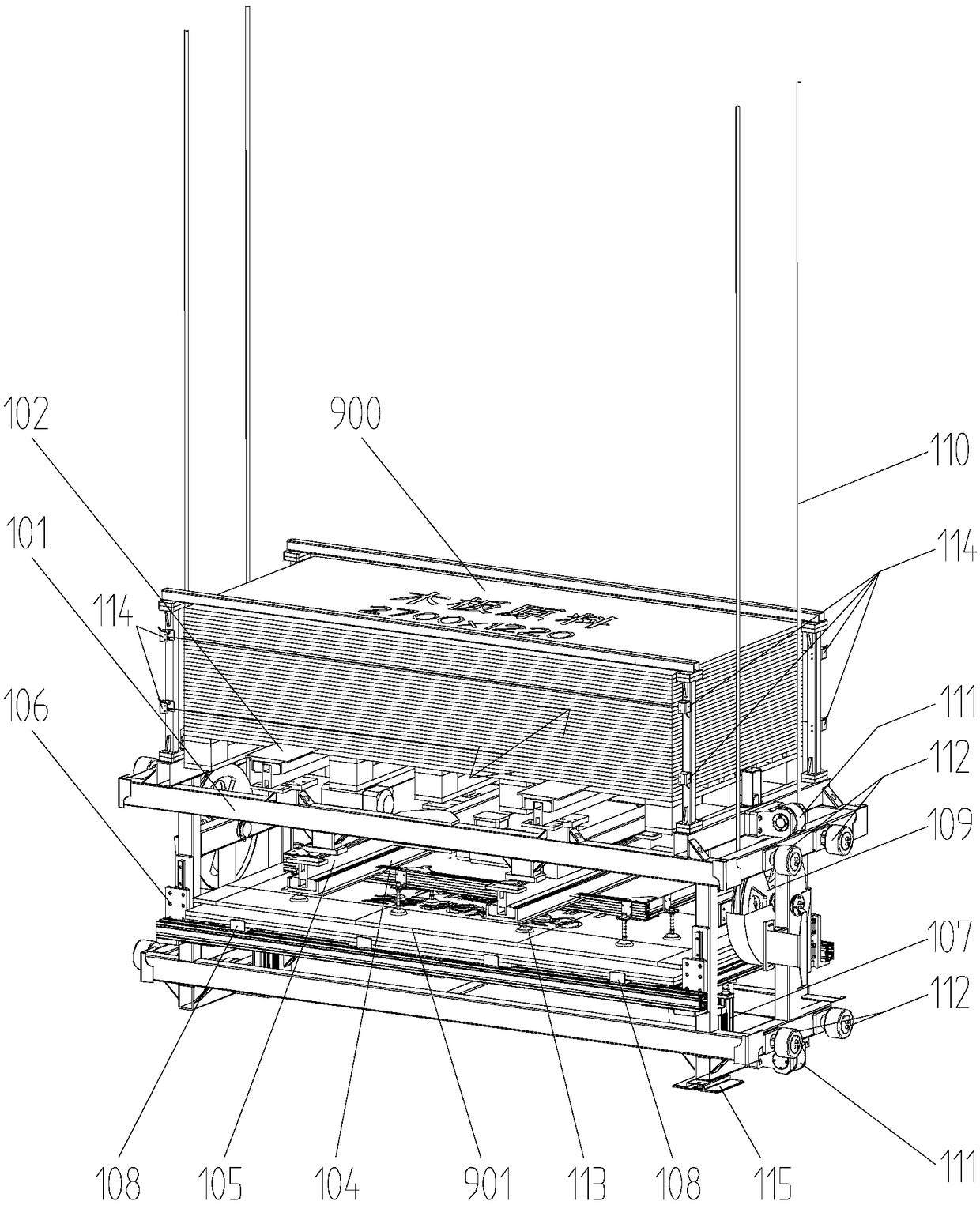

[0026] Such as figure 1 The shown embodiment is a kind of fully automatic shelf stack dismantling and feeding equipment, which is generally used in conjunction with shelves. The equipment is provided with a sky rail 301 and a ground rail 302 along the length direction of the shelf, and a pair of side rails 303 are arranged vertically between the sky rail and the ground rail. The base 304 is fixedly connected so that the side rails, the upper crossbeam, and the walking base enclose a rectangle. There are active rollers on the walking base, which are powered to roll along the ground rail actively, and driven rollers are arranged on the upper beam to passively roll along the sky rail. The power system is controlled by an automatic control center. In this rectangle, there is a reclaimer 100, which can translate along the X direction, that is, th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap