Simple contact net constant-tension wire barrow

A technology of constant tension and catenary, applied in the direction of overhead lines, conveying filamentous materials, thin material processing, etc., can solve the problems of unsteady pay-off tension, poor pay-off quality, insufficient pay-off tension, etc., and achieve pay-off The effect of fast operation speed, high quality of laying-out operation and lightening labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

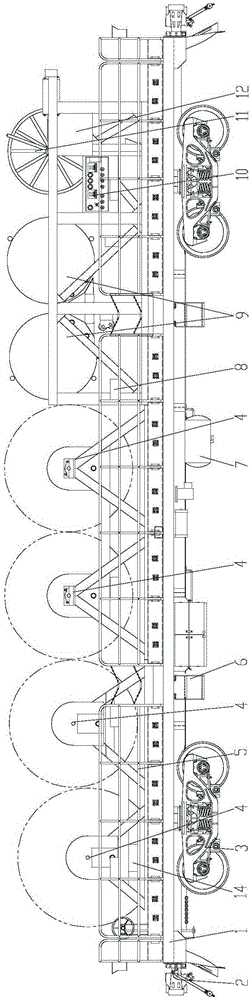

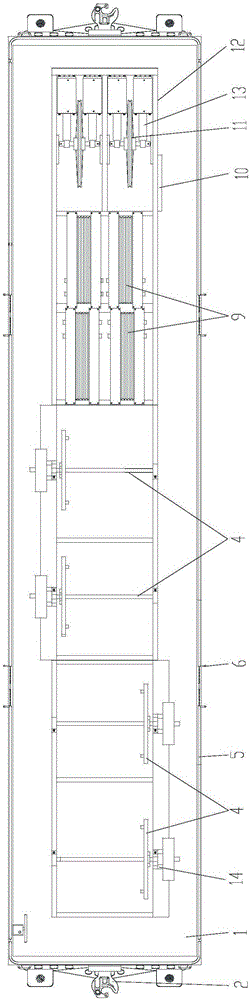

[0018] Attached below Figure 1-2 Embodiments of the present invention are described.

[0019] Simple catenary constant tension pay-off car, such as figure 1 , 2 As shown, there is a vehicle frame 1, and the vehicle frame 1 is the installation basis of all components on the vehicle. Preferably, the overall size of the vehicle frame 1 is 16940mm×3140mm, and the two ends of the vehicle frame 1 are provided with coupler buffer devices 2, The lower part of the frame 1 is provided with a bogie 3, and the bogie 3 adopts two unpowered K2 truck bogies with mature technology, so that the running is stable and reliable; the lower part of the frame 1 is also provided with a braking system 7, The brake system 7 is composed of three parts: an air brake system, a foundation brake and a hand brake. The air brake is preferably a 104-type air brake valve commonly used for passenger cars, and an empty-load vehicle conversion device is added; The upper part of the vehicle frame 1 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com