Linkage receiving mechanism of punch press

A punching machine and feeding chute technology, applied in metal processing equipment, stripping devices, manufacturing tools, etc., can solve the problems of high labor intensity and insecurity, and achieve the effect of high work efficiency, low cost and good safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

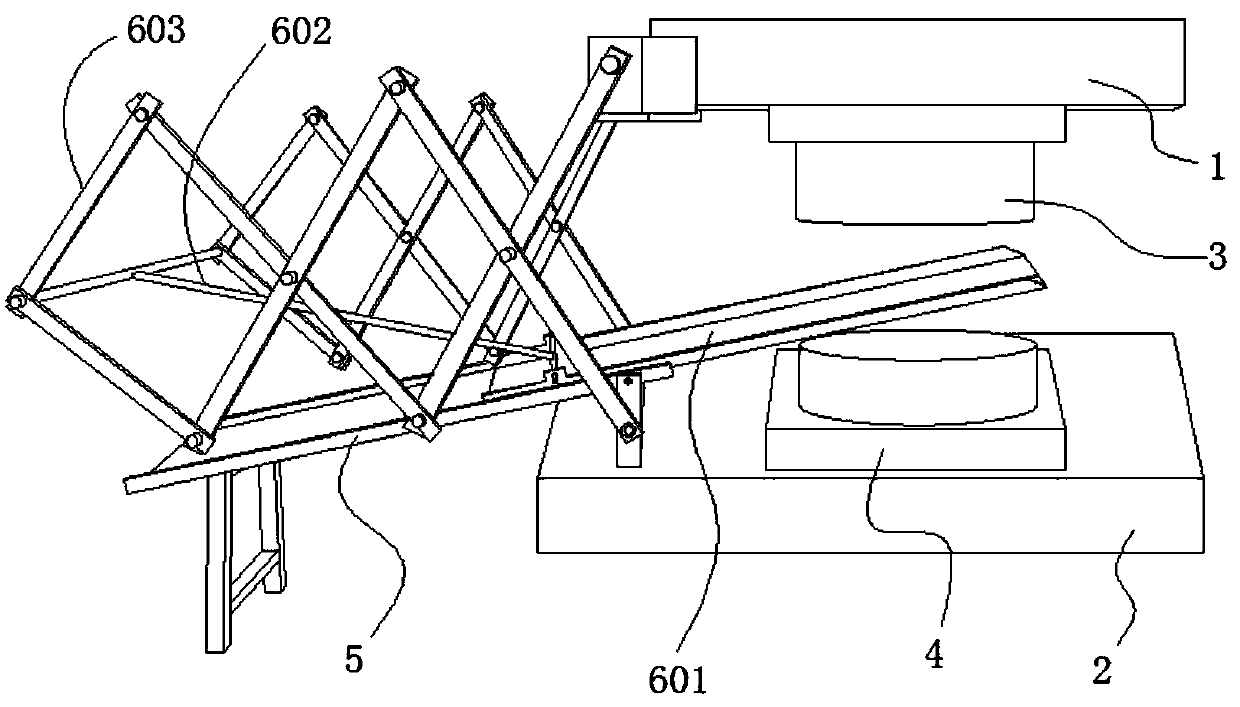

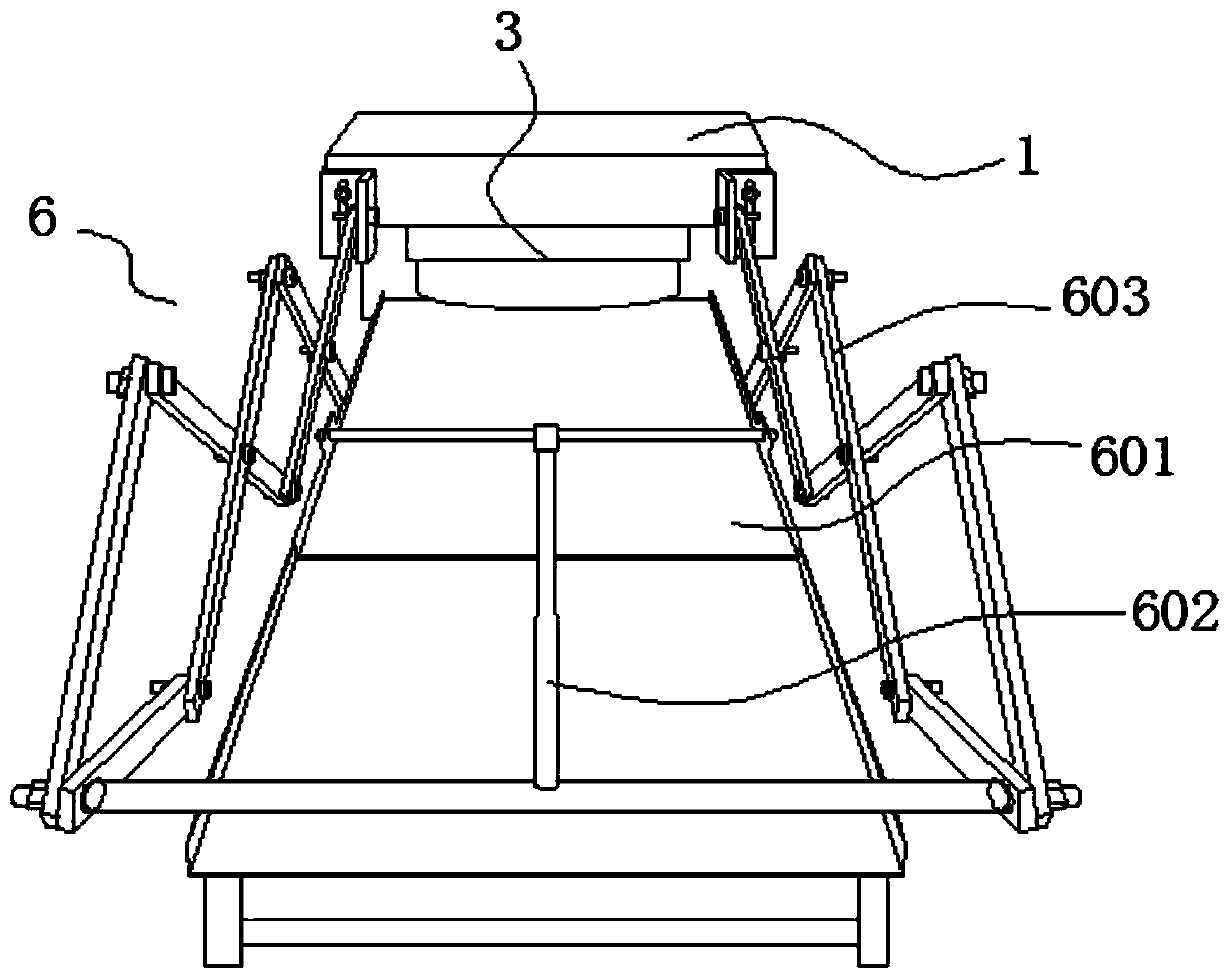

[0015] Such as figure 1 and 2 As shown, a punching machine linkage material receiving mechanism includes a chute 5, a material receiving hand 6, an upper die base 1 and a lower die base 2 arranged on the punch press, the upper die base 1 is provided with an upper die 3, and the lower die base 2 is provided with lower mold 4 correspondingly. The chute 5 is positioned at the left side of the lower die 4, the right end of the chute 5 is fixedly connected with the lower die base 2, and the left end is fixed on the ground by a support. Chute 5 is placed obliquely, and its left end is lower than the right end. The material receiving hand 6 is provided with a material receiving trough 601 , a traction arm 602 and two telescopic arms 603 . The two telescopic arms 603 are arranged symmetrically on both sides of the receiving trough 601, and each telescopic arm 603 is composed of two Z-shaped movable rods that are mirrored and intersected to form a network structure, passing through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com