Nozzle lifting device

A lifting device and nozzle technology, which is applied in the field of sanitation vehicles, can solve problems such as collisions, damage to supports and nozzles, and achieve the effects of reducing collisions, facilitating layout, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

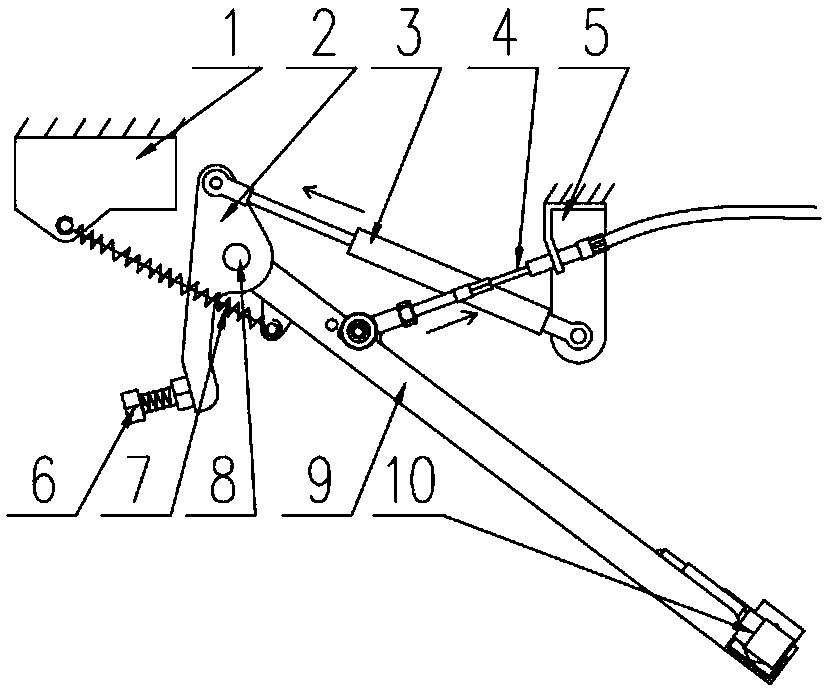

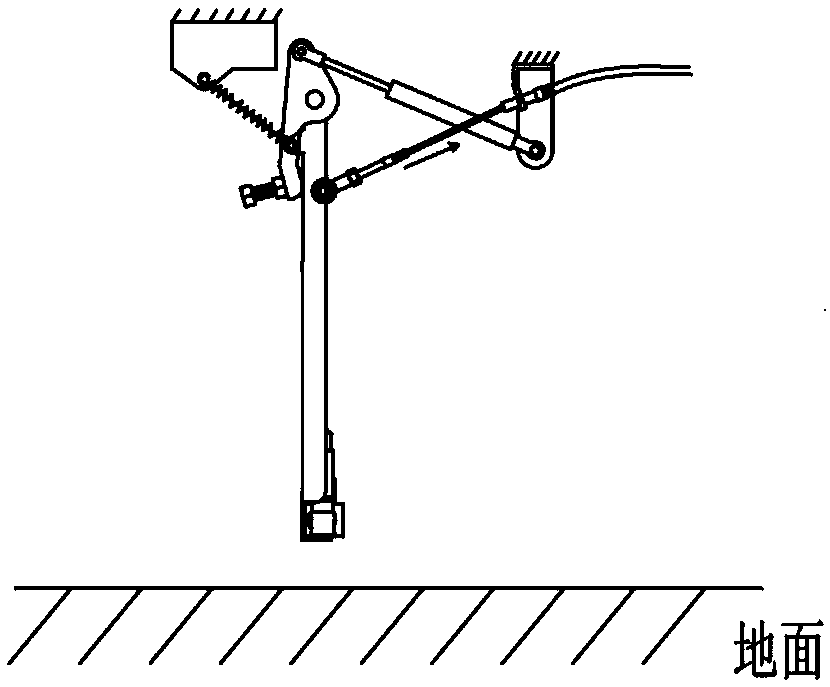

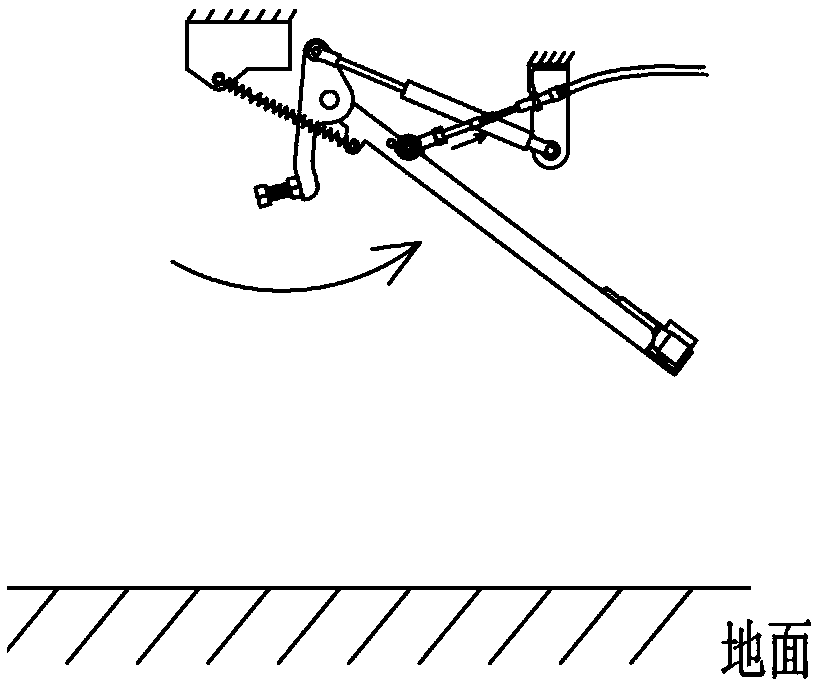

[0023] Such as Figure 1 to Figure 5 As shown, the nozzle lifting device includes a base, a lifting arm 9 , an anti-collision rotary block 2 , a sheath stay wire 4 and a nozzle 10 located at the lower end of the lifting arm 9 .

[0024] The upper end of the lifting arm 9 and the anti-collision turning block 2 are hinged on the base through the rotating shaft 8, the lower end of the anti-collision turning block 2 is aligned with the lifting arm 9 front and rear, and nitrogen gas is provided between the upper end of the anti-collision turning block 2 and the base II5 The spring 3 is provided with a tension spring 7 between the upper part of the lifting arm and the base I1.

[0025] Base Ⅰ1 and base Ⅱ5 are respectively located on both sides of the lifting arm, and both bases are located on the ch...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap