Continuous multi-segment acid displacement washing technological method

A technology of replacement washing and process method, applied in the direction of washing/replacing pulp treatment liquid, etc., can solve the problem of low residual acidity of acid cotton, and achieve the effect of increasing the concentration of washing waste acid, reducing the frequency of decomposition, and ensuring smooth operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

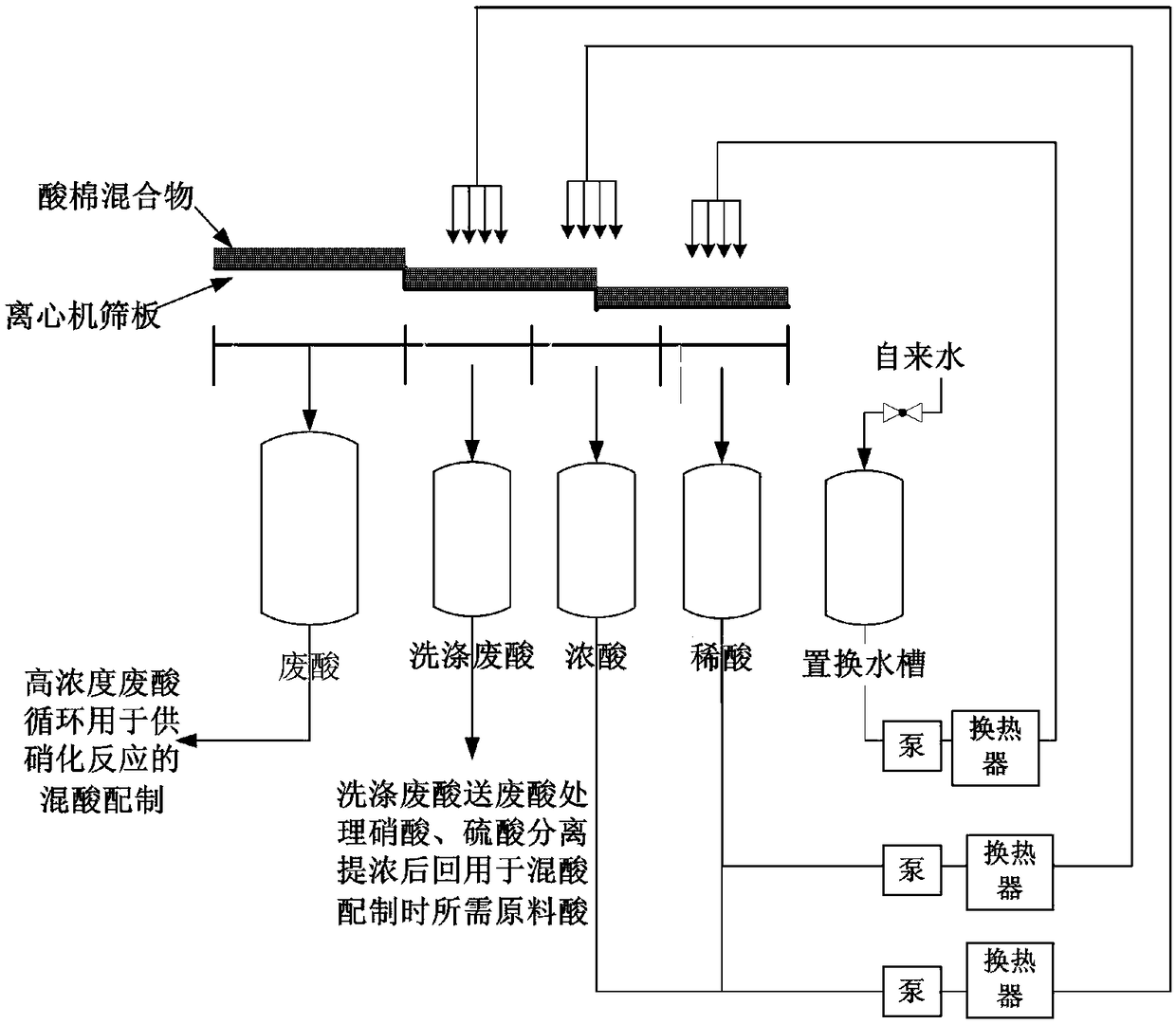

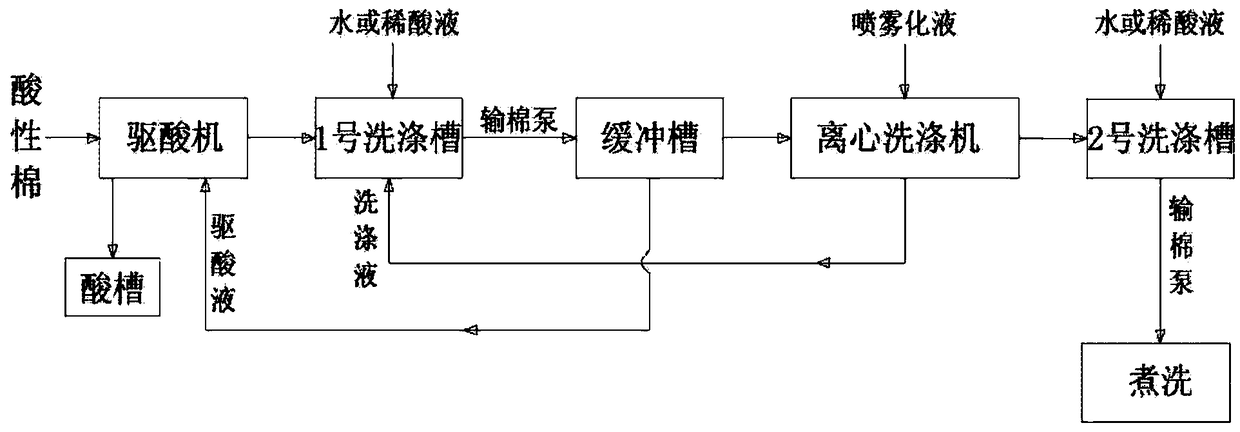

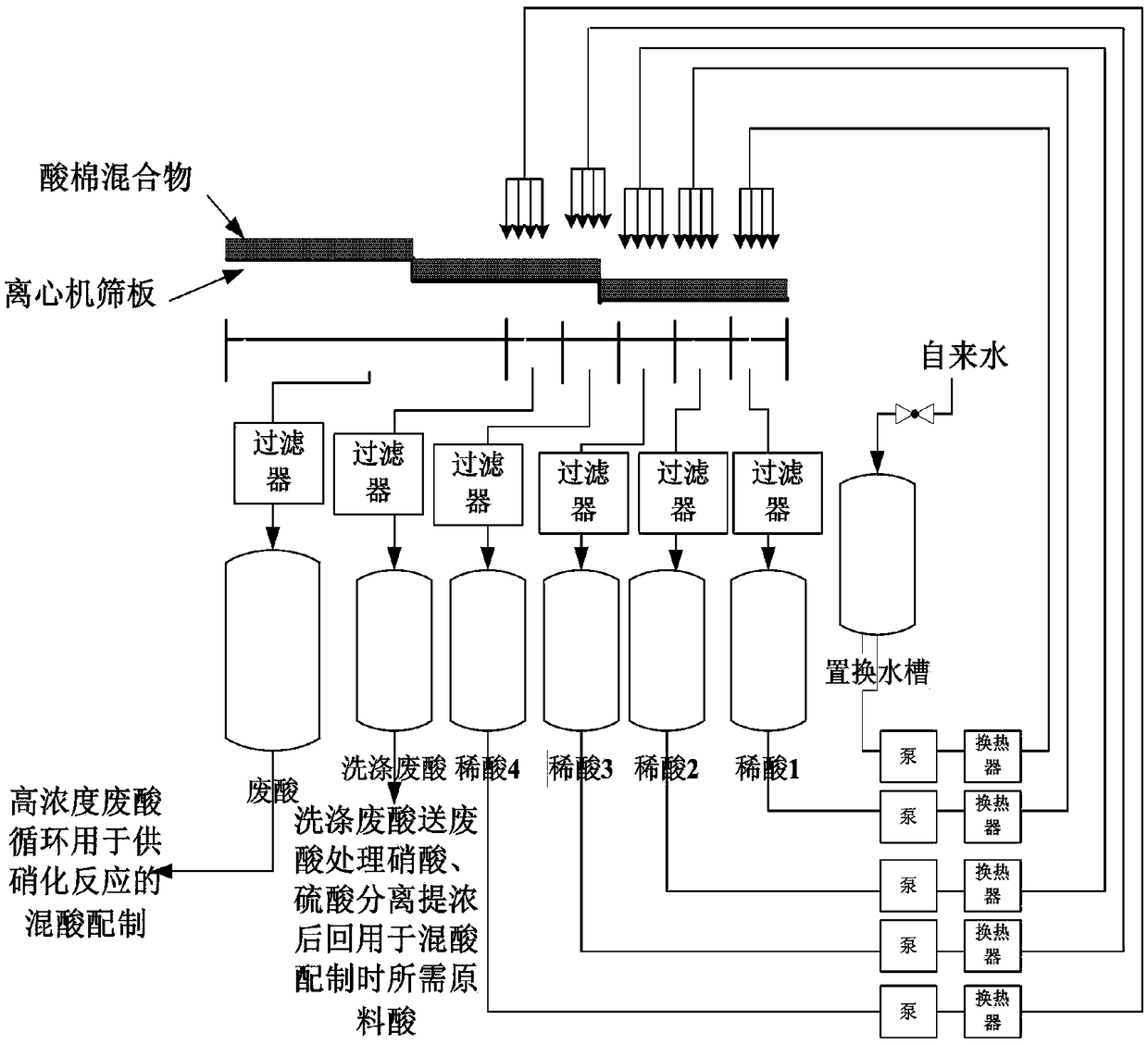

[0035] Such as image 3 As shown, the process flow of the present invention is that the acid cotton mixture after the nitration reaction enters the horizontal pusher centrifuge for acid cotton separation, and the sieve plate of the horizontal pusher centrifuge includes a high-concentration waste acid separation section and a replacement washing section , Carry out five stages of countercurrent displacement washing in the displacement washing section. If the number of washing stages is too small, the number of washings will decrease, and the residual acidity after washing will increase correspondingly; if the number of washing stages is too large, it will be difficult to control the balance of the displacement acid in and out of each stage, and it is not convenient for production control. Therefore, the present invention adopts five stages of countercurr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com