Thermoplastic continuous fiber prepreg braided rope hot-melt winding corrugated pipe and its manufacturing equipment

A continuous fiber, braided rope technology, applied in rigid pipes, mechanical equipment, pipes, etc., can solve the problems of reducing tensile strength, reducing strength, reducing pipe strength, etc., to improve data, save manufacturing materials and pipe costs, The effect of improving compressive strength and ring stiffness strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

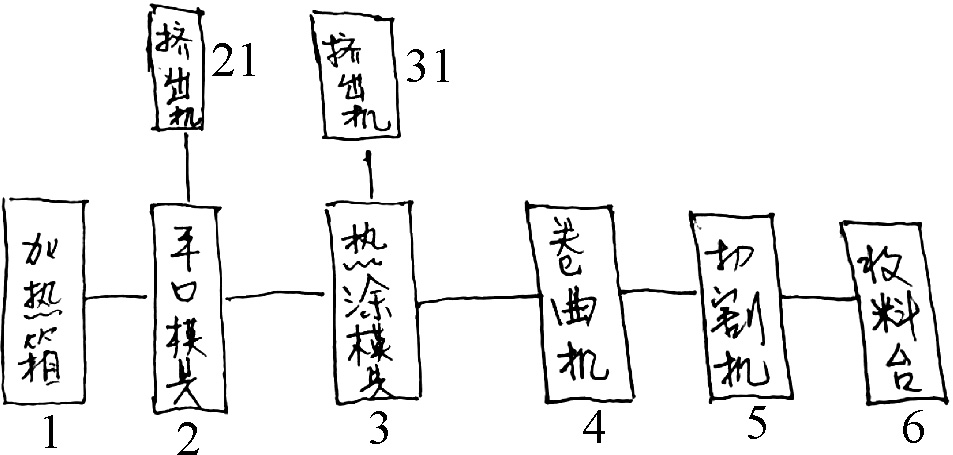

Method used

Image

Examples

Embodiment 1

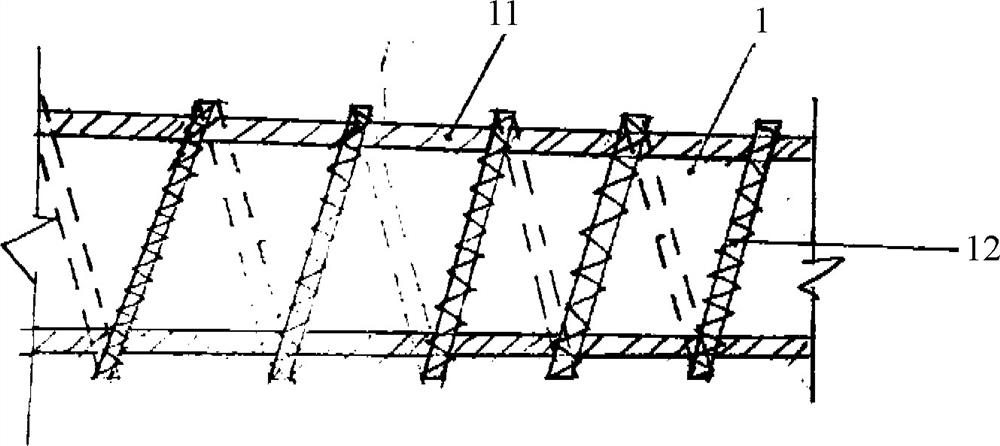

[0025]A thermoplastic continuous fiber prepreg, hot melt winding ripple, such asfigure 1 As shown, the specific structure is: hot melt winding ripple tube 10 consists of continuously wound thermoplastic continuous fiber prepreg woven rope 12 in the outer wall of the plastic inner layer tube 11 and the inner tube 11, such asfigure 1 Indicated;

[0026]The thermoplastic continuous fiber prepreg, which is a thermoplastic pre-shelf braided rope to form a plurality of sets of parallel T-shaped sheets after the molten temperature of the inner layer tube 11 in the molten temperature conditions. tube;

[0027]The thermoplastic continuous fibrous prepreg is composed of a plastic content of 30% to 40% and a fiber content of 70% to 60%, and the joint woven composition is composed of a plurality of continuous fiber pre-sole melting conditions;

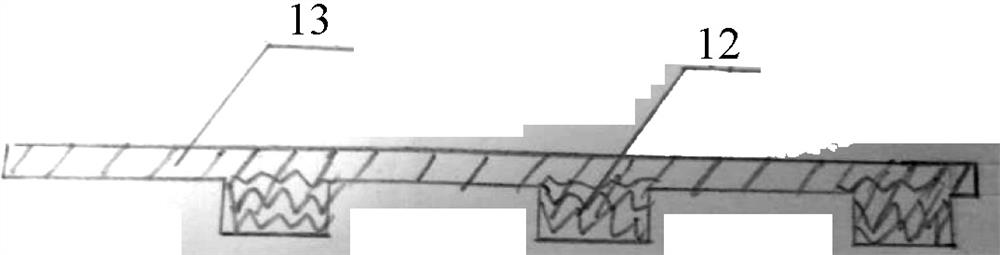

[0028]The hot melt winding ripple 10 is a parallel T-plate plate with an overall group, such asfigure 2 Design, the T-plate plate is composed of a thermoplastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com