Lateral parting core-pulling device with oscillating hook for plastic molds

A lateral parting core-pulling and plastic mold technology, applied in the field of plastic molds, can solve the problems of increased enterprise burden, complex mold structure, increased production cost, etc., and achieves reduction of mold parts, simple mold structure, good economic benefits and social benefits. effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limiting the claims of the present invention.

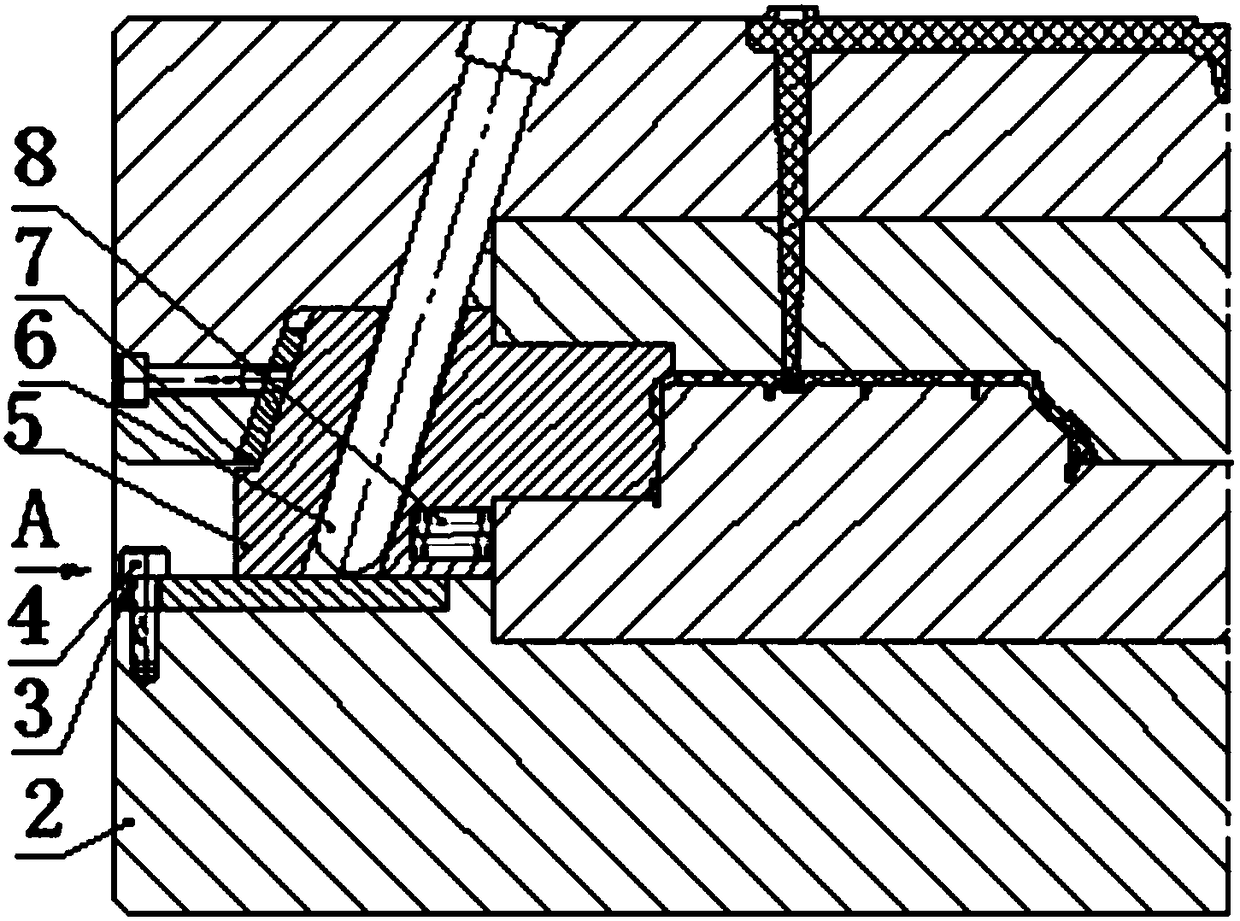

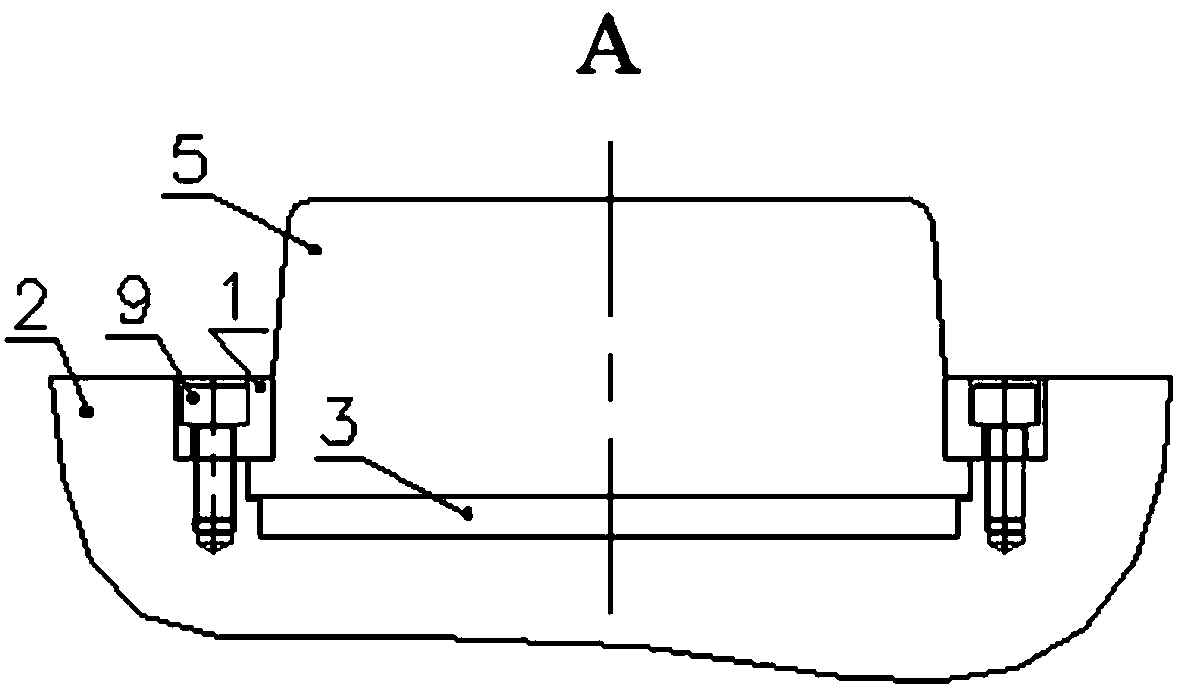

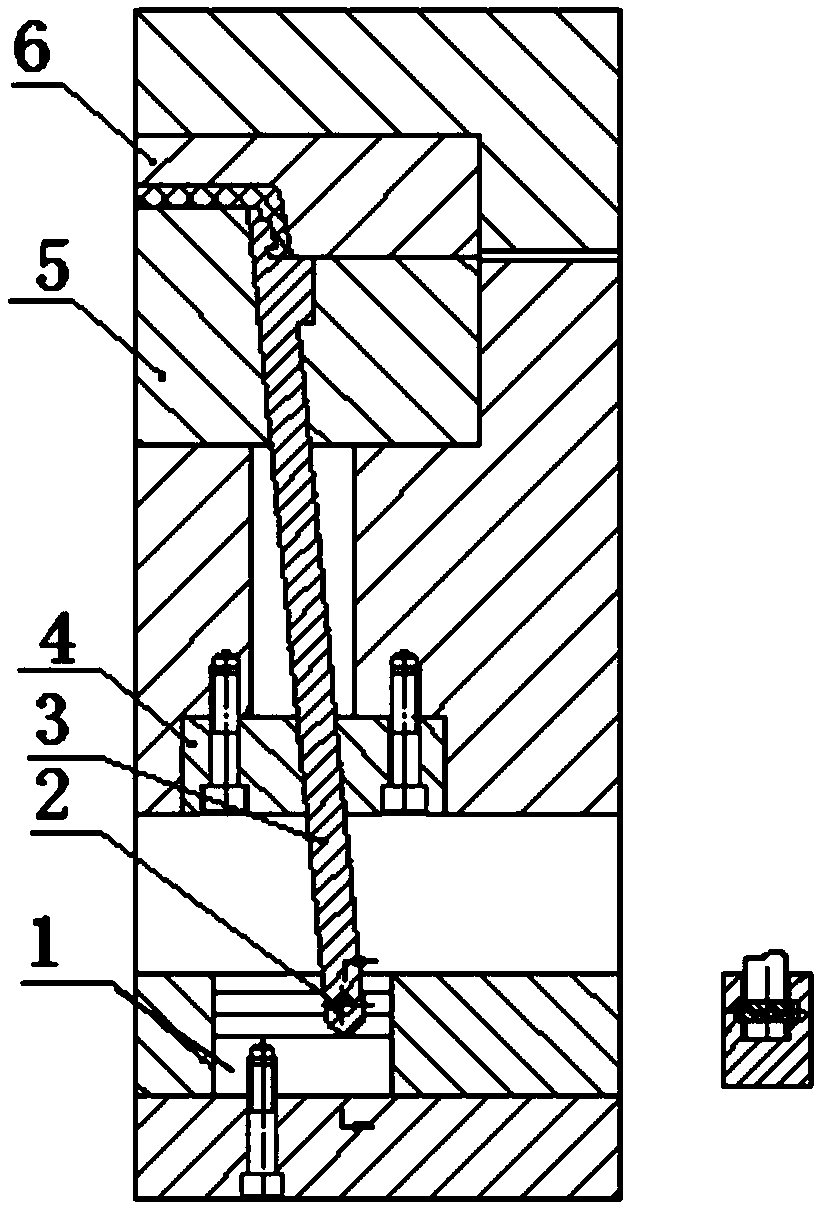

[0038] Such as Figure 6-8 As shown, the present invention includes a movable mold base plate 3, a cushion block 4, a push plate 5, a swing hook pin 6, a swing hook 7, a push rod fixing plate 9, a support plate 11 and a movable template 14, and the movable mold base plate 3 There is a movable mold base plate through hole 3-1 used in conjunction with the ejector pin of the injection machine, and the movable mold base plate 3 is connected with two pads 4 by set screws 2 and is located on the upper surface of the movable mold base plate 3 , a push plate 5 is placed in the middle of the two pads 4, and a push rod fixing plate 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com