A method for manually adjusting the arbitrary spacing of saw blades for cutting plates of different thicknesses

A manual adjustment and saw blade technology, applied in the direction of sawing machine, metal sawing equipment, sawing machine tool, etc., can solve the problems of lower adjustment efficiency, complicated adjustment structure, and inability to adjust cutting thickness, etc., to achieve convenient operation and adjustment efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

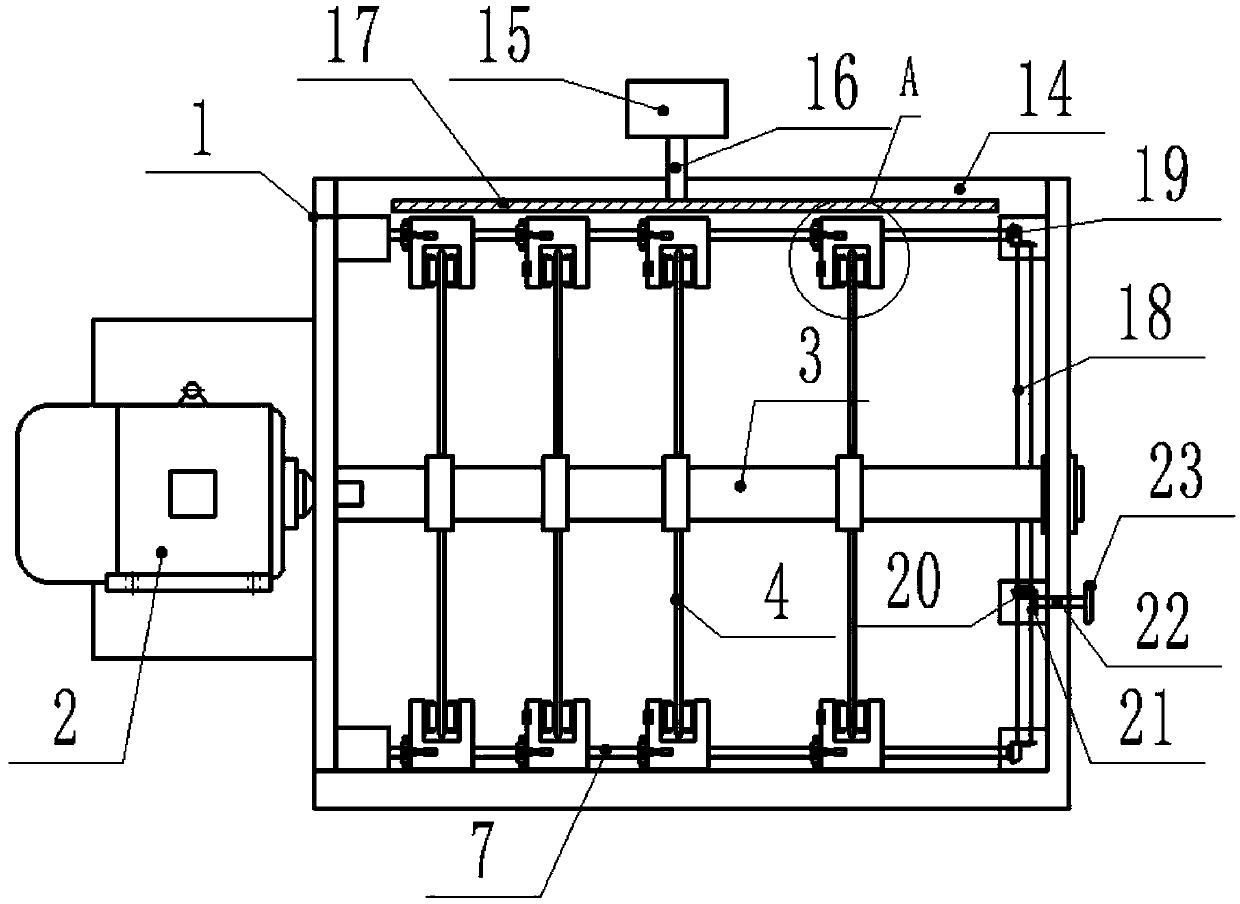

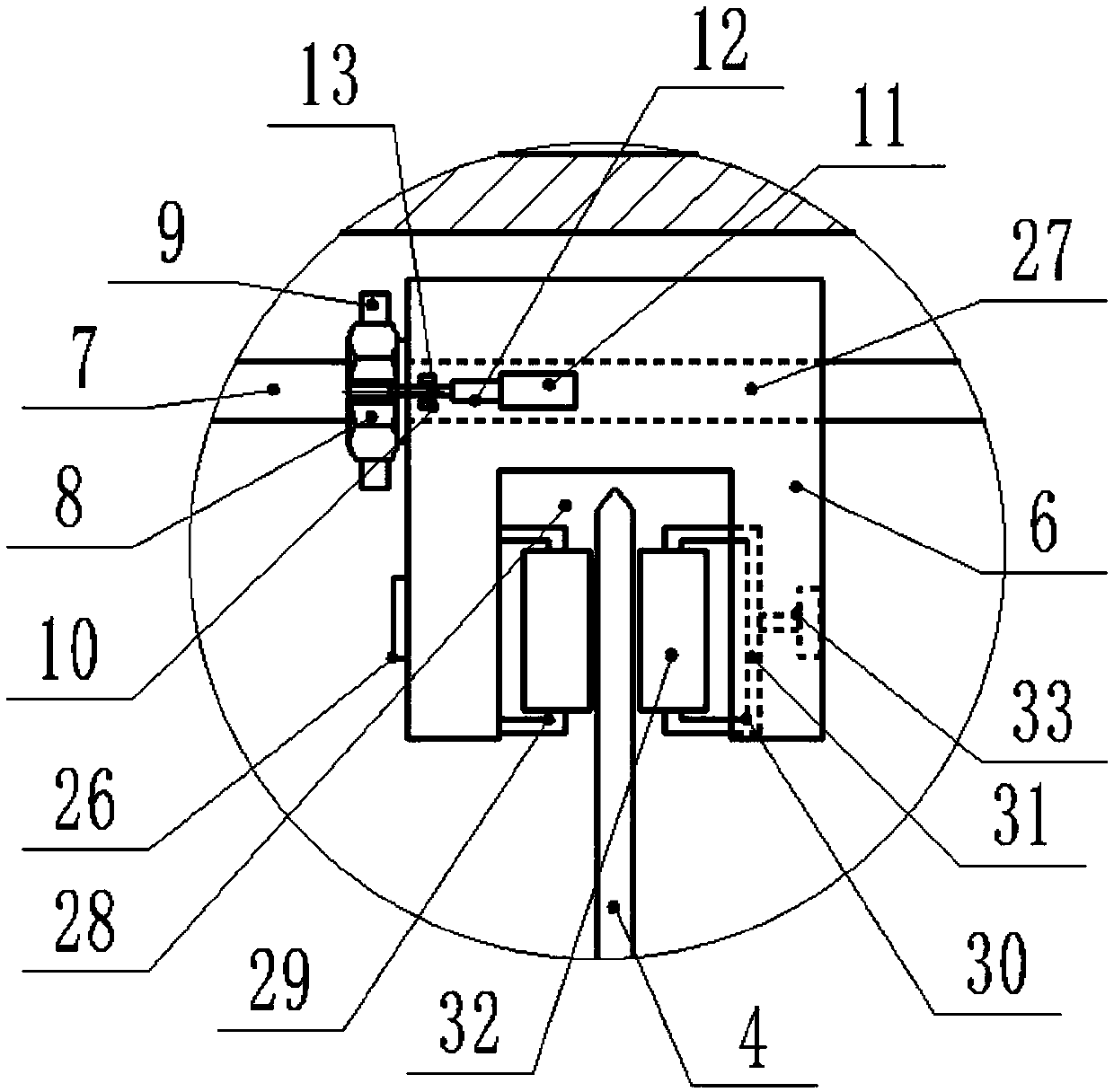

[0038] Such as Figure 1-3 As shown, the present invention provides a method for manually adjusting the arbitrary spacing of saw blades for cutting plates of different thicknesses, comprising steps:

