Automatic foundation pit displacement monitoring system

An automatic monitoring and foundation pit technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of losing the best time for emergency rescue, time lag in the delivery of regular monitoring reports to the construction site, and non-continuous monitoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

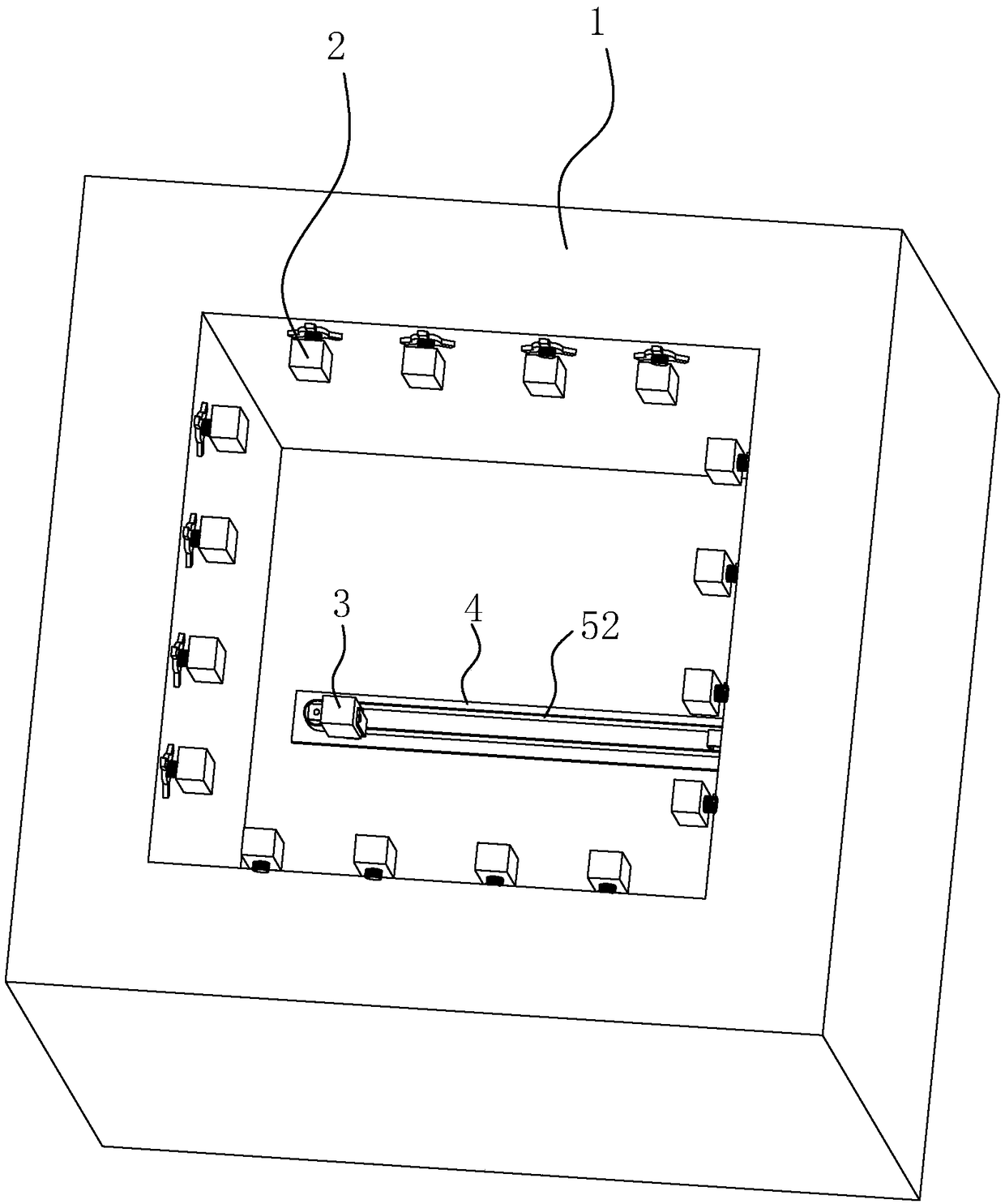

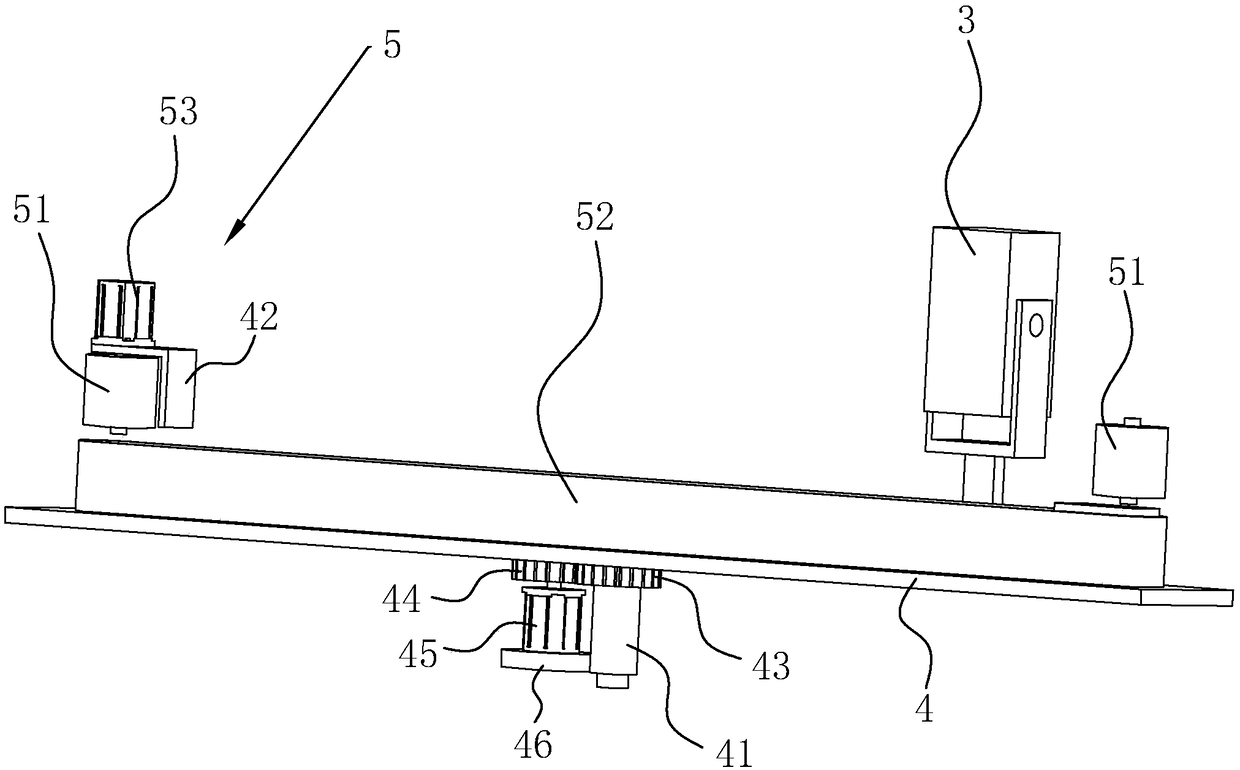

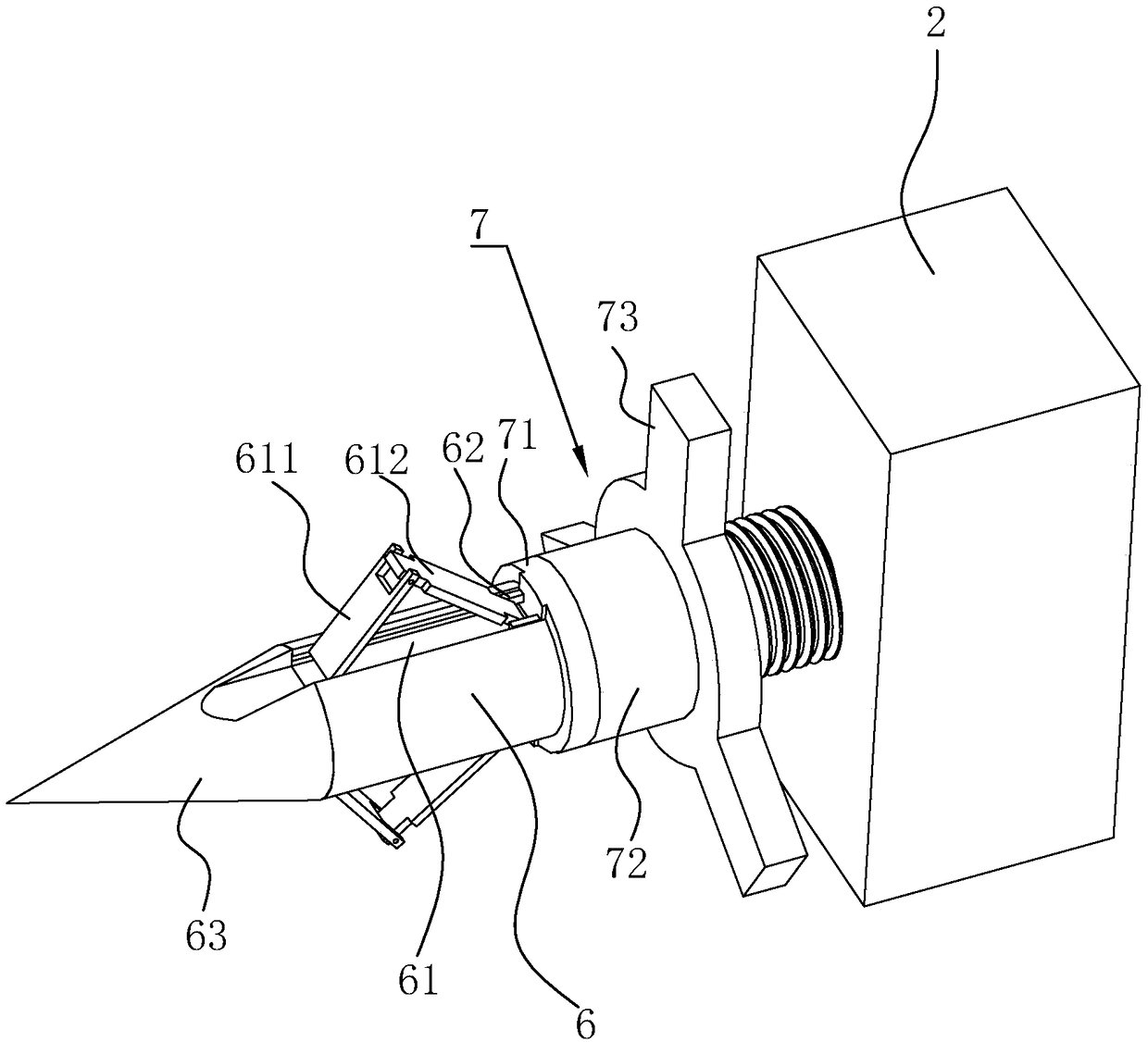

[0034] A foundation pit displacement automatic monitoring system, such as figure 1 As shown, it includes a number of signal receivers 2 arranged in an array on the top of the side of the foundation pit 1. The signal receivers 2 have corresponding numbers. There is a support column 41, and a support seat 4 is arranged on the support column 41. The support seat 4 is parallel to one side of the foundation pit 1. The signal transmitter 3 that moves along the length direction of the support seat 4 is provided with a drive Its driving mechanism 5 slides along the length direction of the support base 4 , the signal receiver 2 and the signal transmitter 3 are respectively connected with control terminals. The driving mechanism 5 drives the signal transmitter 3 to slide along the support base 4 at regular intervals, and sends signals to each signal receiver 2, and the control terminal analyzes the time difference between the signal sent by the signal transmitter 3 and the signal receiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com