Sewing auxiliary device of round collar sewing machine

An auxiliary device and sewing machine technology, which is applied to sewing machine components, sewing equipment, cloth feeding mechanisms, etc., can solve the problems of high labor intensity, curved stitches, and difficulty in unifying quality, and achieve the effect of ensuring sewing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing:

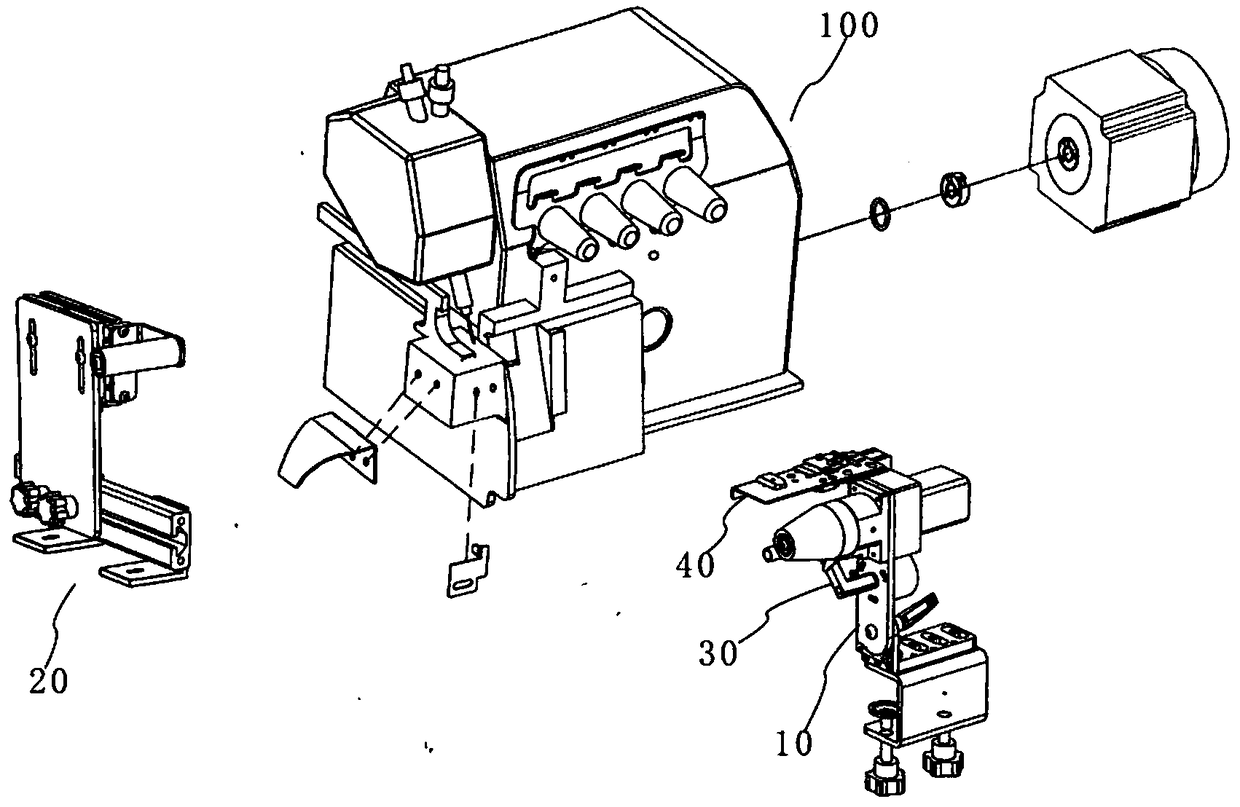

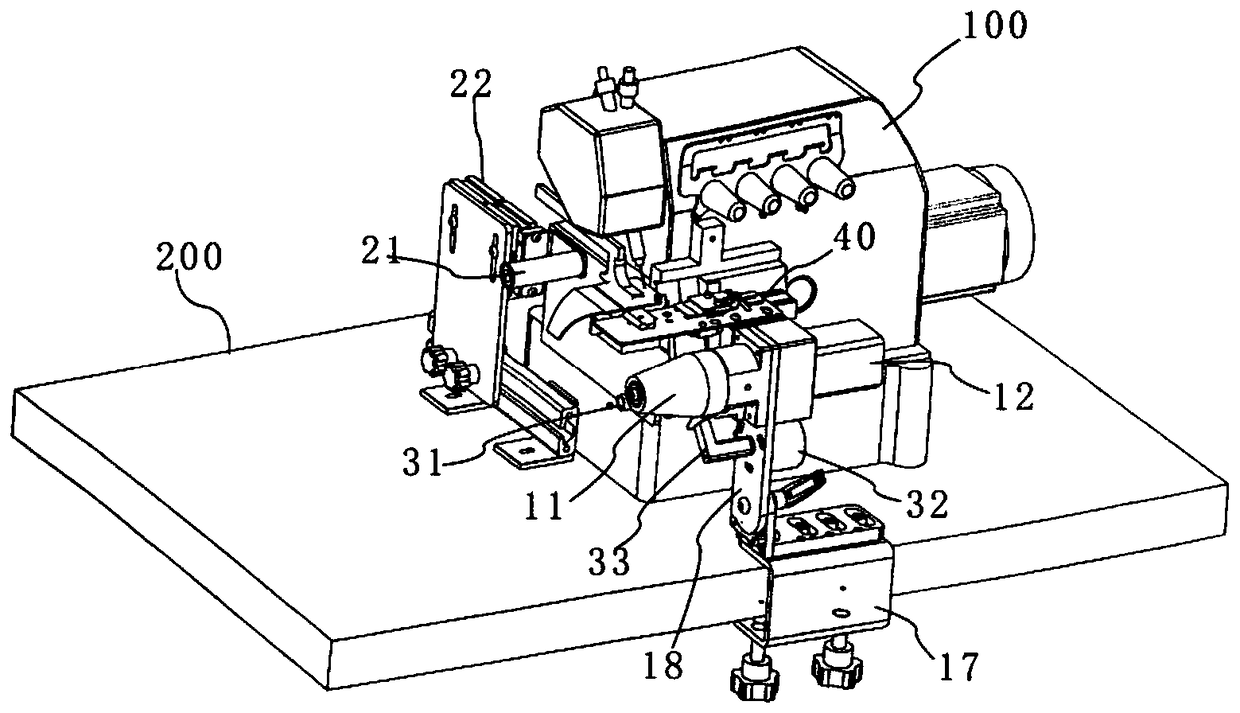

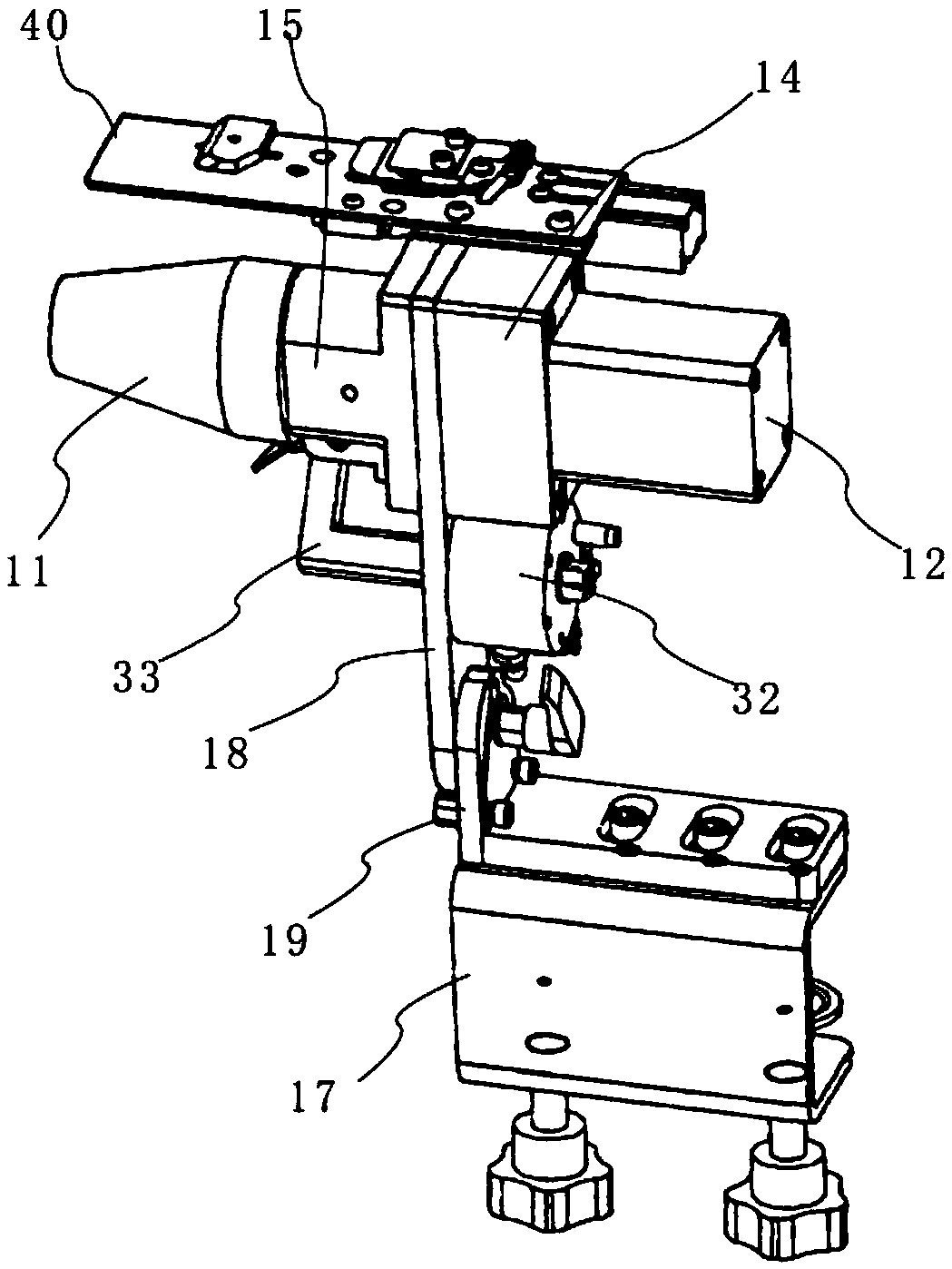

[0034] Such as Figure 1-9 As shown, this embodiment provides a round neck sewing machine, including a frame, a sewing unit 100, a collar device and a sewing auxiliary device, the frame includes a worktable 200, and the sewing unit 100 is installed on the worktable 200 is used to complete the sewing work of the collar cloth and the body, the collar device is installed on the worktable 200 and set close to the sewing unit 100 to complete the automatic collar work, the sewing auxiliary device is installed It is used on the upper collar device and interacts with the collar fabric before sewing to keep the collar fabric neat and beautiful during the sewing process of the collar fabric and the body. The collar cloth of this embodiment needs to be folded in half and sewed together to form the lap before going on the machine.

[0035] In this embodiment, the sewing unit 100 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com