High-precision adjustable bottle mould

A high-precision, pedestal technology, applied in bottle filling, liquid bottling, packaging, etc., can solve problems such as damage to special-shaped bottles, failure to maintain vertical state of special-shaped bottles, and shaking, etc., to achieve the effect of improving speed and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

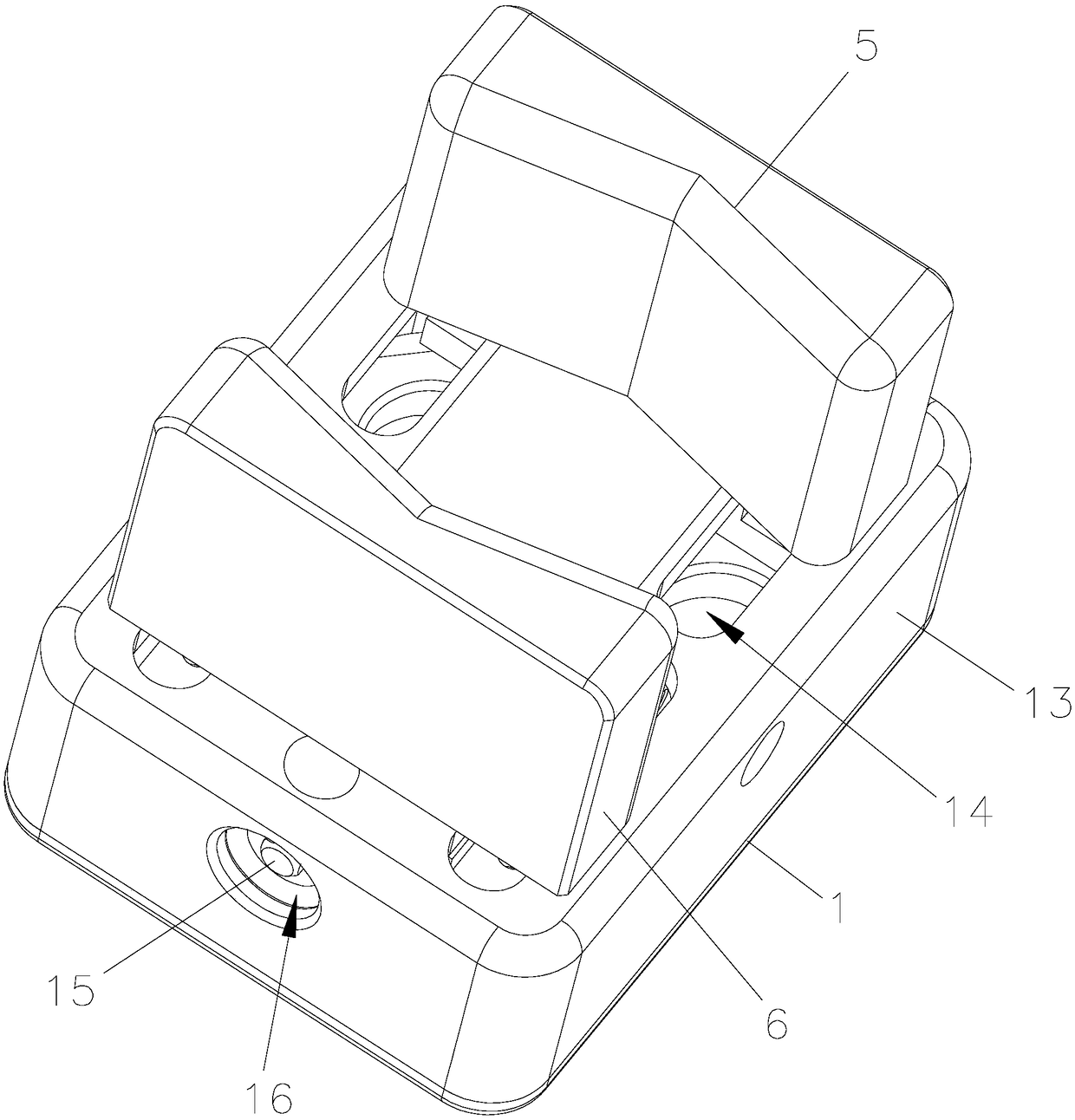

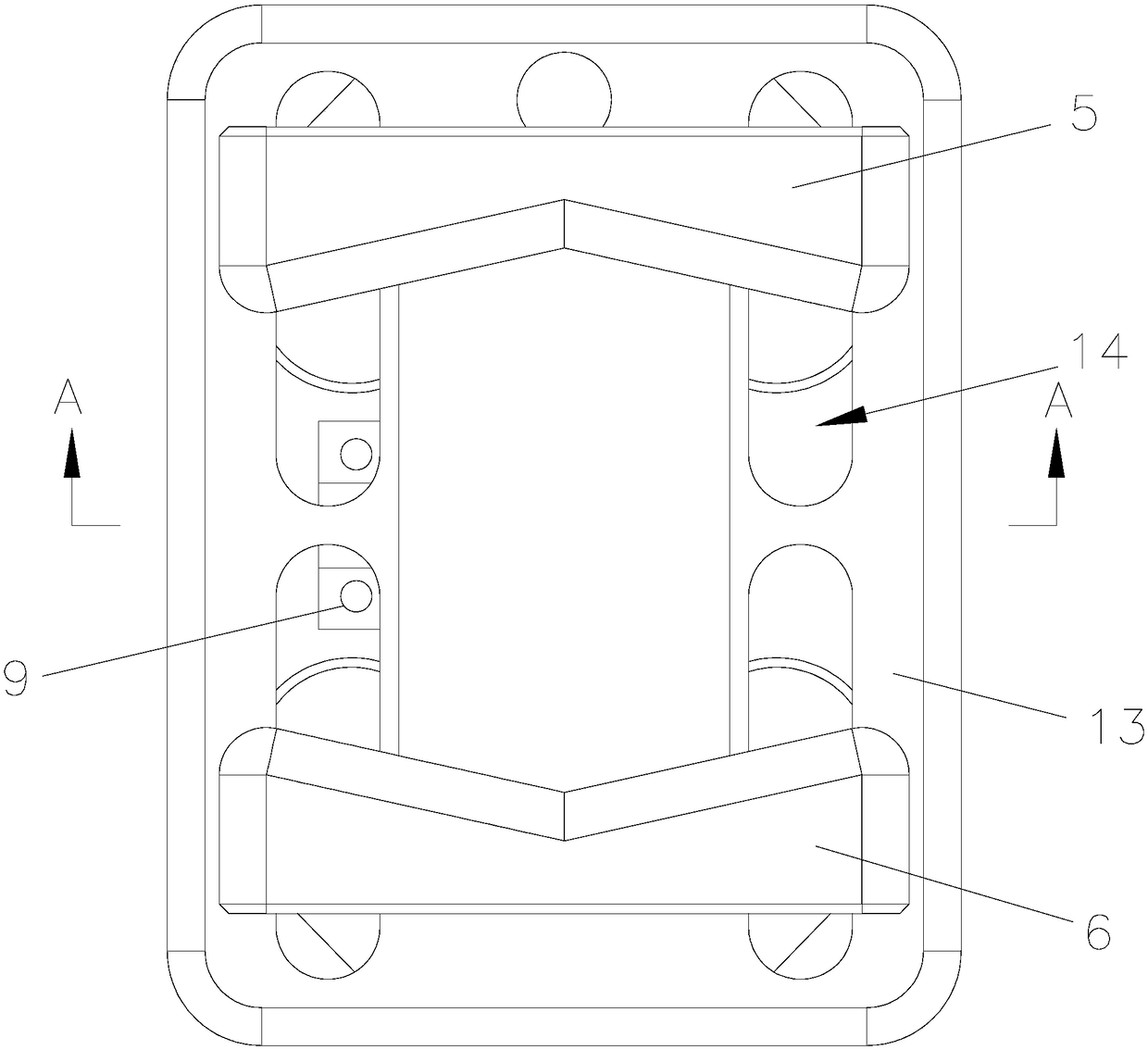

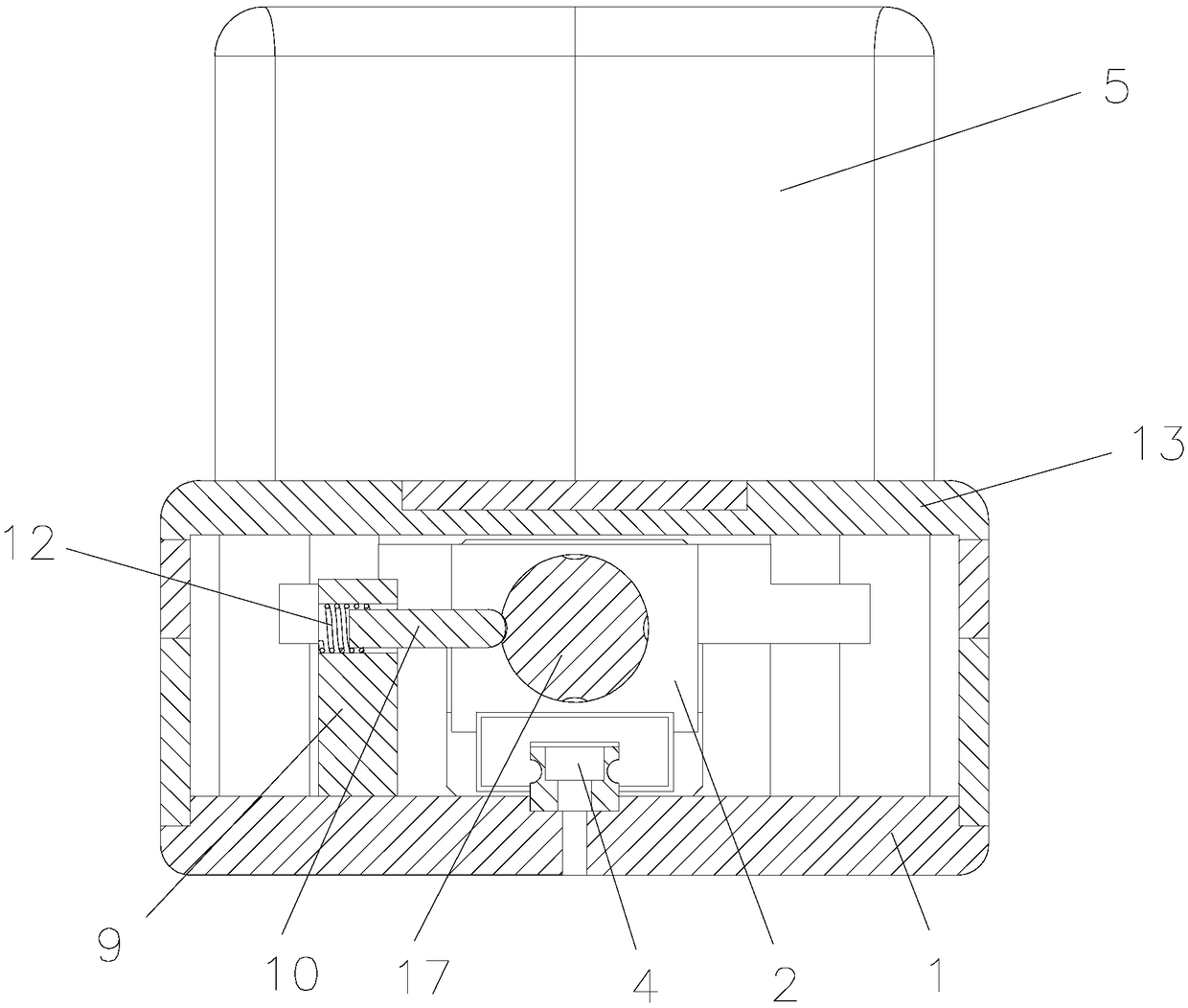

[0028] Such as figure 1 , figure 2 , Figure 4 and Figure 6 A high-precision adjustable bottle mold shown includes a base 1, on which a positive and negative screw rod 17 is rotated through a bearing, and left-handed nuts are respectively driven and mounted on both ends of the positive and negative screw rod 17. Block 2 and right-handed nut block 3, the base 1 is provided with a slide rail 4, the left-handed nut block 2 and the right-handed nut block 33 are all slidably arranged on the slide rail 4 by a slider, the Left-handed nut block 2 is fixedly equipped with left jaw 5, as Figure 5 As shown, the right jaw 6 is fixedly installed on the right-handed nut block 3, and the centerlines of the left jaw 5 and the right jaw 6 coincide with the positive and negative screw rods 17, and the middle of the positive and negative screw rods 17 Coaxially fixedly install the limit ring 7 at the position, such as image 3 As shown, four limit holes 8 are evenly opened on the outer c...

Embodiment 2

[0033] Such as Figure 8 The difference between the illustrated embodiment 2 and the embodiment 1 is that the elastic element is a rubber column 11, one end of the rubber column 11 is fixedly connected with the inner wall of the installation hole, and the other end is connected with one end of the limit rod 10 End face fixed connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com