Wire feeding mechanism, and six-head type constant-tension wire feeding device with wire feeding mechanism

A technology of wire feeding and wire holder, applied in the field of six-head constant tension wire feeding device, which can solve the problems of large land area, scattered overall structure, and poor quality of cabling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

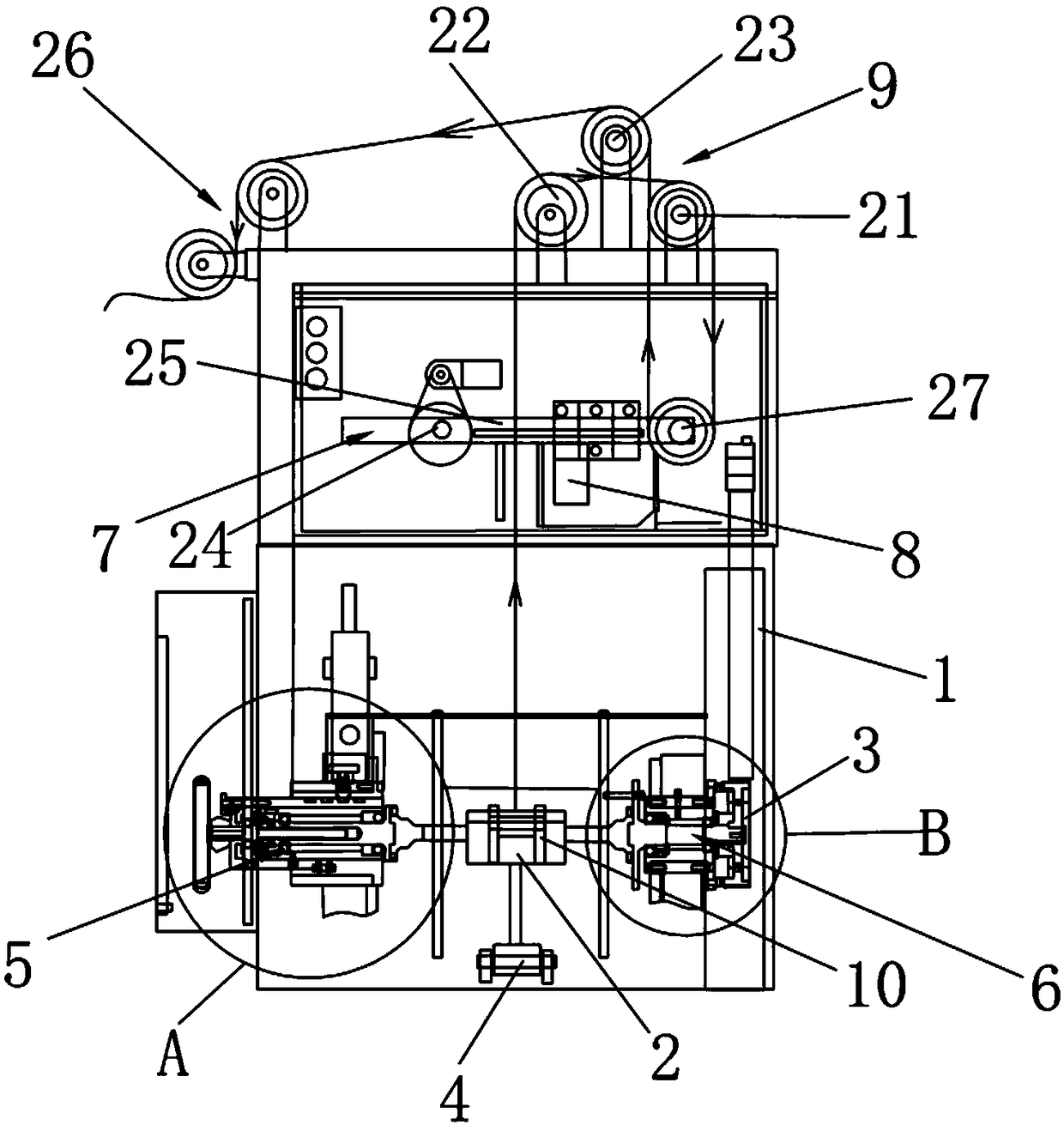

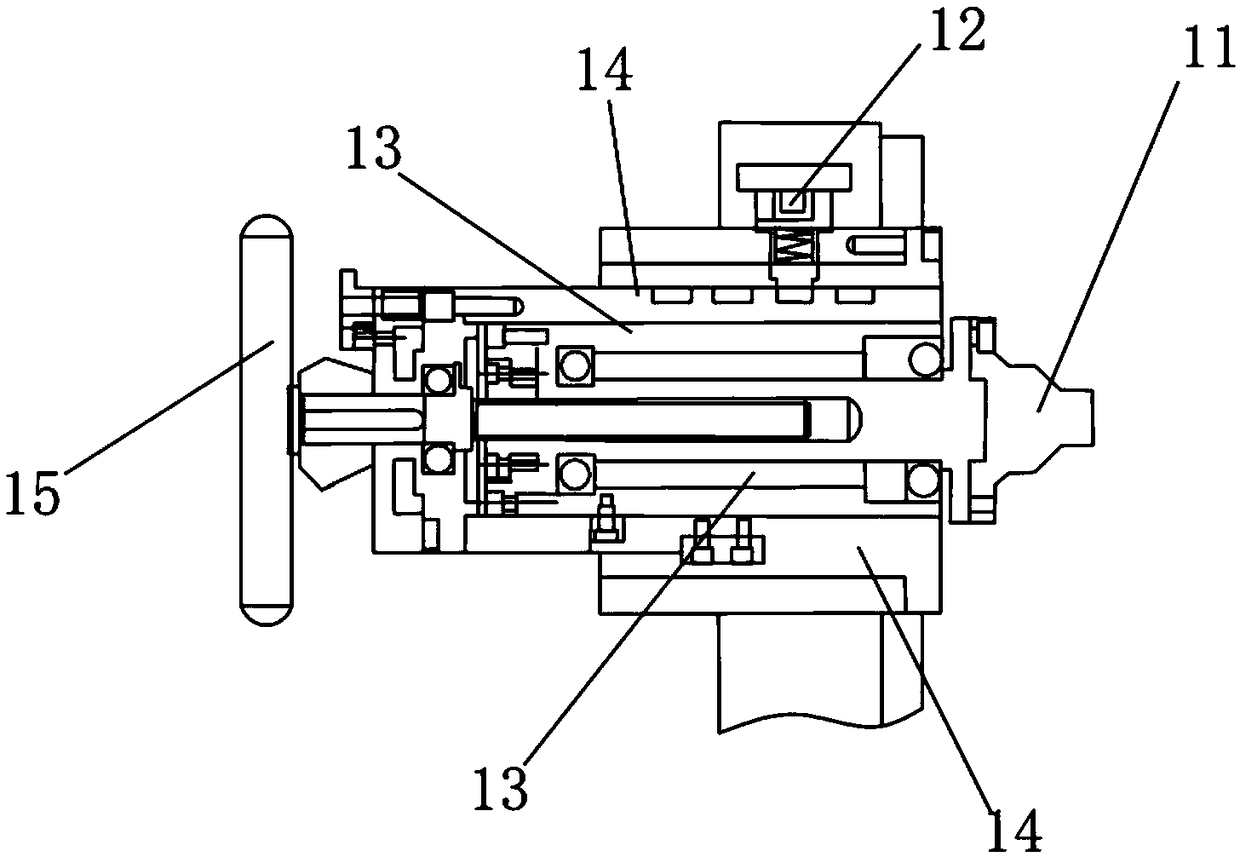

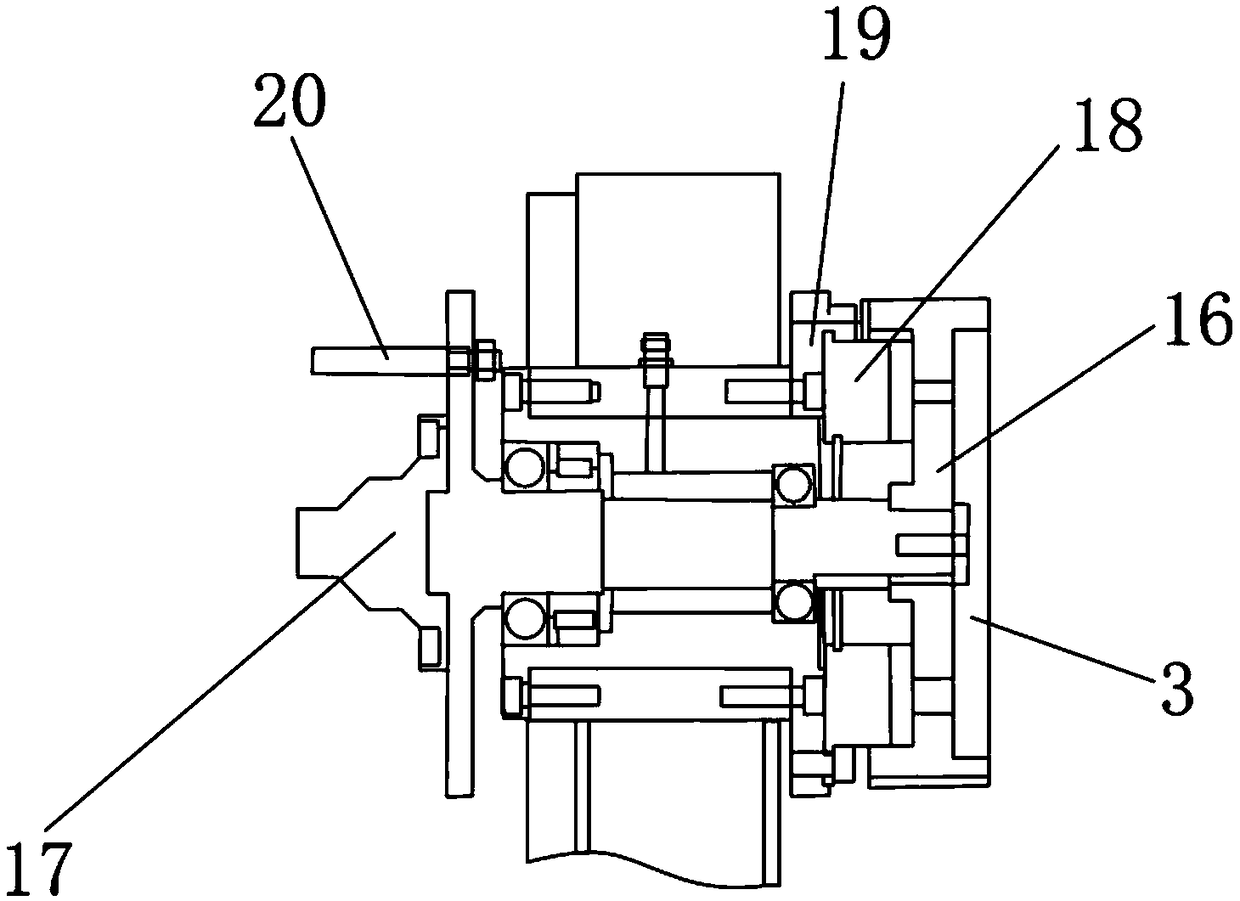

[0024] Such as Figure 1-3 As shown, a wire feeding mechanism provided by the present invention includes a bracket 1, a lifting platform 2, a drive motor 3, a cylinder 4, a movable top cone 5, a fixed top cone 6, a swing arm mechanism 7, a counterweight 8, and