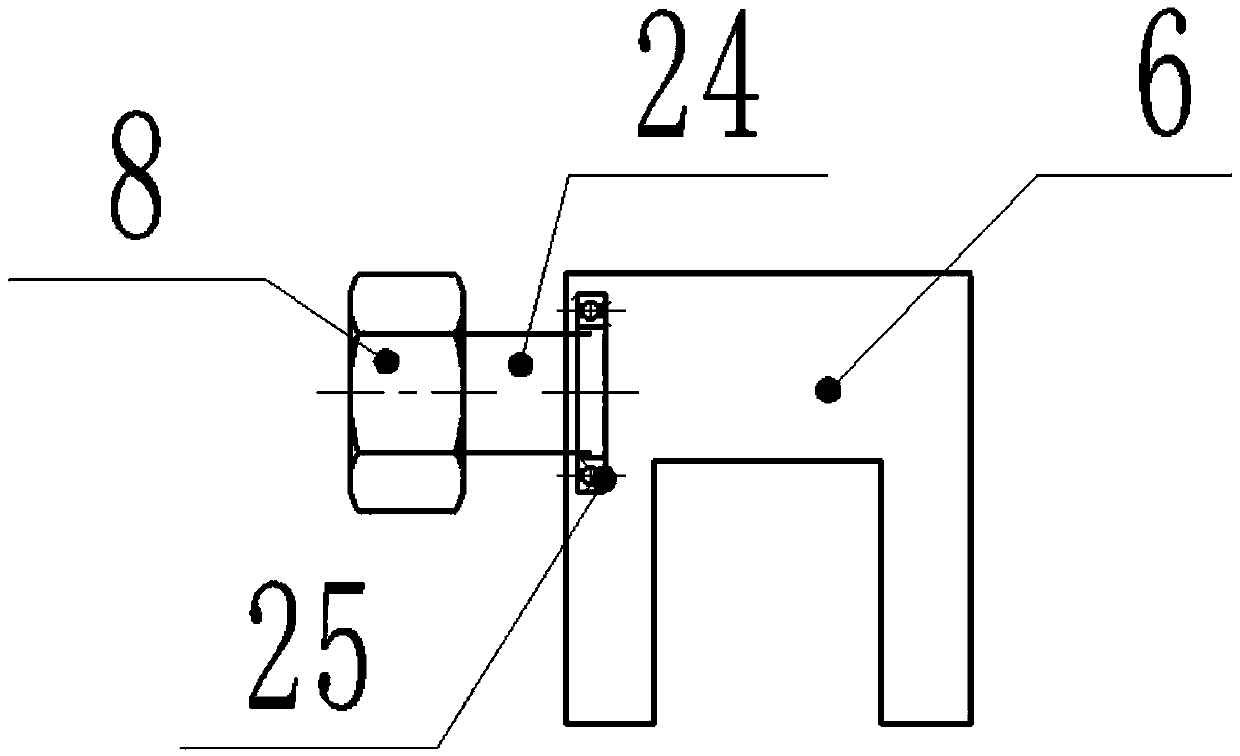

[0039]Step 1: Control the retraction of the locking telescopic arm 16 through the locking cylinder 15, so that the extrusion block 17 is withdrawn from the saw blade adjustment clamp block 6 on the side corresponding to all the saw blades 4;

[0040] Step 2 control needs to adjust the cylinders 11 on both sides of the saw blade 4, and connect the nut limit slot 9 and the clip block limit slot 10 through the pin block 13 of the cylinder 11; the cylinders 11 on both sides of the other saw blade 4 are in the retracted state;

[0041] Step 3: Rotate the adjustment handwheel 23 to drive the adjustment shaft 22, the adjustment screw 18, and the two screw 7 to rotate in turn, and the two screw 7 then drive the adjustment nut 8 corresponding to the saw blade 4 that needs to be adjusted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com