Self-sharpening disc saw blade

A circular saw blade self-sharpening technology, which is applied to metal sawing equipment, tool trimming of sawing machine devices, metal processing equipment, etc., can solve the problem that it is difficult to find the sharpening angle, cannot be adjusted and changed, and the sharpening effect is not very good, etc. problems, to achieve the effect of improving the sharpening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

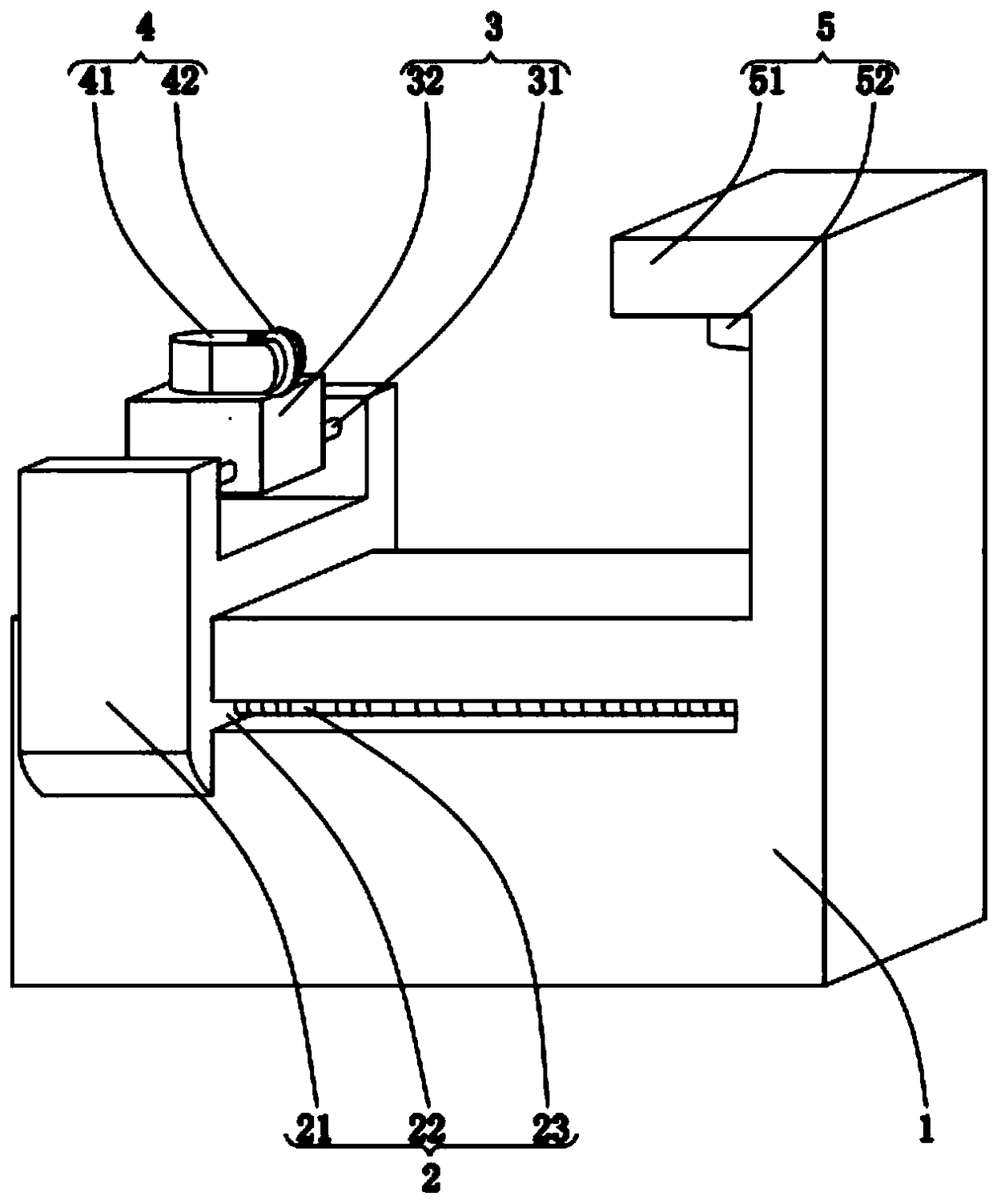

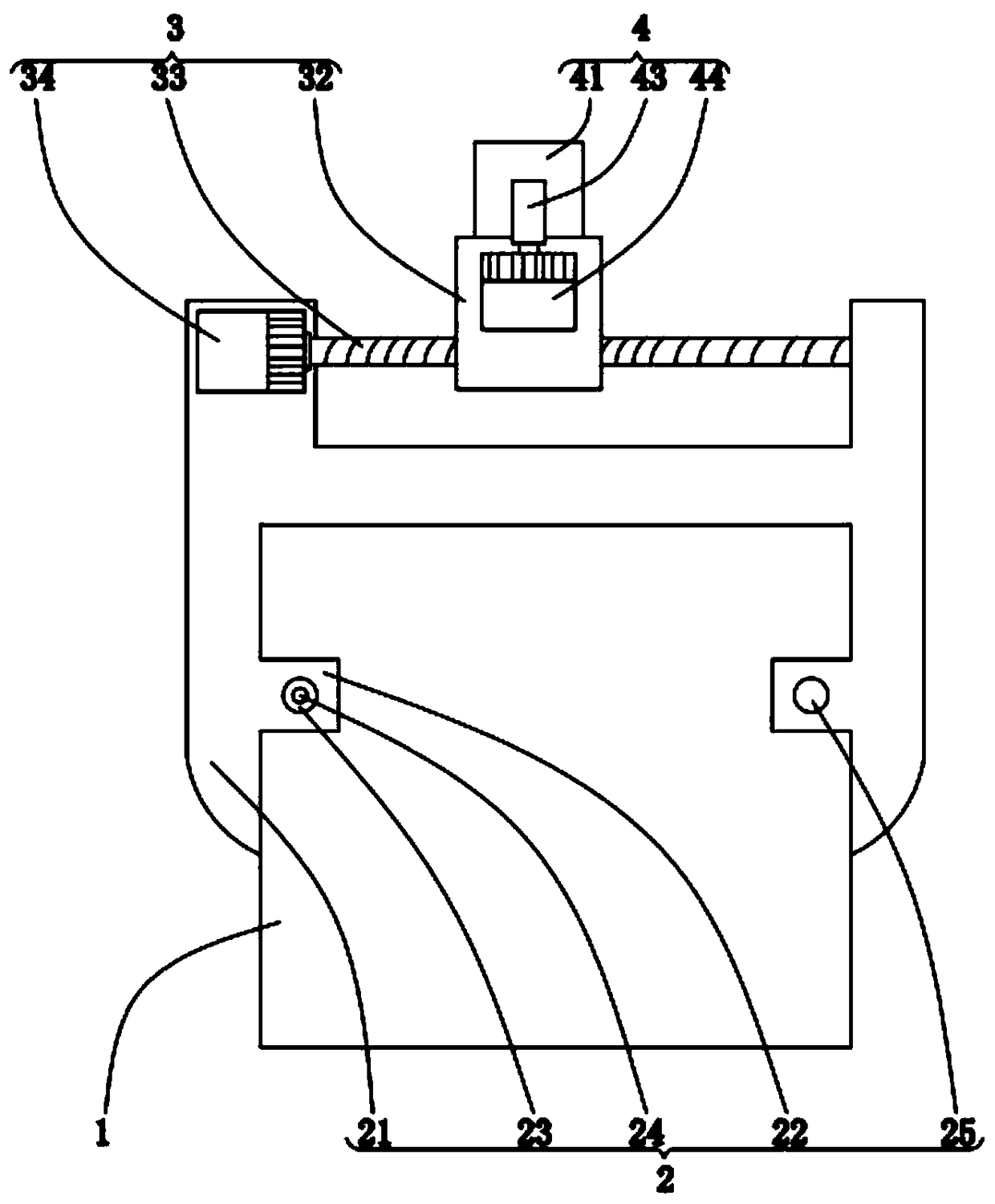

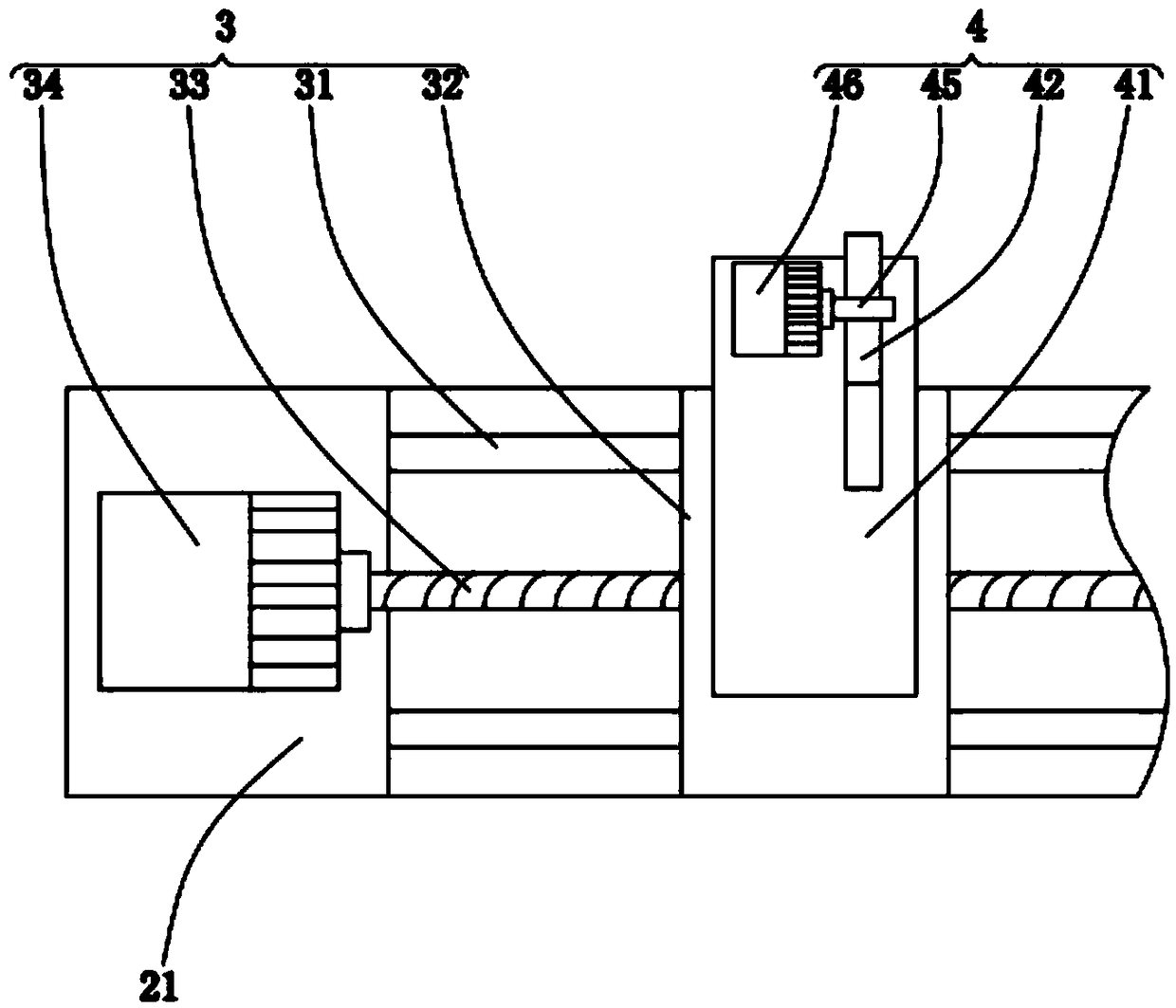

[0023] Such as Figure 1-Figure 4 As shown, a self-sharpening circular saw blade according to the present invention includes an operating table 1, a lateral movement mechanism 2, a longitudinal movement mechanism 3, a grinding mechanism 4, a lifting mechanism 5, a rotating mechanism 6 and a fixing mechanism 7; The traversing mechanism 2 that drives the grinding mechanism 4 to move laterally is connected to the console 1, and the traversing mechanism 2 includes a first fixed plate 21, a limit slider 22, a first screw rod 23, a first A servo motor 24 and a first limit rod 25, the first fixed plate 21 is engaged and slidably connected in the chute on the side wall of the console 1 through the limit slider 22, the limit Two sliders 22 are provided, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com