a lead guide Wheel set 9, pay-off base 10 and feedback system, the lifting platform 2 is connected with the cylinder 4, the pay-off base 10 is installed on the top of the lifting platform 2, the drive motor 3 is used to drive the release The wire seat 10 rotates, one end of the wire release seat 10 is connected to the movable top cone 5, the other end of the wire release seat 10 is connected to the fixed top cone 6, and the swing arm mechanism 7 is rotatably mounted on On the support 1, one end of the swing arm mechanism 7 is provided with a lead wheel 27, the counterweight 8 is movably mounted on the swing arm mechanism 7, and the lead guide wheel group 9 is installed on the upper end of the support 1 , the feedback sy...

Embodiment 2

[0032] Such as Figure 4As shown, a six-head constant tension wire feeding device with the wire feeding mechanism provided by the present invention includes a wire gathering guide wheel set 26 and six wire feeding mechanisms, and the six wire feeding mechanisms are arranged in a matrix , the wire gathering guide wheel set 26 is arranged at the left end of the wire feeding mechanism, and there are six wire gathering guide wheel sets 26 arranged in sequence. The present invention integrates six wire feeding mechanisms inside a whole machine, and adopts a matrix arrangement, uses the wire gathering guide wheel group 26 to stagger the wire feeding angles of each wire feeding mechanism, and makes full use of the vertical space.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com